Process and system for gas freeing on board of a vessel or other installation

A gas and air technology, applied in the field of degassing and systems, can solve complex and time-consuming problems, achieve low operating costs and save the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

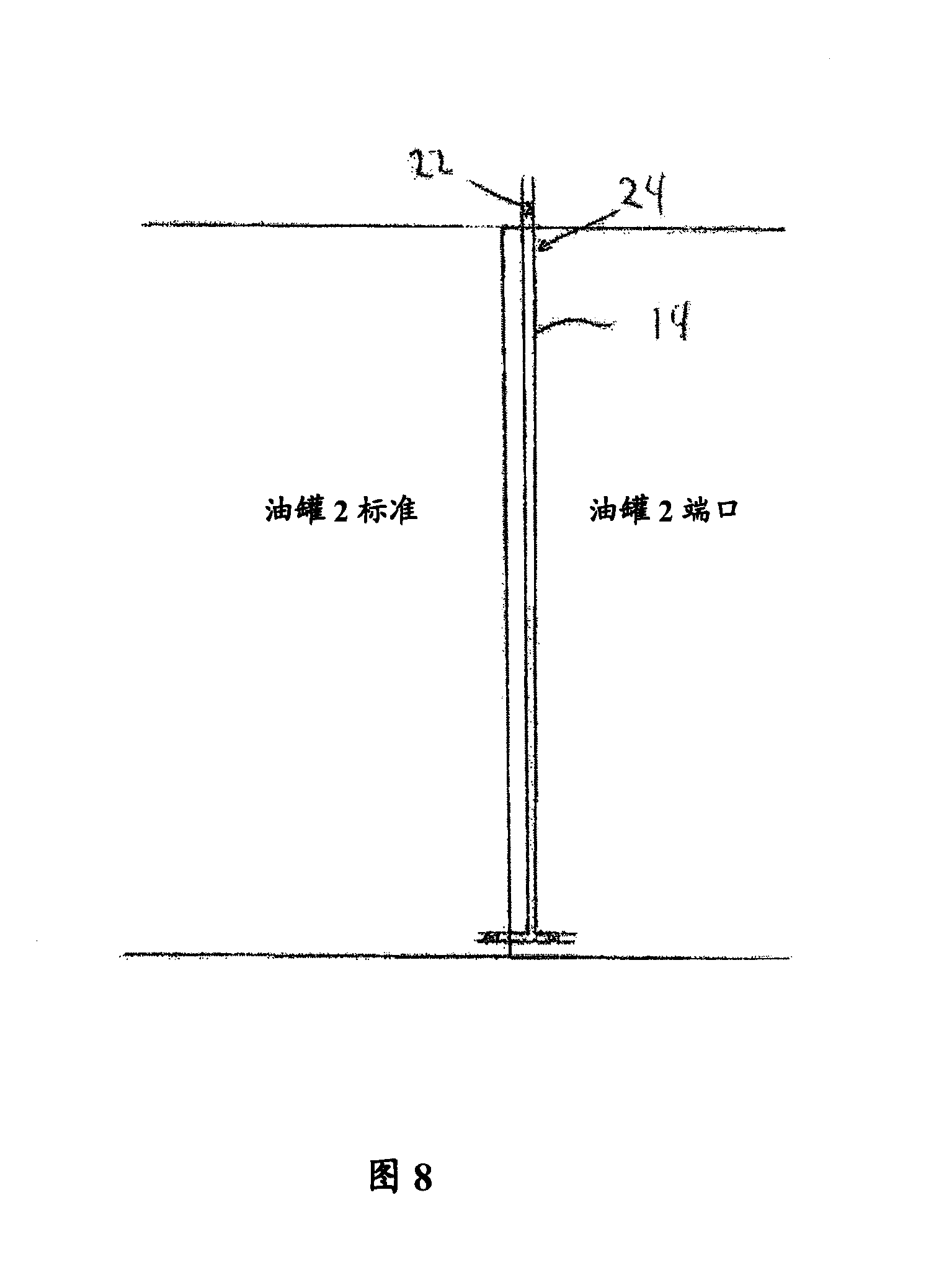

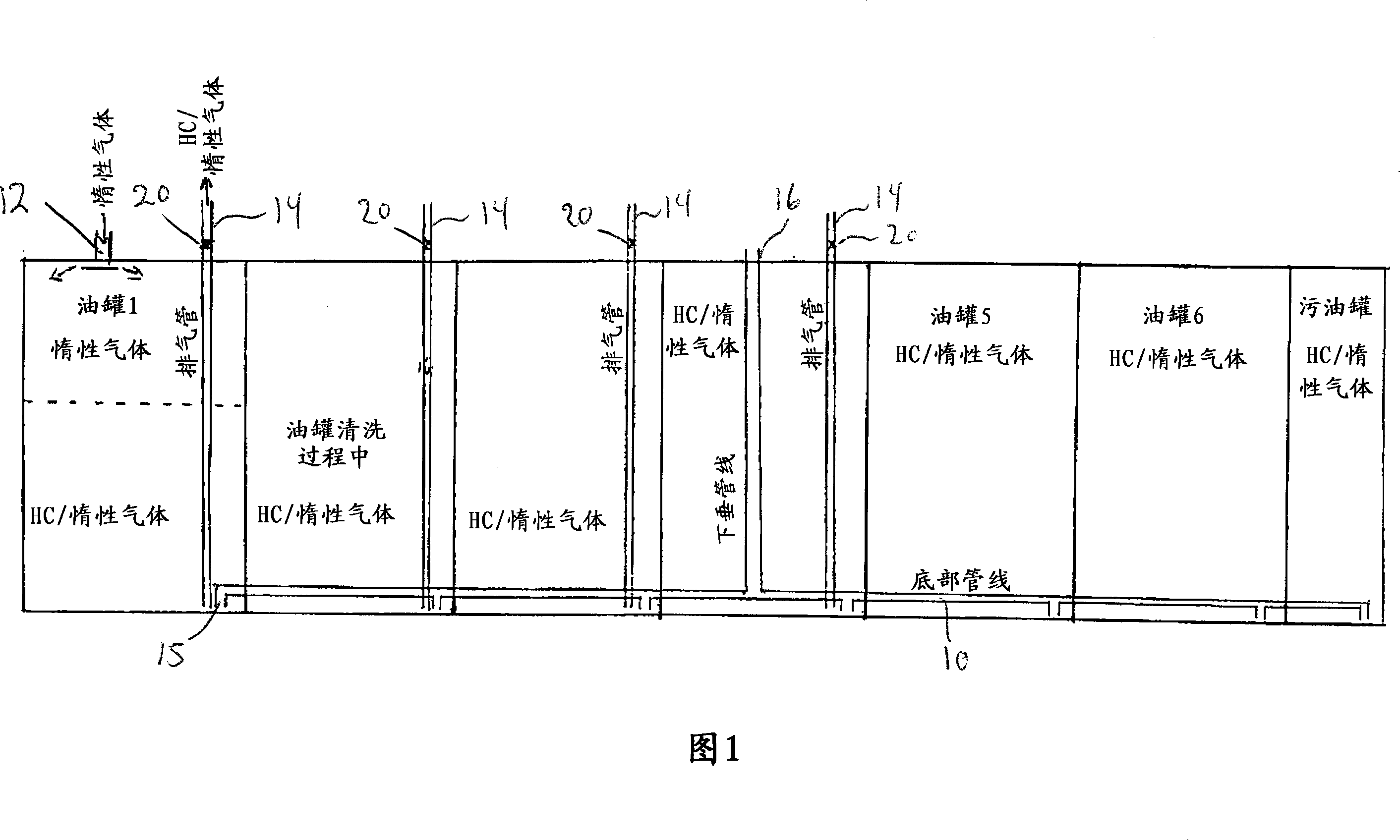

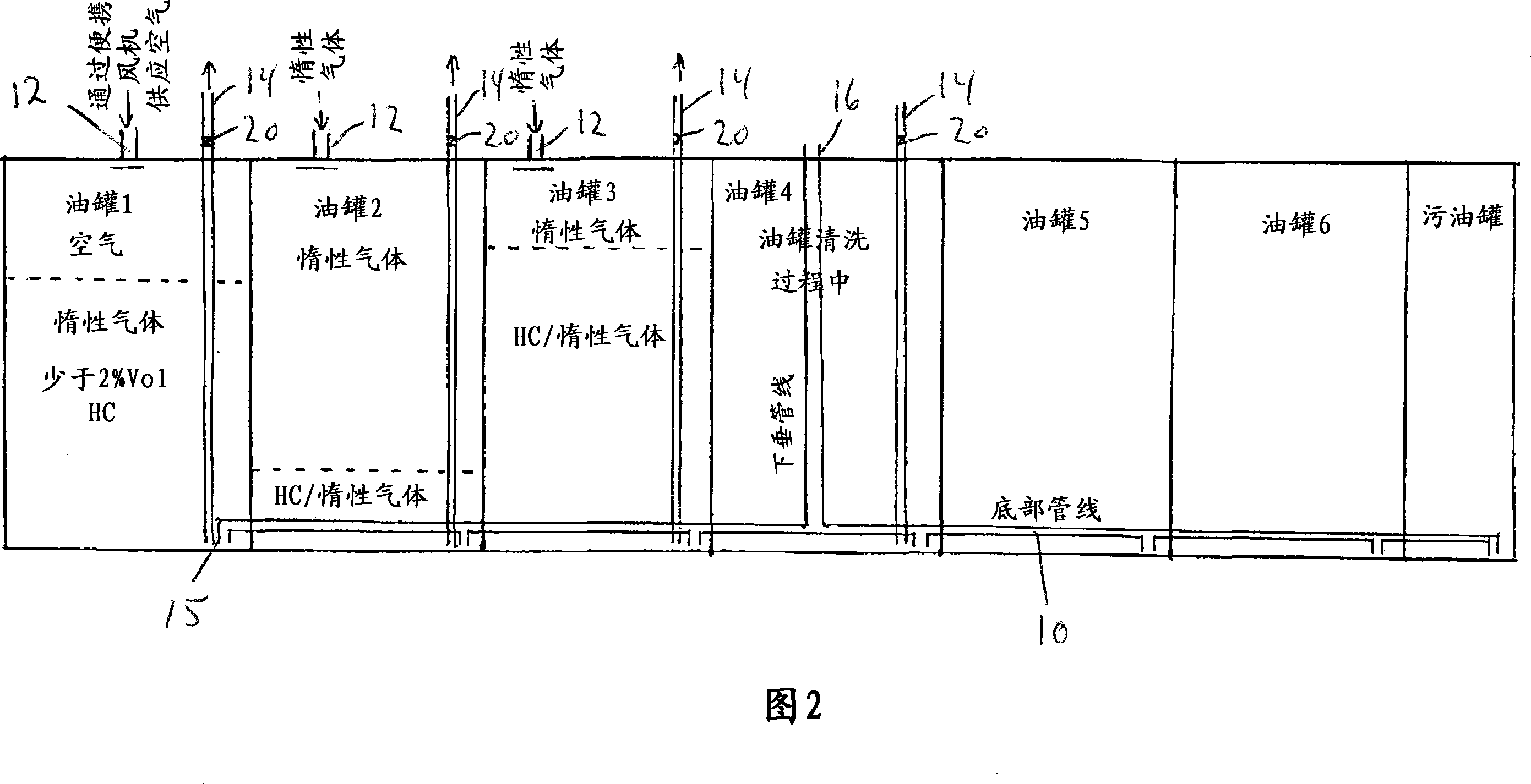

[0025] When the tank leaves the unloading port and is about to enter the workshop, the tank must be cleaned. After that, an inert gas must be supplied in order to reduce the concentration of HC gas to below 2% by volume (Vol.). Then, air was blown in so as to reduce the concentration of HC gas to 1% by volume of 2%. This is called 1% LEL - Lower Explosion Limit. At this time, it is possible to work in the oil tank. Large tankers have tanks eg 20-25m deep and it is time consuming to get the bottom of the tank to 1% LEL if the gas is blown in from the top and the heaviest gas is at the bottom. By utilizing the difference in specific gravity, the HC / inert gas is pressed out from the bottom. The LEL% will also be the highest concentration at the bottom of the tank. The limits of 2% HC and 1% LEL by volume are international requirements.

[0026] During the cleaning of the oil tank, for example, two pumps can be used. One of them supplies pressure to the jet scrubber and suct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com