Treatment method for by-products of methyl formate and methylal in production of dimethyl carbonate by carbonylation method

A technology of dimethyl carbonate and methyl formate, applied in the field of chemical technology, can solve problems such as not being retrieved, and achieve the effects of avoiding hydrogenation conversion, saving consumption, and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

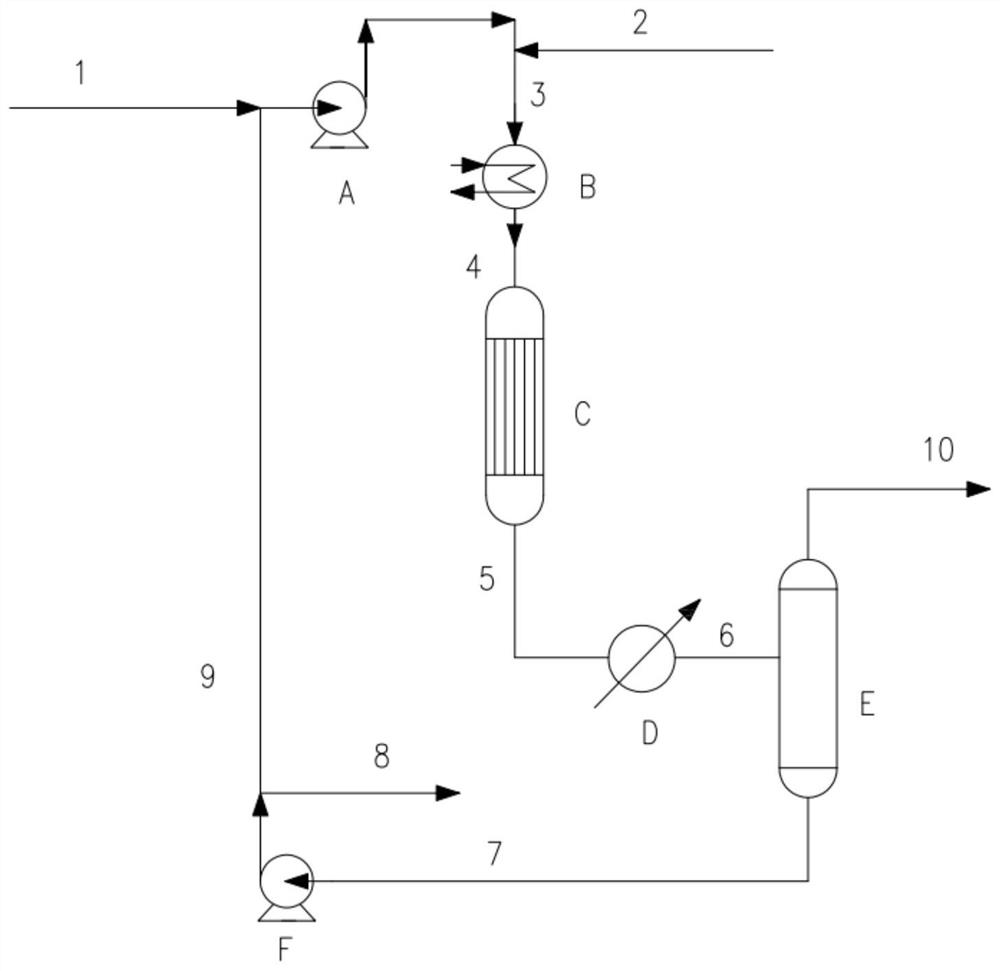

Method used

Image

Examples

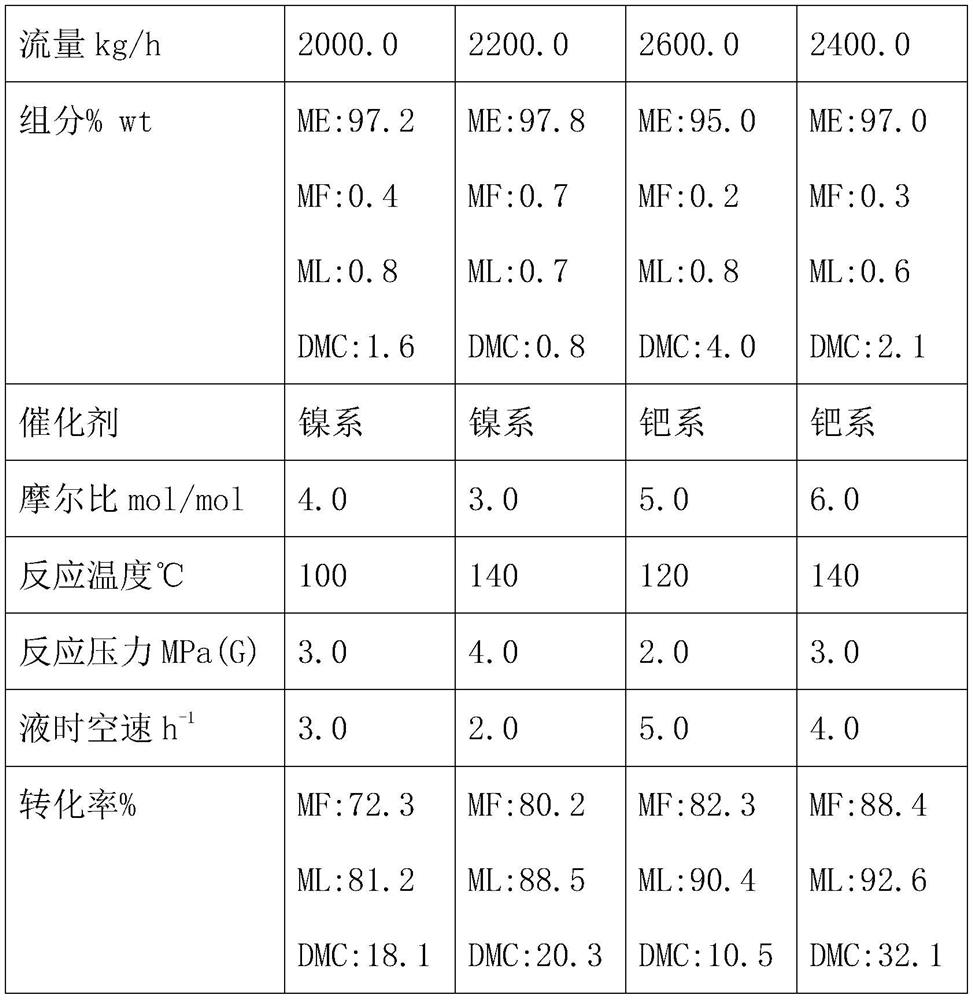

Embodiment 1

[0039] Pressurize 2000.0kg / h of material (the mass content is ME: 97.2%, MF: 0.4%, ML: 0.8%, DMC: 1.6%) to 3.0MPa(G), and the flow rate is 30.73NM 3Mix 3.0MPa(G) hydrogen per hour, heat to 95.0°C, and carry out hydrogenation reaction in the reactor. The hydrogenation catalyst is a nickel-based catalyst. The hourly space velocity is 3.0h -1 , The reacted material is cooled to 40.0°C by a circulating water cooler, and the gas-liquid separation is carried out in the flash tank, and the pressure of the flash tank is 0.5MPa(G). The vent gas is discharged from the top of the flash tank, and the pressure of the control tank is kept constant. The liquid at the bottom of the flash tank is the product after hydrogenation, which is sent to chromatographic analysis. It can be calculated that the conversion rate of MF is 72.3%, the conversion rate of ML is 81.2%, and the conversion rate of DMC is 18.1% %.

Embodiment 2

[0041] Pressurize the 2200.0kg / h material (the mass content is ME: 97.8%, MF: 0.7%, ML: 0.7%, DMC: 0.8%) to 4.0MPa (G), and the flow rate is 30.73NM3 / h 4.0MPa ( G) Hydrogen is mixed, heated to 135.0°C, and hydrogenation reaction is carried out in the reactor. The hydrogenation catalyst is a nickel-based catalyst, the reaction temperature is 140.0°C, the reaction temperature and pressure are 4.0MPa(G), and the liquid hourly space velocity is 2.0h -1 , The reacted material is cooled to 40.0°C by a circulating water cooler, and the gas-liquid separation is carried out in the flash tank, and the pressure of the flash tank is 0.5MPa(G). The vent gas is discharged from the top of the flash tank, and the pressure of the control tank is kept constant. The liquid at the bottom of the flash tank is the product after hydrogenation, which is sent to chromatographic analysis. It can be calculated that the conversion rate of MF is 80.2%, the conversion rate of ML is 88.5%, and the conversion...

Embodiment 3

[0043] Pressurize 2600.0kg / h of material (the mass content is ME: 95.0%, MF: 0.2%, ML: 0.8%, DMC: 4.0%) to 2.0MPa(G), and the flow rate is 40.27NM 3 Mix 2.0MPa(G) hydrogen per hour, heat to 115.0°C, and carry out hydrogenation reaction in the reactor. The hydrogenation catalyst is a palladium-based catalyst. The hourly space velocity is 5.0h -1 , The reacted material is cooled to 40.0°C by a circulating water cooler, and the gas-liquid separation is carried out in the flash tank, and the pressure of the flash tank is 0.5MPa(G). The vent gas is discharged from the top of the flash tank, and the pressure of the control tank is kept constant. The liquid at the bottom of the flash tank is the product after hydrogenation, which is sent to chromatographic analysis. It can be calculated that the conversion rate of MF is 82.3%, the conversion rate of ML is 90.4%, and the conversion rate of DMC is 10.5% %.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com