Preparation method for hydrogen-methane biofuel

A biohydrogen and fuel technology, which is applied in the direction of waste fuel, fuel, gas fuel, etc., can solve the problems of large investment, low gasification rate, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

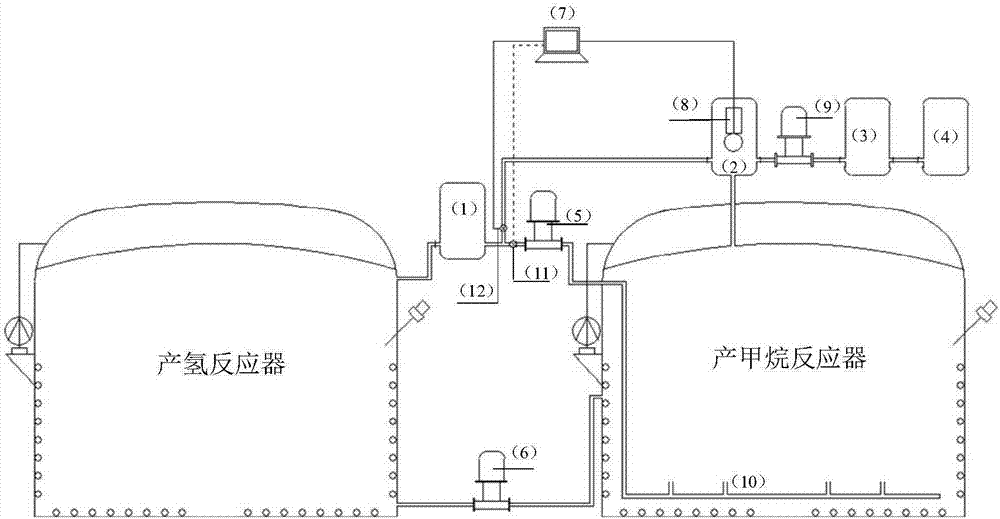

[0017] As shown in 1, the device includes a hydrogen-producing reactor, a methane-producing reactor, a biogas buffer tank, an on-line monitoring and control system and a hydrogen monitoring device; the hydrogen-producing reactor and the lower end of the methane-producing reactor are connected by pipelines with an inlet The upper end of the feed pump is connected to the biogas buffer tank, the first valve and the biogas pressurizing equipment in sequence through pipelines, and another pipeline with a second valve is arranged on the pipeline between the biogas buffer tank and the first valve. Connect the hydrogen alkane fuel gas distribution device, the hydrine fuel booster, and the CO 2 Removal device and hydrogen alkane fuel; among them, the first and second valves are connected with the hydrogen alkane fuel gas distribution device and the on-line monitoring and control system.

[0018] The hydrogen alkane fuel gas distribution device is connected with the on-line monitoring a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com