Ferrotitanium-based hydrogen storage alloy

A hydrogen storage alloy and ferro-titanium technology, which is applied in the field of hydrogen storage alloy materials and hydrogen storage materials, can solve problems such as the reduction of effective hydrogen storage capacity of the alloy, the tilt of the hydrogen absorption and release platform of the alloy, and the unfavorable application of hydrogen storage alloys, etc., to achieve activation performance Improvement, flat hydrogen absorption and desorption platform, and good kinetic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Hydrogen storage alloy TiFe 0.85- mn 0.15 Ce 0.02 Weigh 50g of the raw material according to the weight percentage determined by the alloy formula, and the purity of the metal element used in the experiment is all above 99%. The above raw materials were cleaned and placed in an induction suspension melting furnace, evacuated and smelted in a 0.05MPa argon atmosphere. In order to ensure uniform composition of the alloy, smelting was performed three times. Crush the sample to -30~+80 mesh, then take 2g of the sample and put it in the reaction kettle. Vacuumize the reactor at 353K for 1 hour, and then fill it with 4MPa hydrogen, the alloy can react directly with hydrogen, and the alloy can be fully activated after repeated hydrogen absorption and desorption for 2 times. It is measured that the maximum hydrogen storage capacity of the alloy reaches 1.78wt.% at 298K, 4MPa.

Embodiment 2

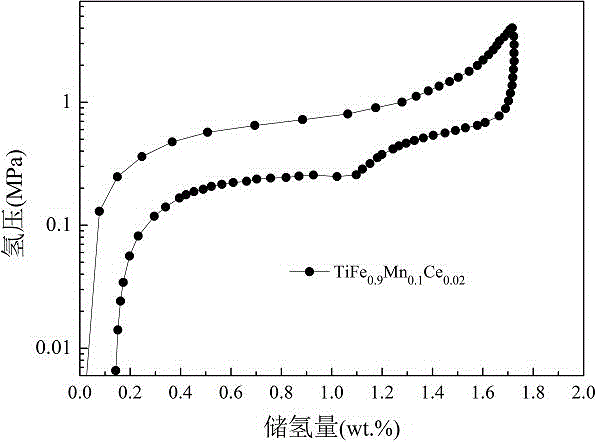

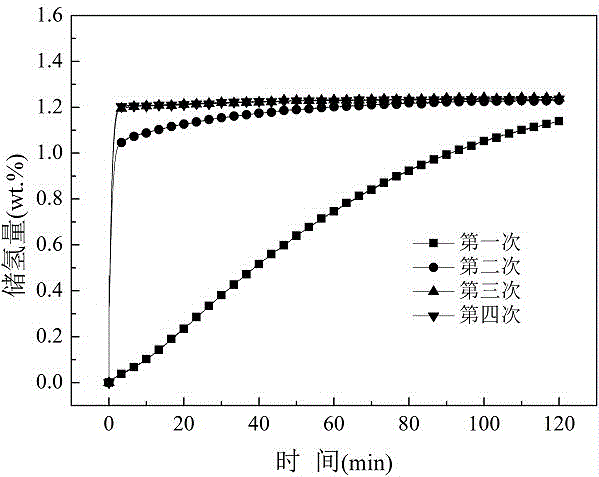

[0021] Hydrogen storage alloy TiFe 0.9- mn 0.1 Ce 0.02 Weigh 50g of the raw material according to the weight percentage determined by the alloy formula, and the purity of the metal element used in the experiment is all above 99%. The above-mentioned raw materials were cleaned and placed in a medium-frequency induction suspension melting furnace, and then smelted in a 0.05MPa argon atmosphere after exhausting. In order to ensure the uniform composition of the alloy, the alloy was smelted three times. Crush the smelted sample to -30~+80 mesh, and then take 2g of the sample and put it in the reaction kettle. The reactor was evacuated at 353K for 1 hour, and then filled with 4MPa hydrogen, the alloy could react directly with hydrogen, and the alloy could be fully activated after repeated absorption and desorption of hydrogen for 5 times. It is measured that the alloy has a maximum hydrogen storage capacity of 1.73wt.% at 298K and 4MPa, and its PCT curve is as follows figure 1 ...

Embodiment 3

[0023] Hydrogen storage alloy TiFe 0.9- mn 0.1 Ce 0.06 Weigh 50g of the raw material according to the weight percentage determined by the alloy formula, and the purity of the metal element used in the experiment is all above 99%. The above raw materials were cleaned and placed in an induction suspension melting furnace, evacuated and smelted in a 0.05MPa argon atmosphere. In order to ensure the uniform composition of the alloy, the alloy was smelted three times. Crush the sample to -30~+80 mesh, then take 2g of the sample and put it in the reaction kettle. Vacuumize the reactor at 353K for 1 hour, and then fill it with 4MPa hydrogen, the alloy can react directly with hydrogen, and the alloy can be fully activated after repeated hydrogen absorption and desorption for 4 times. It is measured that the maximum hydrogen storage capacity of the alloy is 1.71wt.% at 298K, 4MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com