Technology for comprehensive utilization treatment of chemical plant waste hydrochloric acid and special MVR evaporation concentrator thereof

A treatment process, waste hydrochloric acid technology, applied in the chemical industry, sulfur compounds, chemical instruments and methods, etc., can solve problems such as permanent pollution of groundwater, endangering drinking water safety, and high hazards, so as to reduce pollution, increase liquid surface area, product pure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

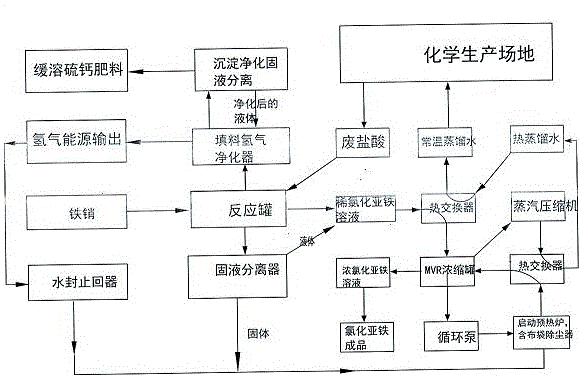

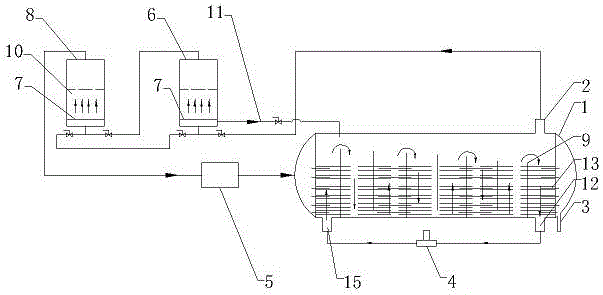

[0048] In the embodiment, the sewage treatment process of the chemical plant adopts the MVR distillation equipment and the hydrochloric acid comprehensive utilization treatment process. The hydrochloric acid comprehensive treatment process adopts a chemical and physical combined treatment scheme.

[0049] Such as figure 1 As shown, a process for comprehensive utilization of waste hydrochloric acid in a chemical plant includes the following steps:

[0050] 1) The waste hydrochloric acid from the chemical production site, with a concentration of about 8-12%, enters the reaction tank with iron pins, and the hydrochloric acid reacts with iron to produce ferrous chloride and hydrogen.

[0051] The specific response is as follows:

[0052] 2HCL+Fe→FeCL2+H2↑;

[0053] 2) After the hydrogen produced in step 1 is processed by the filler hydrogen purifier, it is used as hydrogen energy output and sent to the preheating furnace through the water-sealed backstop as fuel to compensate for the heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com