Temperature control film with underwater gas intercepting or collecting function and preparation method

A functional and gas technology, applied in the field of temperature-controlled membranes and preparations with underwater gas interception or collection functions, can solve problems such as the inability to achieve controllability of gas collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

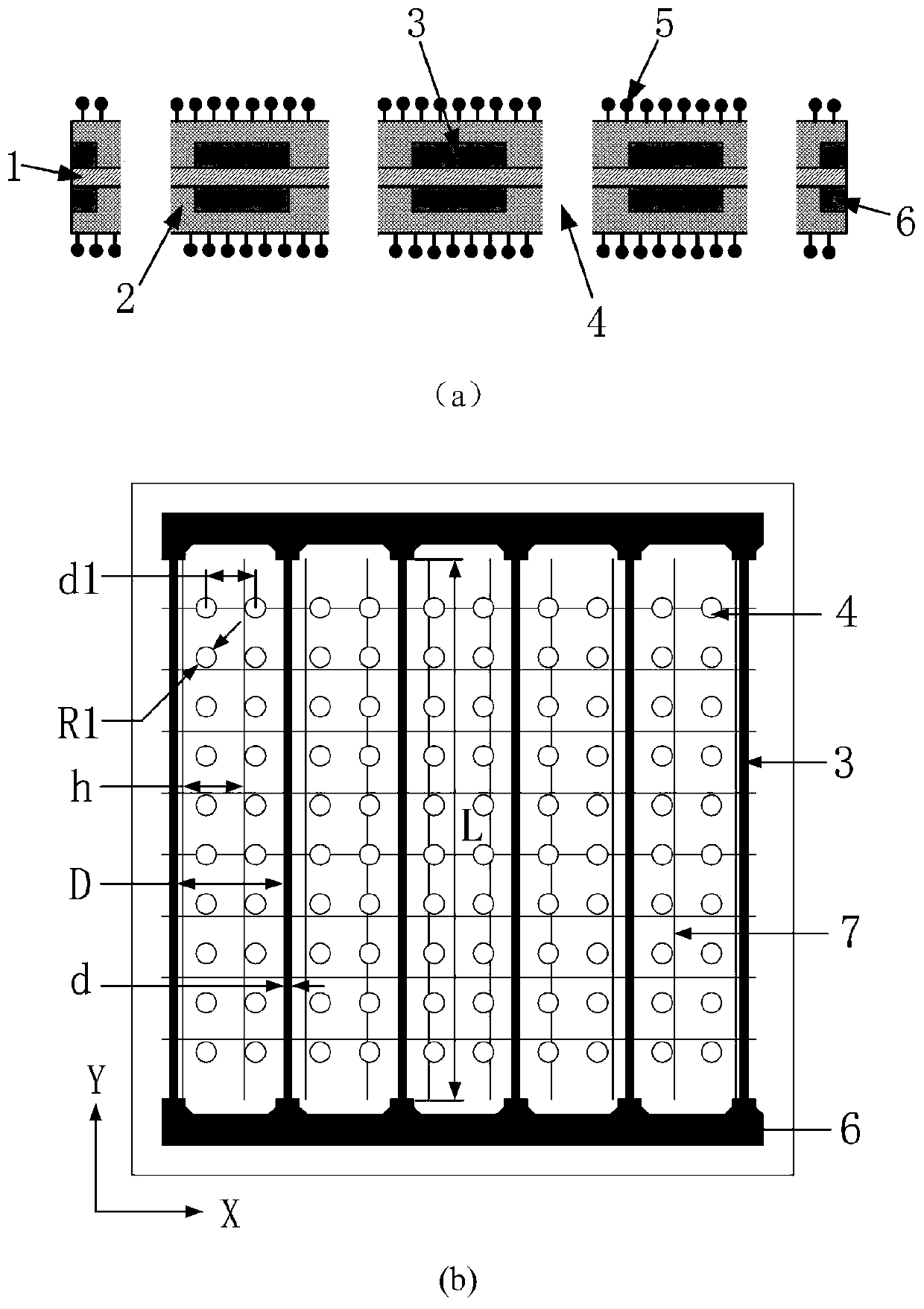

[0041] The temperature control membrane with the function of intercepting or collecting underwater gas in this embodiment, the heating electrode material is platinum; the heat insulating layer is a polyimide film with a thickness of 100 μm; The thickness of base siloxane is 500 μm; the heating electrode spacing D is 5 mm; the through hole diameter R1 is 200 μm; the through hole spacing d1 is 400 μm; the progressive scanning spacing h is 100 μm.

[0042] 1. Prepare heating electrodes on the heat insulating layer;

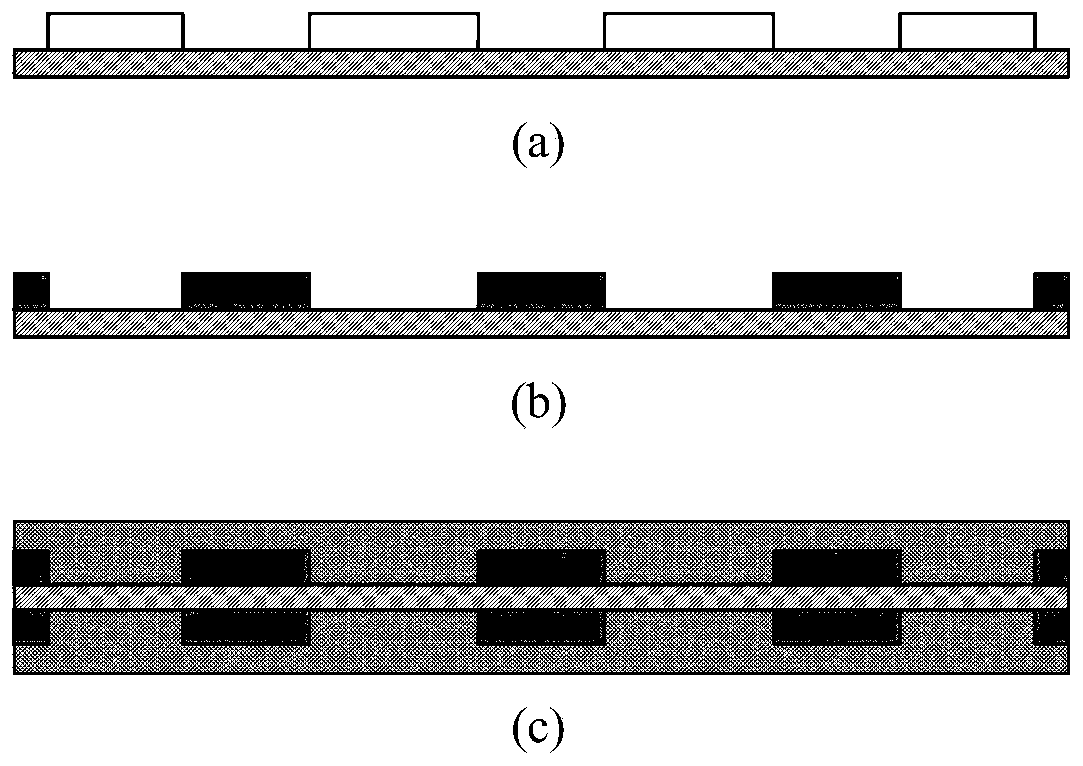

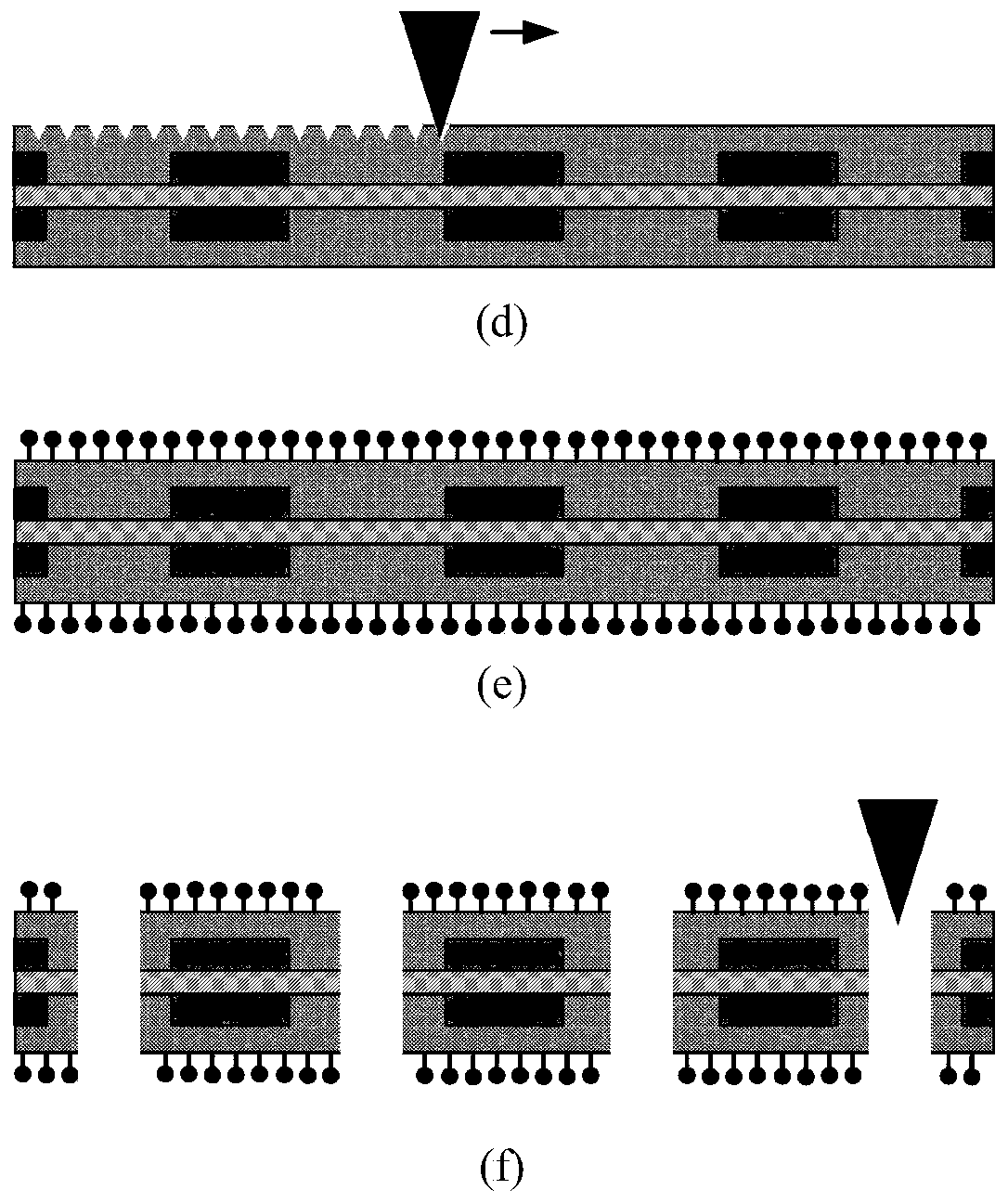

[0043] Spin-coat photoresist on a 4-inch polyimide film 1 with a thickness of 100 μm, and pattern the heating electrode ( figure 2 a), and then sputter-deposit a metal platinum with a thickness of 1 μm, a length L of 6 cm, and a width d of 20 μm to obtain a heated platinum electrode 3 ( figure 2 b). Next, metal platinum 3 is deposited on the other side of the heat-insulating film in the same manner, and the positions of the heating electrodes on the upper and lower...

Embodiment 2

[0056] The temperature control membrane with underwater gas interception or collection function aimed at in this embodiment, the heating electrode material is nickel; the heat insulating layer is a polyimide film with a thickness of 200 μm; The thickness of base siloxane is 100 μm; the heating electrode spacing D is 3 mm; the through hole diameter R1 is 300 μm; the through hole spacing d1 is 1 mm; the progressive scanning spacing h is 150 μm.

[0057] 1. Prepare heating electrodes on the heat insulating layer;

[0058] Spin-coat photoresist on a 4-inch polyimide film 1 with a thickness of 200 μm, and pattern the heating electrode ( figure 2 a), and then sputter-deposit a thickness of 1 μm, a length L of 6 cm, and a width d of 30 μm of metallic nickel to obtain a heated nickel electrode 3 ( figure 2 b). Next, metal nickel 3 is deposited on the other side of the heat-insulating film in the same manner, and the positions of the upper and lower layers of heating electrodes need ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com