Ethylene device driving method of front-end deethanization process

A technology for ethylene plant and ethane, which is applied in ethylene production, hydrotreating process, petroleum industry, etc., to achieve the effect of reducing losses and reducing the amount of ultra-high pressure steam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

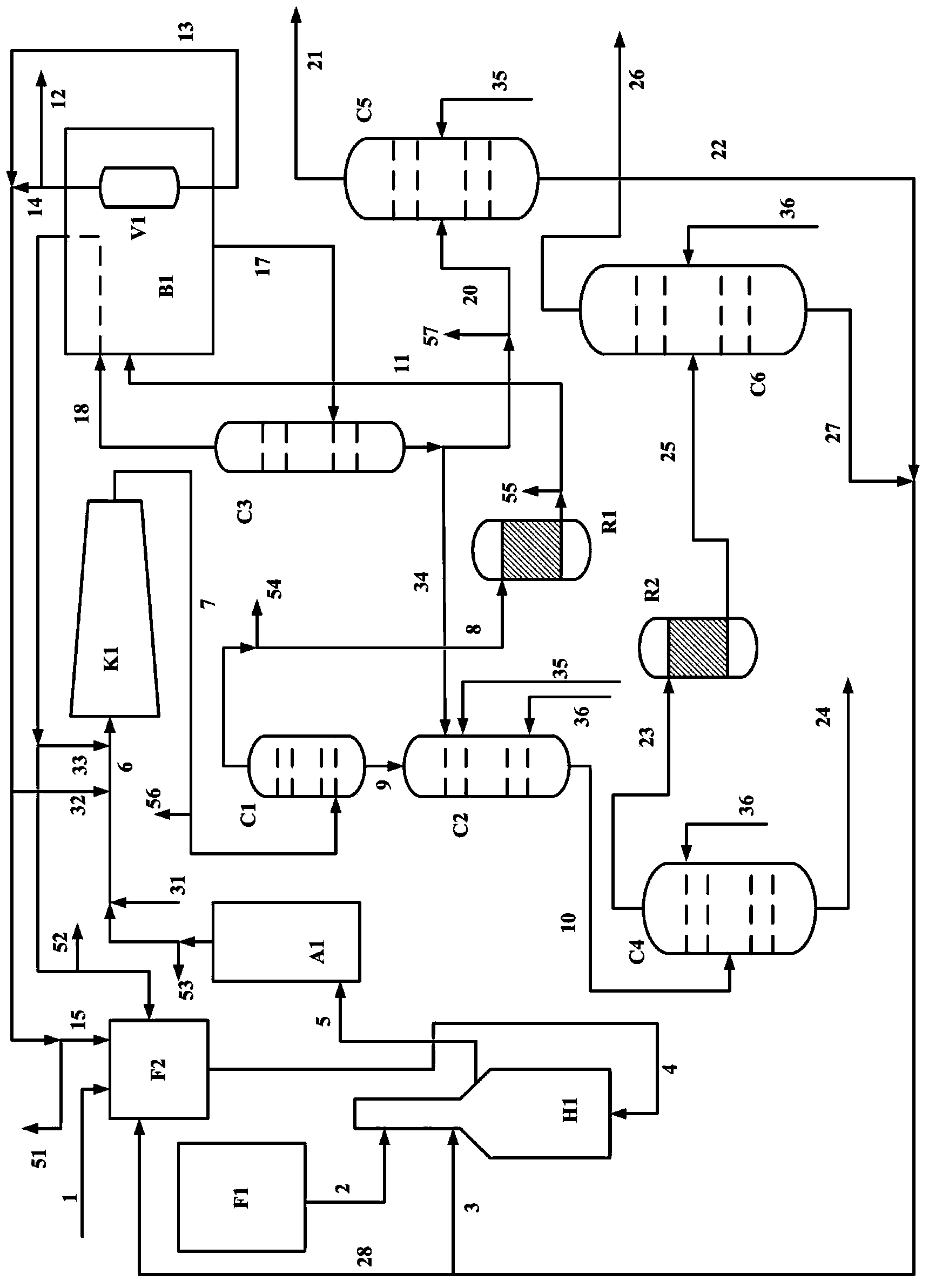

Embodiment 1

[0045] figure 1Shown is the ethylene plant start-up cycle diagram for the existing pre-deethanizer process. Natural gas 1 enters fuel gas system F2 to provide fuel gas 4 to cracking furnace H1. Before cracking furnace H1 feeds ethylene raw material 2, ethylene 35 is fed into deethanizer C2 and ethylene rectification tower C5, propylene 36 is fed into deethanizer C2, deethanizer is operated under pressure circulation, and ethylene rectification tower is fully refluxed Operation; propylene 36 is added to the depropanizer C4 and propylene rectification tower C6, and the two towers realize full reflux operation; nitrogen 31 is added from the suction port of the cracked gas compressor K1, and then passed through the cracked gas compressor K1 and the carbon three absorption tower C1 , carbon two hydrogenation reactor R1, cold box B1 and demethanizer C3, nitrogen 32 and 33 are returned to the inlet of cracked gas compressor K1 through the process flow of hydrogen methane separation ...

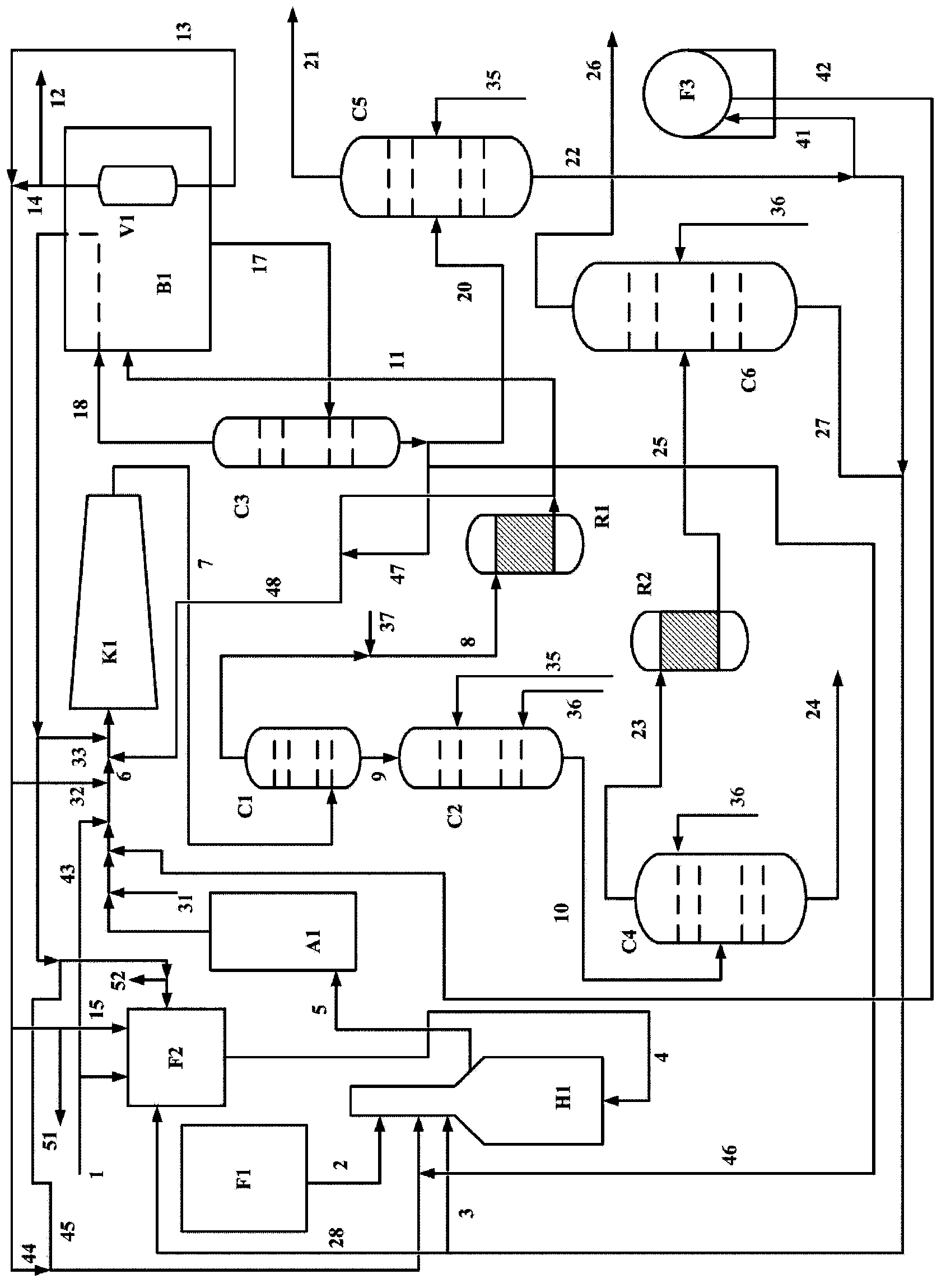

Embodiment 2

[0047] figure 2 Shown is an improvement diagram of the start-up cycle of an ethylene plant for the pre-deethanization process of the present invention. During the normal operation of the ethylene plant, the ethane 41 at the bottom of the ethylene rectification tower C5 is collected in the temporary ethane spherical tank F3. After the nitrogen precooling is completed after the start-up of the ethylene plant, natural gas 43 is introduced into the cracked gas compressor K1 inlet to replace the nitrogen in the compression and separation process system, and the replaced nitrogen is discharged from the streams 51 and 53 to the flare. Introduce ethane 42 from the ethane spherical tank F3 in proportion to the inlet of the cracking gas compressor K1, use the mixed gas of natural gas 43 and ethane 42 as the circulating gas of the cracking gas compressor K1 to pre-cool the separation system such as the cold box, hydrogen 37 is added from the inlet of the C2 hydrogenation reactor R1, th...

Embodiment 3

[0049] An embodiment of the present invention will be described below with respect to a set of ethylene plant of 800kt / a pre-deethanization separation process.

[0050] Two days before the planned shutdown of the ethylene plant, the ethane produced by the ethylene plant began to be collected, and the ethane 41 at the bottom of the ethylene rectification tower C5 was collected in the temporary ethane spherical tank F3, generally storing more than 500 tons of ethane. Prepare start-up materials such as natural gas, ethane and hydrogen. Table 1 shows typical compositions of natural gas and ethane.

[0051] Table 1 Typical composition of natural gas and ethane

[0052] Component

N 2

CO 2

CH 4

C 2 h 4

C 2 h 6

C 3 h 8

C 4 h 10

Natural gas, volume fraction / %

1.67

0.35

92.5

0.0

4.1

0.87

0.51

Circulating ethane, volume fraction / %

0.0

0.0

0.0

5.0

95.0

0.0

0.0 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com