Combined cooling, heating and power composite system based on ammonia energy ship and power supply method

A combined cooling, heating, power, and composite system technology, applied in the direction of propulsion-based emission reduction, ship propulsion, chemical instruments and methods, etc., can solve problems such as energy consumption, and achieve the effect of low cost and wide access

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

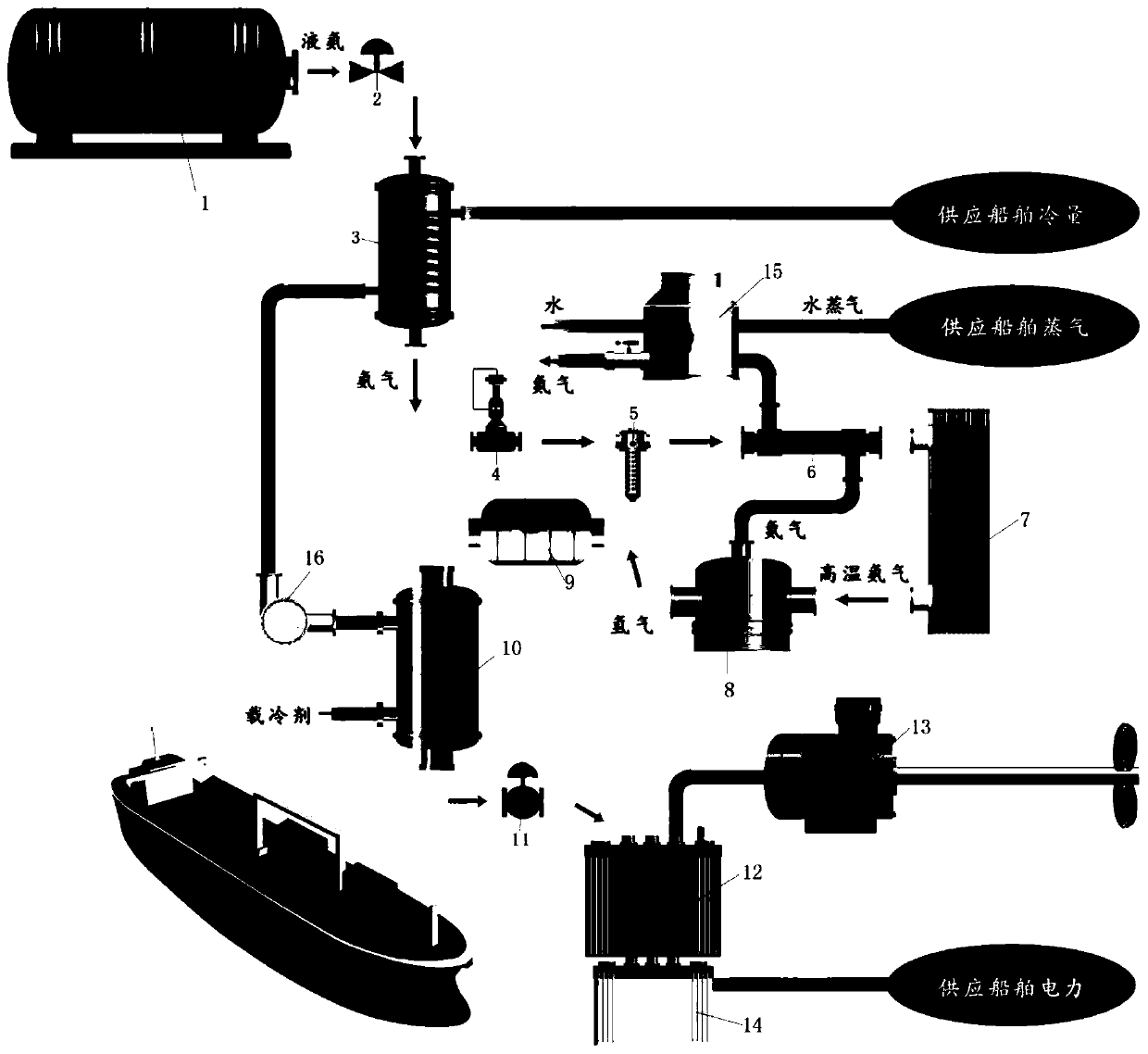

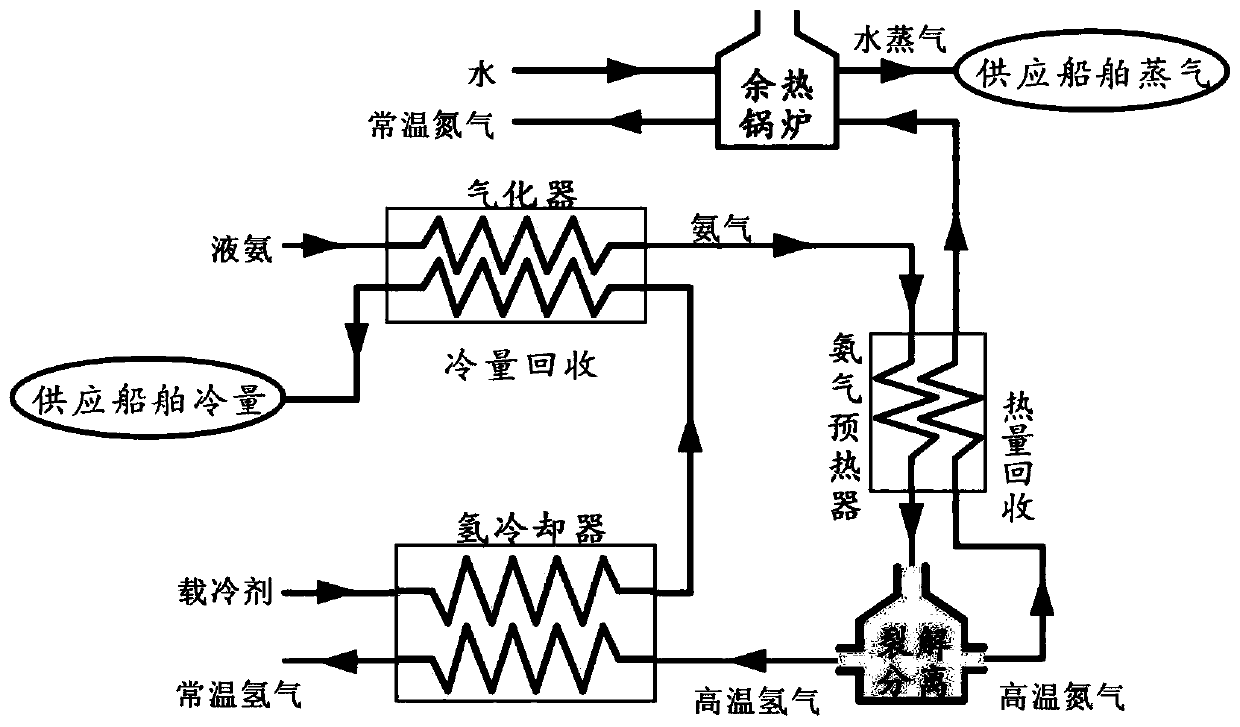

[0049] Such as Figure 1-3 As shown, the present invention provides a combined cooling, heating and power supply system based on ammonia energy ships, including a hydrogen production system, a ship power supply system, and a cooling and heating energy recovery heat exchange cycle system;

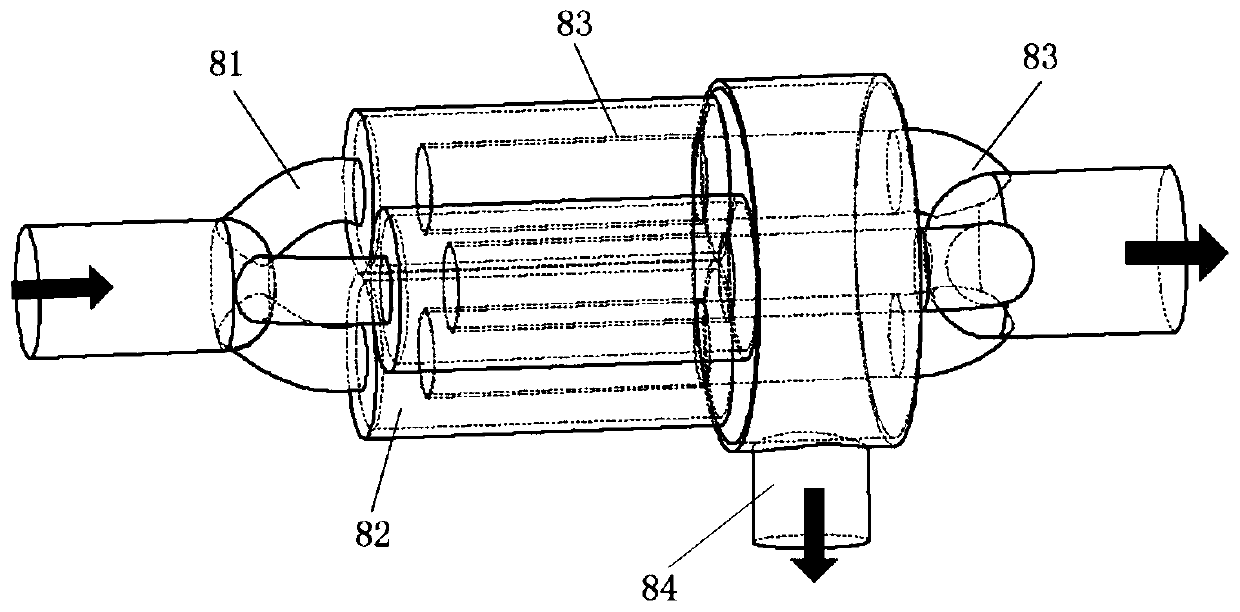

[0050] The hydrogen production system for hydrogen production includes a marine liquid ammonia storage tank 1, a flow regulating valve group 2, a vaporizer 3, a pressure regulating valve group 4, a dry filter 5, an ammonia gas preheater 6, Electric heater 7, ammonia catalytic decomposition hydrogen separation unit 8, hydrogen purifier 9, hydrogen cooler 10 and hydrogen pressure flow control valve group 11; the various devices of the hydrogen production system are connected through pipelines;

[0051] The hydrogen production process of the hydrogen production system includes liquid ammonia storage, gasification, impurity removal and ammonia gas heating, catalytic cracking conversion hydrogen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com