Method for extracting methane from mixed gas containing methane, hydrogen and nitrogen

A mixed gas and methane technology, which is applied in the fields of hydrocarbons, chemical instruments and methods, organic chemistry, etc., can solve the problems of high investment cost, poor separation effect, and low product gas recovery rate, so as to improve the reflux ratio and reduce the load , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

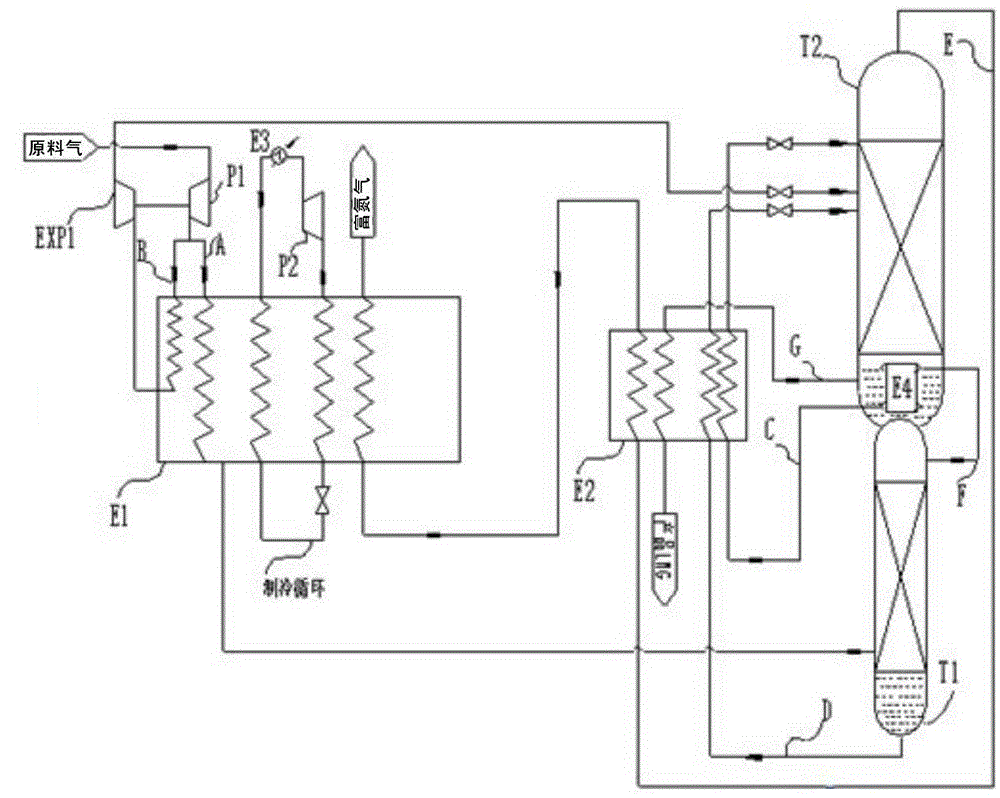

[0031] Such as figure 1 shown in figure 1 In , the equipment represented by each mark is as follows: P1-boosting end of raw gas expander; P2-mixed refrigerant cycle compressor; E1-main heat exchanger; E2-subcooler; E3-mixed refrigerant cooler; E4-condensing evaporator; EXP1-expansion end of raw material expander; T1-high pressure tower; T2-low pressure tower; FL-gas-liquid separator.

[0032] The air streams represented by each mark are as follows: air stream A-the feed gas entering the high-pressure tower after precooling; air stream B-the feed gas entering the low-pressure tower after compression and expansion; air stream C-subcooling and entering the high-pressure tower top nitrogen condensate of the low-pressure tower; air stream D -Crude methane at the bottom of the high-pressure column entering the low-pressure column; gas stream E-nitrogen at the top of the low-pressure column for reheating; gas stream F-gas stream from the top of the high-pressure column; gas stream G...

Embodiment 2

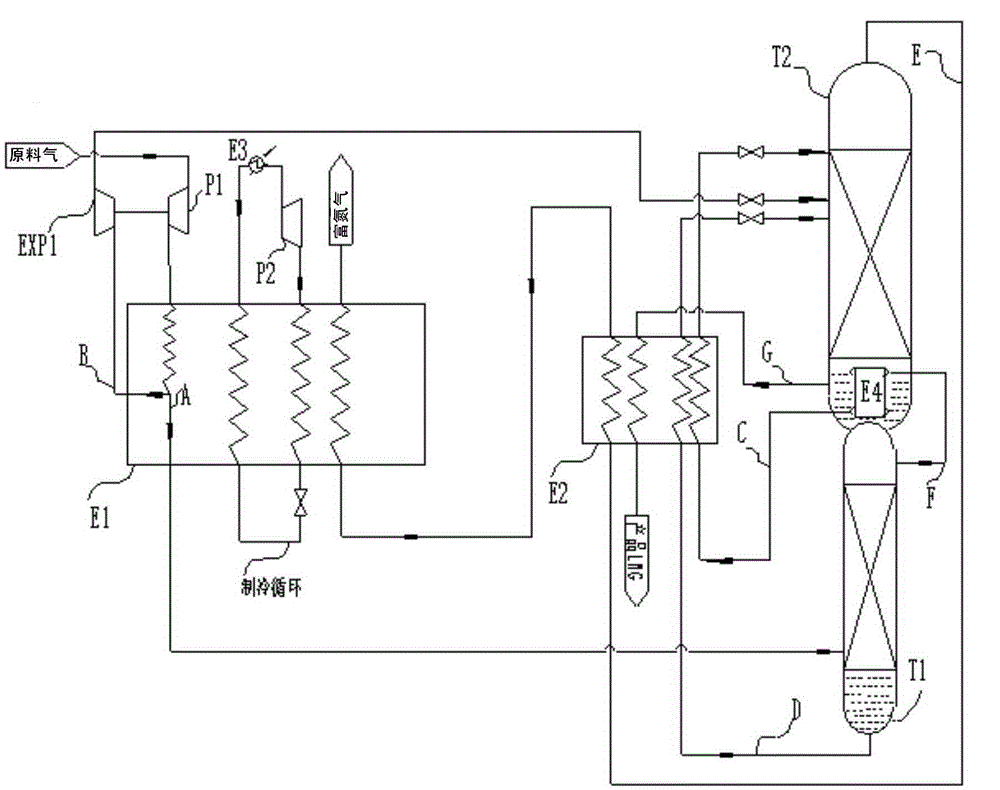

[0042] Such as figure 2 shown in figure 2 In , the equipment represented by each mark is as follows: P1-boosting end of raw gas expander; P2-mixed refrigerant cycle compressor; E1-main heat exchanger; E2-subcooler; E3-mixed refrigerant cooler; E4-condensing evaporator; EXP1-expansion end of raw material expander; T1-high pressure tower; T2-low pressure tower; FL-gas-liquid separator.

[0043] The air streams represented by each mark are as follows: air stream A-the feed gas entering the high-pressure tower after precooling; air stream B-expanding the feed gas entering the low-pressure tower; air stream C-subcooling and entering the high-pressure tower top nitrogen condensate of the low-pressure tower; The crude methane at the bottom of the high-pressure tower that enters the low-pressure tower; the gas stream E-nitrogen at the top of the low-pressure tower for reheating; the gas stream F-the gaseous stream drawn from the top of the high-pressure tower; the gas stream G-the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com