Recycling hydrogen purification processing method for producing polysilicon by reducing trichlorosilane

A technology of trichlorosilane and polysilicon, which is applied in the fields of hydrogen separation, climate sustainability, using solid contact hydrogen separation, etc., can solve the problems of hydrogen waste, environmental pollution, purity lower than 99.9999, etc., and achieves high purity and quality improvement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

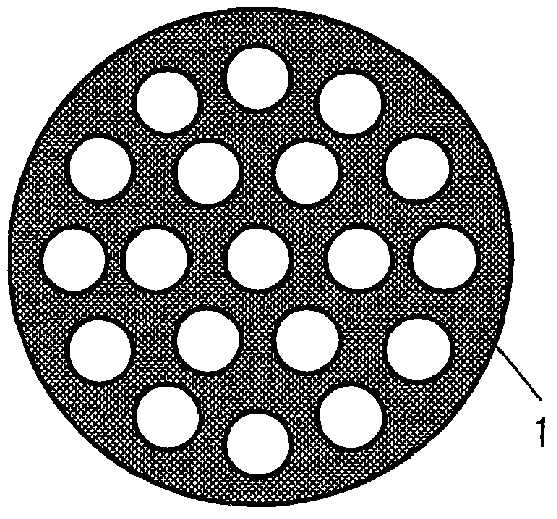

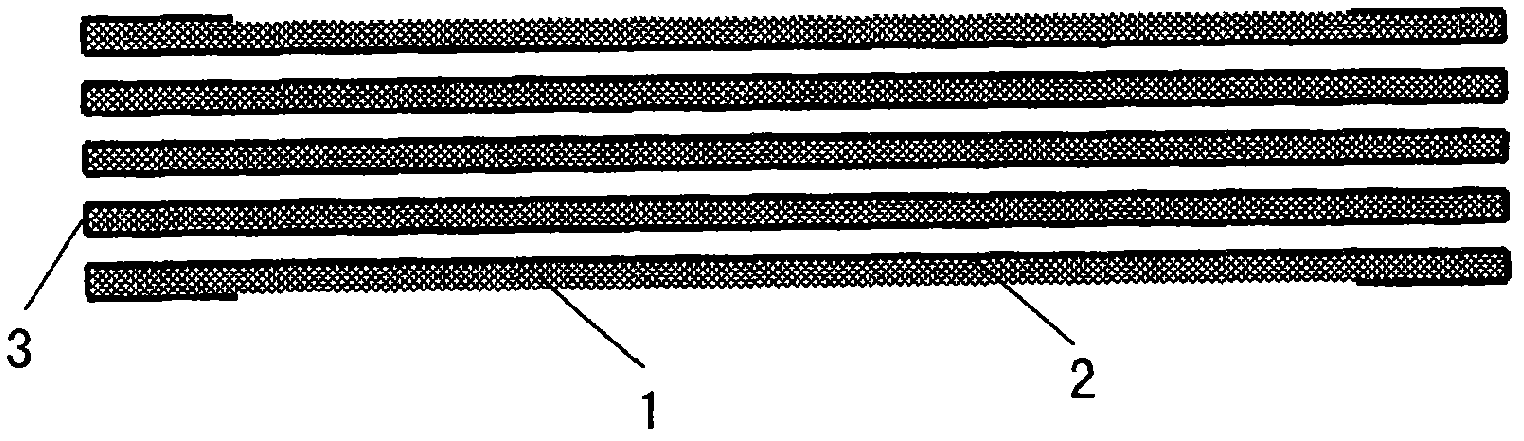

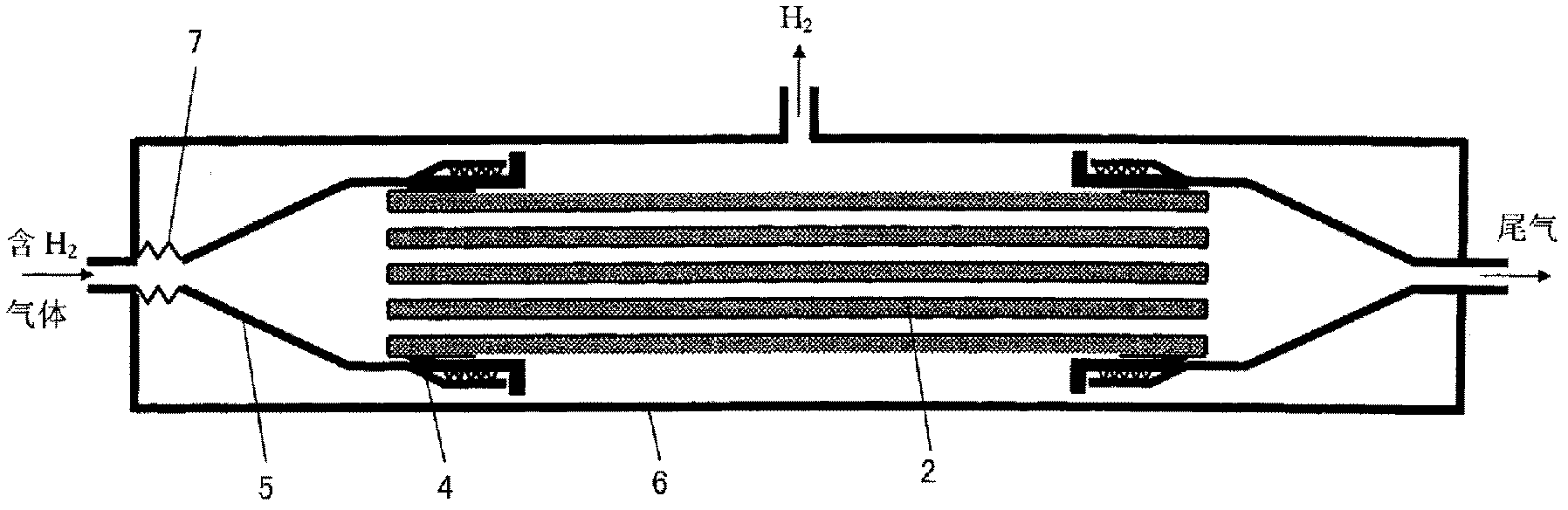

[0038] The hydrogen containing 20ppm methane, 5ppm oxygen and 50ppm nitrogen is used as the simulated dechlorinated trichlorosilane reduction cycle hydrogen. Two sets of multi-channel metal palladium composite membrane hydrogen purifiers in series are used to purify the above hydrogen. The palladium composite membrane has a length of 1m and a diameter of 30mm. It consists of 19 channels with a channel diameter of 4mm. The structure is shown in the attachment image 3 . The area of the palladium composite membrane of the first group of hydrogen purifiers is 2m 2 , The area of the palladium composite membrane of the second group of hydrogen purifier is 0.25m 2 The hydrogen purification temperature is 400°C, the raw material gas pressure is 1.0 MPa, and the pressure of permeating hydrogen is 0.4 MPa. The results show that the amount of hydrogen recovered by the first group of hydrogen purifiers is 85m 3 / h, using gas chromatography hydrogen flame detector and thermal conductiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com