Mobile hydrolyzed-aluminum hydrogen production device

A hydrogen production device and mobile technology, applied in the field of hydrogen production, can solve the problems of hidden safety hazards, high cost, bulky hydrogen storage tanks, etc., and achieve the effects of safe, convenient and reliable use, easy automatic control, and the use of many standard parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] For further understanding technical content feature and function of the present invention are described as follows:

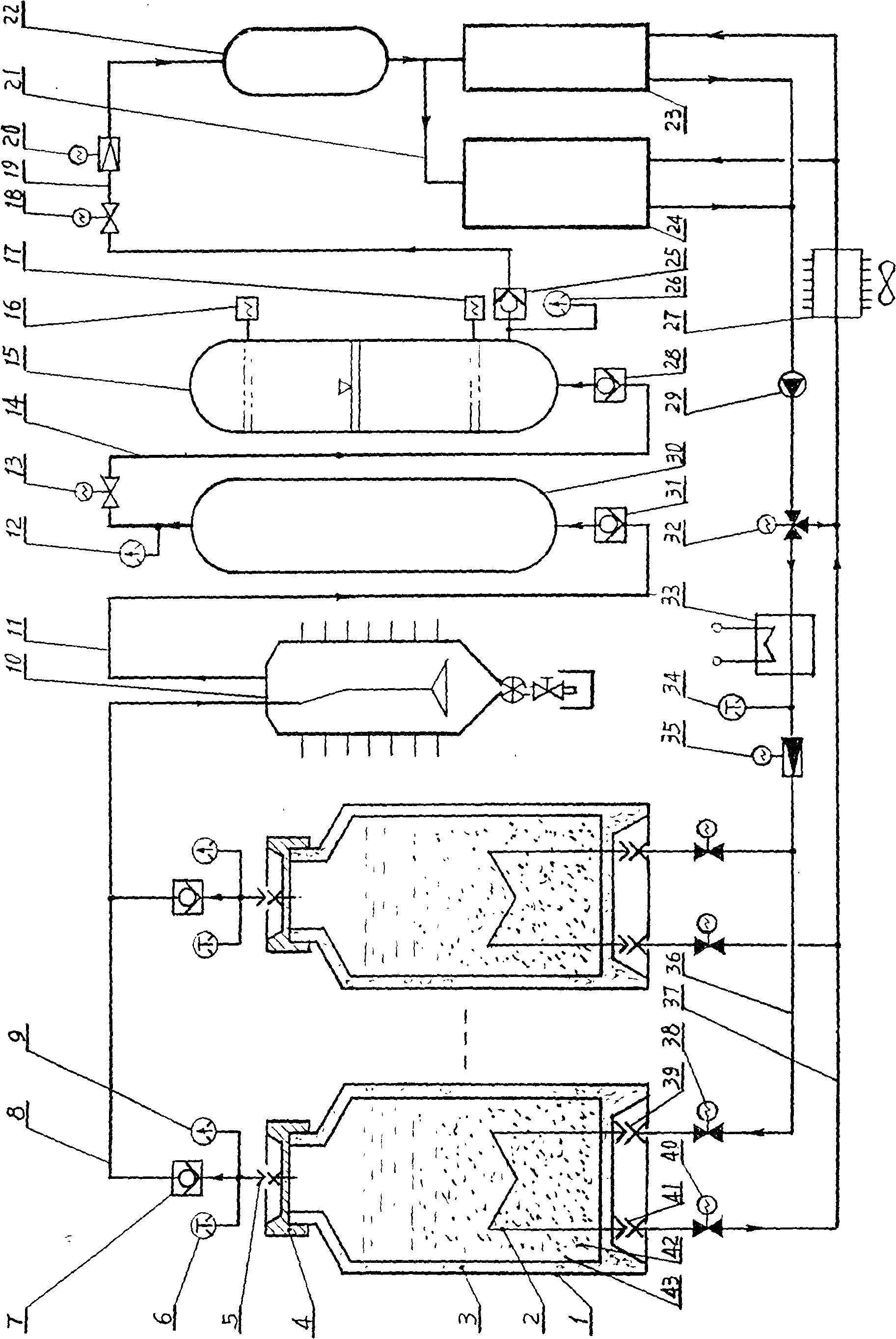

[0012] Please refer to the attached picture, the mobile water splitting aluminum hydrogen production device is mainly composed of three parts, one is the hydrogen production barrel for recycling; the other is the hydrogen supply part; the third is the hot water supply part.

[0013] The circulating hydrogen production barrel is made of plastic and mainly consists of a barrel body 1, a water inlet joint 39, a return water joint 41, a heating water pipe 2, an insulation layer 3, a barrel cover 4, and a hydrogen outlet joint 5. It is characterized in that: the bottom of the barrel body 1 A water inlet joint 39 and a water return joint 41 are provided. The barrel body 1 is provided with a heating water pipe 2. The interlayer of the barrel body 1 is provided with an insulating layer 3. The barrel lid 4 is sealed and connected with the barrel body 1. The barrel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com