Method for preparing Al2O3 composite powder with uniformly dispersed carbon nanotubes by in-situ synthesis process

A technology of carbon nanotubes and composite powders, which is applied in the field of in-situ synthesis to prepare Al2O3 composite powders with uniform dispersion of carbon nanotubes, which can solve the problems of inability to generate carbon nanotubes and no catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method of in situ synthesis to prepare carbon nanotubes uniformly dispersed Al 2 o 3 The method for compound powder, comprises the following steps:

[0038] 1) According to Ni 2+ with Al 3+ The mol ratio is 1: 2, put 11.6316g of nickel nitrate hexahydrate and 30.0104g of aluminum nitrate nonahydrate into 200ml distilled water, then follow the method of citric acid monohydrate and metal ion (Ni 2+ with Al 3+ The molar ratio of the total) is 1:2, 12.6084g of citric acid monohydrate is added to the solution, and fully dissolved under the condition of a magnetic stirrer; then the resulting solution is poured into a corundum crucible and heated in a muffle furnace to Calcining at 950°C for 1 hour, the heating rate of the furnace is 10°C / min, after the calcination is completed, cool to room temperature and grind to obtain NiAl 2 o 4 Solid solution catalyst precursor powder;

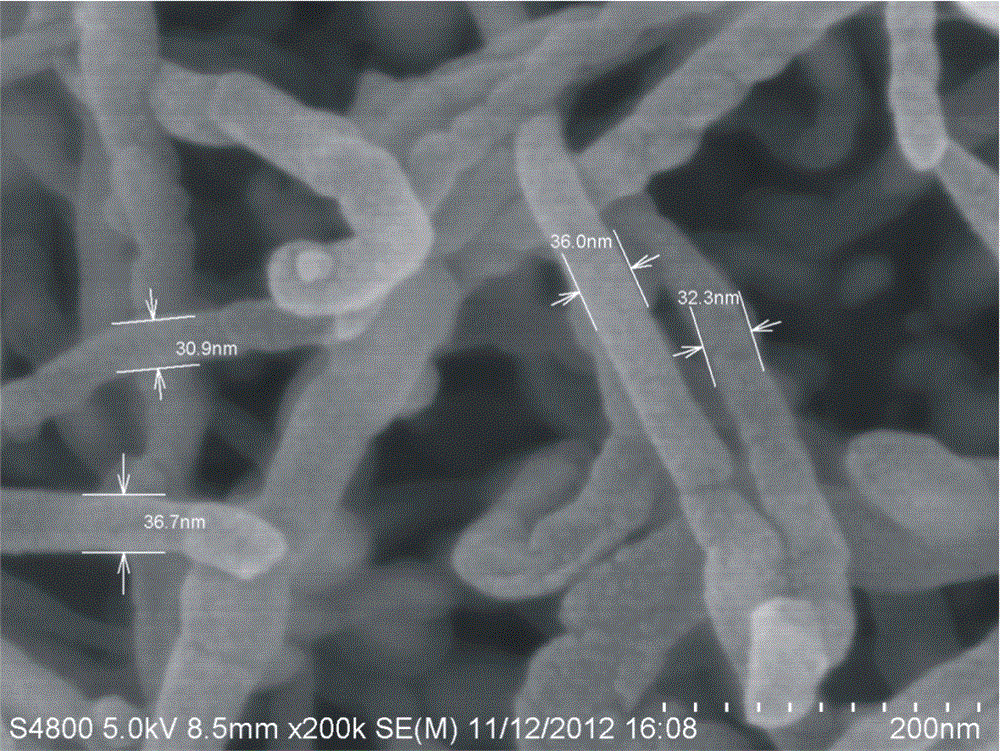

[0039] 2) Take the NiAl obtained in step 1 2 o 4 The solid solution catalyst precursor pow...

Embodiment 2

[0042] The specific method and steps are the same as in Example 1, the different conditions are that the holding time of step 2) is 30min, and the final carbon nanotube content is 11.17% and uniformly dispersed Al 2 o 3 Composite powder.

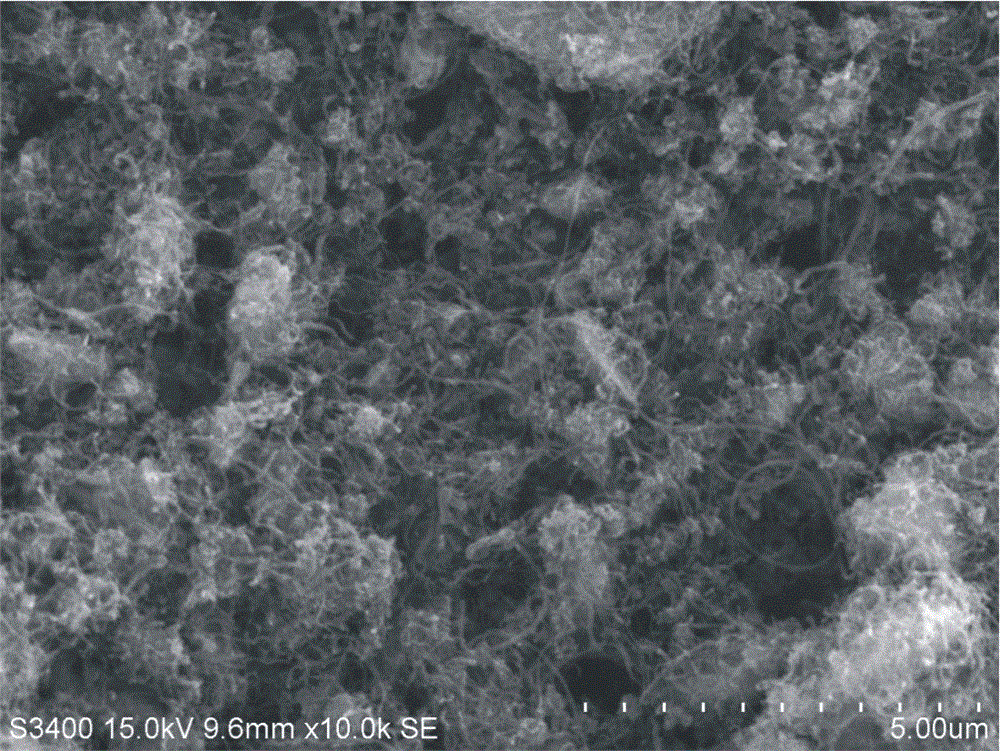

[0043] pass image 3 It can be seen that the carbon nanotubes are uniformly dispersed in the matrix.

Embodiment 3

[0045] The specific method and steps are the same as in Example 1. The different conditions are that the molar ratio of the added citric acid to the metal ion is 1:1 (25.2168g), the holding time of step 2) is 30min, and finally the carbon nanotube content is 8.68% and homogeneously dispersed Al 2 o 3 Composite powder.

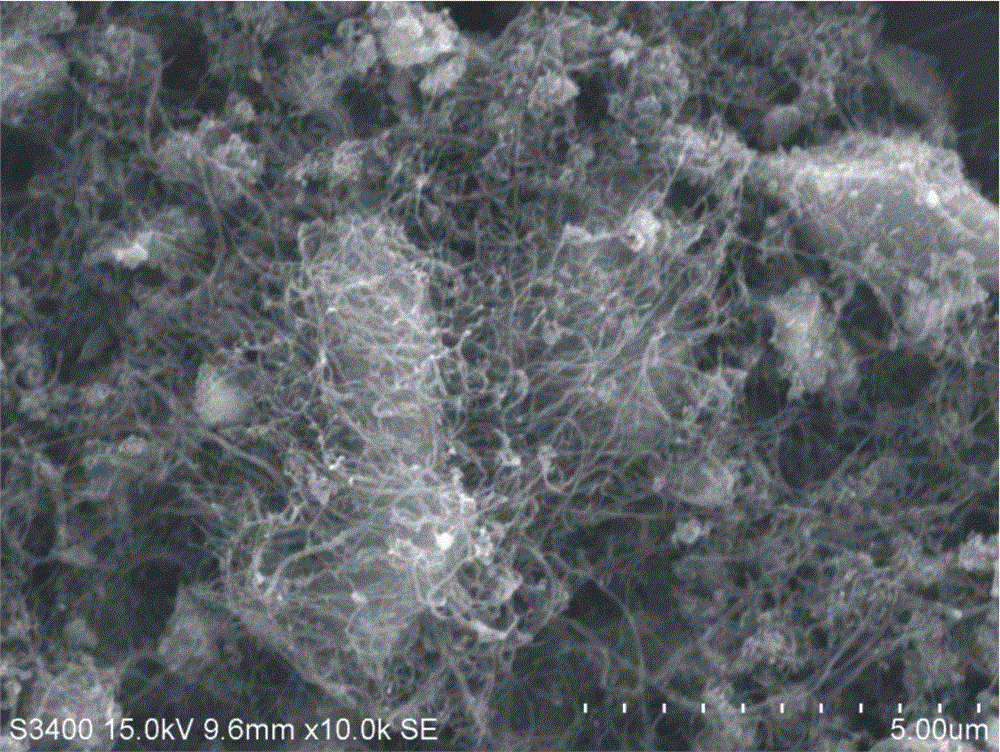

[0046] pass Figure 4 It can be seen that the carbon nanotubes are uniformly dispersed in the matrix, but the content of the carbon nanotubes is reduced compared with the examples 1 and 2 due to the variation of the experimental parameters.

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com