Patents

Literature

64 results about "Hydrogen+Methane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methane (US: /ˈmɛθeɪn/ or UK: /ˈmiːθeɪn/) is a chemical compound with the chemical formula CH4 (one atom of carbon and four atoms of hydrogen). It is a group-14 hydride and the simplest alkane, and is the main constituent of natural gas.

Process for the conversion of ethane to aromatic hydrocarbons

InactiveUS20090209795A1Low levelSacrificing overall activity and aromatics selectivityMolecular sieve catalystsRefining to change hydrocarbon structural skeletonChemistryBenzene

A process for producing aromatic hydrocarbons which comprises (a) contacting ethane with a dehyroaromatization aromatic catalyst which is comprised of about 0.005 to about 0.1 % wt platinum, an amount of an attenuating metal which is no more than about 0.02 % wt less than the amount of platinum, from about 10 to about 99.9 % wt of an aluminosilicate, and a binder, and (b) separating methane, hydrogen, and C2-5 hydrocarbons from the reaction products of step (a) to produce aromatic reaction products including benzene.

Owner:SHELL OIL CO

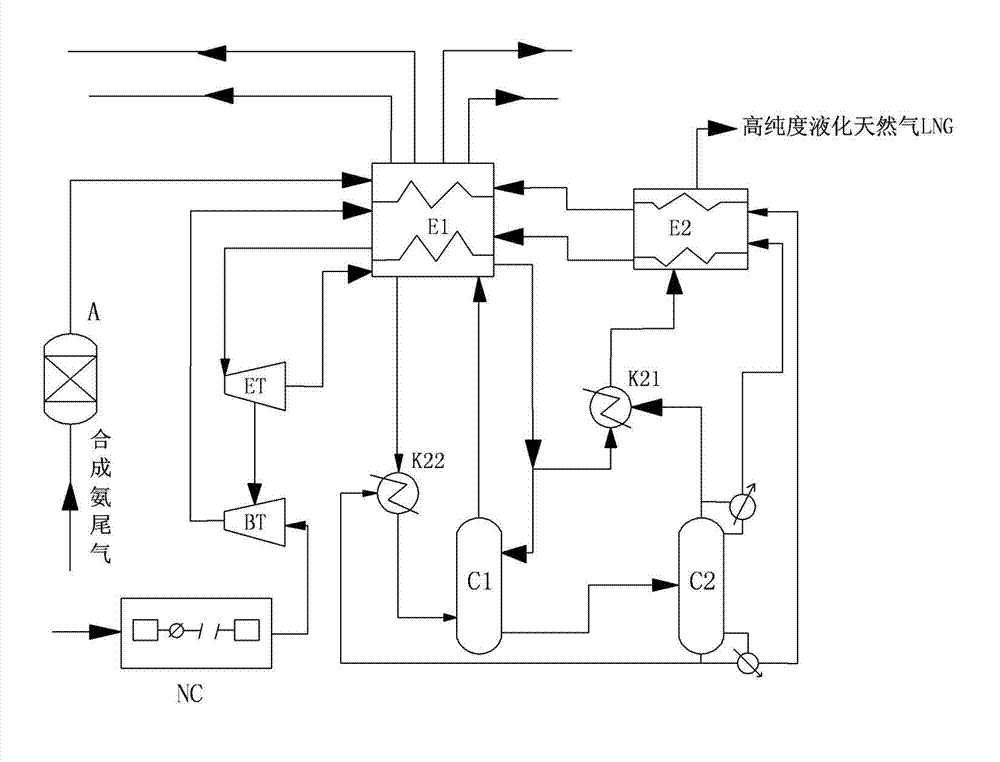

Method for preparing high-purity liquefied natural gas from ammonia synthesis tail gas

InactiveCN102827658AReduce wasteAvoid wastingHydrocarbon from carbon oxidesGaseous fuelsMolecular sieveDehydrogenation

The invention discloses a method for preparing high-purity liquefied natural gas from ammonia synthesis tail gas. The method includes filling the ammonia synthesis tail gas in a molecular sieve absorber to perform purification treatment for the ammonia synthesis tail gas, sequentially delivering the purified tail gas into a main heat exchanger and an evaporator to cool the tail gas, filling the cooled tail gas in a dehydrogenation rectifying tower to perform rectification separation for the tail gas; exhausting oxygen-rich gas from the top of the tower after the separation and obtaining methane-rich liquid from the bottom of the tower; and delivering the methane-rich liquid into a product rectifying tower to perform further rectification separation for the methane-rich liquid and obtaining a high-purity liquefied natural gas LNG product at the bottom of the product rectifying tower after the rectification separation. By the method, resources such as methane and hydrogen in the tail gas can be effectively recycled, so that the resources are recycled, waste of the resources is reduced, the waste resources are turned into wealth, and environmental pollution and waste of energy are avoided. Accordingly, the method has remarkable economical benefit and social benefit.

Owner:HENAN KAIYUAN AIR SEPARATION GRP CO LTD

Process for the conversion of ethane to aromatic hydrocarbons

ActiveUS8772563B2Sacrificing overall activity and aromatics selectivityHigh activityMolecular sieve catalystsRefining to change hydrocarbon structural skeletonBenzenePlatinum

A process for producing aromatic hydrocarbons which comprises (a) contacting ethane with a dehyroaromatization aromatic catalyst which is comprised of about 0.005 to about 0.1 wt % platinum, an amount of gallium which is equal to or greater than the amount of the platinum, from about 10 to about 99.9 wt % of an aluminosilicate, and a binder, and (b) separating methane, hydrogen, and C2-5 hydrocarbons from the reaction products of step (a) to produce aromatic reaction products including benzene.

Owner:SHELL USA INC

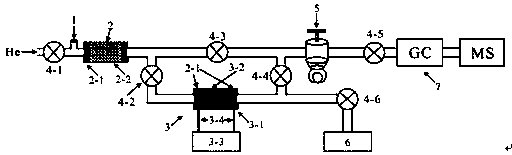

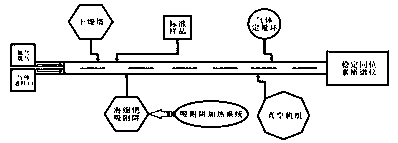

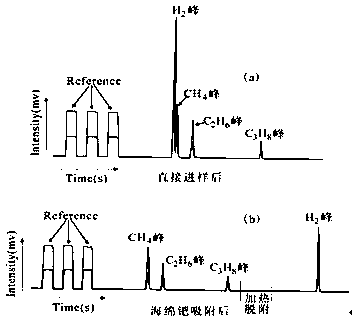

Device and method capable of separating hydrogen and methane in mixed gas and measuring hydrogen isotope

ActiveCN109603413ASmall distortionHigh precisionGas treatmentComponent separationProduct gasHydrogen adsorption

The invention belongs to the field of oil gas geochemistry, and in particular to a device and method capable of separating hydrogen and methane in a mixed gas and measuring a hydrogen isotope. The device comprises a gas sample inlet, a drying unit, a hydrogen adsorption separation unit, a quantifying loop, a vacuum unit and an isotope measuring unit; and the gas sample inlet, the drying unit, thehydrogen adsorption separation unit, the quantifying loop and the isotope measuring unit are sequentially connected in series; the hydrogen adsorption separation unit can release adsorbed hydrogen tomeasure the hydrogen isotope, so that the methane and hydrogen in the mixed gas are separated, the separated hydrogen and methane are used for measure of the hydrogen isotopes respectively, and measure of the hydrogen isotope of the hydrogen and the hydrogen isotope of the methane in the hydrogen-methane mixed gas is realized; and the vacuum degree of the whole system is high, deviation caused bymutual interference between a hydrogen peak and a methane peak in the prior art is overcome, and accuracy of an analytical test is improved.

Owner:NORTHWEST INST OF ECO ENVIRONMENT & RESOURCES CAS

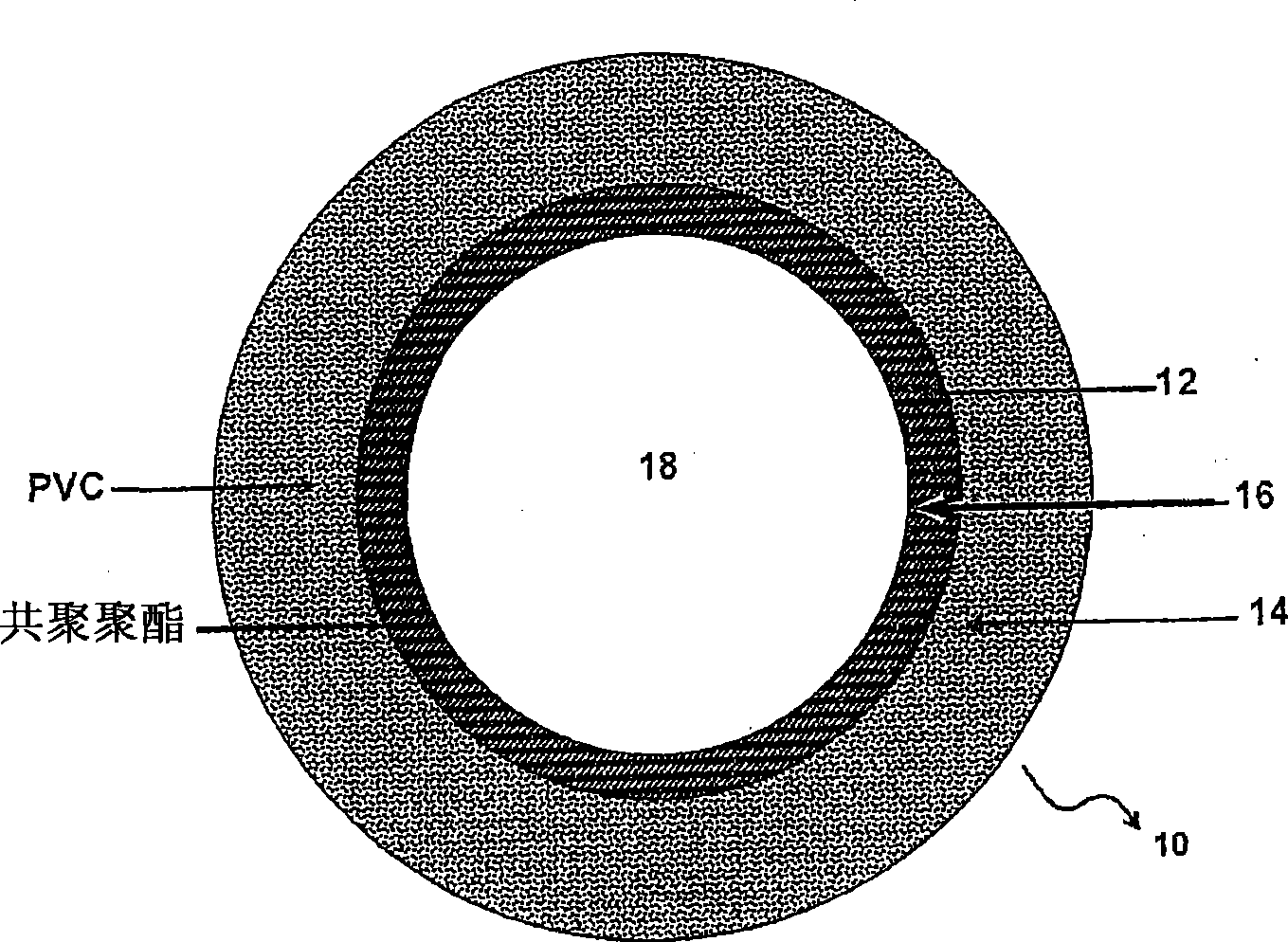

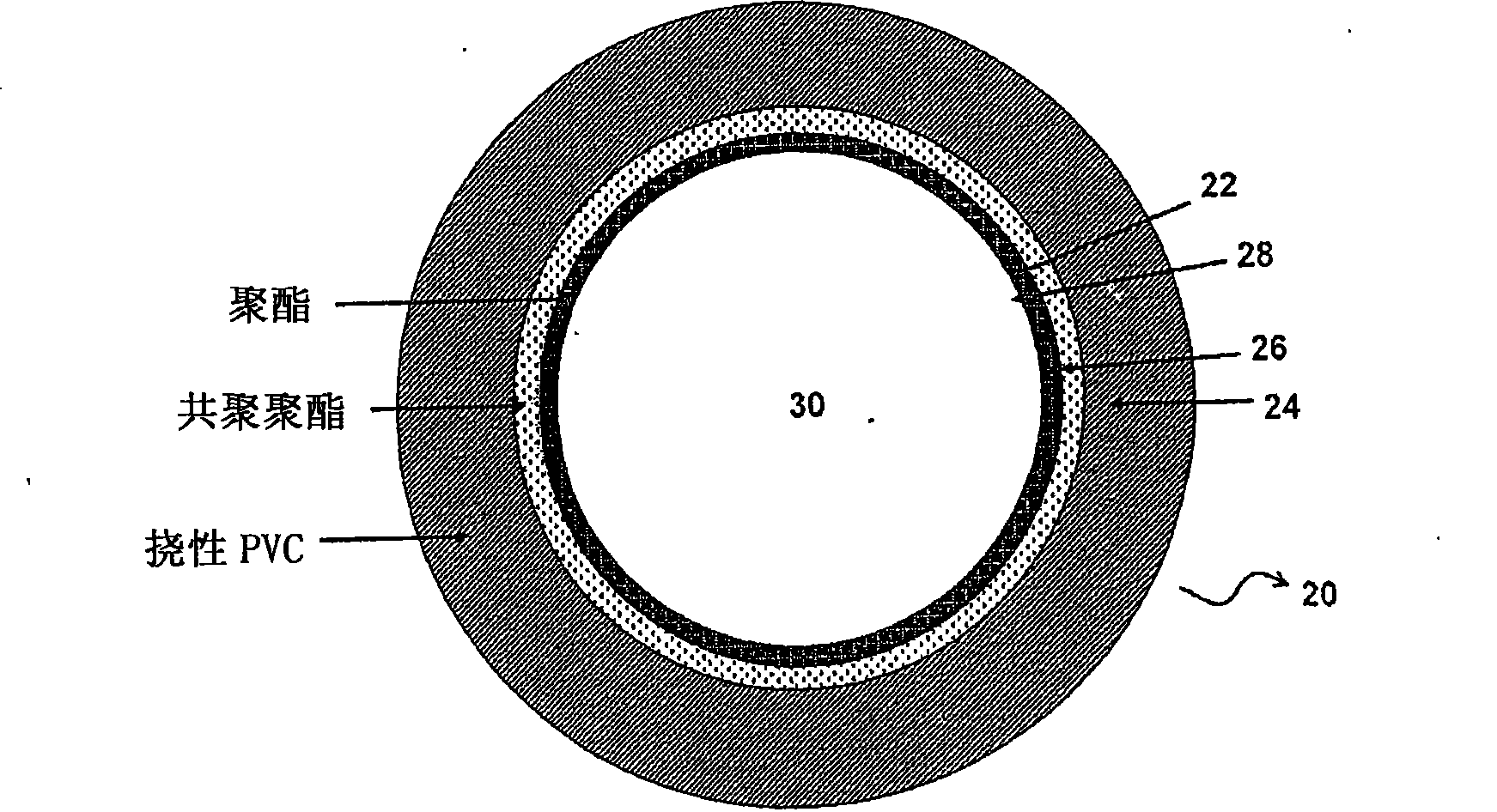

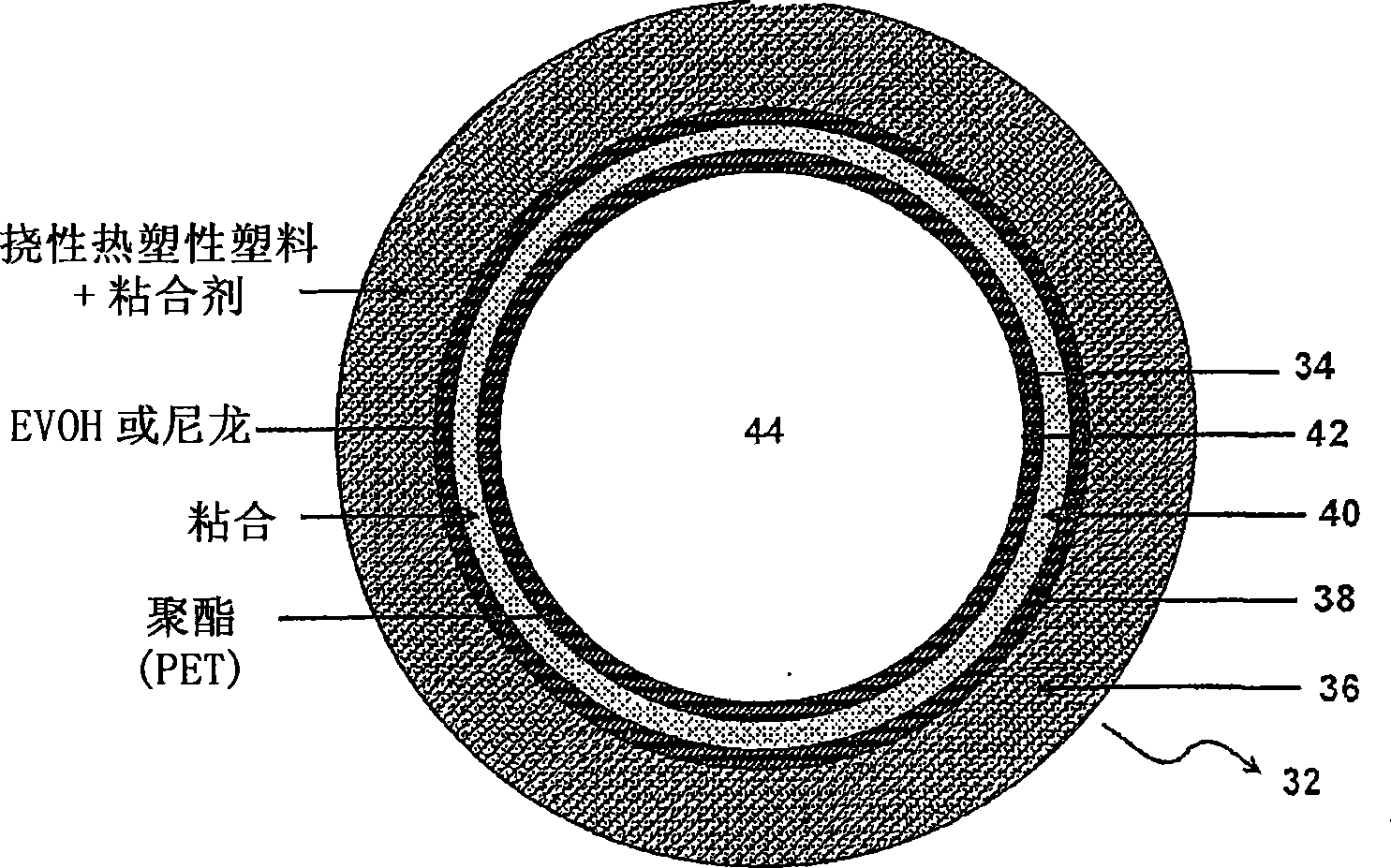

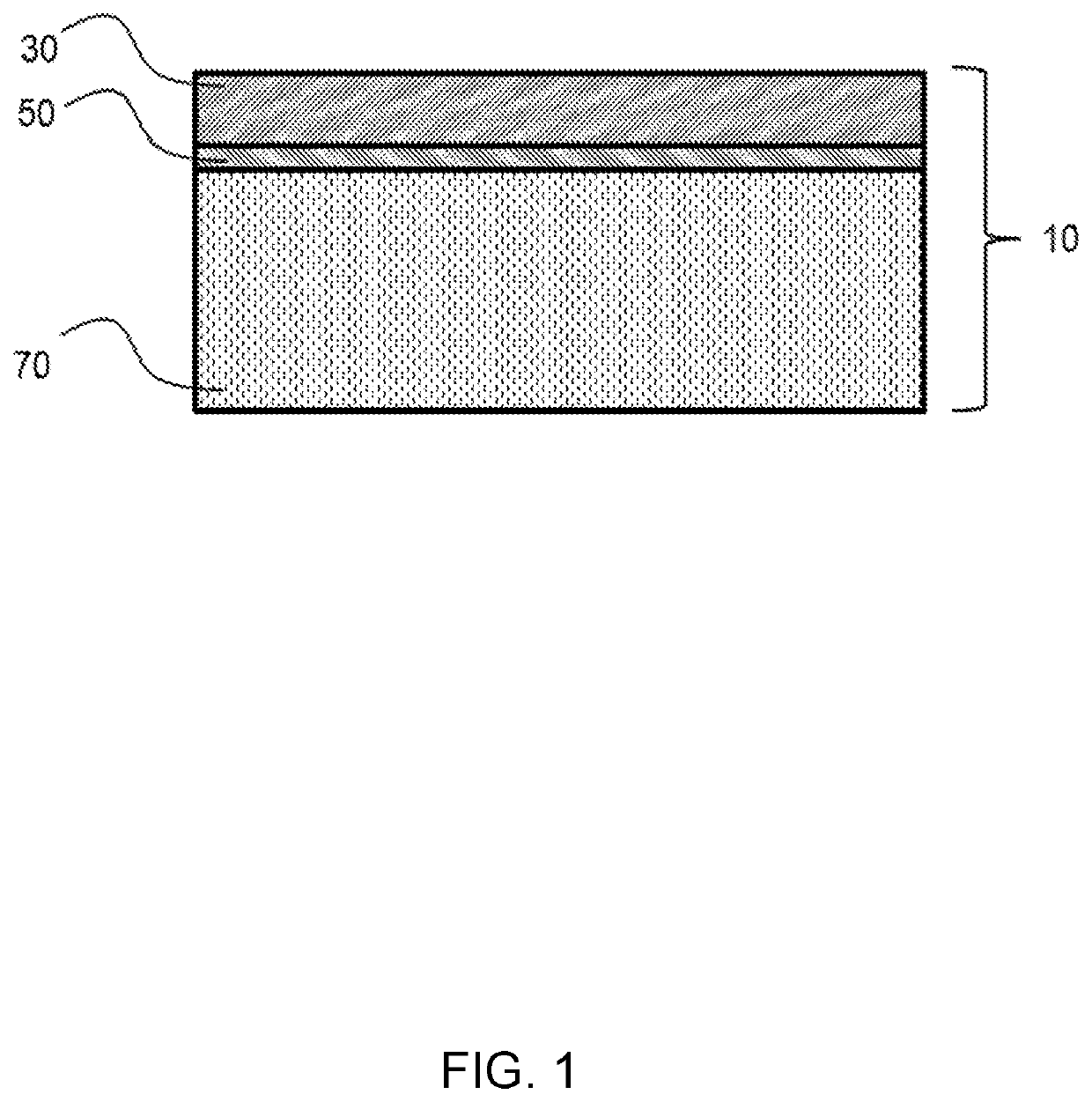

Sustainable and safe pipe for supplying gas fuel to cooking range combusting device

The invention discloses a impermeable, sustainable and safe multi-layer pipeline which is used for transporting gaseous fuel for stove equipped with a combustor and other appliance, such as liquefied petroleum gas (LPG), natural gas (NG) and hydrogen-methane mixture fuel. The thermoplastic layered pipeline comprises an innermost layer, a middle layer and an outer layer, at least one of which comprises polyester and polyethylene terephthalate to fully prevent penetration. The polyester is used as performance [blocking] layer. The performance PET layer is preferably constructed as snake-shaped / corrugated cylindrical structure. The other inner layer, the middle layer and the outer layer of the gaseous fuel pipeline are thermoplastic polymer in various combination forms, and have better structure or bonding layer. The performance blocking layer can also be composed of single-layer or combined copolyester, EVOH or nylon, so as to reduce the penetration to the minimum which can be neglected, but not zero realized by using PET. The pipeline of the invention, known as 'SST', provides pollution (penetration) pipelines used at present, and reduces discharge of the greenhouse gas, therefore the problem that non-polluting alternatives for global warming exist for a long term is solved.

Owner:马克西玛(加拿大)实验室

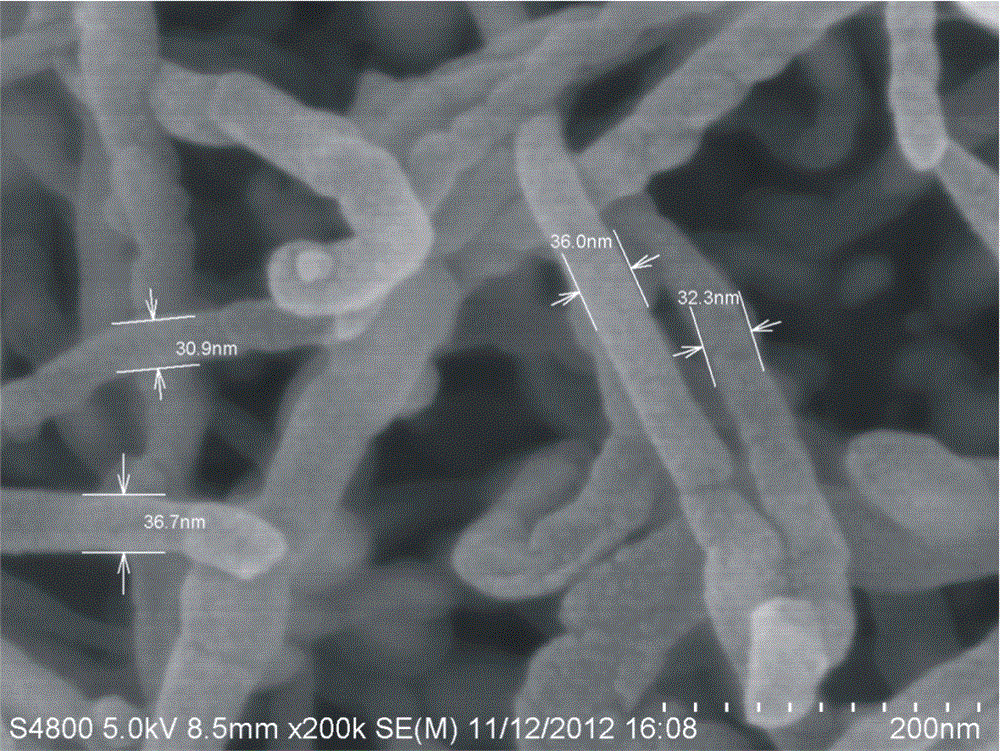

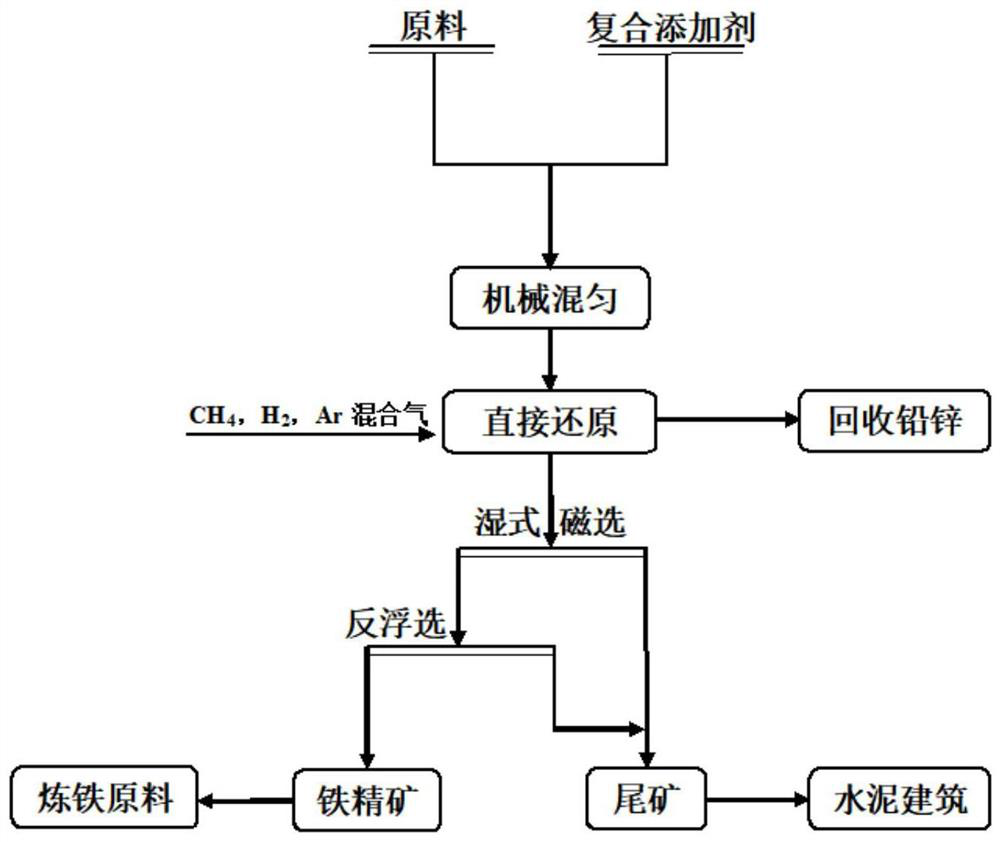

Method for preparing Al2O3 composite powder with uniformly dispersed carbon nanotubes by in-situ synthesis process

The invention discloses a method for preparing Al2O3 composite powder with uniformly dispersed carbon nanotubes by an in-situ synthesis process, which comprises the following steps: proportionally preparing aluminum nitrate, nickelous nitrate and citric acid into a solution, and heating and calcining the obtained solution to initiate the combustion reaction, thereby obtaining the NiAlxO3x+1 solid solution catalyst precursor powder; and putting the obtained solid solution in a pipe furnace, introducing a gas mixture containing methane, hydrogen and nitrogen, heating to reaction temperature, reacting for some time, and cooling to obtain the Al2O3 composite powder with uniformly dispersed carbon nanotubes. The content of the catalyst nickel is controlled to control the content of the carbon nanotubes; and meanwhile, the invention solves the problem that the carbon nanotubes can not be easily dispersed in the ceramic matrix, so that the nanotubes are uniformly dispersed in the product.

Owner:WUHAN UNIV OF TECH

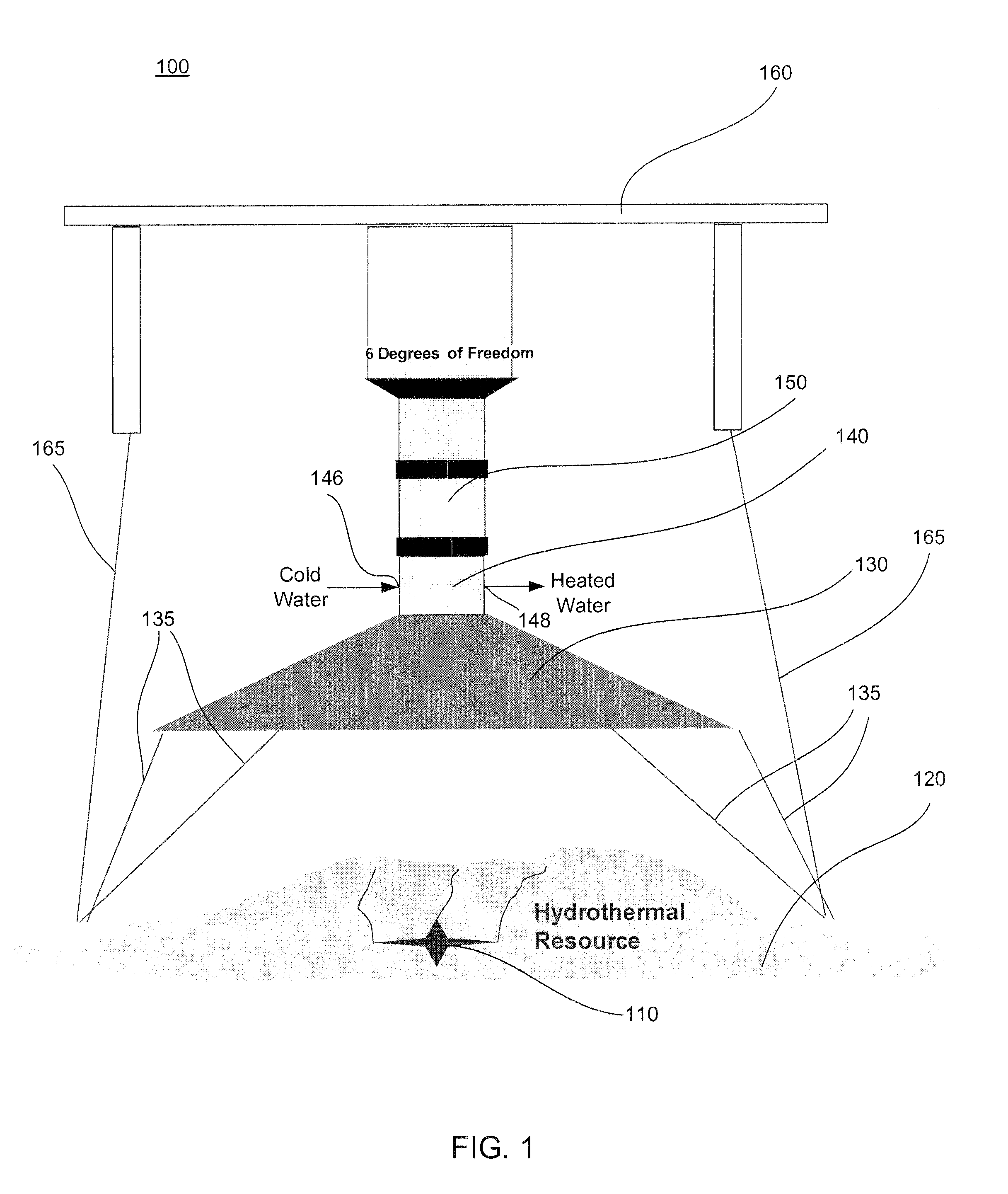

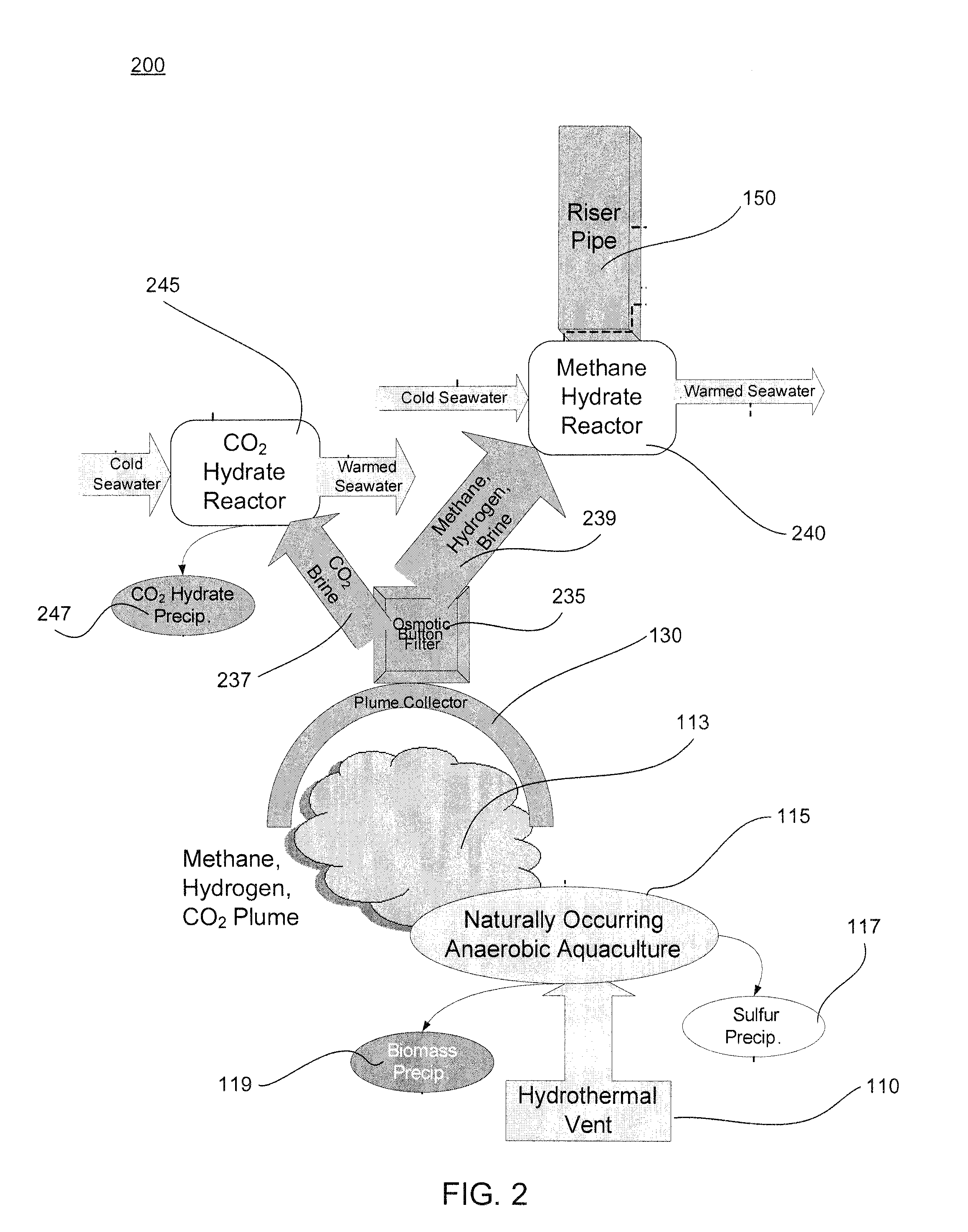

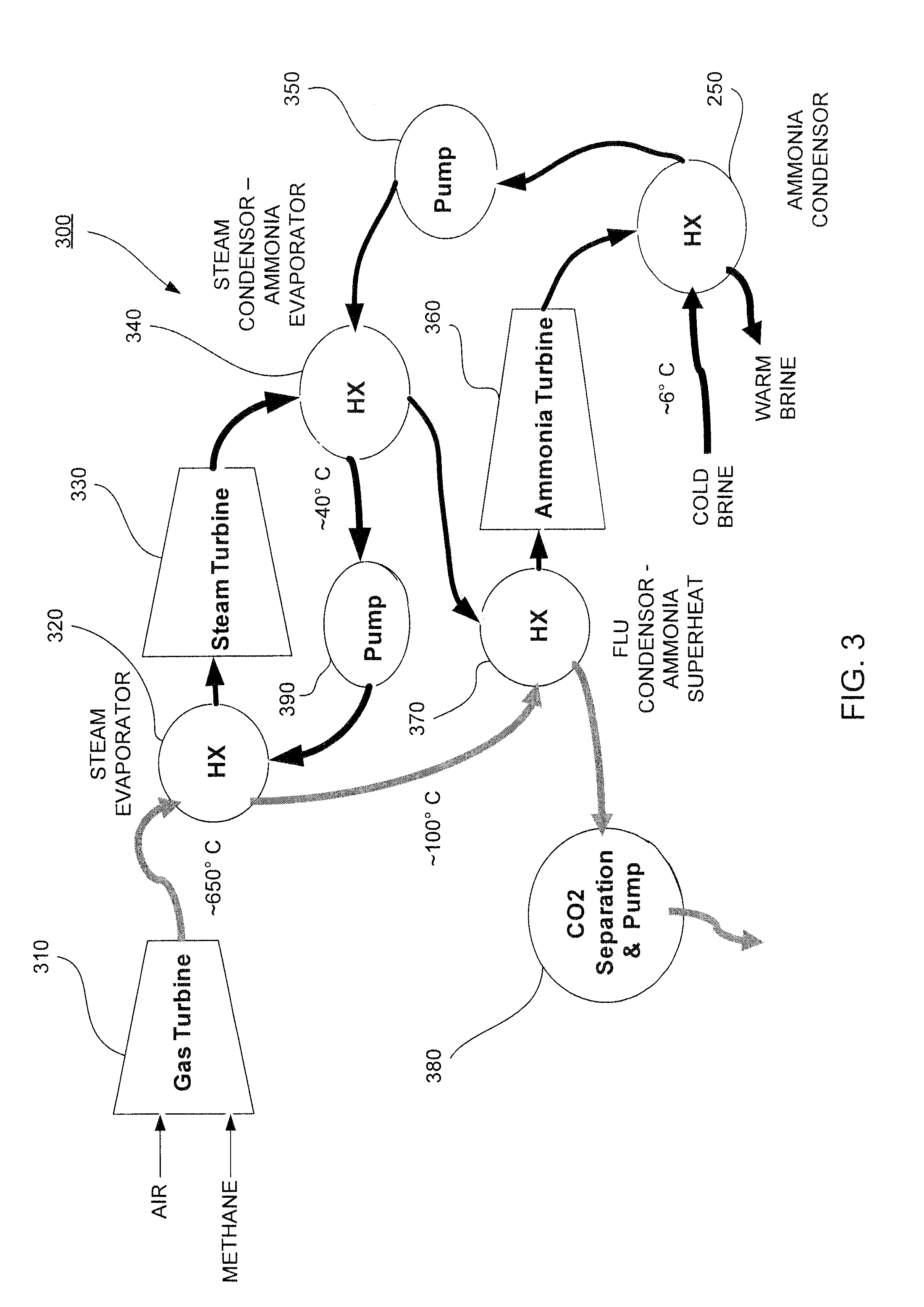

Method and system for harvesting hydrothermal energy

A method for extracting fuel gases from an underwater plume emitted from an underwater hydrothermal vent includes the step of collecting via an underwater fluid collector an underwater plume emitted from the hydrothermal vent. The underwater plume includes methane and hydrogen. The method further includes a step of directing a first fluid containing the underwater plume into a first inlet of a first underwater heat exchanger and a second fluid into a second inlet of the first underwater heat exchanger. The second fluid at the second inlet is at a temperature sufficiently lower than the temperature of the first fluid to transfer sufficient heat therebetween to form methane hydrate and hydrogen-methane hydrate in the first fluid. The method further includes the step of conveying the methane hydrate and hydrogen-methane hydrate to the surface of the water body via a duct connected to a first outlet of the first heat exchanger.

Owner:LOCKHEED MARTIN CORP

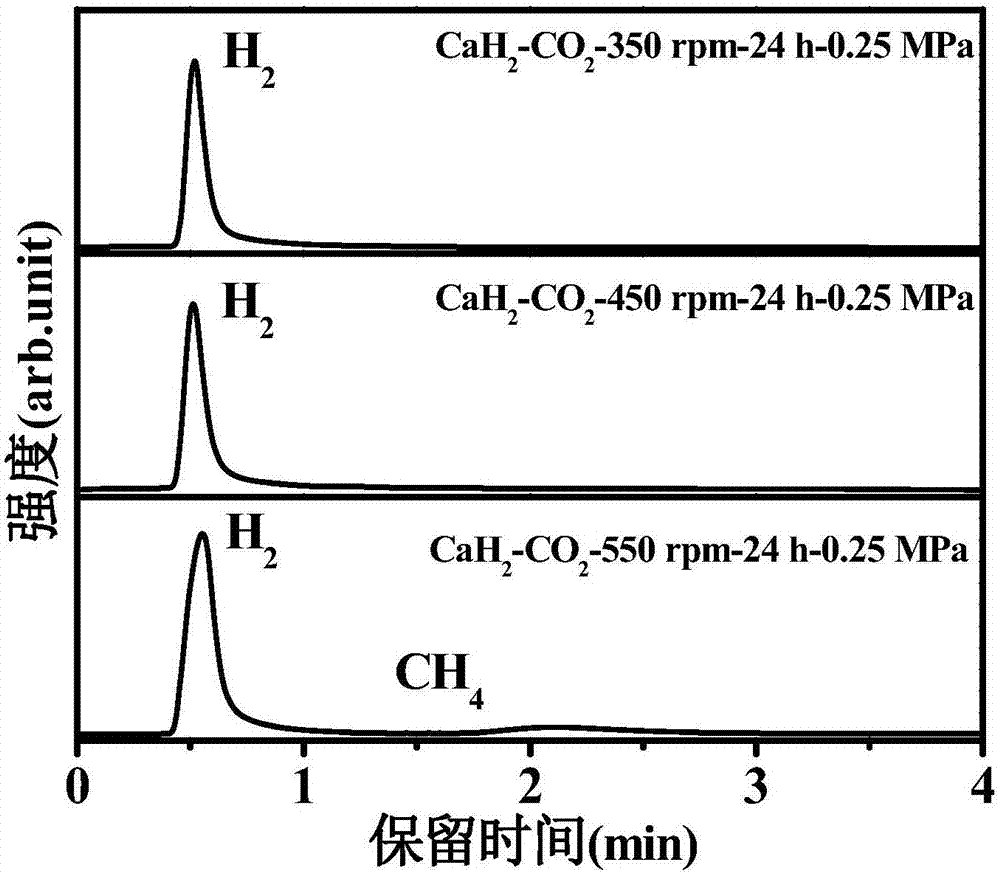

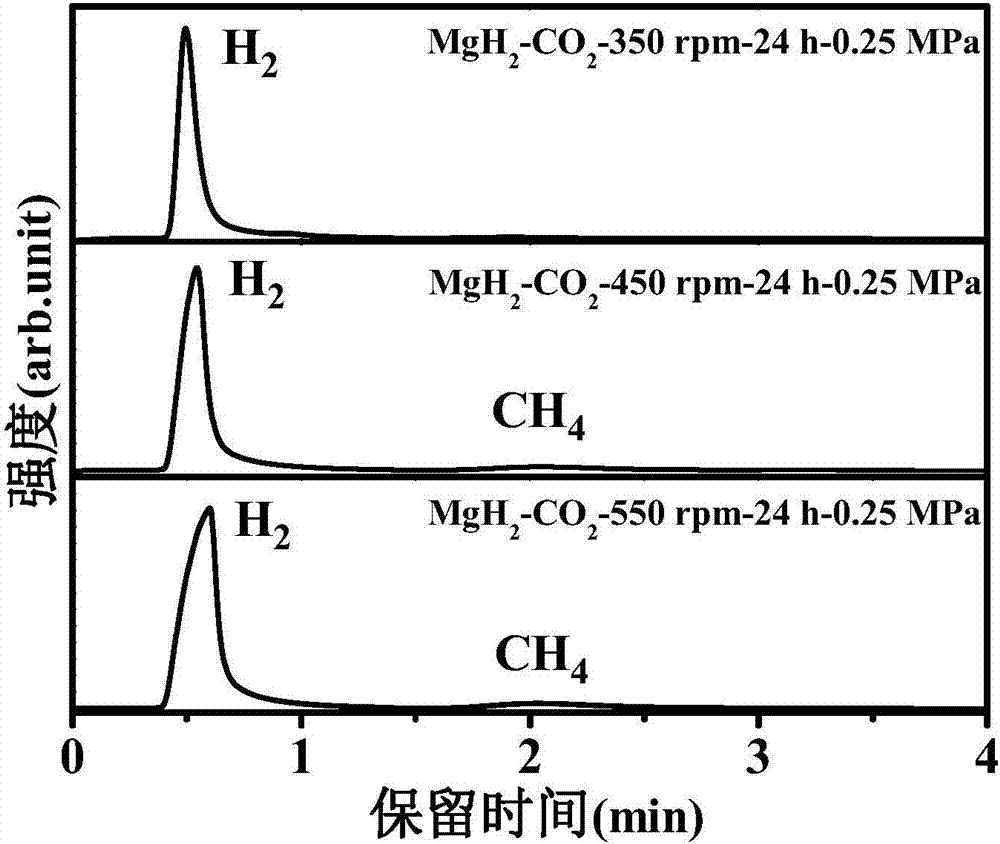

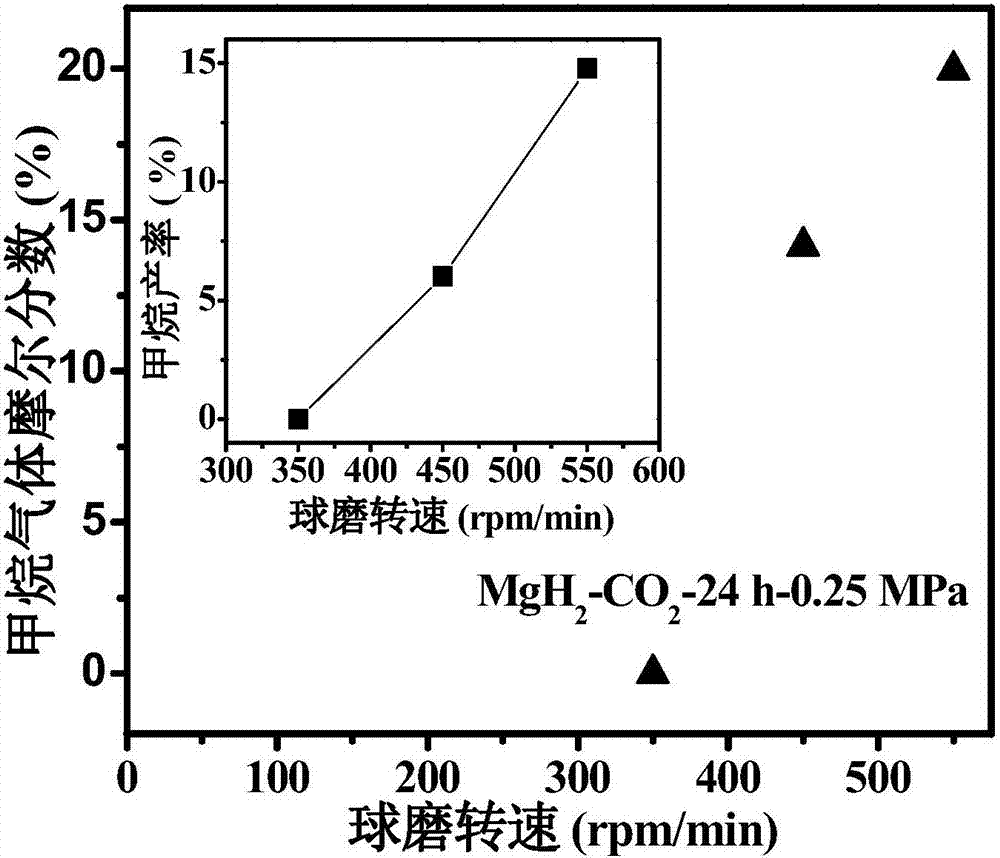

Method of using alkaline earth metal hydrides to prepare hydrogen-methane mixed fuel

InactiveCN107188118AAvoid insecurityTo achieve the purpose of recyclingHydrocarbon from carbon oxidesHydrogen productionAlkaline earth metalMethanation

The invention discloses a method of using alkaline earth metal hydrides to reduce carbon dioxide to prepare a hydrogen-methane mixed fuel. According to the method, in an argon atmosphere, alkaline earth metal hydrides are placed in a ball mill tank, argon is extracted from the ball mill tank, highly pure CO2 gas is filled into the ball mill tank, and a ball milling machine is adopted to carry out ball milling reactions at a room temperature to obtain the hydrogen-methane mixed fuel. The method can prepare hydrogen-methane mixed gas at a room temperature, a novel method is provided for high density storage and preparation of methane, and a novel technology, which can carry out carbon dioxide methanation under mild conditions, is also provided.

Owner:YANGZHOU UNIV

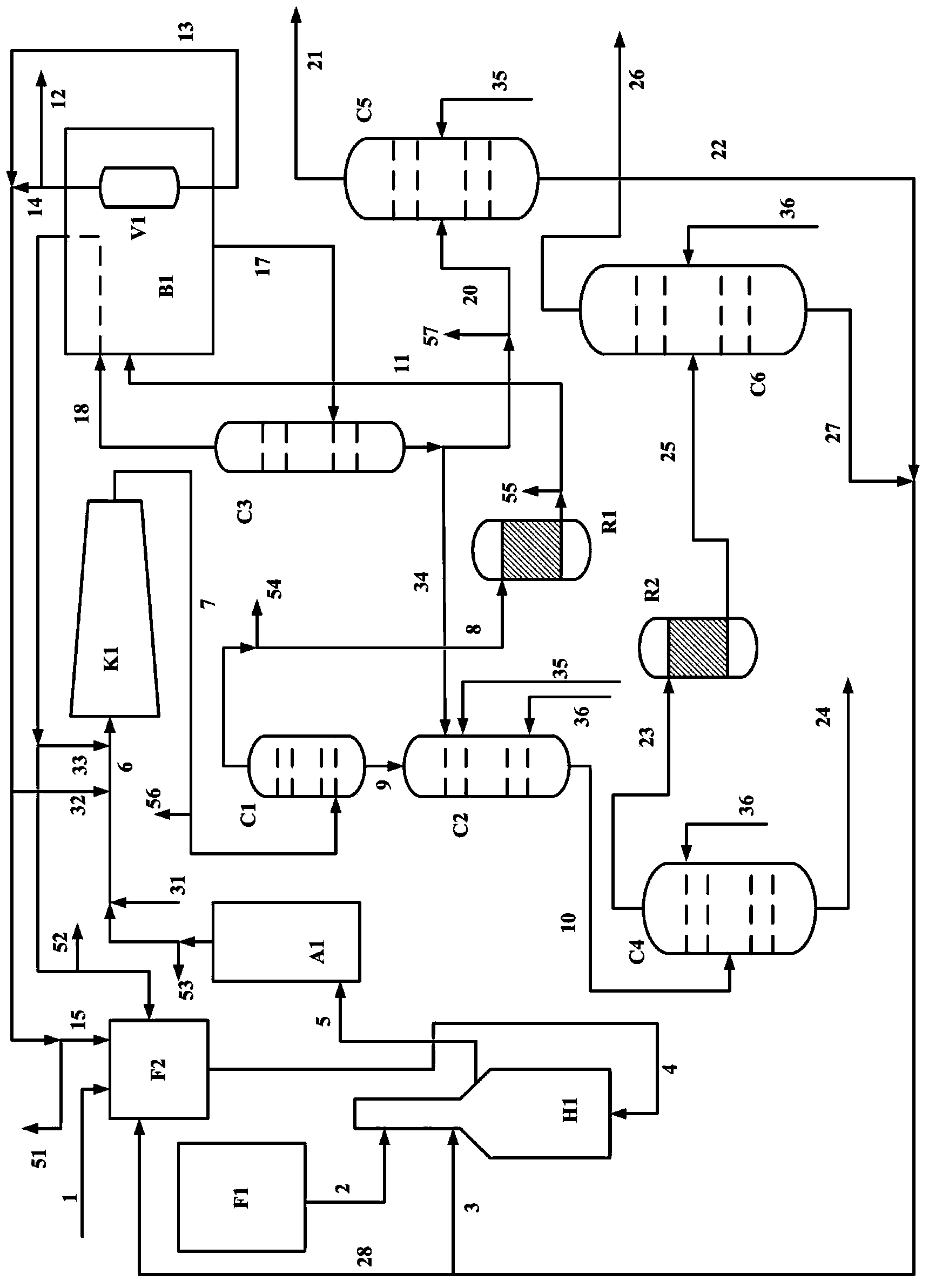

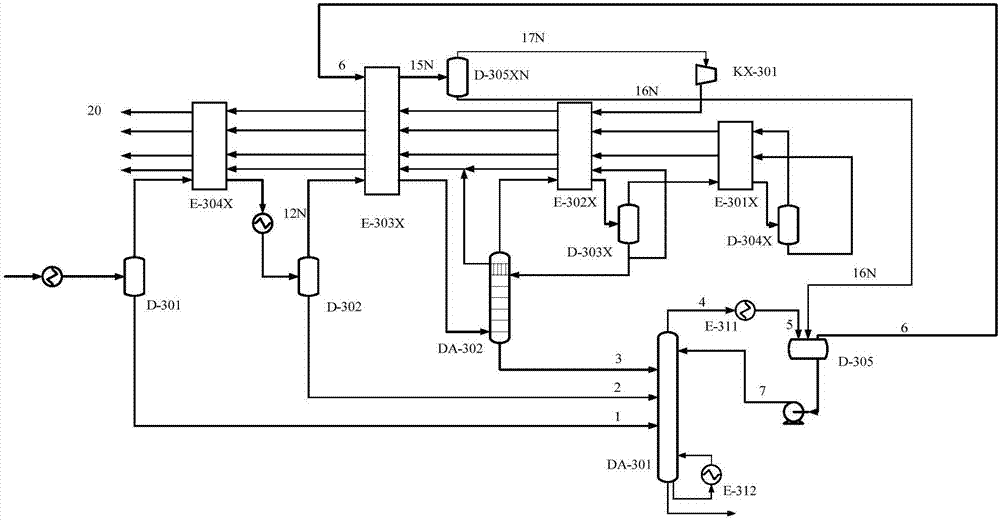

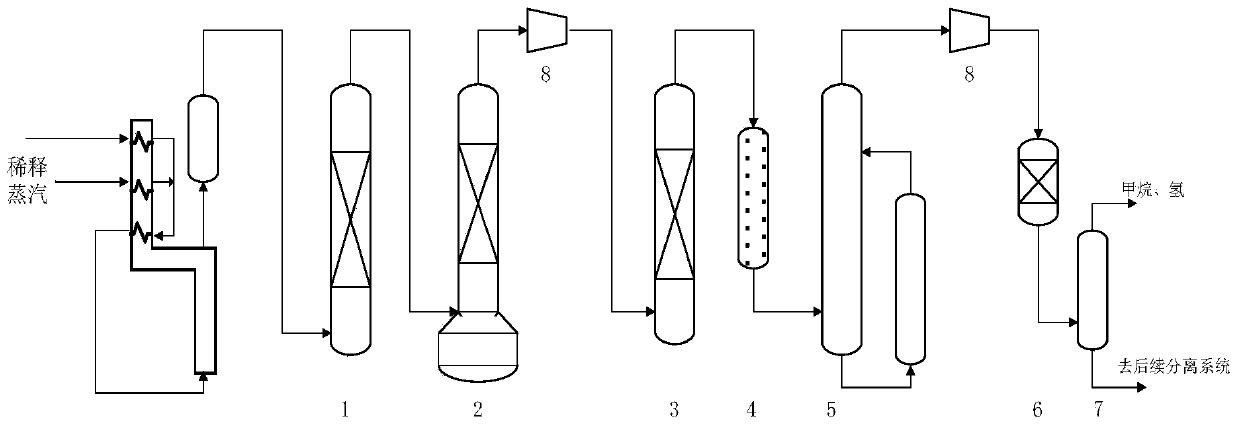

Ethylene device driving method of front-end deethanization process

ActiveCN104342205AEnsure balanceReduce generationEthylene productionTreatment with hydrotreatment processesGas compressorNitrogen

The invention relates to an ethylene device driving method of a front-end deethanization separation process. The method comprises the following steps: in the operation period of recycle gas of a cracking gas compressor, returning materials in a cold box hydrogen methane separation tank and on the tower top of a demethanizer to a cracking furnace after the content of nitrogen in the recycle gas is qualified; arranging a temporary ethane spherical tank, a connecting pipeline and heat exchange facilities, collecting ethane acquired from the tower bottom of an ethylene rectification tower into the ethane spherical tank before shut-down repair of an ethylene device, and in the driving period of the ethylene device, using ethane as supplementary ethane of a first-section suction inlet of the cracking gas compressor after recycling cooling energy of ethane in the spherical tank; and arranging the connecting pipeline and heat exchange facilities among the tower bottom of the demethanizer, the first-section suction inlet of the cracking gas compressor and the cracking furnace, and in the driving period of the ethylene device, recycling the cooling energy of the materials at the tower bottom of the demethanizer, and then returning to the cracking furnace or the first-section suction inlet of the cracking gas compressor. According to the method disclosed by the invention, a large amount of hydrocarbon material discharge torches cannot be generated basically in the driving period of the ethylene device, and the driving time can also be shortened.

Owner:PETROCHINA CO LTD

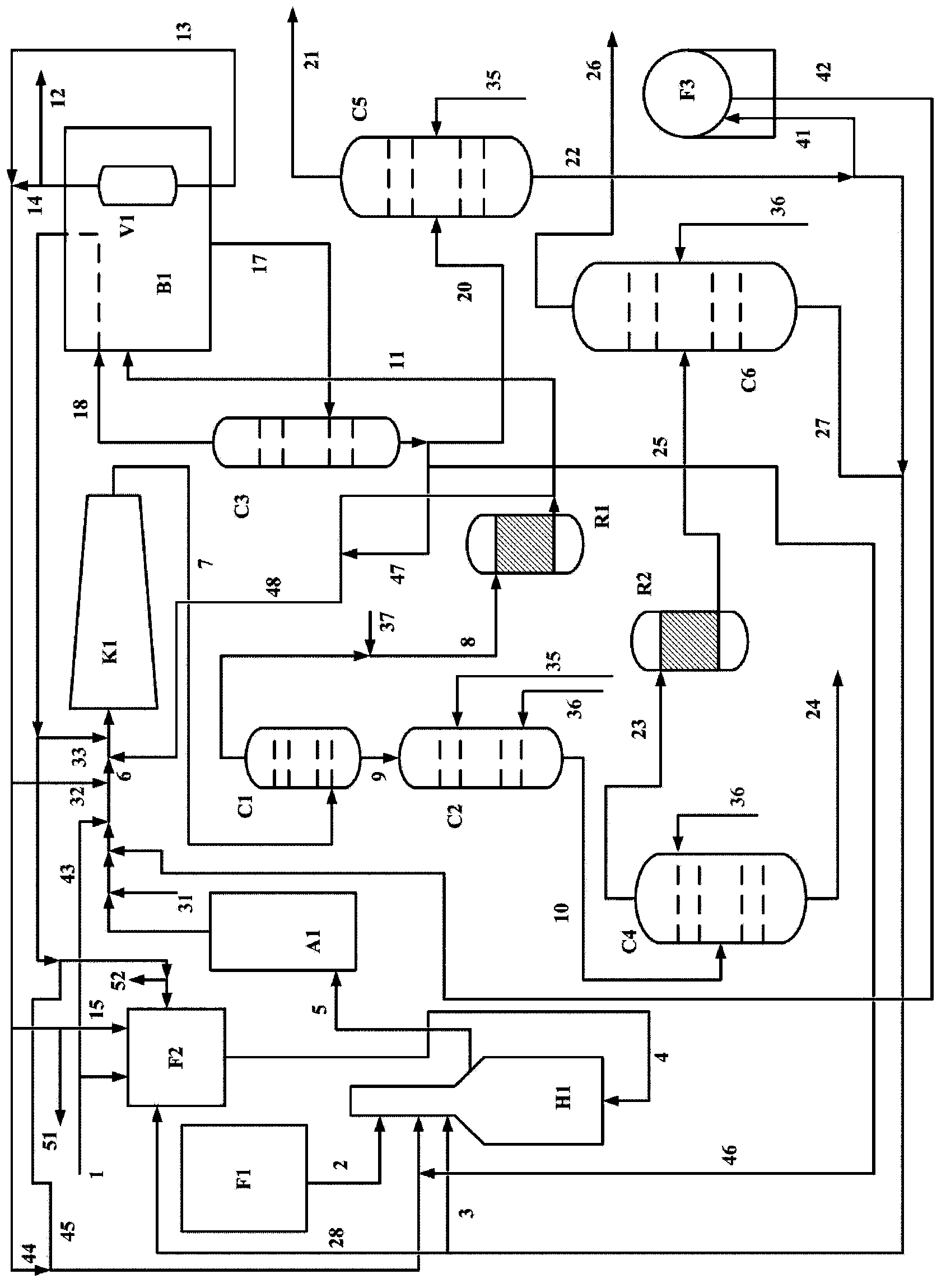

Heat exchange system of demethanizer and heat exchange method

ActiveCN107285981AReduce the temperatureIncrease heat transfer temperature differenceHydrocarbon purification/separationHydrocarbonsGas phaseTemperature difference

The invention discloses a heat exchange system of a demethanizer and a heat exchange method. The heat exchange system adopts one of the following manners: A, a branch separated from an outlet pipeline at the bottom of a 1# hydrogen-methane separation tank is connected with the demethanizer or a demethanizer return tank; B, an aftercooler is arranged at the top of the demethanizer return tank, and a branch separated from the outlet pipeline at the bottom of the 1# hydrogen-methane separation tank is connected with the aftercooler and then connected with the demethanizer return tank; C, a gas-liquid separation tank is arranged behind a cooling box, a gas phase outlet of the demethanizer return tank is connected with the cooling box and then connected with the gas-liquid separation tank, and the bottom of the gas-liquid separation tank is connected with the demethanizer return tank. Under the condition that the coolant level and compressor outlet pressure are unchanged, the gas phase at the top of the demethanizer return tank is cooled by use of local rich cold energy through reasonable optimization of matching of self cold energy of deep cooling, the heat transfer temperature difference of a condenser of the demethanizer is increased, and the loss of ethylene is reduced.

Owner:SINOPEC ENG +1

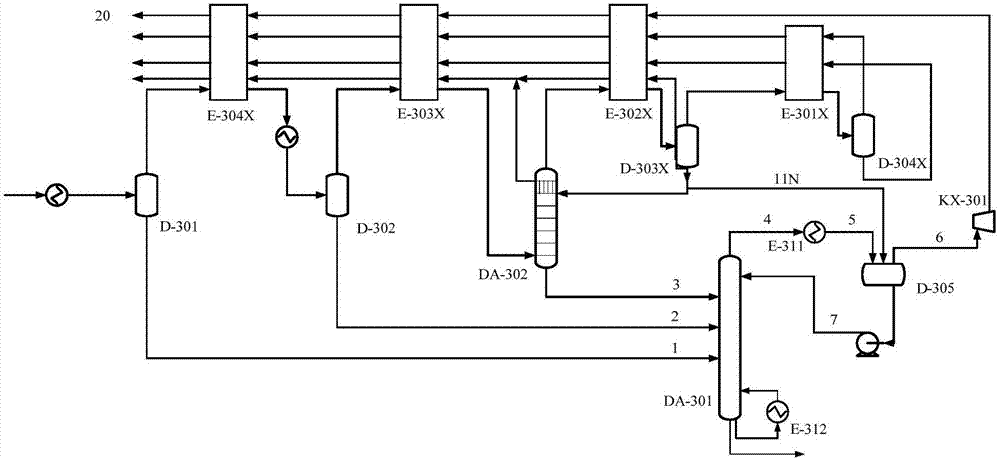

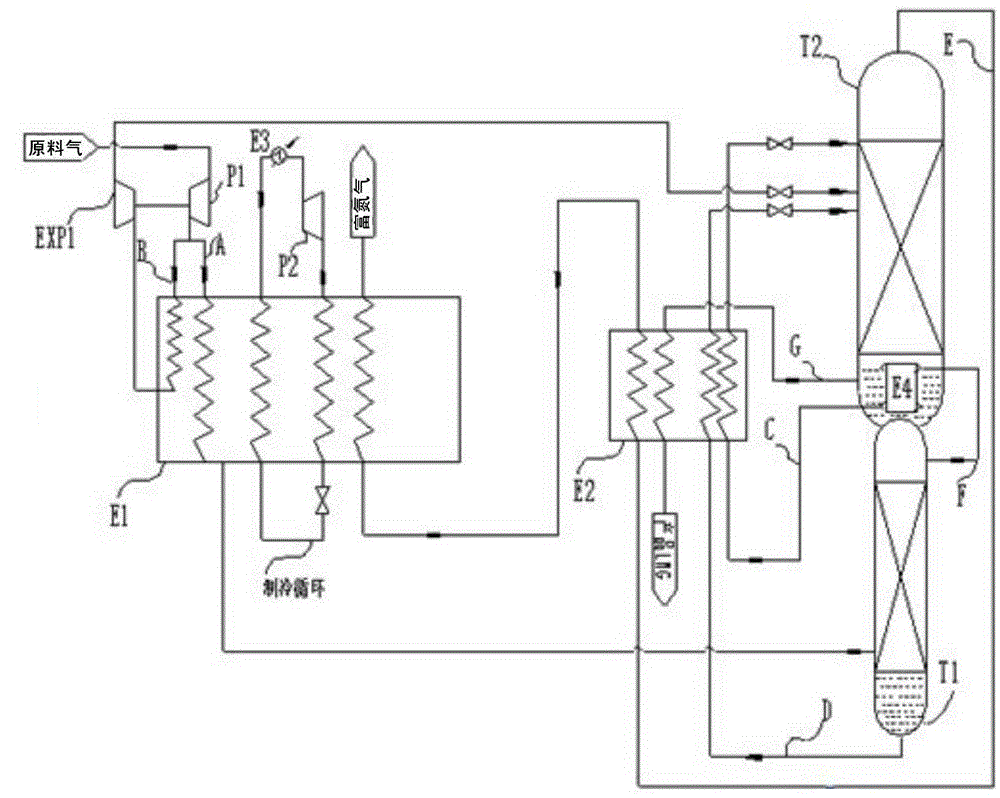

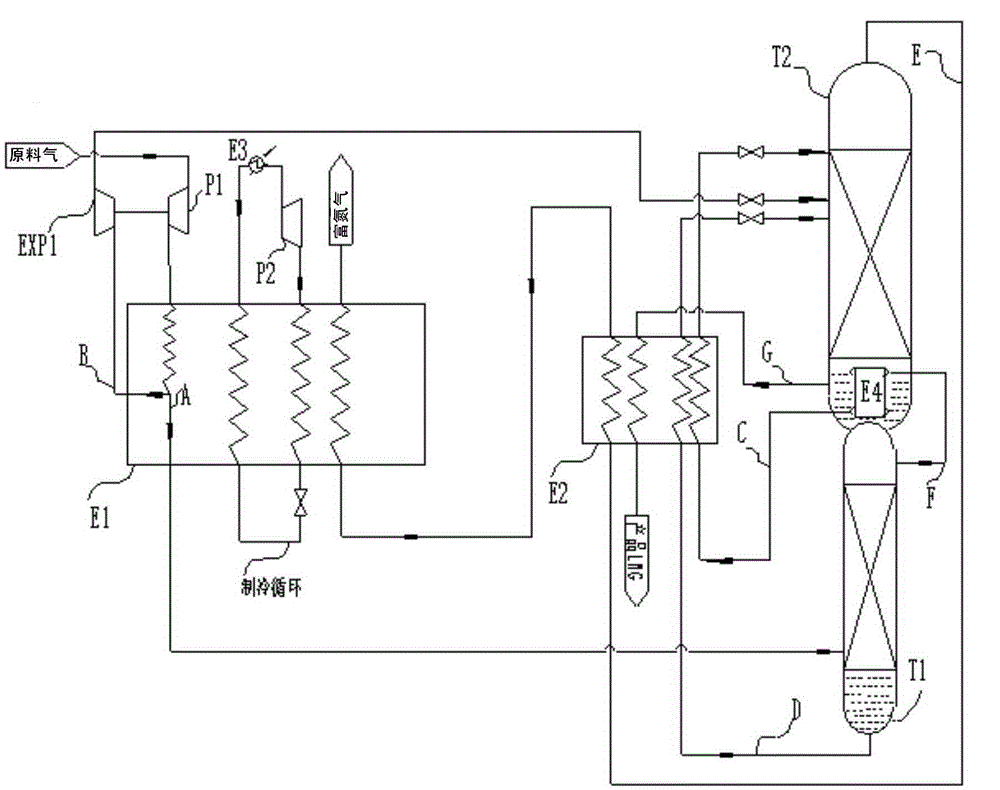

Method for extracting methane from mixed gas containing methane, hydrogen and nitrogen

ActiveCN105254463AHigh recovery rateReduce energy consumptionSolidificationLiquefactionHydrogenNitrogen

The invention discloses a method for extracting methane from mixed gas containing the methane, hydrogen and nitrogen. The method comprises the steps that feed gas is divided into two steams, namely, an air stream A and an air stream B, and the air stream A enters a high-pressure tower to be rectified and separated after being cooled through a main heat exchanger; the air stream B is pumped out from the heat exchanger after being cooled for a certain stage through the main heat exchanger, the pumped-out air stream B is directly fed into a low-pressure tower to be rectified after being depressurized, refrigerated and cooled through an expansion machine, and a liquid methane product is obtained at the tower bottom. Or after the feed gas enters the main heat exchanger and is cooled to a certain stage, the feed gas is divided into the two streams, namely, the air stream A and the air stream B, wherein the air stream A continuously enters the main heat exchanger and is cooled, then the cooled air stream A enters the high-pressure tower to be rectified and separated, the air stream B is directly fed into the low-pressure tower to be rectified after being depressurized, refrigerated and cooled through the expansion machine, and the liquid methane product is obtained at the tower bottom. By means of the method for extracting the methane from the mixed gas containing the methane, the hydrogen and the nitrogen, non-pressurized liquified natural gas with the purity being 98 percent or above can be directly obtained, the product does not need to be liquified again, energy consumption can be greatly reduced, the recovery rate of the methane can reach up to 99.5 percent, the recovery rate of the nitrogen can reach up to 99 percent, and the rewarmed nitrogen can be used as industrial nitrogen.

Owner:SUZHOU XINGLU AIR SEPARATION PLANT SCI & TECH DEV CO LTD

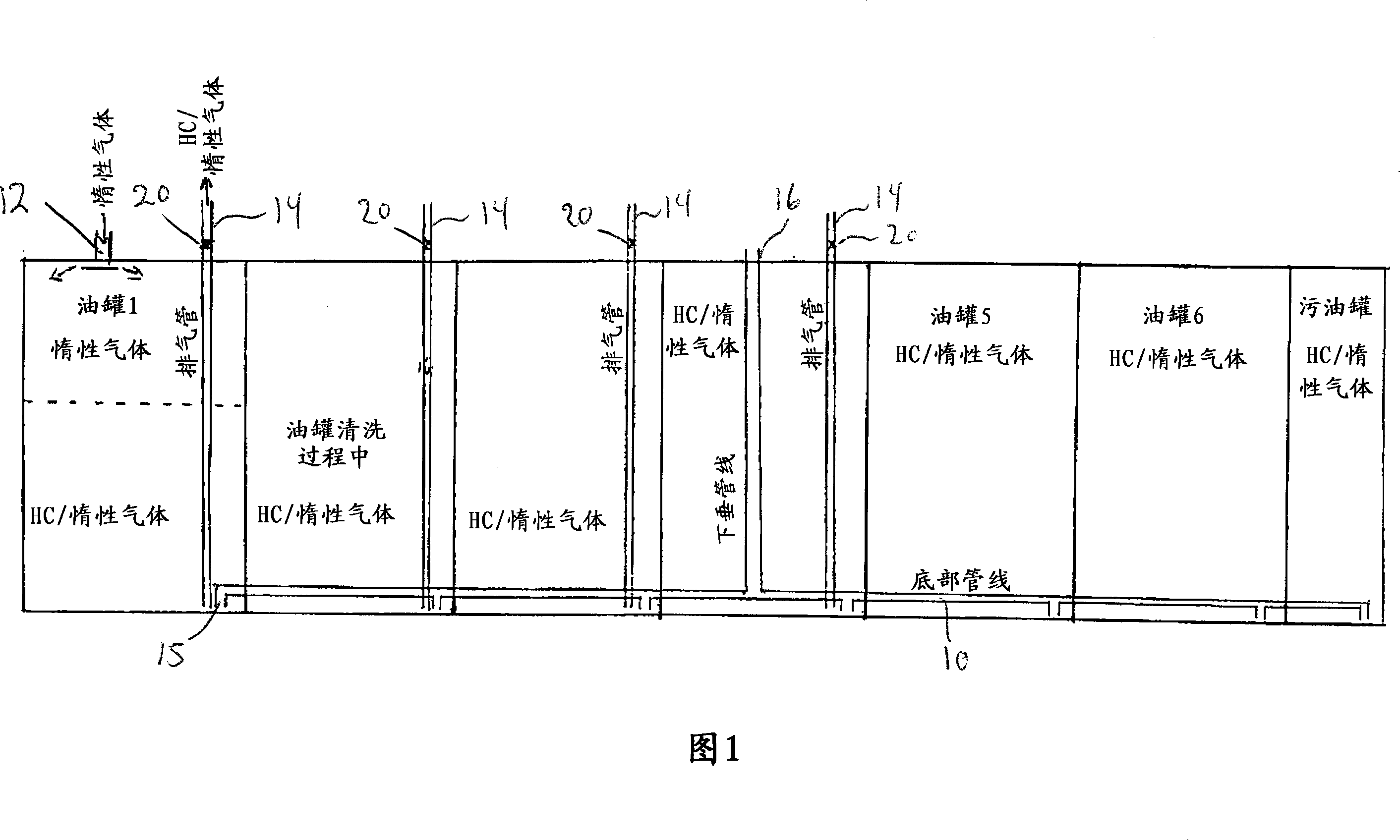

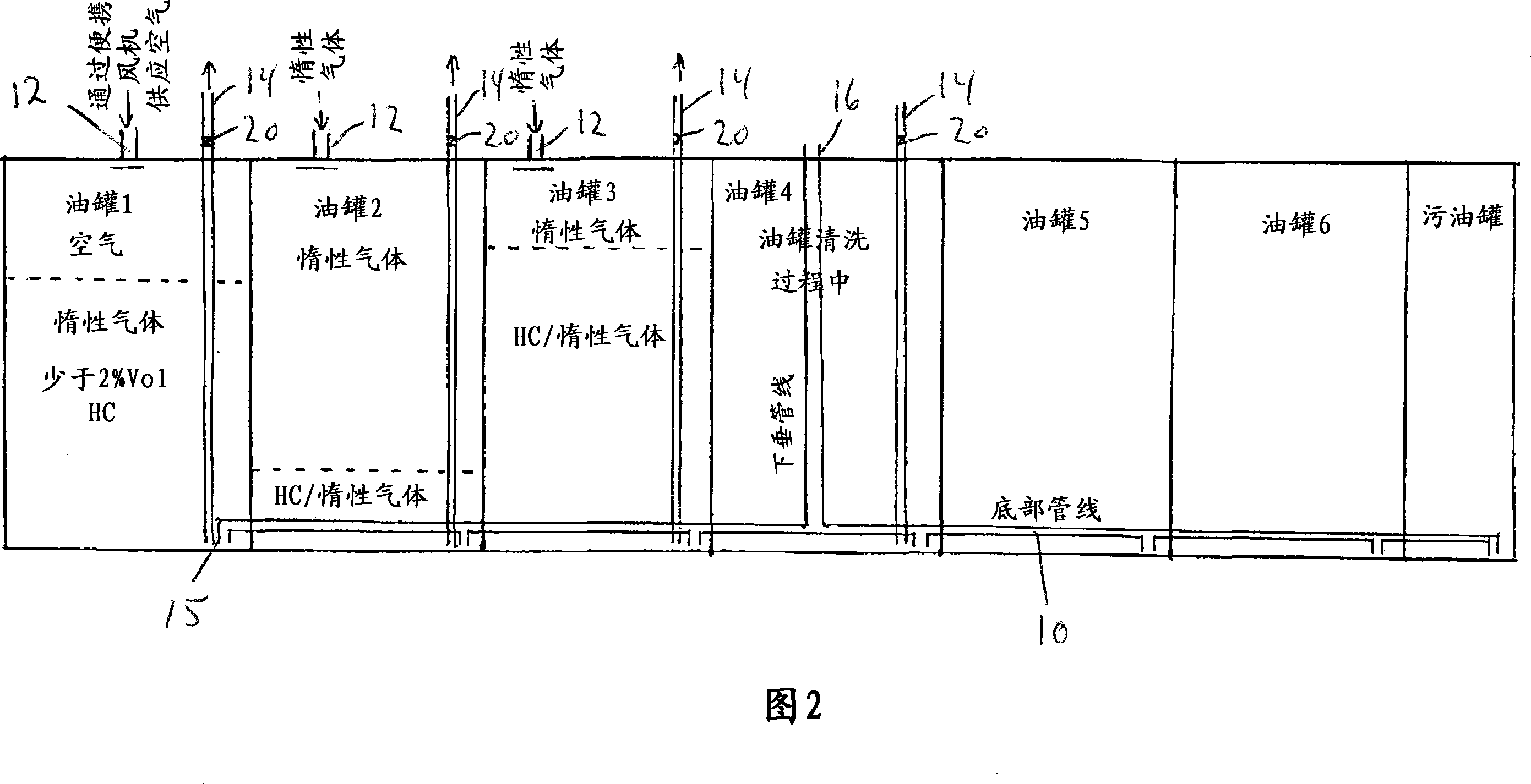

Process and system for gas freeing on board of a vessel or other installation

The invention discloses a degassing system on the ship or the other device, comprising a plurality of adjacent oil tanks connected by the bottom pipeline system. After emptying the oil, the oil tank is filled with gas such as carburetted hydrogen gas. The oil tank comprises at least one air intake for receiving and guiding the gas with specific gravity less than the existing gas in the oil tank such as inert gas and / or air; and an exhaust port for outputting the mixture of the existing gas and the supplied gas. A plurality of oil tanks mounted before the pendulous pipeline in the oil tank array or adjacent to the oil tank array ventilate the mixture of the existing gas and the supplied gas from the bottom of the oil tank by a vertical vent pipe, wherein the vertical vent pipe extends from the bottom of the adjacent oil tank and extends outside the oil tank. A plurality of oil tanks mounted behind the pendulous pipeline in the oil tank array ventilate the mixture of the existing gas and the supplied gas from the bottom of the oil tank by a bottom pipeline system and comes out from the pendulous pipeline.

Owner:WARTSILA MOSS AS

Process for the removal of contaminants

A method of reducing carbonyl sulfide (COS) in a gas stream is described. The method includes contacting a gas stream with an iron oxide-based material. The present invention relates to a process for the removal of COS from any type of gas stream, especially a gas stream comprising one or more of ethane, methane, hydrogen, carbon dioxide, hydrogen cyanide, ammonia, hydrogen sulfide and inert gases. They include natural gas, and especially synthesis gas. Syngas can be used in the Fischer-Tropsch process. The present invention provides a simple and effective method of reducing COS, especially with materials that can be easily placed in existing shelter beds, thus avoiding any rebuilding time and costs. The iron oxide-based material can also be used for other impurities, providing a single bed solution.

Owner:SHELL INT RES MAATSCHAPPIJ BV

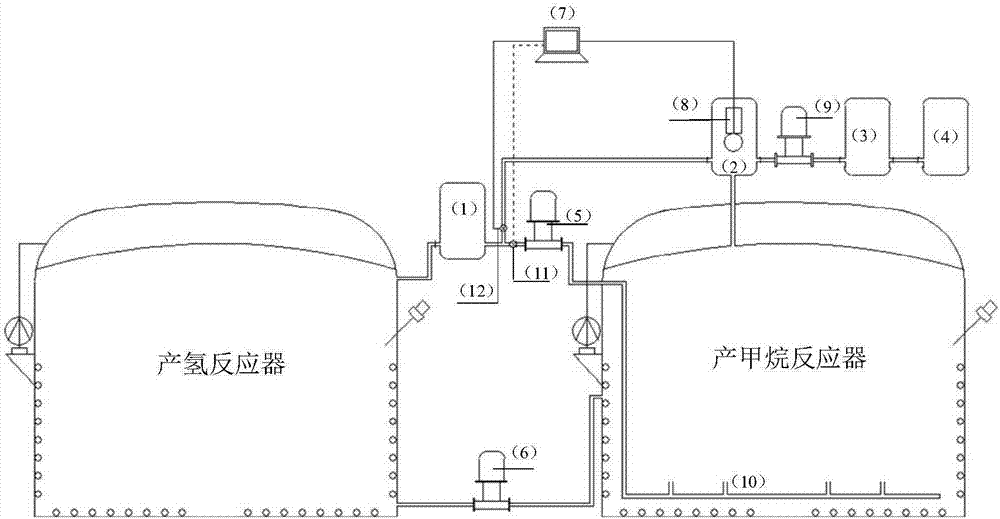

Preparation method for hydrogen-methane biofuel

InactiveCN107974316AImprove qualitySolve difficult-to-apply problemsGaseous fuelsWaste based fuelEnvironmental resistanceHydrogen concentration

The invention relates to a preparation method for a hydrogen-methane biofuel. The method employs two-step anaerobic fermentation technology to convert waste biomass into hydrogen and methane. According to the requirement for hydrogen concentration of a hydrogen-methane fuel, the flow direction of produced hydrogen in the first step is determined through feedback control: (1) hydrogen is directly mixed with biogas produced in a second step; or (2) a proper amount of hydrogen produced in the first step is further converted into methane in a biogas fermentation cylinder in virtue of hydrogen-consuming methane bacteria. Produced mixed gas is subjected to decarburization and purification so as to produce a hydrogen-methane biofuel product with stable quality and with hydrogen content of 5 to 25%. The preparation method provided by the invention has the advantages of environment friendliness, low cost and the like, can overcome the problem that biologically produced hydrogen is difficult toapple due to lack in infrastructures, provides technical support for production of hydrogen-methane biofuel products with stable quality, and can produce good economic, social and environmental benefits.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

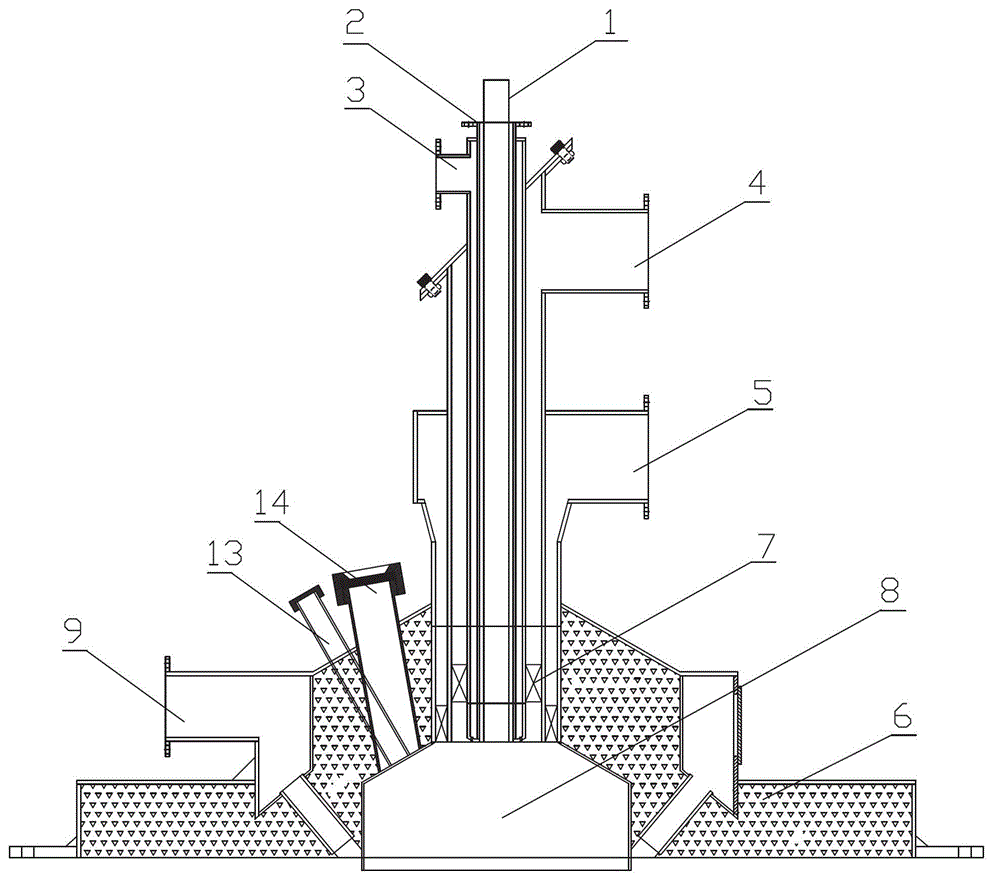

Combustor special for coal water slurry combustion type cracking furnace

ActiveCN102878554AEasy to switchMeet the requirements of working conditionsBurnersCoal waterAutomatic control

The invention relates to a combustor technology, and aims to provide a combustor special for a coal water slurry combustion type cracking furnace. A combustor main body is provided with a hollow pre-combustion chamber; a coal water slurry spray gun is arranged on the top of the pre-combustion chamber; a protecting sleeve, a gas jacket, a primary air pipe and a gas air sleeve are sequentially sleeved around the coal water supply spray gun; a secondary air pipe is connected to a plurality of secondary air outlets which are formed in the side surface of the top of the pre-combustion chamber; the secondary air outlets are uniformly distributed in a wall of the pre-combustion chamber at intervals; the same rotating included angles are formed between the secondary air outlets and the corresponding radial center lines; and an oil gun hole is also formed in the side surface of the top of the pre-combustion chamber, and an oil gun is inserted in the oil gun hole. The combustor can be powered by fuels such as coal water slurry, light diesel oil and hydrogen-methane / natural gas; the coal water slurry is mainly used and can replace the hydrogen-methane, and products with high additional values can be produced; and the combustor is switched over quickly and conveniently in a running process so as to meet requirements on various working conditions, labor can be saved by an automatic control system, and economical efficiency and operability are improved.

Owner:ZHEJIANG UNIV +1

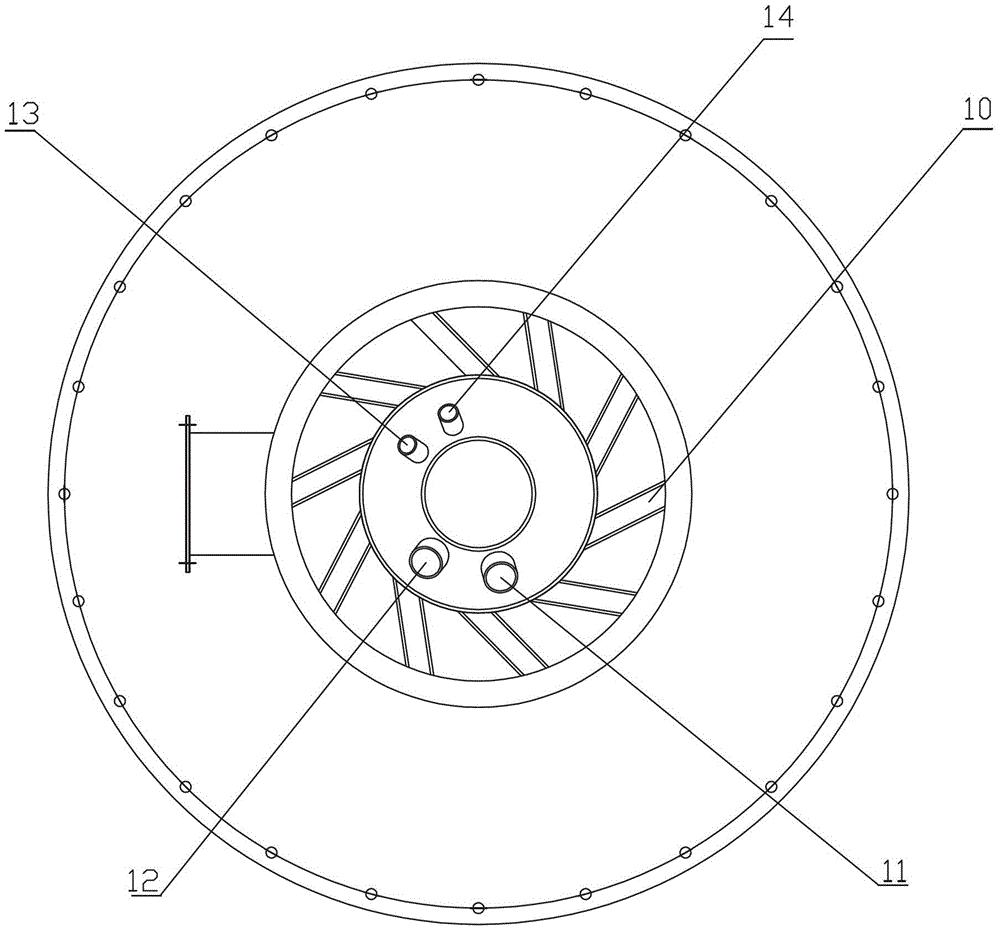

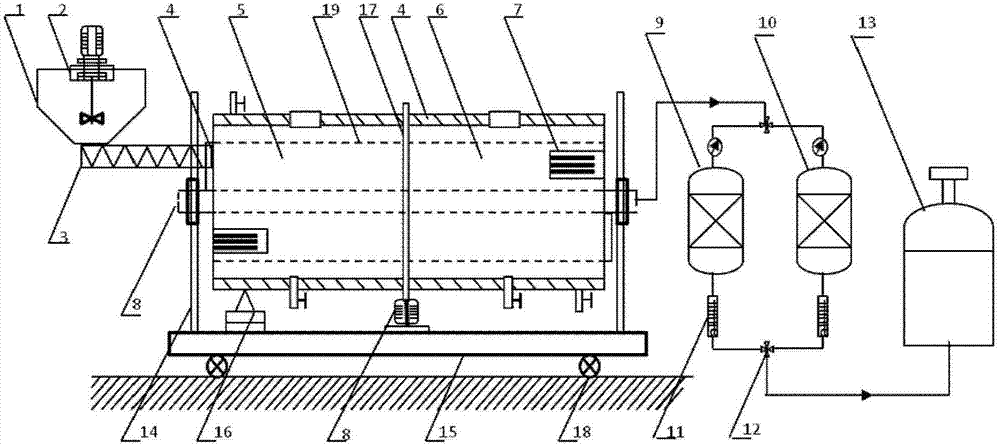

Small-sized hydrogen methane fuel gas generation device for residents in villages and towns and using method

InactiveCN102876410AStart fastGuaranteed uptimeGas production bioreactorsGaseous fuelsProcess engineeringEngineering

The invention relates to a small-sized hydrogen methane fuel gas generation device for residents in villages and towns, wherein a garbage crushing and conveying device is connected with a feed port of a hydrogen methane generator through a packing auger; the crushed garbage is subjected to anaerobic fermentation in the hydrogen methane generator; a one-way openable valve of an anaerobic methane generation chamber is arranged between an anaerobic hydrogen generation chamber and the anaerobic methane generation chamber; the gas outlet end of a nanoceramic coating rolling shaft which runs through the center of the hydrogen methane generator is connected with a hydrogen purifier and a methane purifier respectively; purified hydrogen and purified methane are controlled by a gas mixing valve to be mixed and then are conveyed to a hydrogen storage tank; the hydrogen methane generator is arranged on a pedestal; a gravity lifting device is arranged between the pedestal and the hydrogen methane generator; a 360-degree rotatable universal wheel is arranged at the lower part of the pedestal; and brackets are arranged on two sides of the pedestal and are respectively used for fixing the packing auger, the hydrogen purifier and the methane purifier. The invention further provides a method for preparing hydrogen methane fuel gas by using the hydrogen methane generation device.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

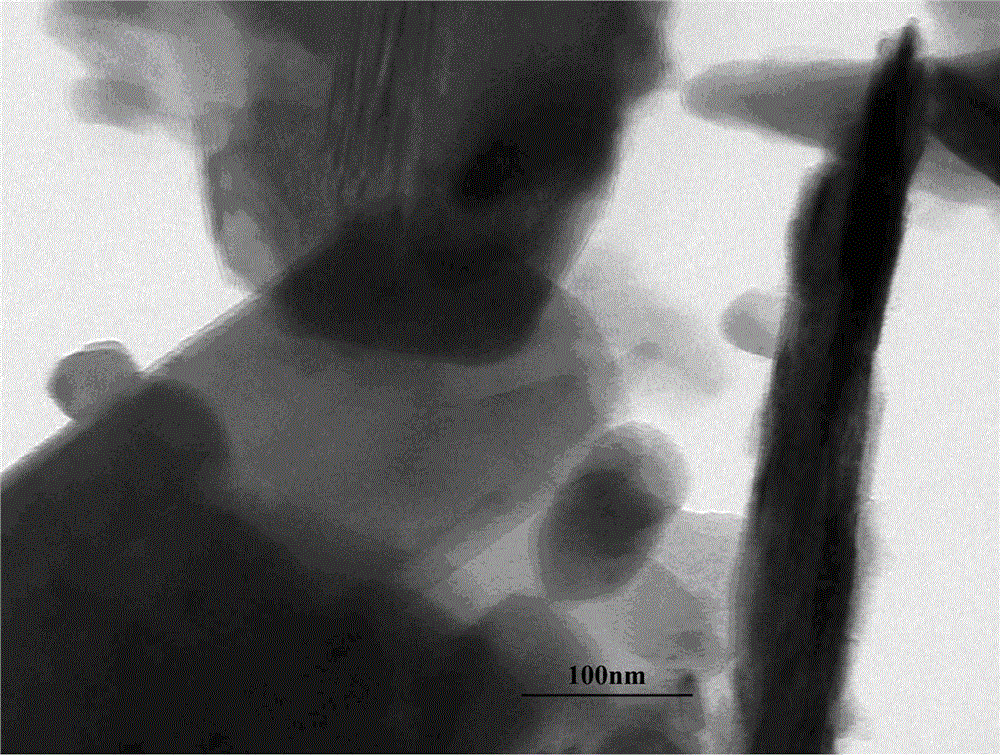

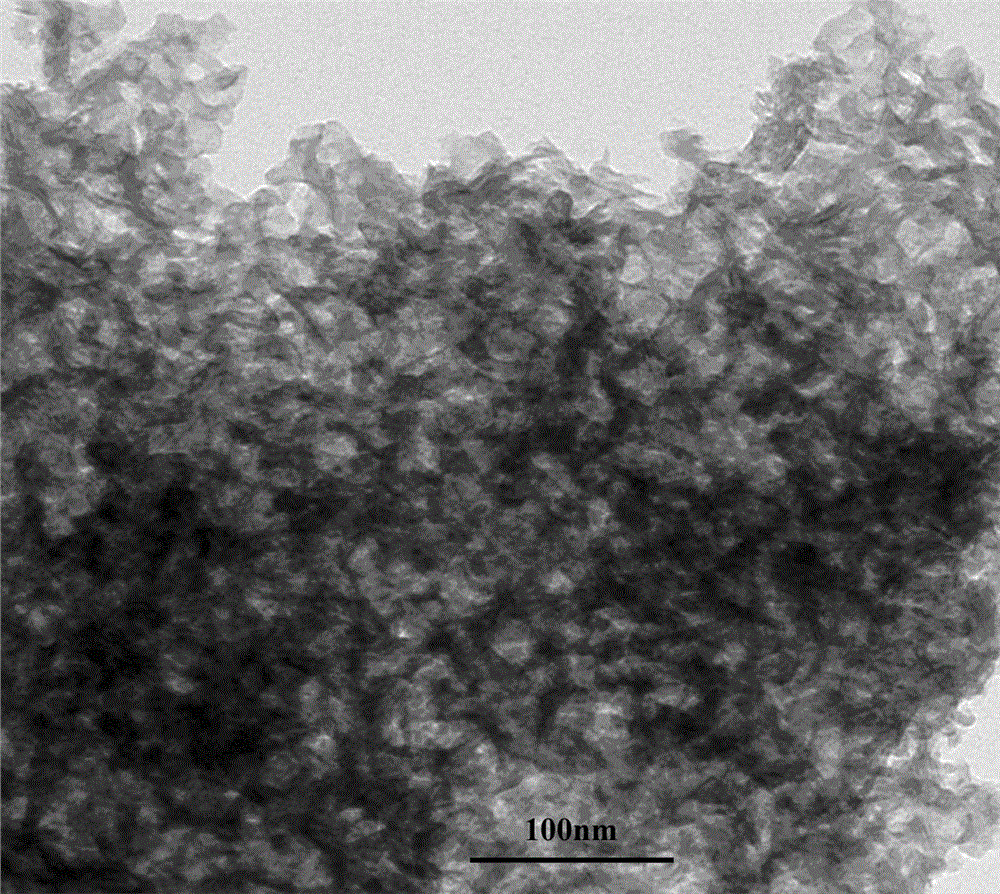

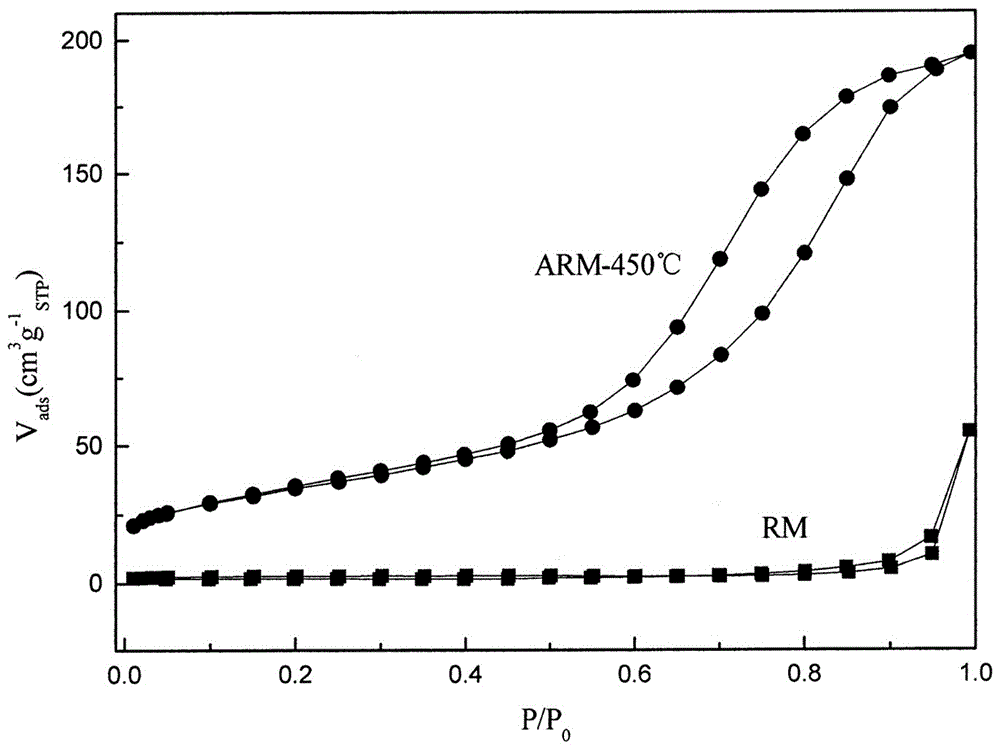

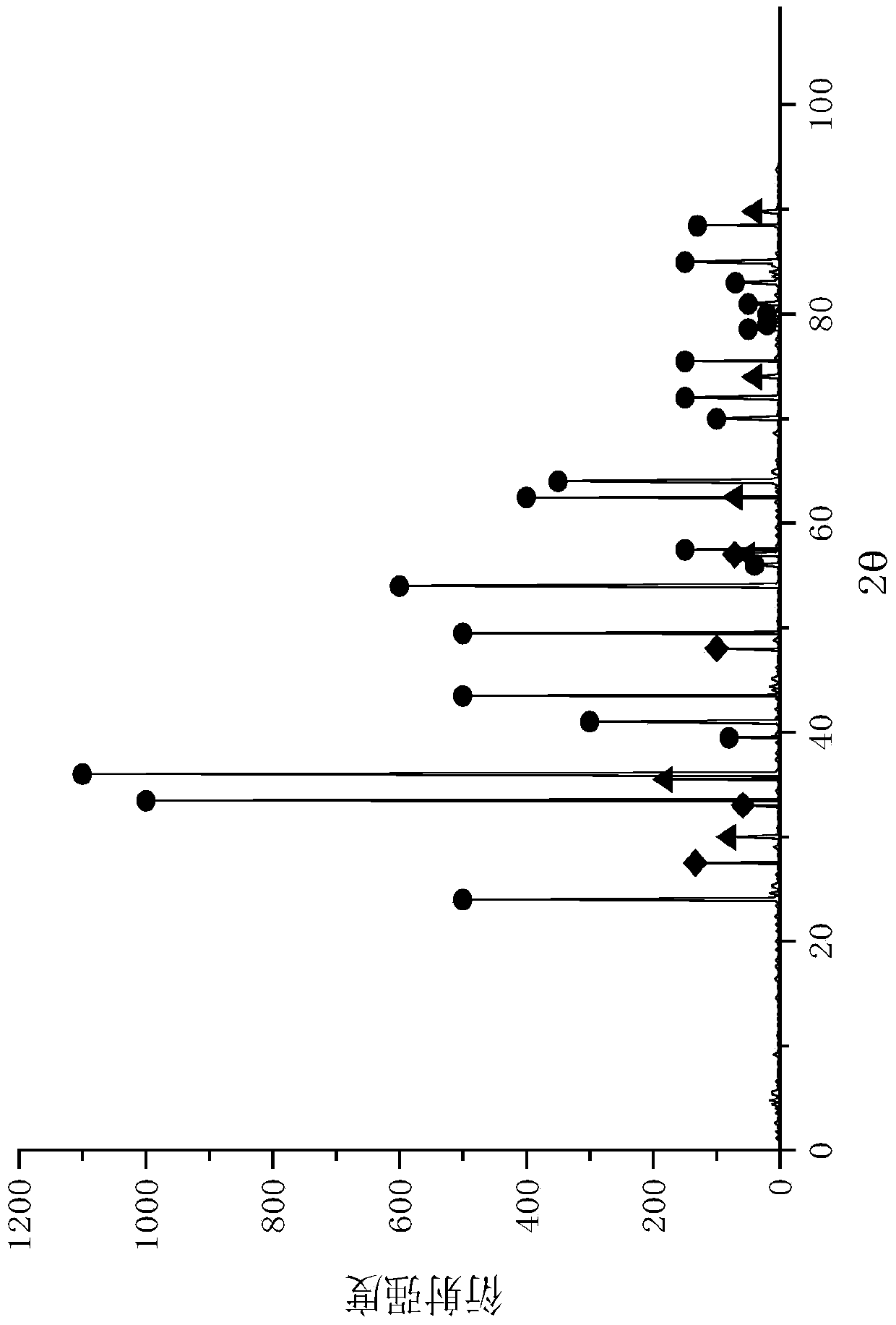

A method for hydrogen production by catalytic methane cracking from modified red mud

InactiveCN104627960BWell-developed pore structureImprove cracking hydrogen production activityHydrogenMetal/metal-oxides/metal-hydroxide catalystsResource utilizationRed mud

Owner:HENAN POLYTECHNIC UNIV

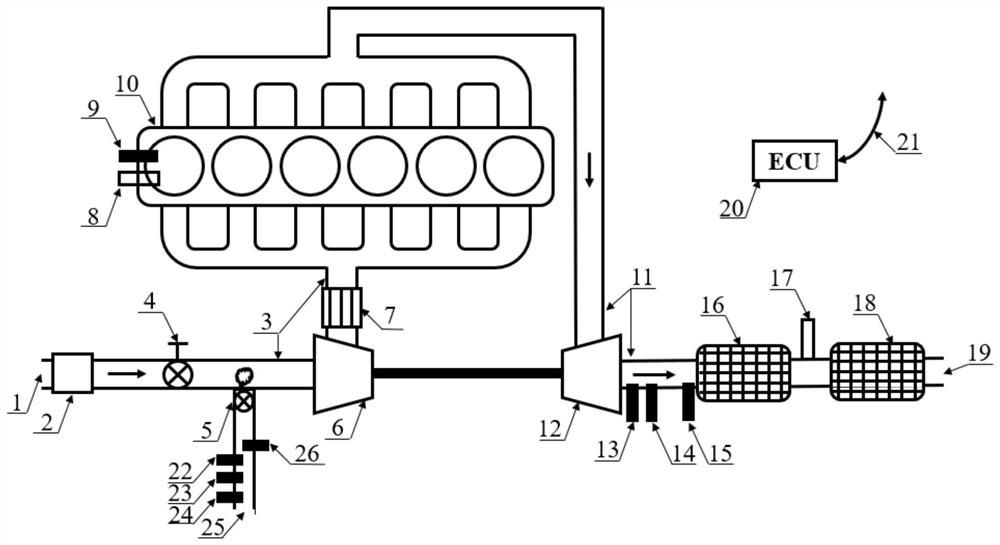

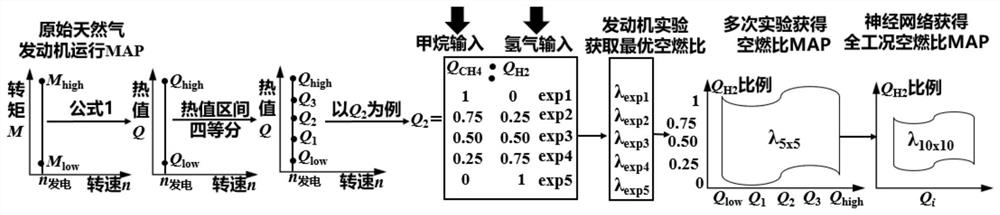

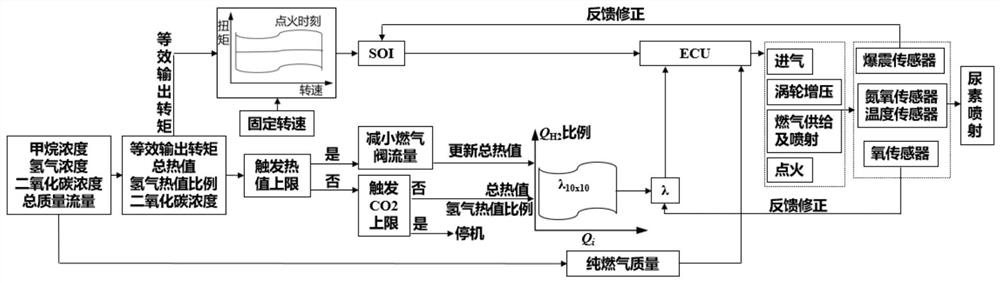

Self-adaptive control method of power generation internal combustion engine applied to various gas sources

ActiveCN113756945ARealize rational utilizationElectrical controlInternal combustion piston enginesTreatment systemChemistry

The invention discloses a self-adaptive control method of a power generation internal combustion engine applied to various gas sources. The self-adaptive control method comprises the following steps: detecting the concentrations of methane, hydrogen and carbon dioxide and gas mass flow in gas sources through a methane concentration sensor, a hydrogen concentration sensor, a carbon dioxide concentration sensor and a gas mass flow meter, and inputting the concentrations of methane, hydrogen and carbon dioxide and the gas mass flow into an ECU; matching an air-fuel ratio through ECU according to a self-adaptive air-fuel ratio MAP obtained by an embedded algorithm, and controlling ignition time according to the rotating speed and the equivalent torque of the total heat value of the incoming flow gas through ECU; and controlling a gas inlet system, a gas supply and injection system, an ignition system and a turbocharging system based on pure gas mass flow in the incoming flow gas, the carbon dioxide concentration and the air-fuel ratio and achieving self-adaptive combustion of the engine. An oxygen sensor feeds back and corrects the air-fuel ratio; a knock sensor feeds back and corrects ignition time; and a temperature sensor and a nitrogen oxide concentration sensor control urea injection of a post-treatment system. According to the self-adaptive control method of the power generation internal combustion engine applied to various gas sources, the efficient and stable combustion power generation process of enabling the engine to be adapted to different gas sources can be realized; and ultra-low emission is only generated.

Owner:TIANJIN UNIV

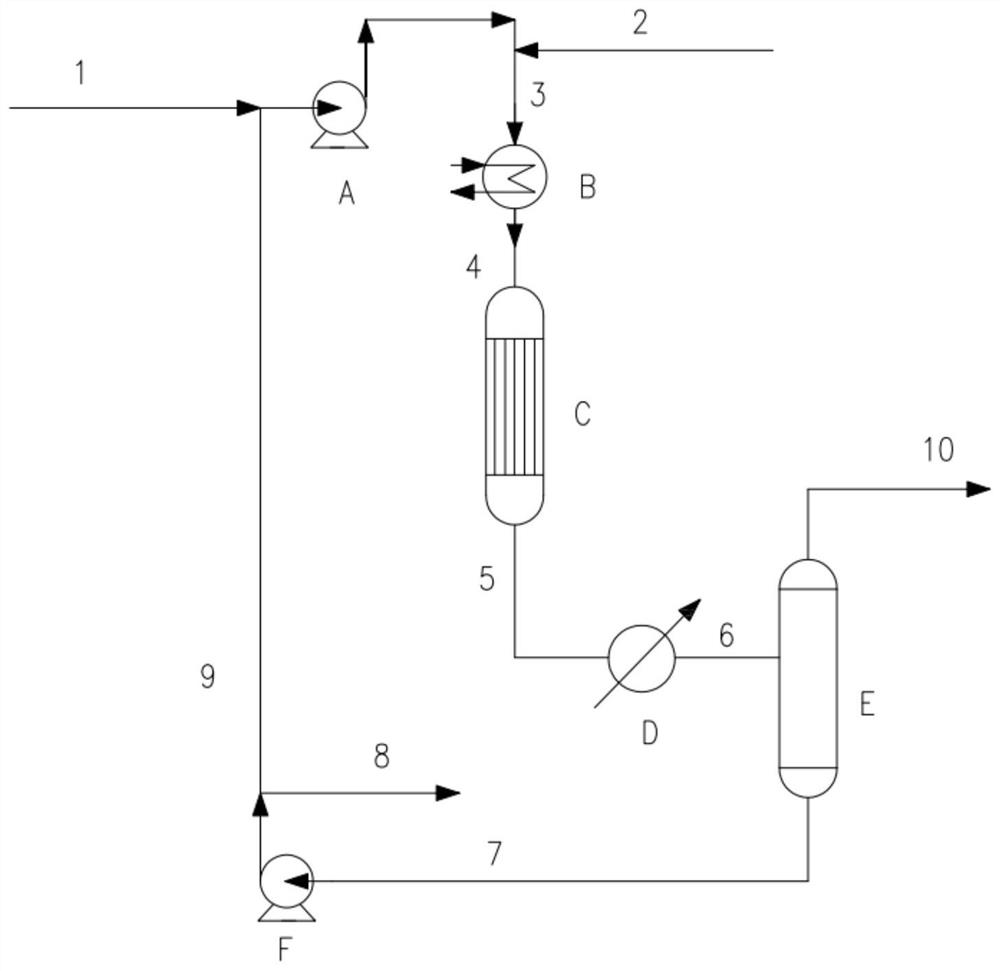

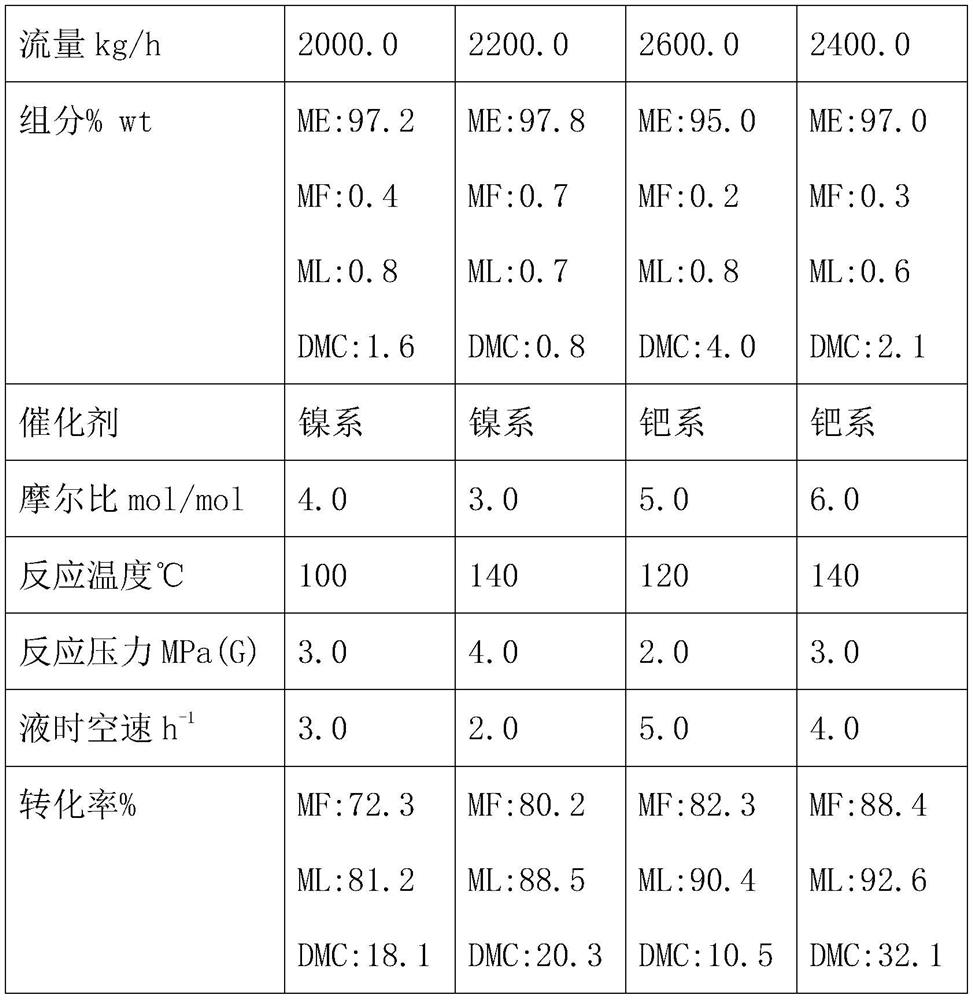

Treatment method for by-products of methyl formate and methylal in production of dimethyl carbonate by carbonylation method

PendingCN112457157AReduce consumptionLow reaction temperatureOrganic compound preparationPreparation by oxygen reductionHigh pressure hydrogenReaction temperature

The invention discloses a treatment method for by-products of methyl formate and methylal in production of dimethyl carbonate by a carbonylation method, and relates to the field of chemical processes.The process flow comprises the following steps: materials of mixture of methanol, methyl formate, methylal, dimethyl carbonate and the like are pressurized by a pump and then mixed with high-pressurehydrogen of the materials to form materials, the materials are heated to the reaction temperature by a preheater, and the heated materials are sent into a reactor; a cooled material is fed into a low-pressure flash tank; and non-condensable gas methane, hydrogen and other materials are discharged from the tank top of the low-pressure flash tank, the materials obtained from the tank kettle of thelow-pressure flash tank are high-concentration methanol, the materials pressurized by the pump can be fed into a dimethyl carbonate reaction process to be recycled, and part of the materials can be subjected to cyclic hydrogenation. According to the invention, a mixture of methanol, methyl formate, methylal and dimethyl carbonate does not need to be gasified, and the reaction can be carried out under the working condition of a trickle bed, so that the consumption of steam and circulating water is reduced, the hydro-conversion efficiency of methyl formate and methylal is improved, and the hydro-conversion of dimethyl carbonate is avoided.

Owner:上海诺哈尔化工技术有限公司

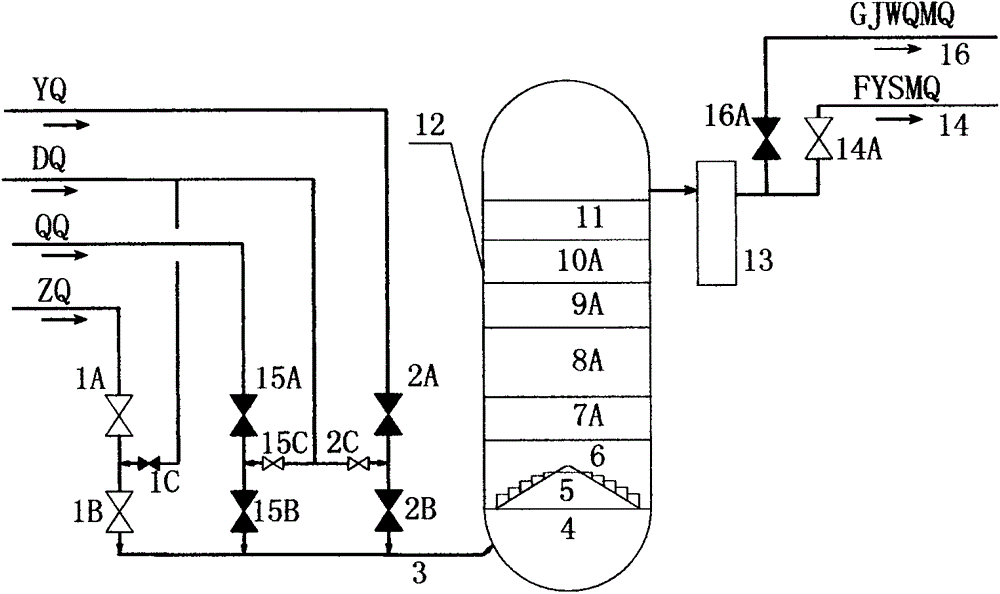

Process and device for producing methane-rich coal gas by moving bed pressurized coal gasification

InactiveCN104927922AIncrease concentration limitConcentration upper limit increasedChemical industryFixed-bed gasificationCarbon layerHydrogen

Provided are a process and device for producing methane-rich coal gas by moving bed pressurized coal gasification, and the height-to-diameter ratio of a coal gasification bed layer in a moving bed pressurized gasification furnace is improved to optimize gasification conditions for optimizing the methane production rate. On an oxygen-rich steam charging pipeline at the bottom of the gasification furnace, a hydrogen gasification agent adding pipeline is additionally arranged, an oxygen-rich steam gasification agent and a hydrogen gasification agent are respectively sent into the pressurized gasification furnace from the furnace bottom in turn, and a technological process for preparation of low-methane water coal gas through oxygen-rich steam and a technological process for preparation of high-methane hydrogen coal gas through hydrogen are cyclically repeatively performed on a furnace internal carbon layer. Before the two charging gasification agents are transformed with each other, an inert gas displacement process is designed, so as to prevent the two gasification agents from meeting with each other in the charging pipeline and the furnace bottom interior to prevent safety accident. Because the technological process for preparation of the high-methane hydrogen coal gas through hydrogen is increased in the moving bed pressurized coal gasification technology, the methane content in coal gas is substantially increased, not only can the coal gas heat value be improved but also the coal-to-gas thermal efficiency is improved.

Owner:李宁

Carbon dioxide separation membranes and process

PendingUS20210016231A1Facilitate the high CO<sub>2 </sub>permeanceSemi-permeable membranesGas treatmentThin membraneNitrogen gas

This invention discloses a thin-film composite membrane and process for the separation of carbon dioxide from non-hydrophilic gases such as methane, hydrogen, and nitrogen. The thin-film composite membrane has a gas-separation layer and a nonporous high-diffusion-rate layer, and has carbon dioxide to non-hydrophilic gas selectivity that is greater than the intrinsic selectivity of the gas-separation layer alone.

Owner:COMPACT MEMBRANE SYST INC

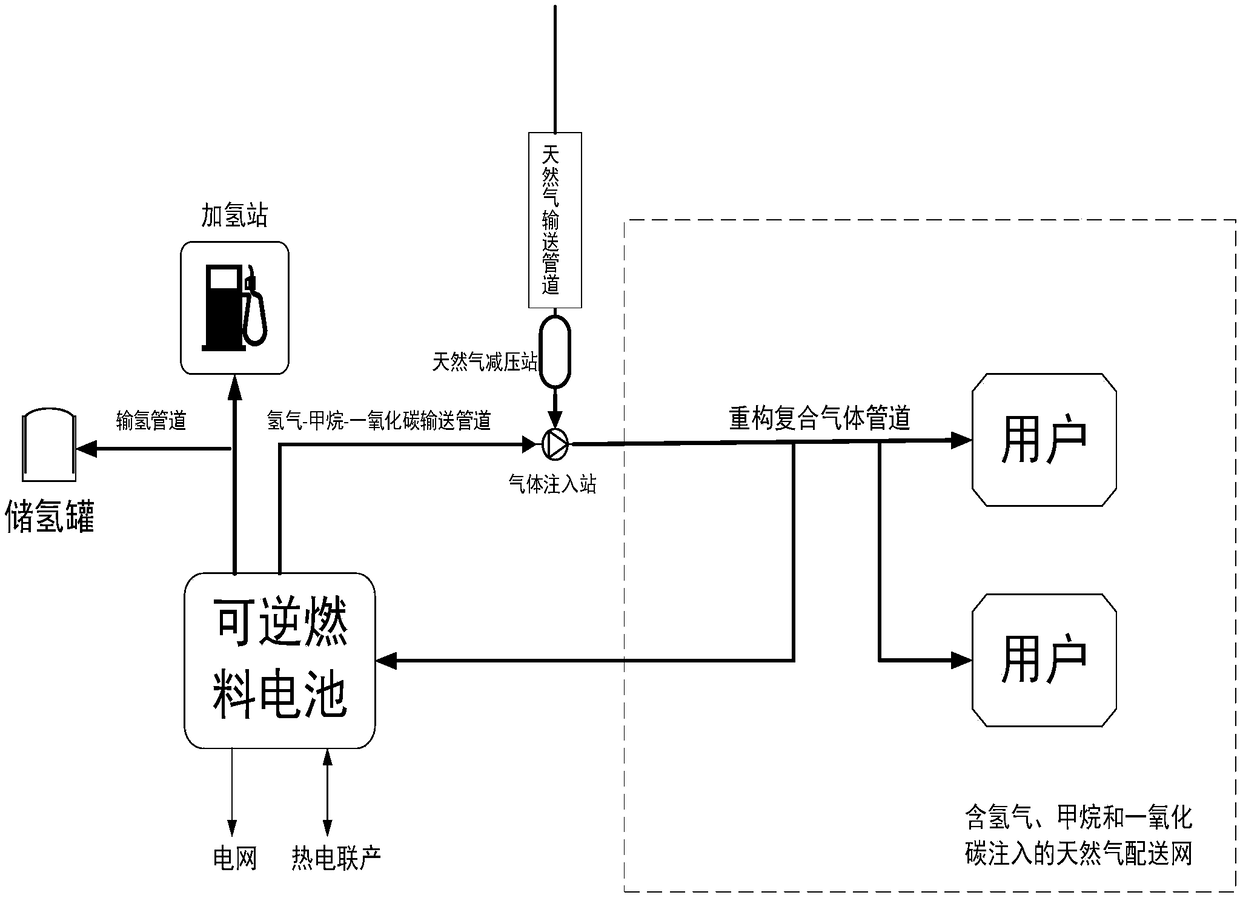

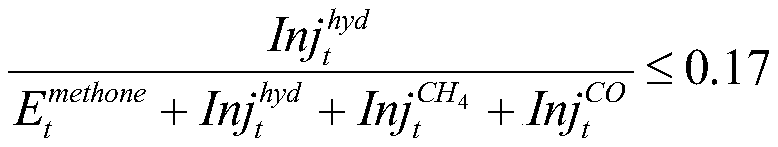

Gas-power interconnection system based on reversible fuel cell under compound gas condition

ActiveCN109411798AIncrease injection volumeReduce the cost of hydrogen storageElectrolysis componentsPipeline systemsPressure reductionElectric power

The invention discloses a gas-power interconnection system based on a reversible fuel cell under a compound gas condition. The gas-power interconnection system comprises a reversible fuel cell and a natural gas conveying pipeline connected with the reversible fuel cell through a hydrogen-methane-carbon monoxide conveying pipeline; the reversible fuel cell is communicated with a hydrogen filling station and a hydrogen storage tank through hydrogen conveying pipelines; a pressure reduction station is arranged at the upstream of the hydrogen-methane-carbon monoxide conveying pipeline connected with the natural gas conveying pipeline; the gas-power interconnection system also comprises a power grid which is jointly communicated with the reversible fuel cell and the natural gas conveying pipeline; a reconstructed compound gas pipeline and users at the downstream form a natural gas distribution network with injection of hydrogen, methane and carbon monoxide. According to the gas-power interconnection system, under the condition of not changing the existing technical conditions, the hydrogen injection ratio is not greater than 17%; meanwhile, a compound gas composed of hydrogen, methane and carbon monoxide is injected into a natural pipe network so as to obtain an injection ratio being higher than that of injection of pure hydrogen, so that the overall injection amount of the fuel isincreased, and the overall power-gas conversion power of the system is improved.

Owner:XI AN JIAOTONG UNIV

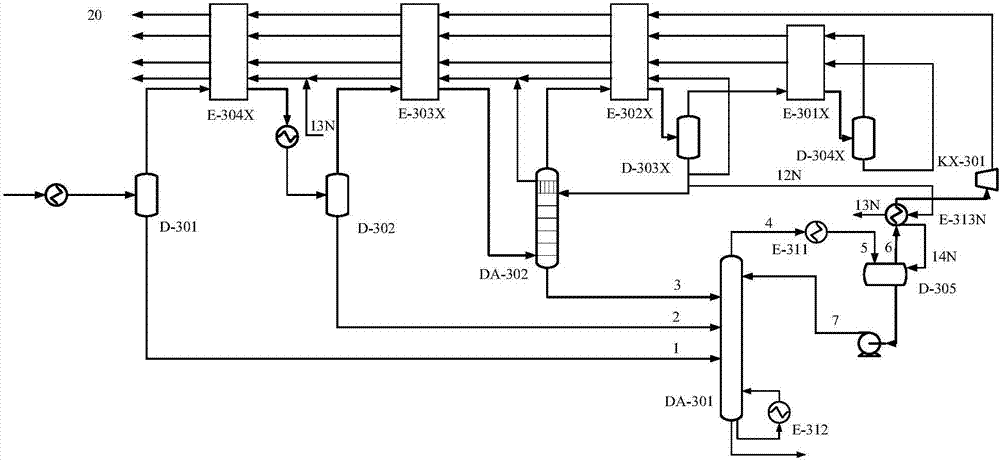

Full-temperature-range simulated rotating moving bed pressure swing adsorption process for separating and extracting H2/CO from synthesis gas

ActiveCN114748980AHigh purityHigh yieldGas treatmentHydrogen separation using solid contactSyngasFluidized bed

The invention discloses a full-temperature-range simulated rotating moving bed pressure swing adsorption process for separating and extracting H2 / CO from synthesis gas, which is based on pressure swing adsorption and comprises a multi-tower middle temperature pressure swing adsorption concentration system, a multi-tower middle temperature intermediate gas pressure swing adsorption system, a methane hydrogen hydrogen extraction pressure swing adsorption system and a concentrated gas temperature swing adsorption system, a full-temperature-range simulated rotating moving bed pressure swing adsorption FTrSRMPSA system for deacidifying synthesis gas and separating and extracting H2 and CO product gas with high purity and high yield is formed, so that cyclic operation of multiple steps of adsorption and desorption in simulated rotating moving bed pressure swing adsorption and temperature swing adsorption on the basis of axial flow fixed bed pressure swing adsorption is realized; the device is suitable for fluctuation working conditions of flow, component concentration, pressure or temperature corresponding to synthesis gas while realizing'high yield and purity 'and avoiding deep adsorption, and overcomes the defects of fixed bed, circulating bed, fluidized bed, rotating wheel adsorption and simulated moving bed processes in the prior art.

Owner:SICHUAN TECHAIRS

Methanol-to-olefin (MTO) reaction-regeneration process and product separation method

ActiveCN111072438ALower the pressure valueEfficient separationMolecular sieve catalystDistillation purification/separationAlkeneRefrigerant

The invention relates to a methanol-to-olefin (MTO) reaction-regeneration process and a product separation method. The pressure value is reduced in the three-stage compression and pressurization in the methanol-to-olefin reaction process, and part of unreacted methanol, dimethyl ether and other impurities are also removed by matching with the temperature. In product separation, the temperature ofa demethanizer is higher than that in the prior art, methane, hydrogen and other components are also effectively separated by properly increasing the pressure, and effective recovery of ethylene and propylene is realized. The temperature of the separation process is relatively high, so that the temperature of the used refrigerant is higher than that of other ethylene refrigerants and propane refrigerants, and the energy consumption is reduced.

Owner:JIUTAI ENERGY ZHUNGEER CO LTD

Method for preparing darunavir

The invention relates to the technical field of medicines and discloses a method for preparing darunavir. The method comprises the following step: preparing 20-30 parts of cobalt, 10-20 parts of triethylamine, 10-20 parts of ferrous oxide, 10-20 parts of zinc oxide, 3-5 parts of 1.2 equivalent of marina hydrogen methane, 20-30 parts of zinc, 50-80 parts of a ferric nitrite solution, 30-40 parts ofa metal base, 40-50 parts of alumina, 10-20 parts of silica, 3-5 parts of p-acetamide benzoyl sulfonyl chloride, 3-5 parts of a precipitant, 50-80 parts of an ethanol solution and 20-30 parts of nickel for later use. According the method for preparing the darunavir, 20-30 parts of cobalt, 10-20 parts of triethylamine, 10-20 parts of ferrous oxide, 10-20 parts of zinc oxide, 3-5 parts of 1.2 equivalent of marina hydrogen methane, 10-20 parts of silica, 3-5 parts of p-acetamide benzoyl sulfonyl chloride, 3-5 parts of the precipitant, 50-80 parts of the ethanol solution and 20-30 parts of nickelare adopted for later use, the reaction materials used in the method are low in price and low in reaction environment requirement, correspondingly, the preparation cost of the darunavir is greatly reduced, patients can afford the darunavir, and the darunavir can truly benefit the patients.

Owner:ABA CHEM CORP

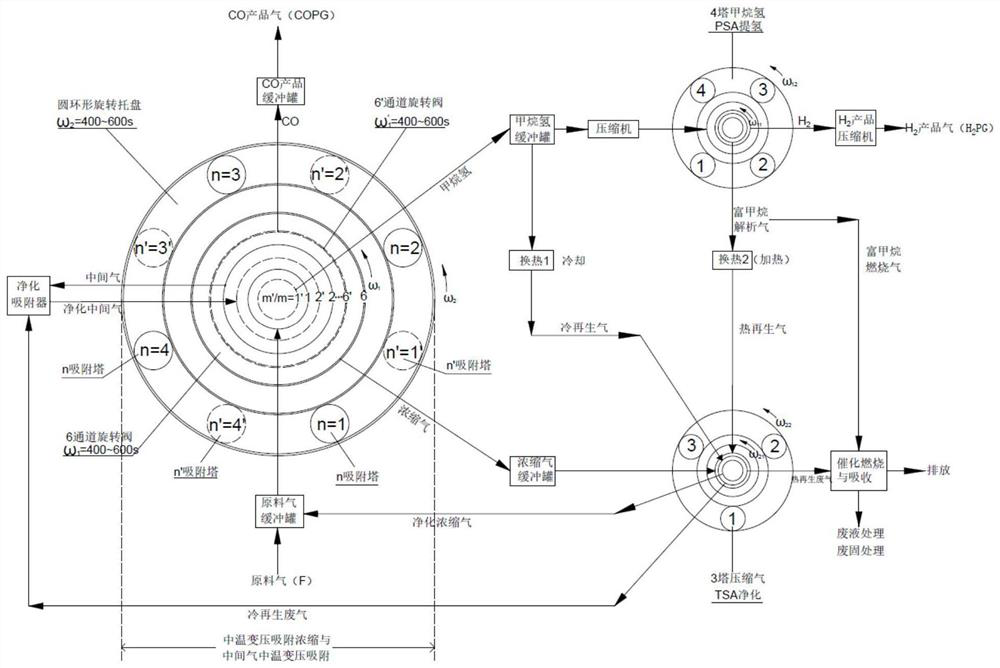

Method for comprehensively recovering various valuable metals in copper slag floating copper tailings

ActiveCN113061738AImprove resource utilizationLow reduction temperatureFlotationMagnetic separationFayaliteMagnetite

The invention discloses a method for comprehensively recovering various valuable metals in copper slag floating copper tailings, and belongs to the technical field of metal element recovery. The method comprises the steps of direct reduction roasting, magnetic separation and reverse flotation. According to the method for comprehensively recovering the various valuable metals in the copper slag floating copper tailings provided by the invention, the mixed gas of methane, hydrogen and argon is introduced for direct reduction roasting, magnetite in the copper slag can be completely converted into metal iron, and a composite additive is matched for dissociating fayalite in the copper slag, so that the purpose of resourceful ore phase reconstruction is achieved; and a phase composition in the copper slag is improved, an iron phase in the slag is subjected to a decomposition reaction, and lead and zinc are gasified in the form of metal steam, so that the various valuable metals in the copper slag are comprehensively recycled. Meanwhile, roasting products are treated through magnetic separation and reverse flotation, so that the iron ore concentrate grade is effectively improved, the effective utilization rate of resources is high, the recycling process is simple, energy consumption is low, and high economic benefits are achieved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Temperature control film with underwater gas intercepting or collecting function and preparation method

The invention discloses a temperature control film with an underwater gas interception or collection function and a preparation method, and belongs to the technical field of functional materials. Thetemperature control film is composed of a heat insulation layer, two super-hydrophobic / super-aerophilic microstructure layers, two heating electrode layers and two temperature-sensitive layers, wherein the two heating electrode layers are symmetrically distributed on the upper surface and the lower surface of the heat insulation layer; the two super-hydrophobic / super-aerophilic microstructure layers are adopted to wrap the heating electrodes and form a sandwich structure with the heat insulation layer; the temperature-sensitive material layers are fixed on the outer surfaces of the two super-hydrophobic microstructure layers; and through holes penetrating through the whole temperature control film are formed between the heating electrodes. The temperature control film can be used for intercepting or collecting bubbles in water medium, and due to the fact that underwater interception or collection is mainly related to physical properties of the bubbles and is irrelevant to gas types, various gases such as air, oxygen, methane, hydrogen and nitrogen can be intercepted or collected.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

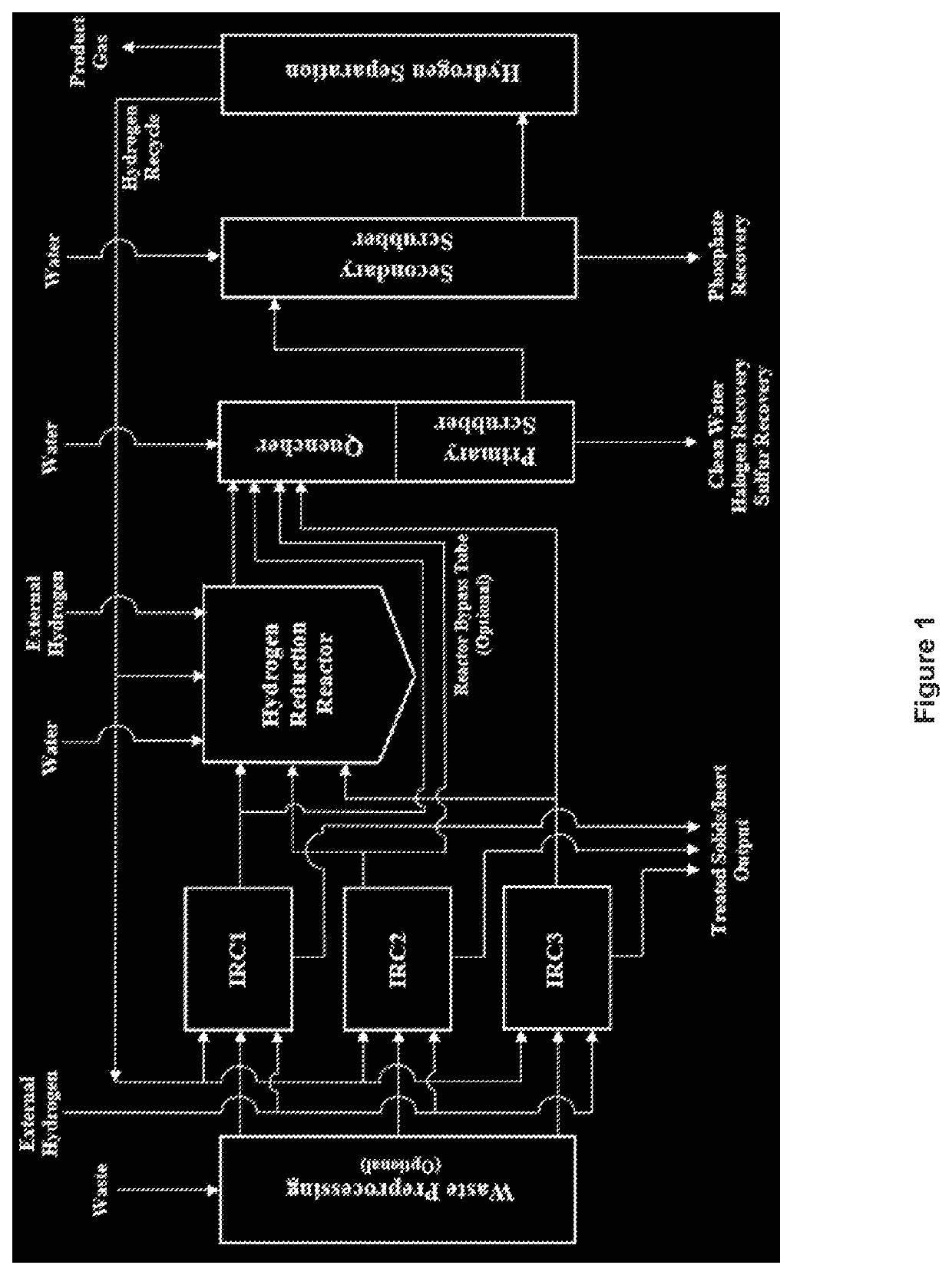

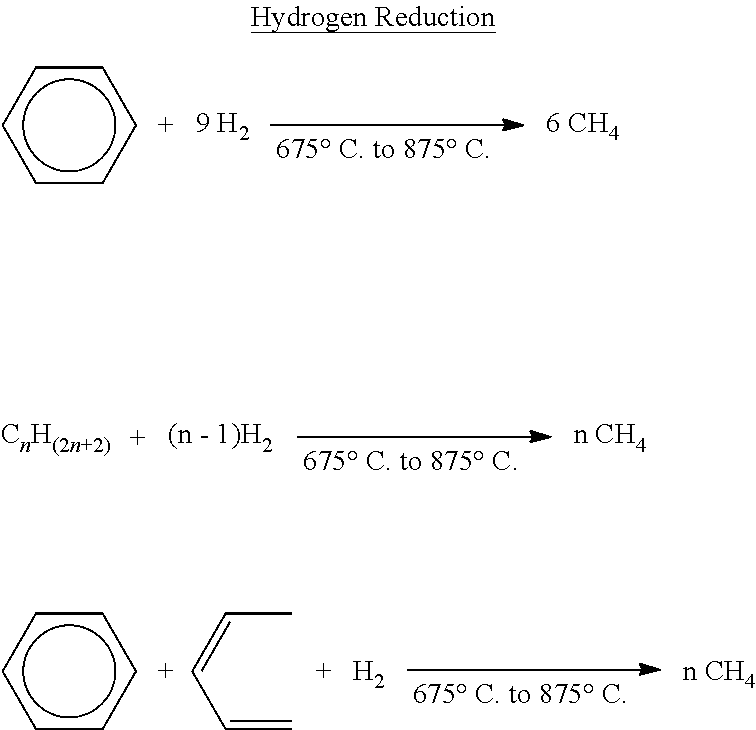

Process for reducing an organic material to produce methane and/or hydrogen

A process for reducing an organic material to produce methane and / or hydrogen is disclosed. The process includes: (a) contacting the organic material with an excess amount of hydrogen gas in an enclosed reduction chamber at ambient temperature, where the reduction chamber is substantially free of oxygen, and heating the reduction chamber to cause a temperature increase in the organic material from ambient temperature to up to 425° C. at a rate of up to about 8° C. per minute, under positive pressure, to form a first gaseous mixture comprising methane, hydrogen, acid, and partially reduced volatile organic molecules; (b) heating the first gaseous mixture to a temperature of about 675° C. to about 875° C. in the presence of an excess amount of hydrogen gas to form a second gaseous mixture comprising methane, hydrogen, and acid; and (c) neutralizing the second gaseous mixture with a base.

Owner:HALLETT DOUGLAS JOHN FREDERICK +1

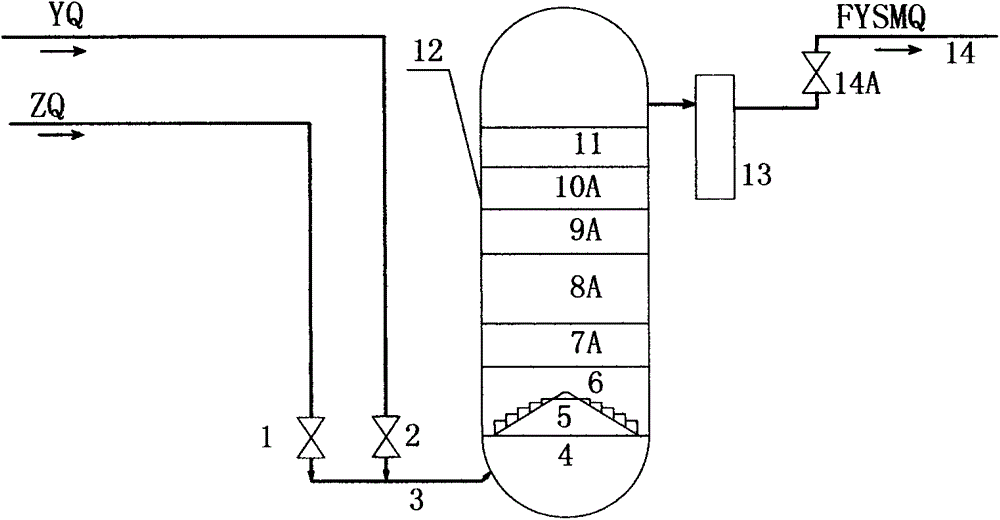

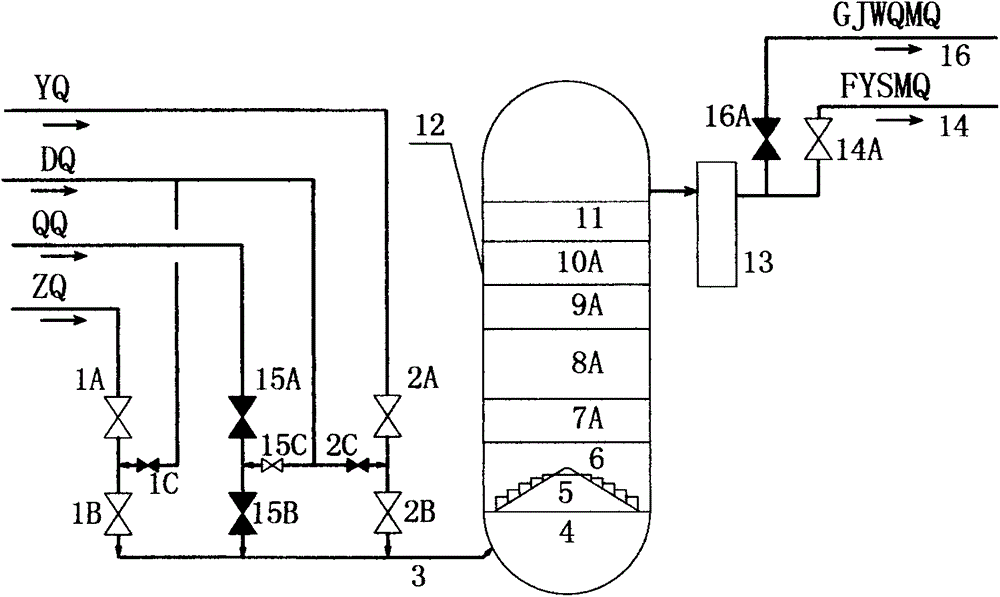

A method for removing alkyne by hydrogenation before depropanization

A method for removing acetylene by hydrogenation before depropanization. The volume composition of hydrogenation raw materials is mainly: methane 30~40%, hydrogen 15-25%, ethane 8~15%, ethylene 30~45%, propane 5~10%, propylene 5~10%, and allene 0.1~ 0.5%, acetylene 0.5~1.0%, propyne 0.1~0.5%. The reaction conditions are: the inlet temperature of the first stage is 50~100℃, the inlet temperature of the second stage is 50~100℃, the inlet temperature of the third stage is 50~100℃, the reaction pressure is 1.5~4.0MPa, and the reaction volume space velocity is 10000~20000h. ‑1 . The hydrogenation catalyst is an Fe-based selective hydrogenation catalyst, and the carrier is a high-temperature resistant inorganic oxide. Using the acetylene removal method of the present invention, the catalyst has moderate reaction activity, good operating flexibility, good ethylene selectivity, and the amount of "green oil" generated is much lower than that of precious metals. catalyst.

Owner:PETROCHINA CO LTD

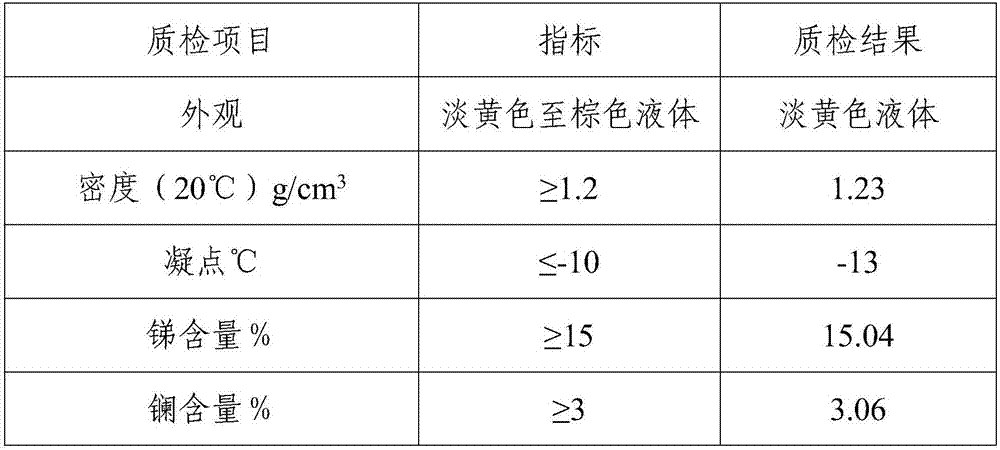

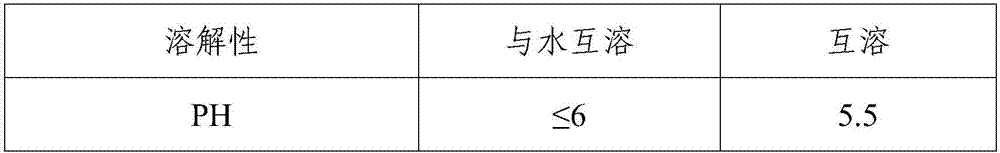

Multi-metal deactivator for catalytic device of refinery plant and preparation method thereof

InactiveCN107159315AImprove microreactivityImprove hydrolysis resistanceCatalytic crackingCatalyst protectionAntimony trioxideLanthanum

The invention provides a multi-metal deactivator for a catalytic device of a refinery plant and a preparation method thereof. An agent A and an agent B at the mass ratio of 1:(0.2-0.3) are compounded into the multi-metal deactivator; the agent A comprises antimonous oxide, triethylamine, tartaric acid, hydrogen peroxide and deionized water; and the agent B comprises lanthanum acetate, glacial acetic acid and deionized water. Reasonable compound ratio is adopted for the poison of the metal, such as, nickel and vanadium in the raw materials of the refinery plant to the splitting catalyst according to the invention, the hydrogen methane ratio is reduced while the micro-activity of the catalyst is promoted, the deactivating effect is effectively improved, the technical efficiency is promoted, the preparation technology is simple and convenient, the matching ratio is flexible and the applicability is high.

Owner:安徽卓远化工科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com