Self-adaptive control method of power generation internal combustion engine applied to various gas sources

An adaptive control and internal combustion engine technology, applied in engine control, electrical control, combustion engine, etc., can solve the problems of high methane and hydrogen, large difference in calorific value, etc., and achieve low-emission and reasonable utilization, reliable and reasonable utilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions in the embodiments of the present invention will be apparent from the drawings in the embodiment of the present invention. The described embodiments are merely the embodiments of the invention, not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art are in the range of the present invention without making creative labor premise.

[0035] The direction and position term mentioned herein, such as the left, right, above, below, and the like, are merely or in the direction or position of the accompanying drawings. Thus, the direction and location terms used are used to illustrate and understand the present invention, and are not limited to the scope of the invention.

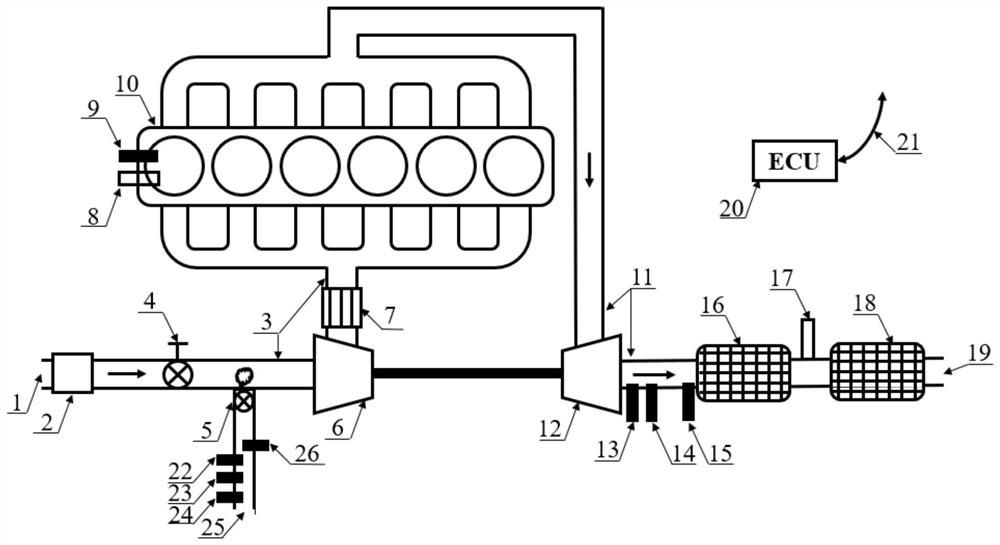

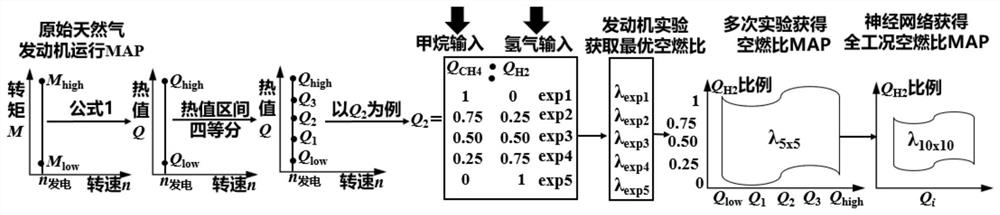

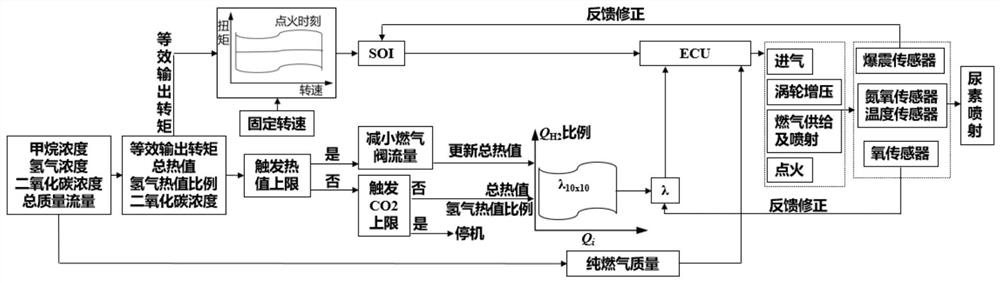

[0036] Append figure 1 The present invention is an adaptive control system suitable for a plurality of gas sources, including intake systems, exhaust gas turbine booster systems, exhaust rear proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com