Patents

Literature

77results about How to "Meet the requirements of working conditions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of producing aluminum alloy cylinder

InactiveCN1928341AImprove cooling effectMeet the requirements of working conditionsAnodisationCylinder headsSurface finishMicro arc oxidation

The invention discloses a production method for Al-alloy cylinder. A series of problems that surface finish of cylinder inner face machined by prior production method is not fit to technology and use demand of cylinder, internal combustion engine scuffs cylinder easily, the stability of cylinder is bad and life time is short, are solved. The primary scheme is that cavity of Al-alloy cylinder is machined mechanically; the cavity surface machined mechanically is treated with micro arc oxidation in alkaline solution by DC pulse power supply to form alumina ceramic layer; the layer is washed and dried; the layer is machined mechanically and washed thereafter.

Owner:SHANDONG HUASHENG PESTICIDE APPL MACHINERY CO LTD

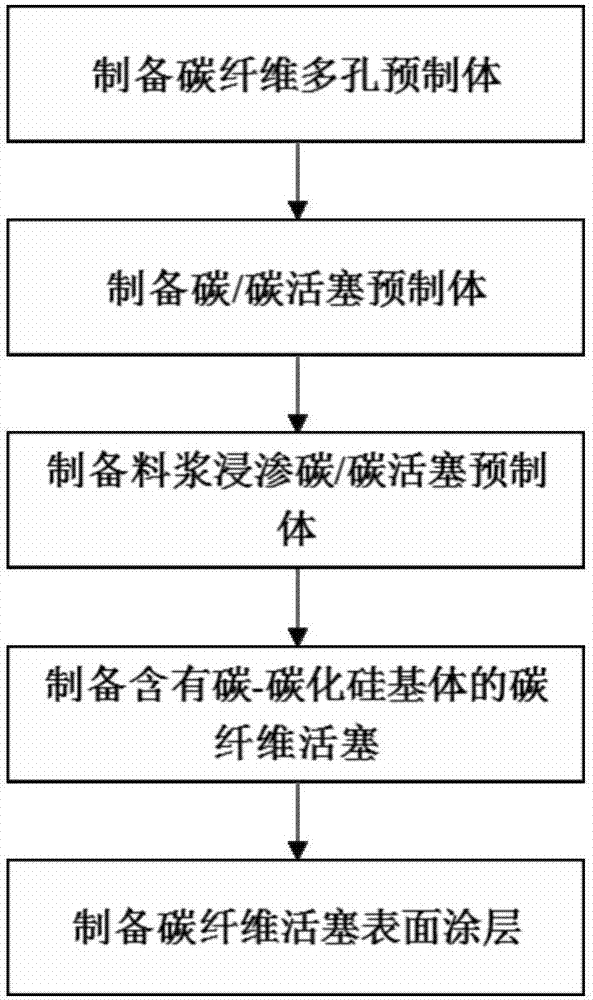

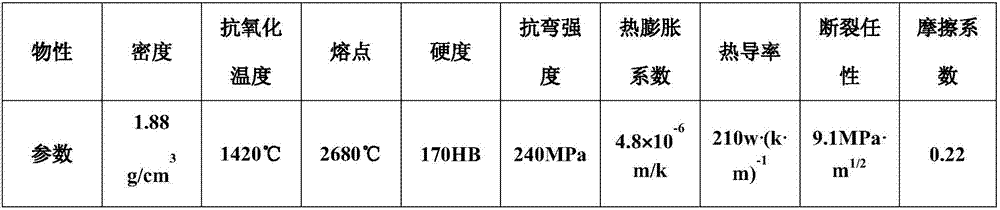

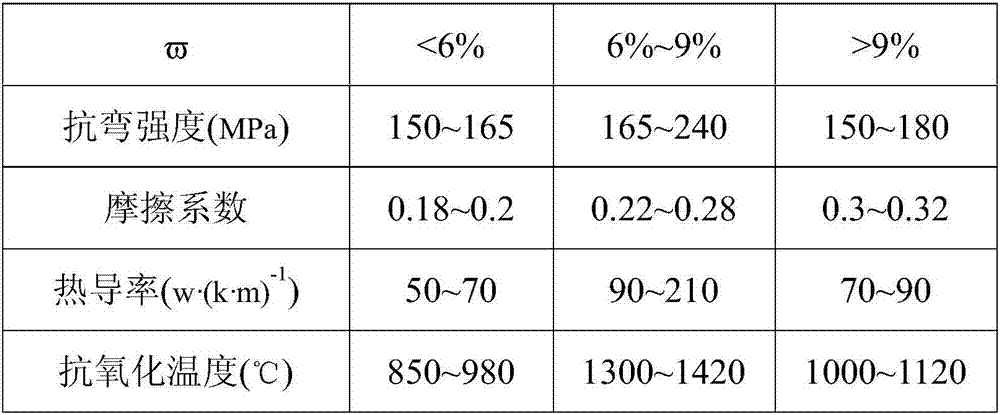

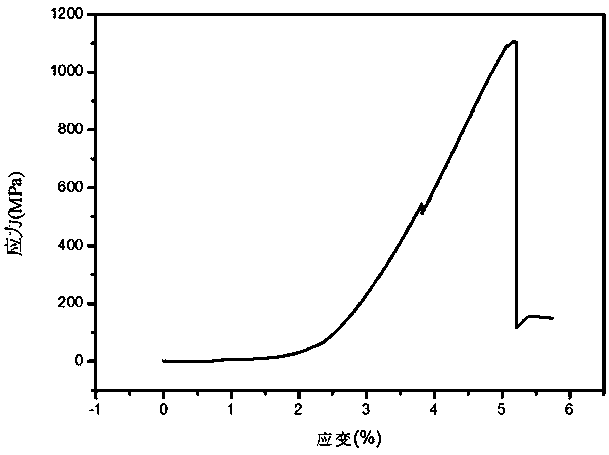

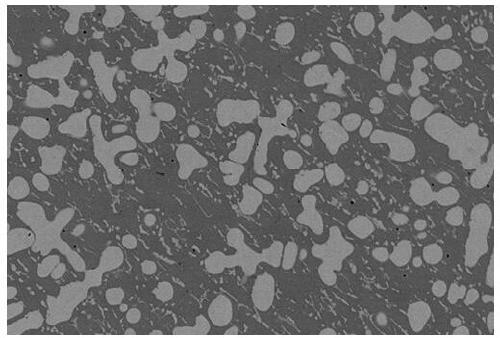

Cf/C-SiC composite material as well as preparation method and application thereof

The invention designs a composite material. The composite material comprises carbon-fiber perform, matrix carbon, filler and diamond-like carbon, wherein the matrix carbon is uniformly adhered on the carbon fiber of the perform to form the carbon-fiber perform with the matrix carbon; the filler fills the inside of the carbon-fiber perform with the matrix carbon and coats the outside of the carbon-fiber perform with the matrix carbon to form a semifinished product; the diamond-like carbon comprises a diamond-like carbon layer coated on the semifinished product; and the filler contains a Ti element, a Si element, a C element and a Mo element. The composite material has the advantages that a method of combining four processes of CVI, SI, RMI and PECVD to prepare a finished product with the advantages of high compactness, low thermal expansion coefficient and friction coefficient, high self-lubricating property, high thermal conductivity, oxidation resistance, thermal shock resistance, ablation resistance, wear resistance, high strength and toughness and the like; and simultaneously, the process is simple, the preparation period is short, the equipment requirement is low, the cost is low, net shaping can be realized and convenience is brought for large-scale industrial application.

Owner:XIANGTAN UNIV

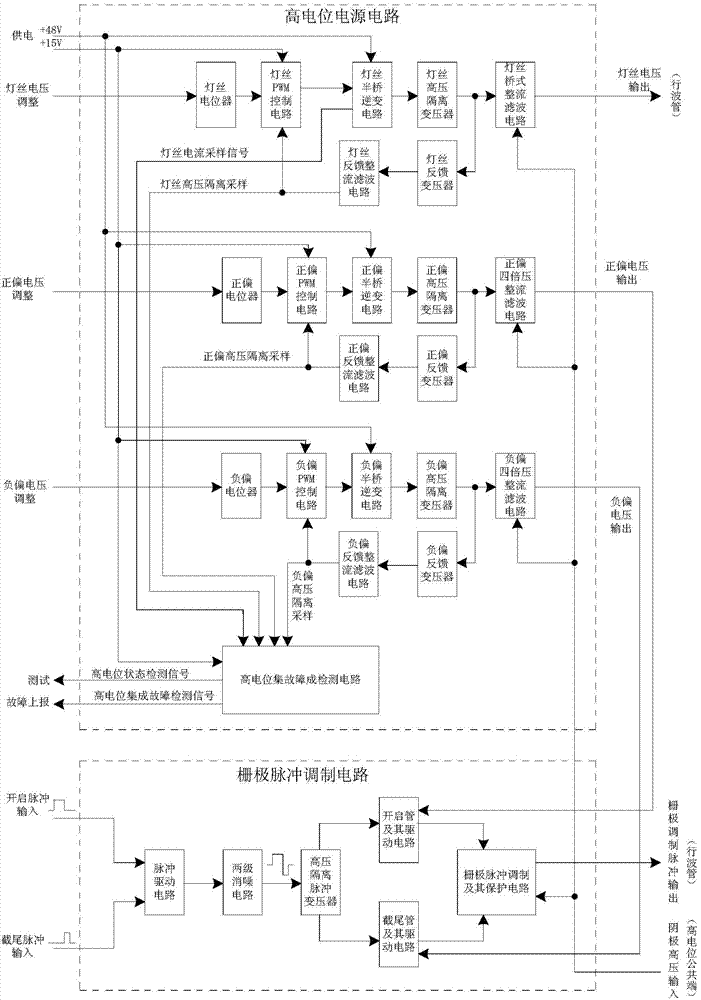

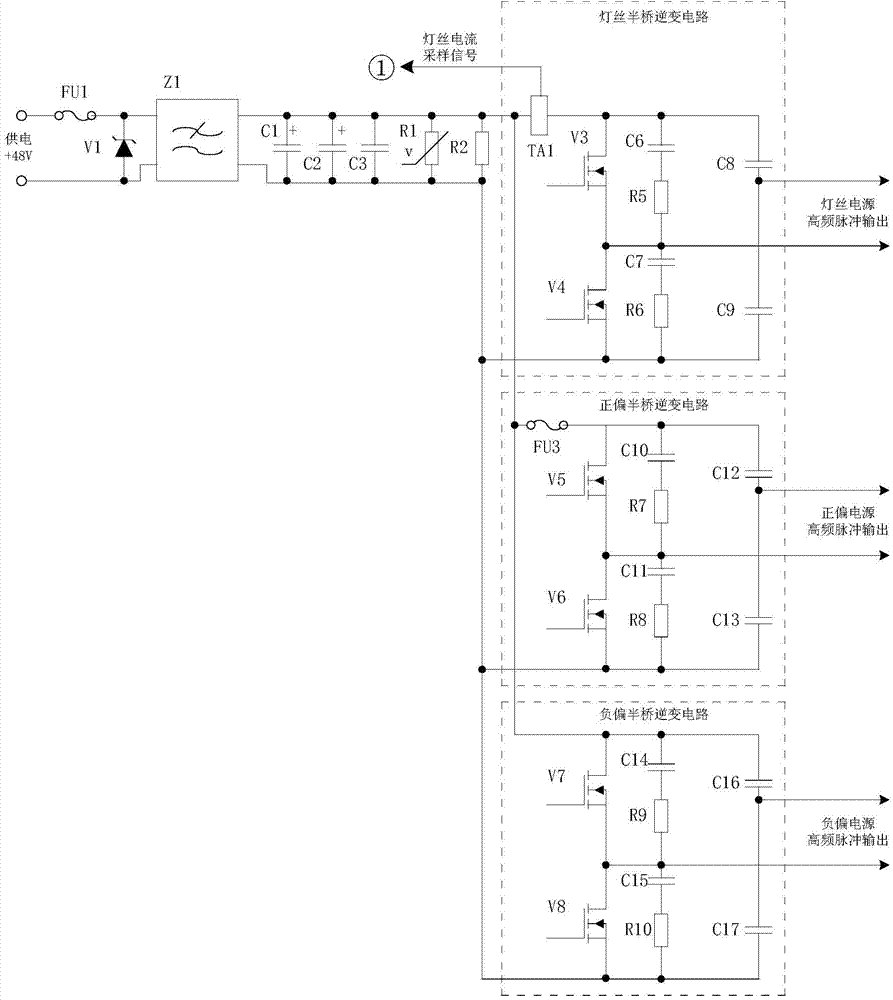

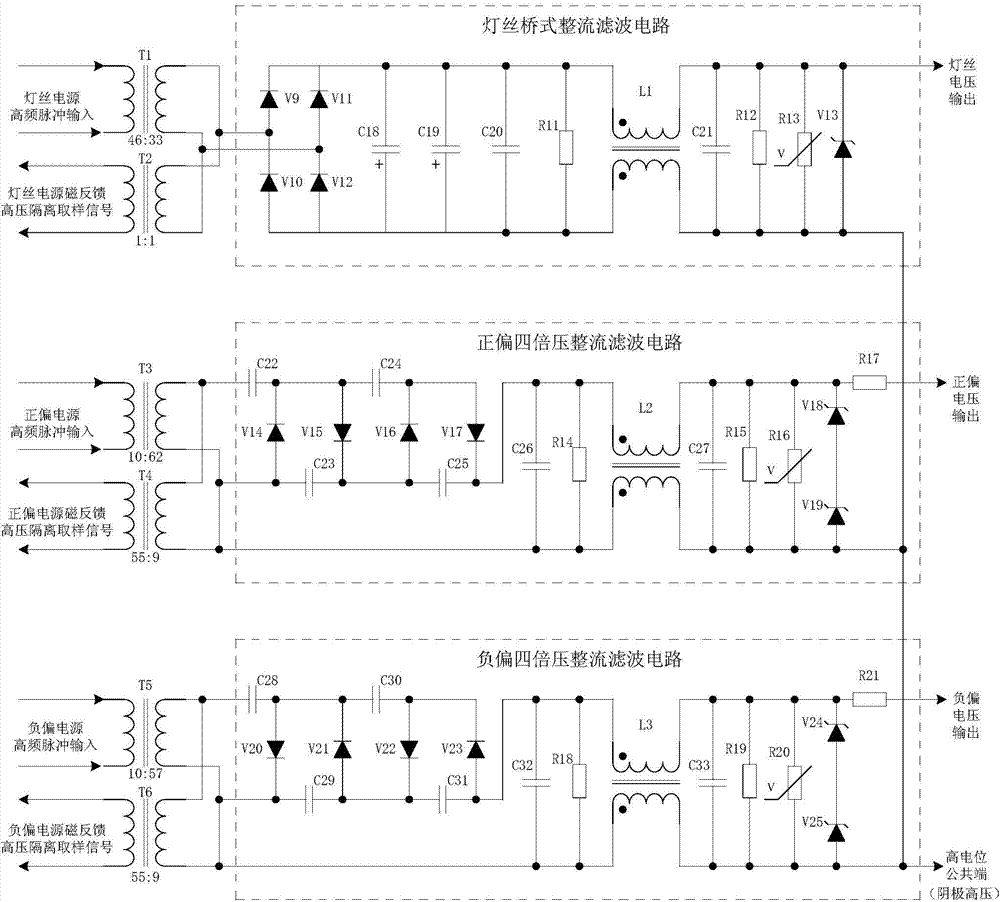

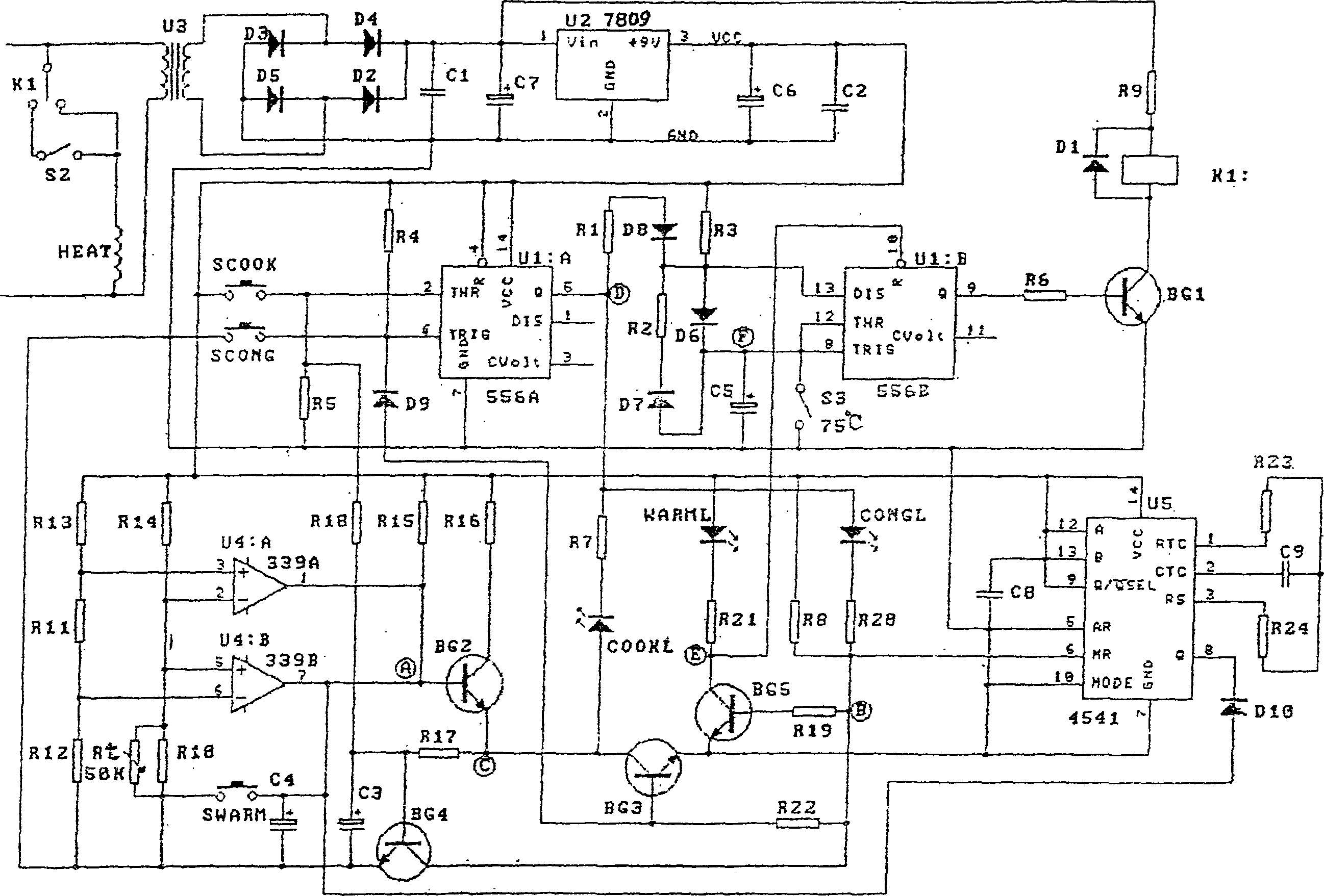

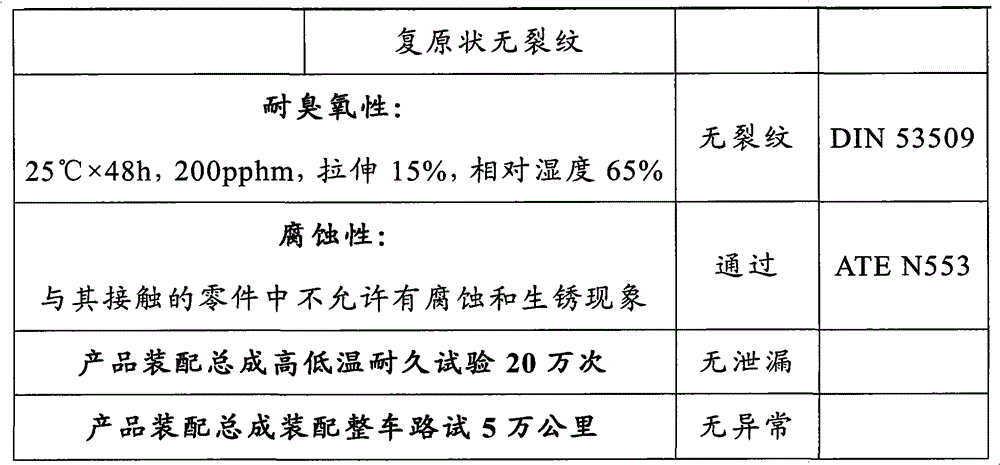

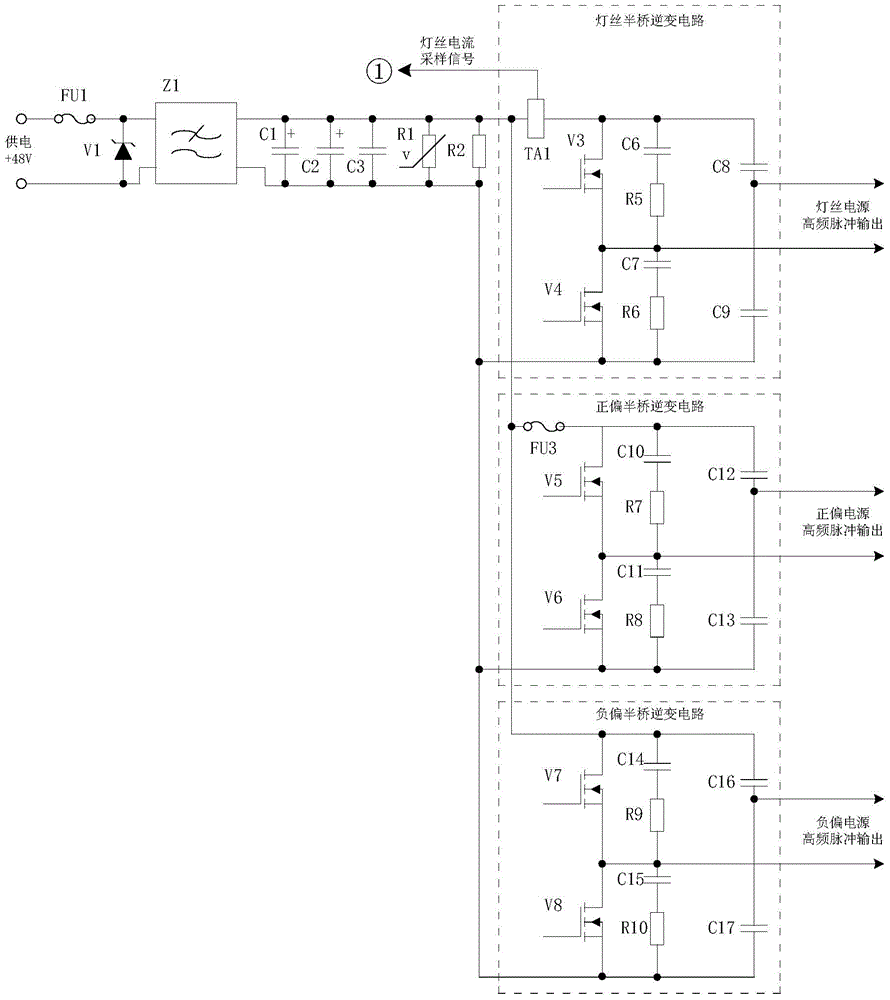

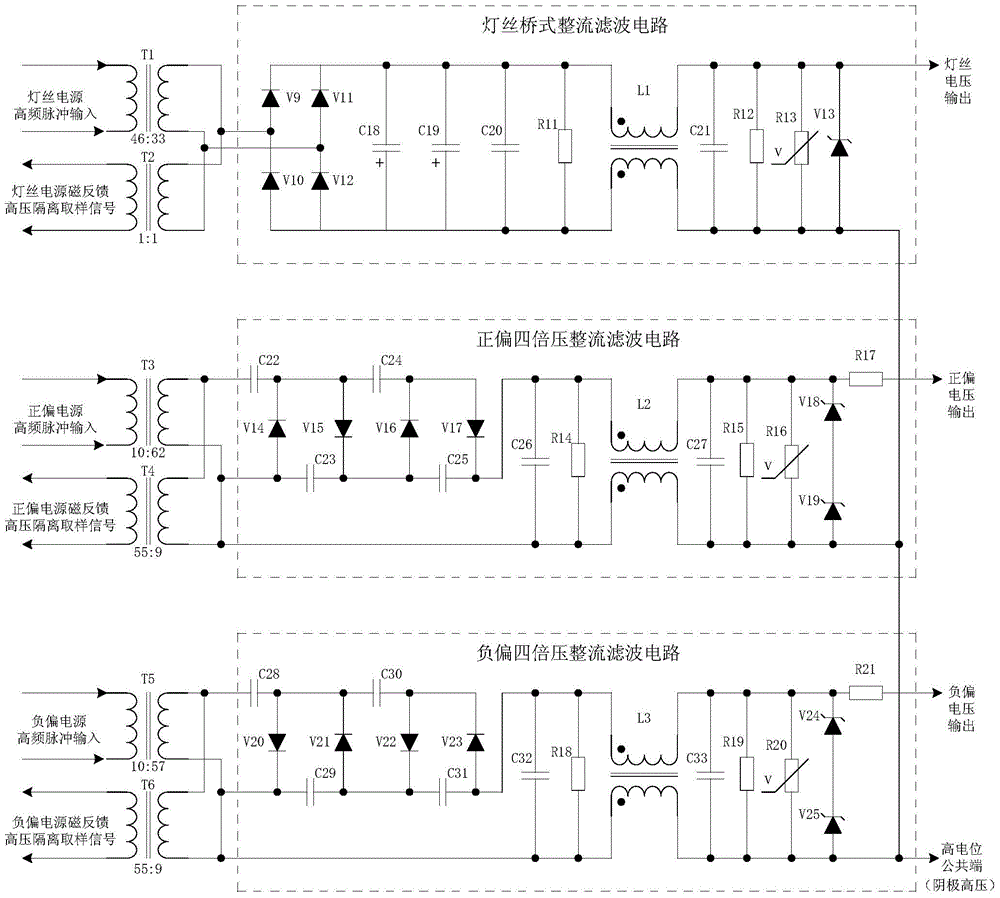

Adjustable integrated high-voltage grid electrode pulse modulator

ActiveCN103929847AMeet the requirements of working conditionsPerfect protection circuitElectric light circuit arrangementPower conversion systemsLow voltageEngineering

The invention relates to an adjustable integrated high-voltage grid electrode pulse modulator. An improved design is conducted on a filament high potential power supply circuit, a positive biased high potential power supply circuit, a negative biased high potential power supply circuit and a grid electrode pulse modulator circuit, and the high dense integration of the three high potential power supply circuits and the grid electrode pulse modulator circuit is achieved; a feedback circuit of a high potential power supply is improved, a magnetism feedback high voltage isolation sampling technology is adopted, and respectively independent adjustment to the high potential power supply output voltage values is achieved at the low voltage side; a high potential integrated failure detecting circuit is added, and the high potential power supply multi-circuit failures are integrated into one circuit signal; a pulse driving circuit is improved, and a dual-level denoising circuit is added; a grid electrode floating plate modulating circuit is improved, and an fire-making resistance protection circuit protection modulator and a traveling wave tube are added; a high-voltage transformer structure used for the modulator is improved, the size is reduced, and high-voltage isolation is achieved.

Owner:CNGC INST NO 206 OF CHINA ARMS IND GRP

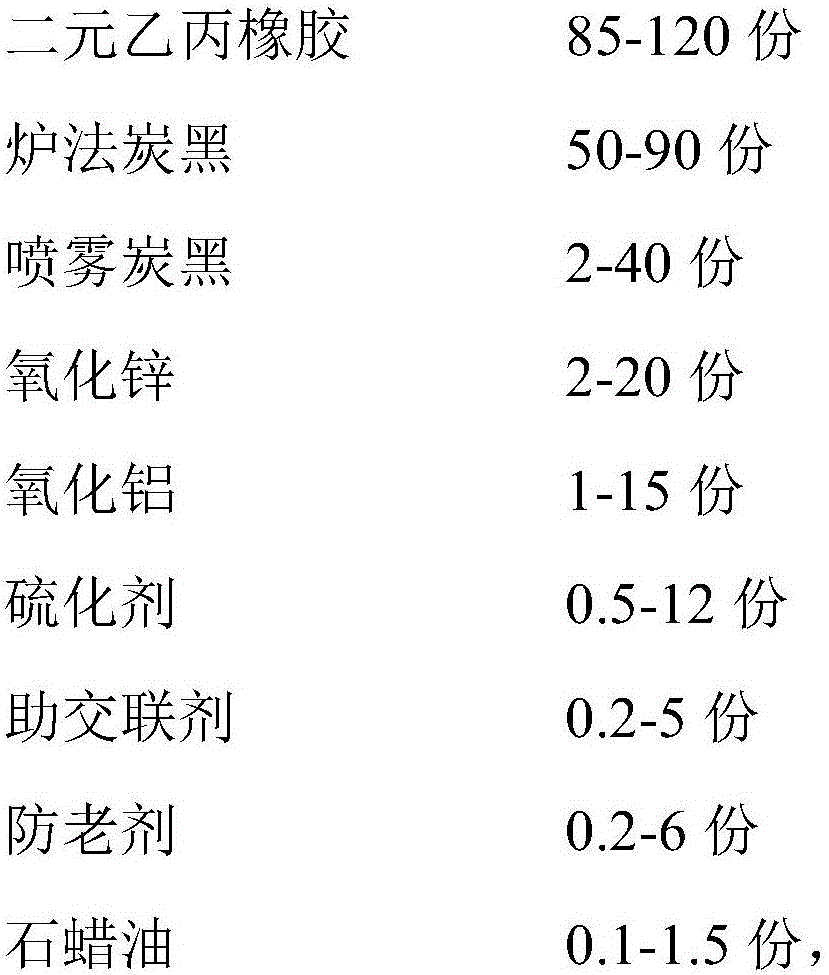

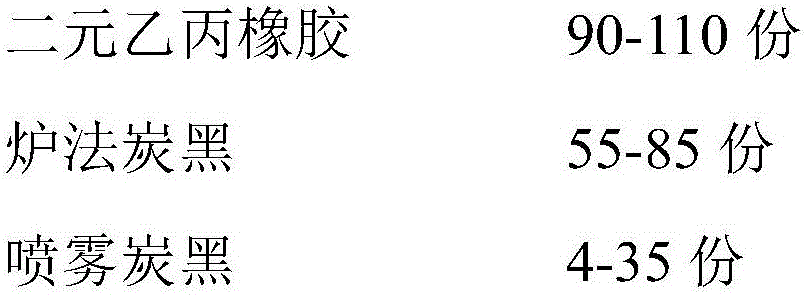

High-temperature-resistant ethylene propylene rubber sealing pad and preparation method and application thereof

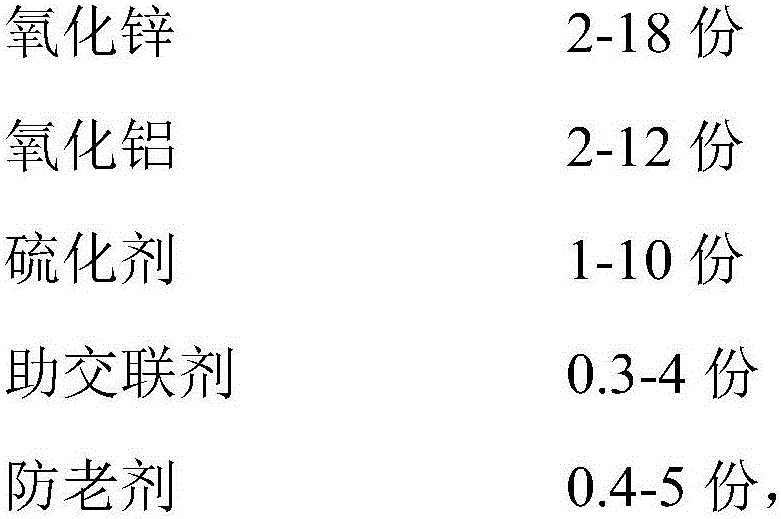

The invention relates to the technical field of ethylene propylene rubber sealing pads, in particular to a high-temperature-resistant ethylene propylene rubber sealing pad and a preparation method and application thereof. The high-temperature-resistant ethylene propylene rubber sealing pad is made from ethylene propylene copolymer, furnace carbon black, spray carbon black, zinc oxide, aluminum oxide, a vulcanizing agent, an assistant cross-linker, an anti-aging agent and the like, wherein fully saturated ethylene propylene copolymer is used as a rubber raw material, and the prepared high-temperature-resistant ethylene propylene rubber sealing pad has excellent weatherability, dielectric resistance and temperature tolerance, may be used for a long time at 150 DEG C and may be used temporarily or intermittently at 180 DEG C, fatigue resistance and high-temperature aging resistance of the traditional ethylene propylene rubber sealing pad are improved, and the problems of the prior art that high-temperature fatigue performance is low and the use at 150 DEG C is only temporary or intermittent are solved.

Owner:兰州瑞普科技实业有限责任公司

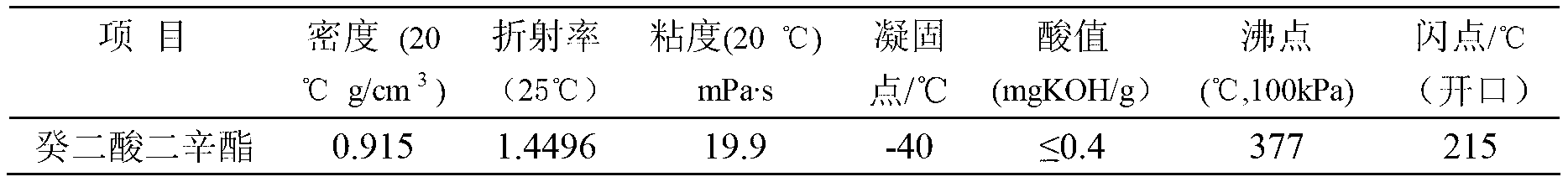

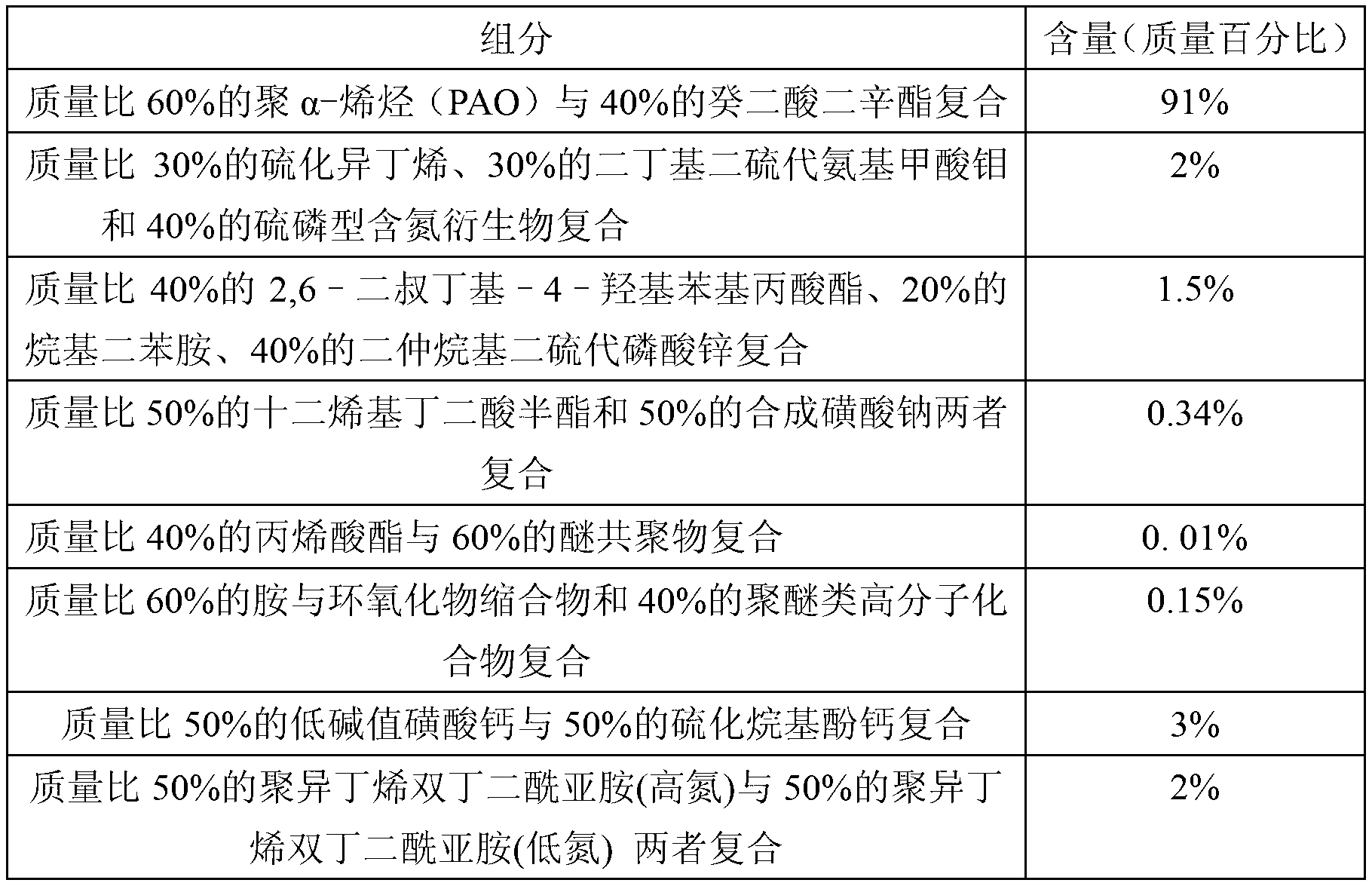

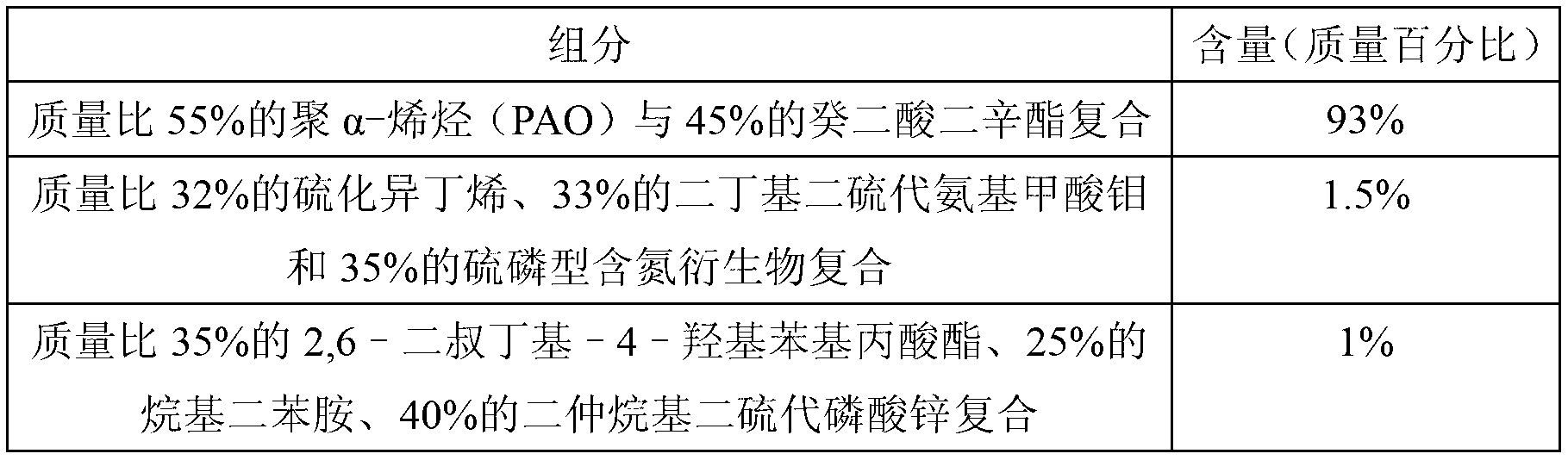

Environmentally-friendly energy-saving-type heavy loading screw compressor oil

ActiveCN103194301AGood low viscosityLow volatilityLubricant compositionLubricationEnvironmentally friendly

The invention provides environmentally-friendly energy-saving-type heavy loading screw compressor oil. The environmentally-friendly energy-saving-type heavy loading screw compressor oil comprises 90-95% of composite base oil and 10%-5% of other additives in percentage by weight. Poly Alpha-Olefins (PAO) and dioctyl sebacate are compounded to serve as the base oil of the environmentally-friendly energy-saving-type heavy loading screw compressor oil. The environmentally-friendly energy-saving-type heavy loading screw compressor oil provided by the invention has the advantages of good operating characteristics, long service life and good biodegradability and also has effects of improving the efficiency of a screw compressor, reducing the abrasion and corrosion of a screw, effectively prolong the service life and the oil draining period of the screw compressor and meeting the requirements under special service conditions. The environmentally-friendly energy-saving-type heavy loading screw compressor oil provided by the invention is not only suitable for the requirements of various middle-heavy loading screw compressors under service conditions, and but also can meet the lubrication, cooling and sealing requirements of the middle-heavy loading sliding vane compressors.

Owner:GUANGXI UNIV

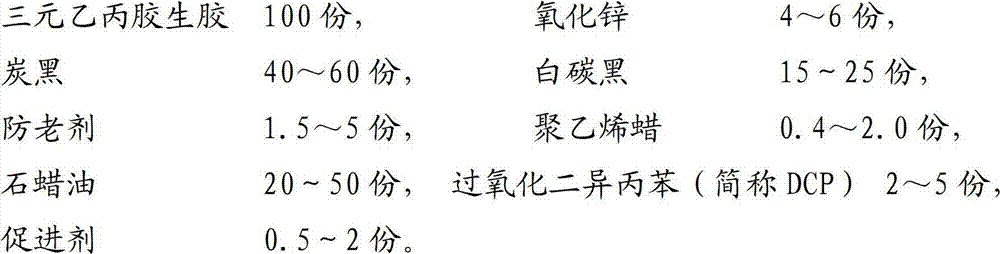

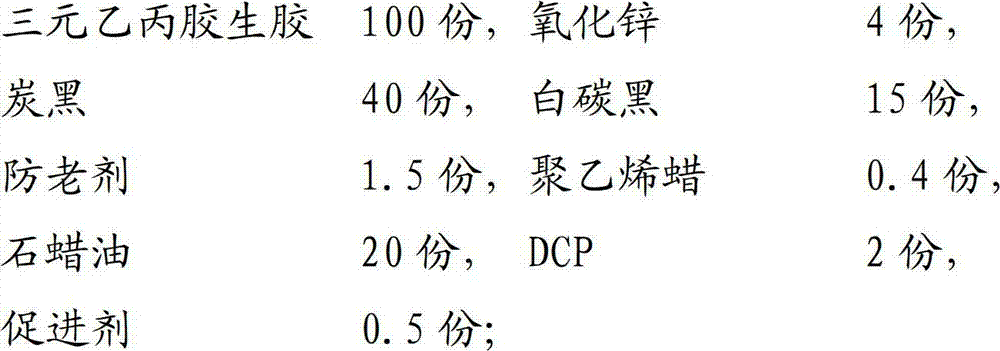

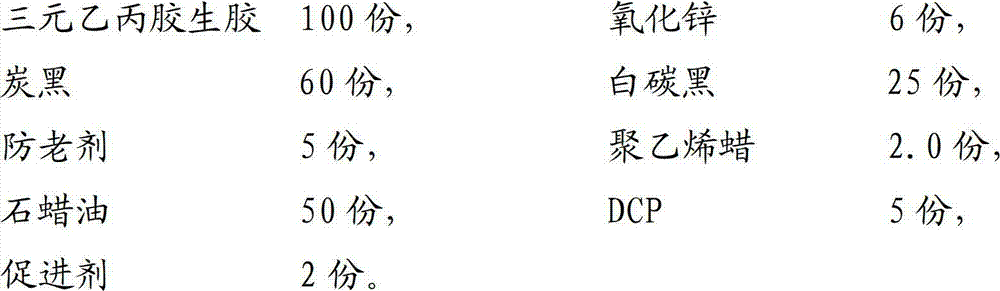

Low-pressure-variation ethylene-propylene rubber mixed compound and mixing method

The invention discloses low-pressure-variation ethylene-propylene rubber mixed compound which is made of, by weight, 100 parts of ethylene-propylene-diene-terpolymer rubber, 4-6 parts of zinc oxide, 40-60 parts of carbon black, 15-25 parts of white carbon black, 1.5-5 parts of anti-aging agent, 0.4-2.0 parts of polyethylene wax, 20-50 parts of paraffin oil, 2-5 parts of DCP (dicumyl peroxide) and 0.5-2 parts of accelerant. The low-pressure-variation ethylene-propylene rubber mixed compound is low in pressure variation under standard temperature and time and can completely meet requirements of operating conditions.

Owner:QINGDAO TKS SEALING IND

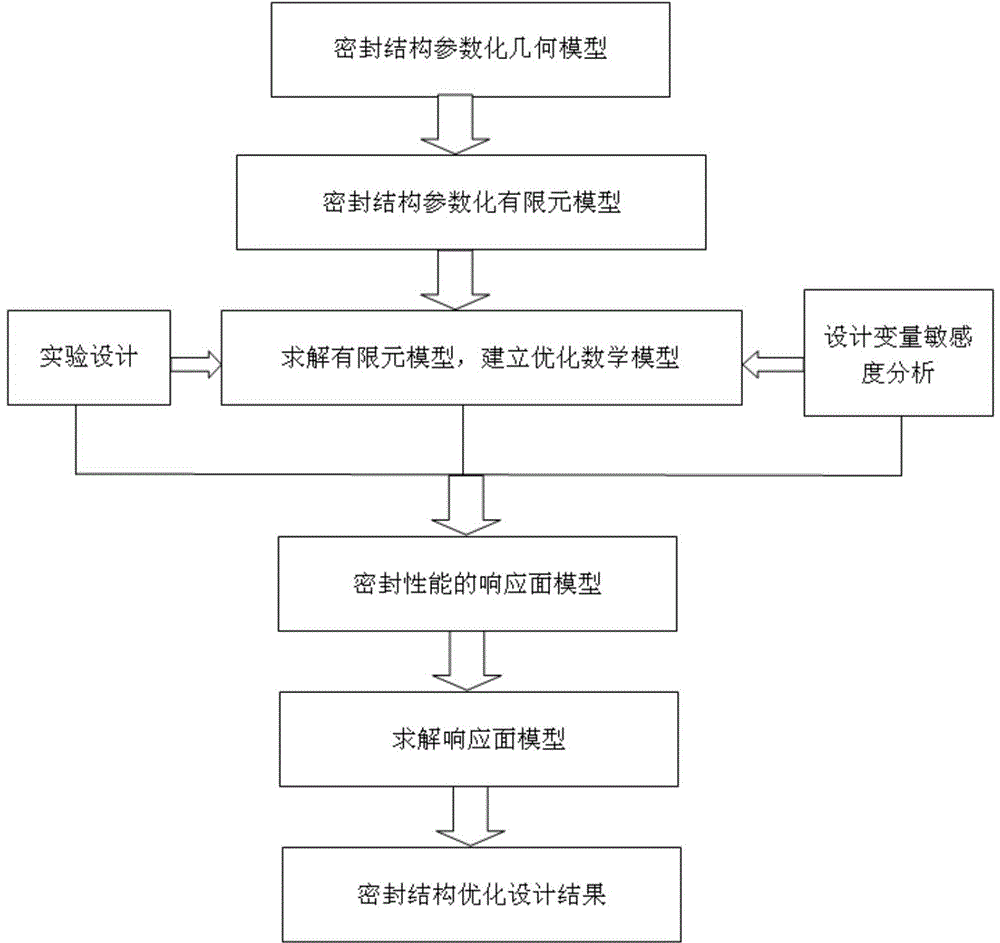

Optimization design method for oil casing screwed-joint sealing structure

ActiveCN104573212AImprove sealingMeet the requirements of working conditionsSpecial data processing applicationsElement modelElement analysis

The invention discloses an optimization design method for an oil casing screwed-joint sealing structure. The optimization design method includes the following steps: 1), creating a parameterized geometric model of the special screwed-joint sealing structure; 2), creating a parameterized finite element model of the special screwed-joint sealing structure; 3), solving the finite element model, determining three optimization design elements, and creating an optimized mathematical model of the sealing structure; 4), performing design of experiments (DOE) on the optimized model, determining optimization solution settings, and solving the optimized model on experiment samples; 5), performing sensitivity analysis on design variables, and fitting a response surface model of sealing performance on experiment sample points; 6) selecting a proper optimization algorithm to perform iteration solution according to the response model; 7), modifying the sealing structure according to a solution result to acquire a structural optimization design result. The optimization design method has the advantages that a structural optimization design philosophy and a finite element analysis method are adopted, and accordingly, optimal design parameter combinations capable of meeting requirements of various working conditions can be achieved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

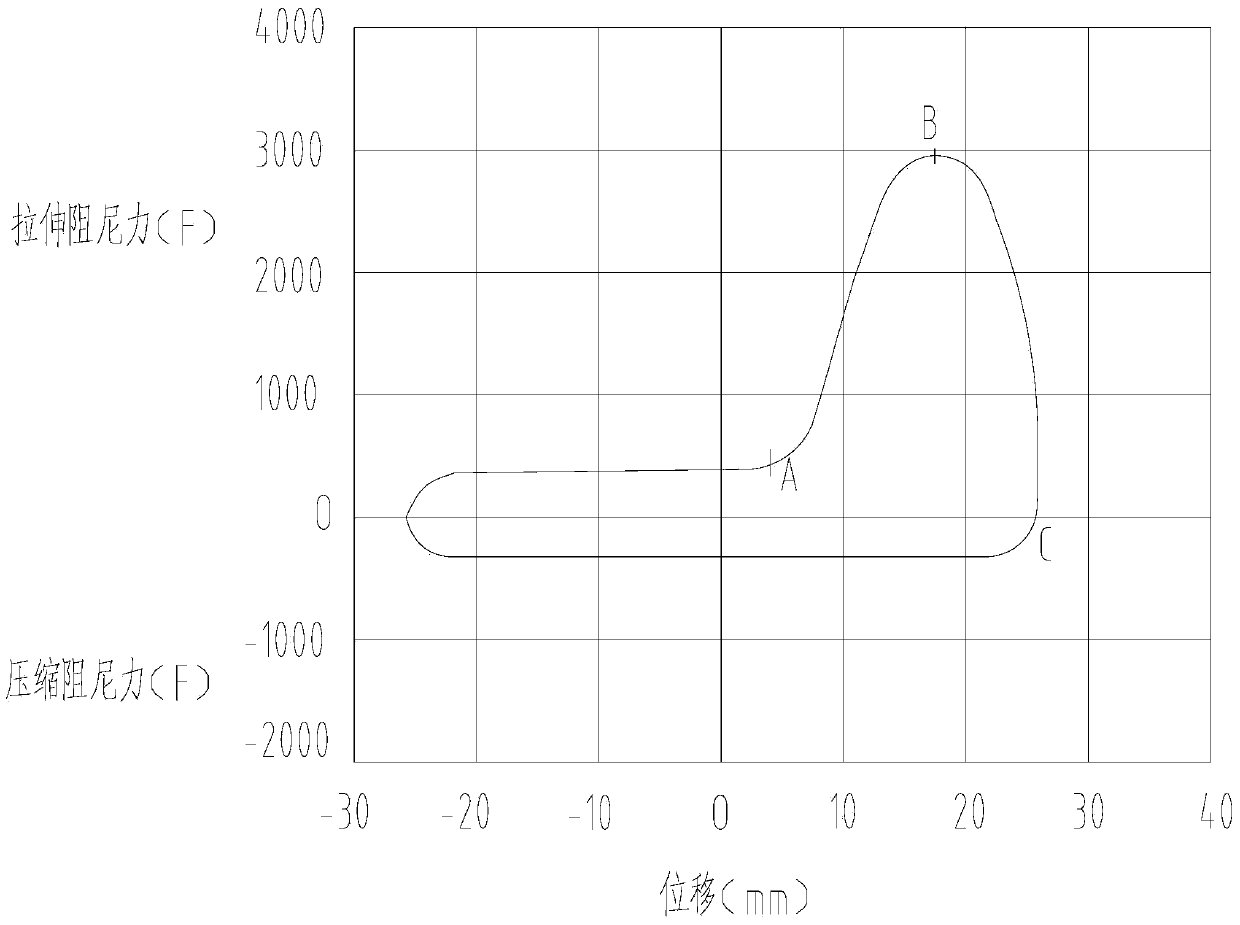

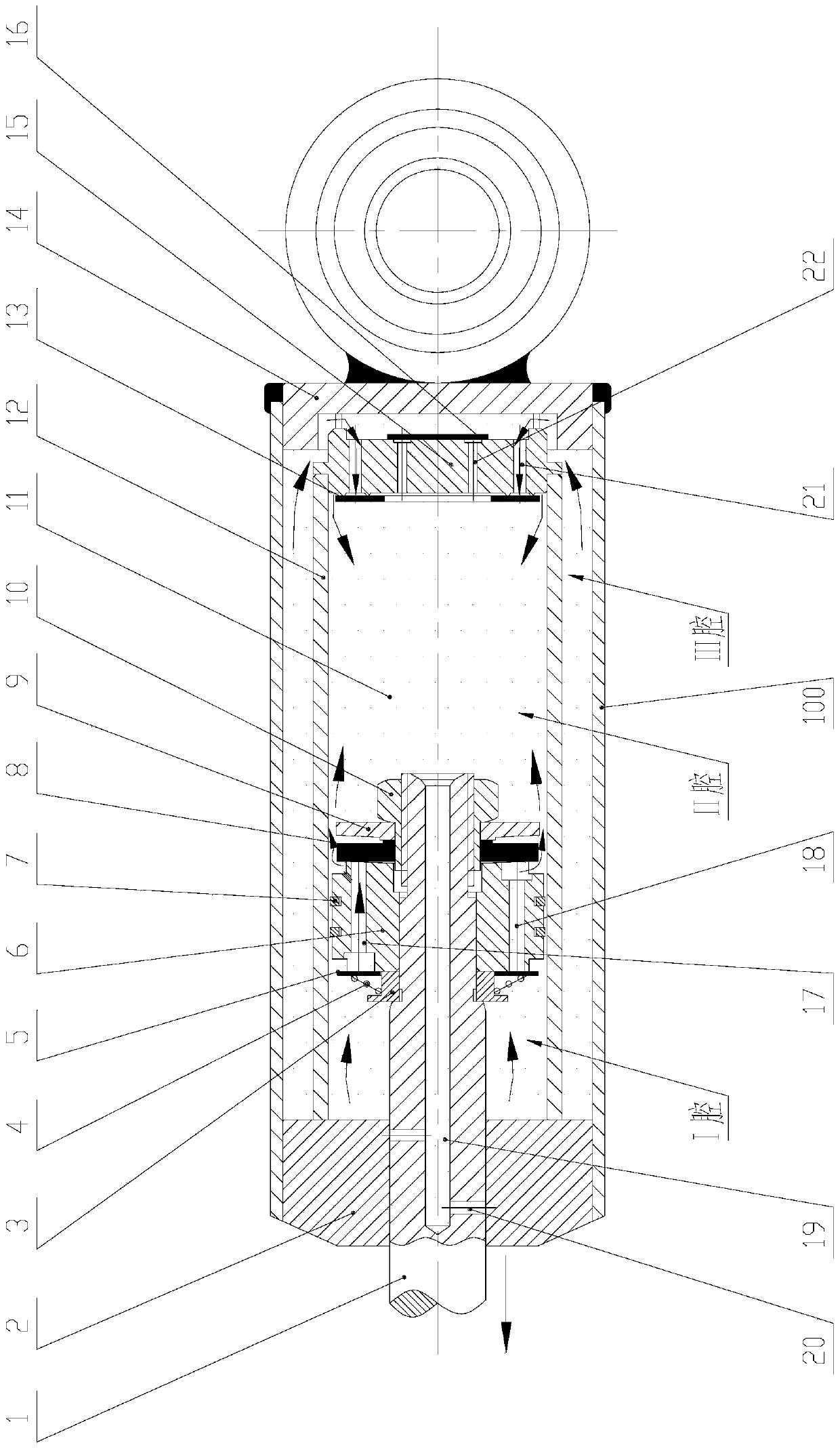

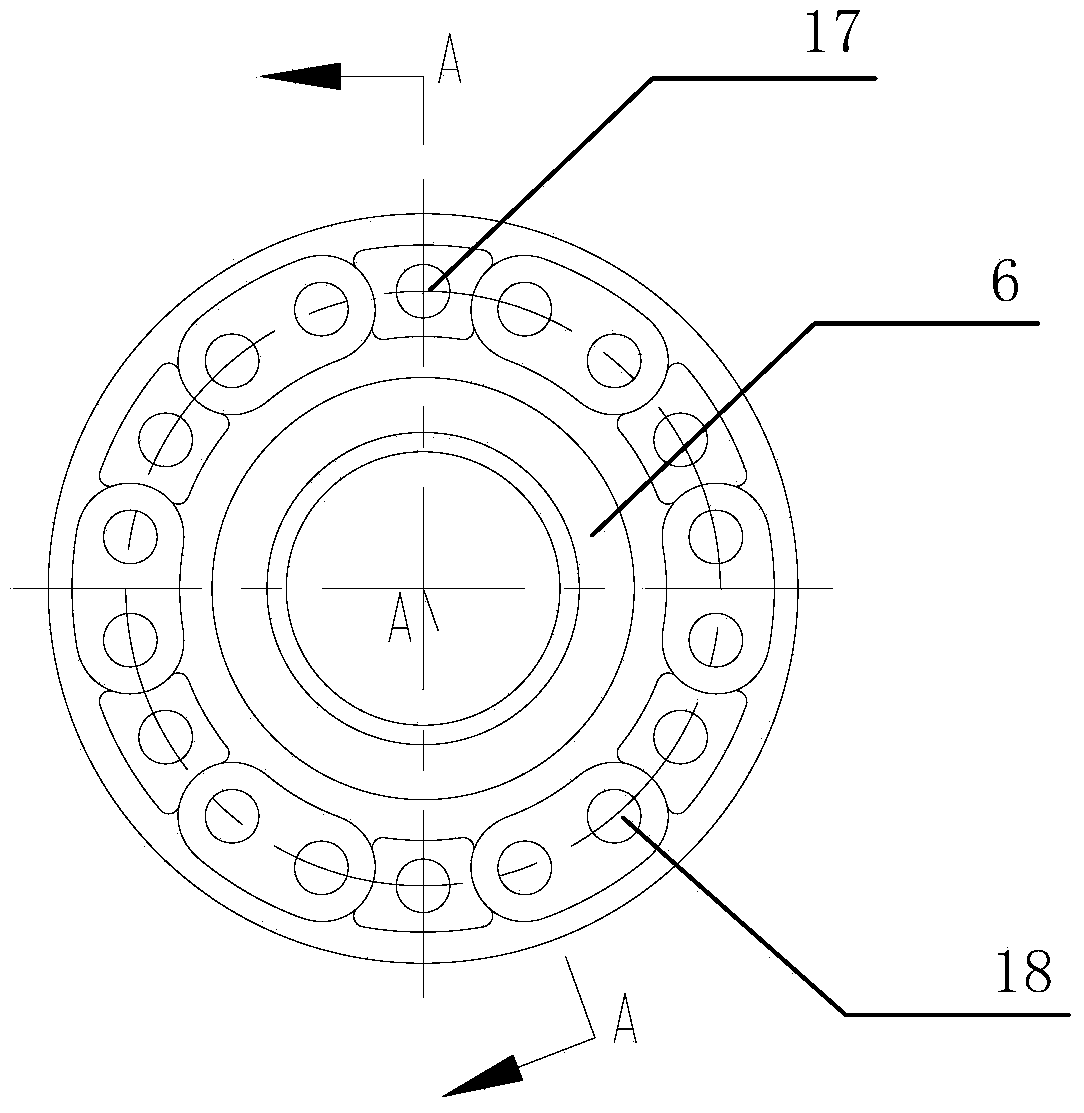

Pantograph damper damping throttling device

ActiveCN103438140AImprove flow qualityMeet the requirements of working conditionsSpringsShock absorbersPantographEngineering

The invention discloses a pantograph damper damping throttling device. One end of an oil cylinder is sealed through a guide bearing. A center hole is formed in the guide bearing which provides supporting and guiding for a piston rod. The other end of the oil cylinder is sealed through a bottom valve seat. A piston, a spring base, springs, a compression valve plate, an stretchable spring valve plate and a stop plate are installed on the piston rod. The oil cylinder is divided into a first cavity and a second cavity through the piston. Stretchable throttling holes and compression throttling holes are formed in the piston, wherein the stretchable throttling holes and the compression throttling holes are oppositely arranged. The compression valve plate located at the position, close to the end face of one side of the first cavity of the oil cylinder, of the piston covers the compression throttling holes and is pressed through the springs, and the springs are fixed on the spring base. The stretchable spring valve plate located at the position, close to the end face of one side of the second cavity of the oil cylinder, of the piston covers the stretchable throttling holes and is pressed through the stop plate, and the stop plate is fixed on the piston rod through a locking nut. The pantograph damper damping throttling device can overcome the technical defect that in the prior art, when the piston rod is stretched to the final stroke, damping force can not be adjusted and controlled at will.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

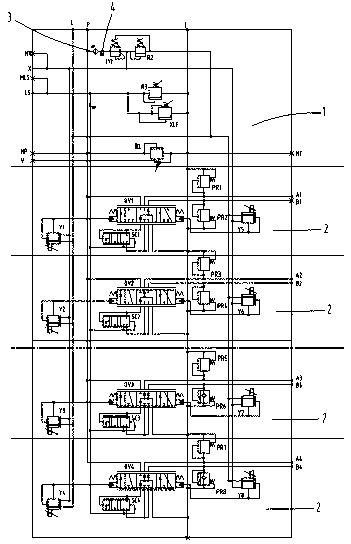

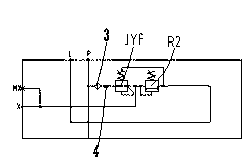

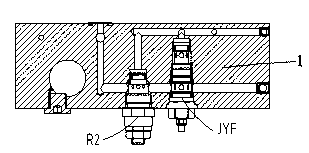

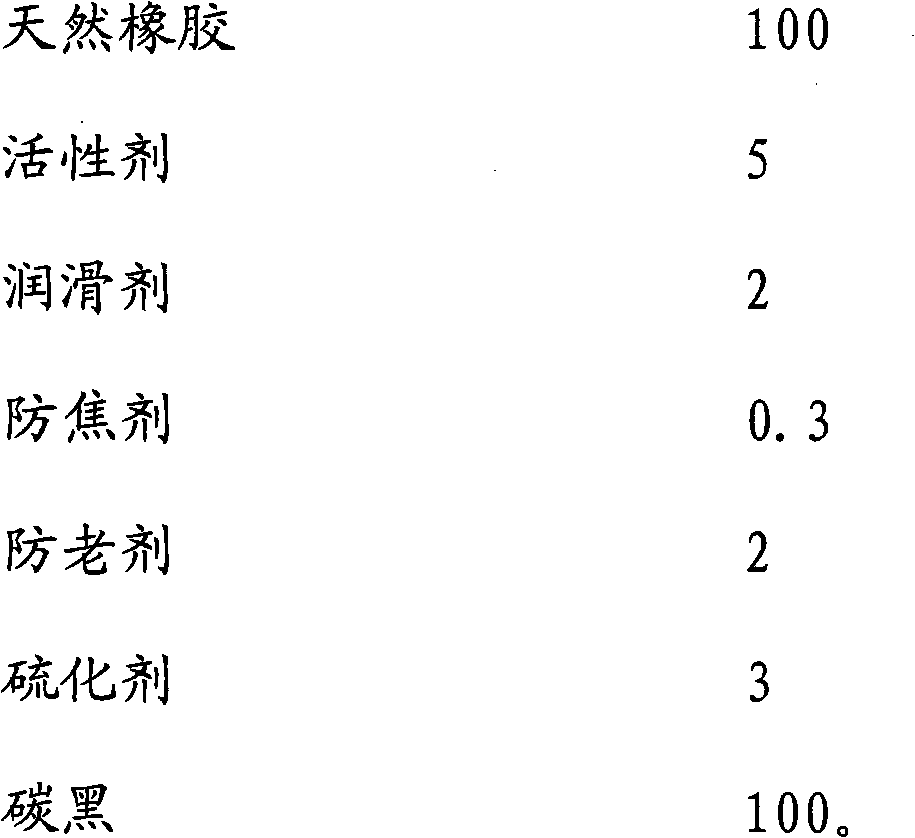

Integrated electro-hydraulic proportional hydraulic valve bank

ActiveCN102705287AConducive to piping and maintenanceSystem stabilityServomotor componentsElectro hydraulicSafety valve

The invention discloses an integrated electro-hydraulic proportional hydraulic valve bank, which includes an oil inlet pair and a unit basic pair that are matched in an adhering way, wherein the oil inlet pair is internally provided with a pilot-operated reducing valve and a first safety valve; the inlets of the pilot-operated reducing valve and the first safety valve are connected with a pressure oil passage; the outlet of the pilot-operated reducing valve is connected with a pilot oil passage, and the outlet of the first safety valve is connected with an oil return passage; the unit basic pair is internally provided with unit proportional reversing valves, and unit electromagnetic proportional reducing valves are mounted at the two drive ends of each unit proportional reversing valve; the pressure opening of each unit proportional reversing valve is connected with the pilot oil passage; the proportional speed regulation superimposition and multiple actuating mechanisms are adopted, and the proportional flowrate distribution during the linkage operation is free from the influences of the external load variation and the maximum pump output; the pressure stabilizing oil source arranged on the oil inlet pair provides a pilot oil source for the system; and by adopting the electromagnetic proportional reducing valve on the two sides of the basic pair to control the pushing of the valve rod, the electric signals are converted into hydraulic force, and the repeatability precision is high.

Owner:卢宇

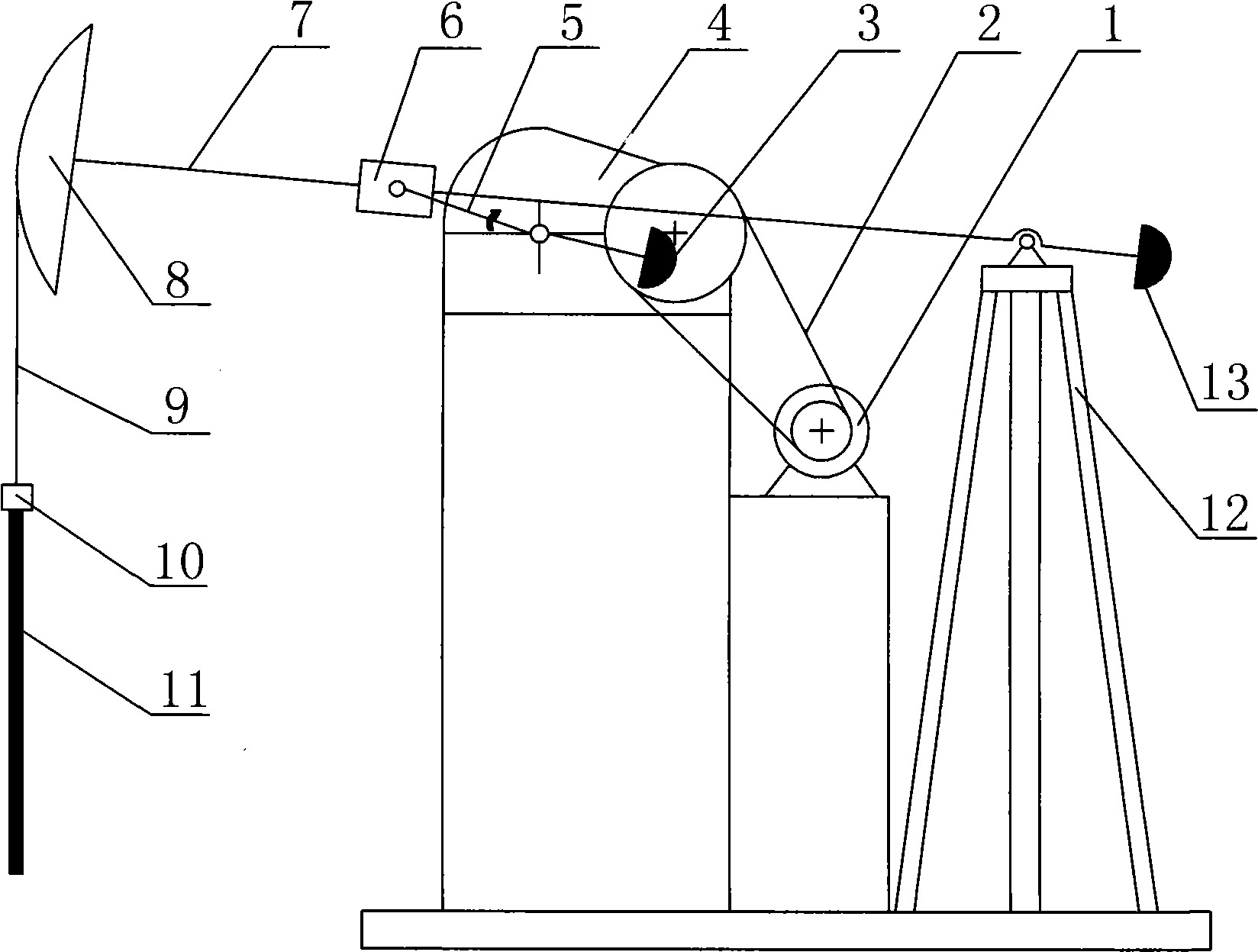

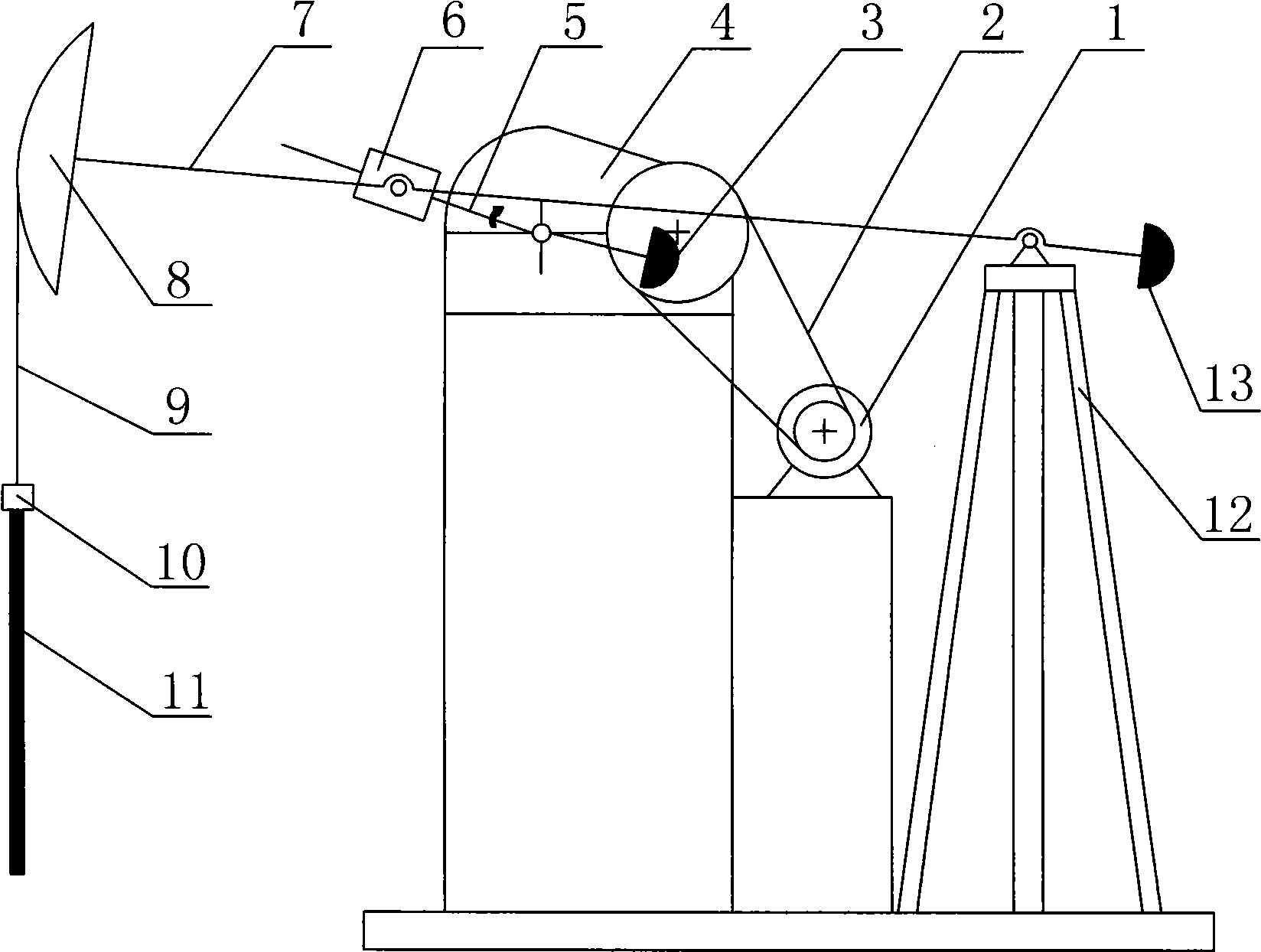

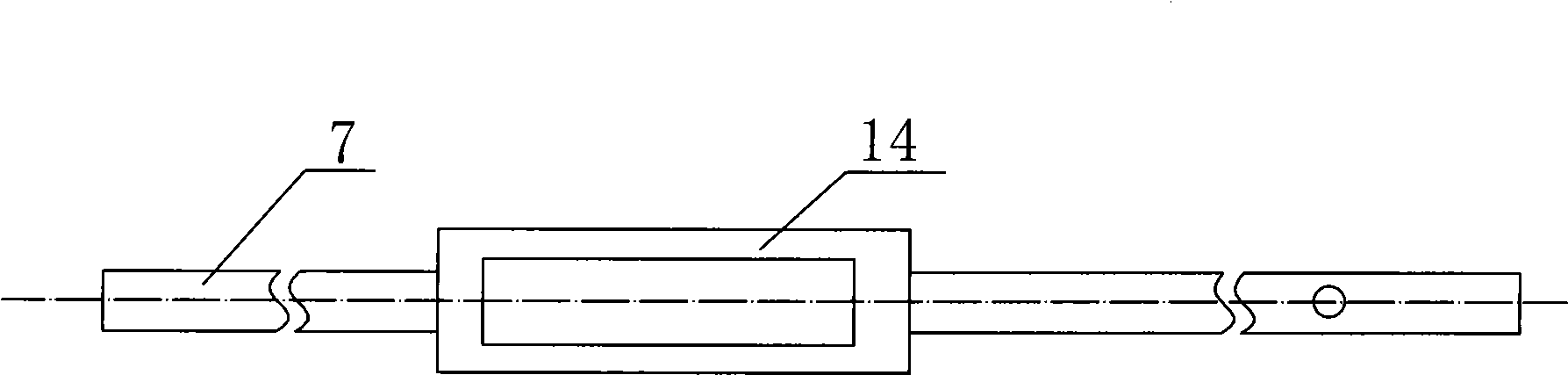

Pendulum guide rod type pumping unit

InactiveCN101509364AMeet the requirements of working conditionsImprove balanceFluid removalReduction driveReducer

The invention discloses an oscillating guide bar type oil extractor, comprising a stander, an electric motor, a belt gear, a speed reducer and a crank shaft installed on a reducer output shaft; wherein, an oscillating bar is movably installed on the stander; a horsehead is installed at the front end of the oscillating bar; the lower end of the horsehead is connected with a rope-bar connector; a sucker rod is installed on the rope-bar connector; a slide block is installed on the crank shaft and a guide rail used for the slide block to slide is installed on the oscillating bar; or the slide block is installed on the oscillating bar and the guide rail used for the slide block to slide is installed on the crank shaft; the crank shaft slides on the guide rail by virtue of the slide block and drives the oscillating bar to oscillate up and down with the stander as the fulcrum; the oscillating bar drives the sucker rod to reciprocate up and down by the horsehead, a wire cable and the rope bar. The oil extractor is compact in structure, safe and reliable in working, good in balance and evident in energy-saving effect.

Owner:XI'AN PETROLEUM UNIVERSITY

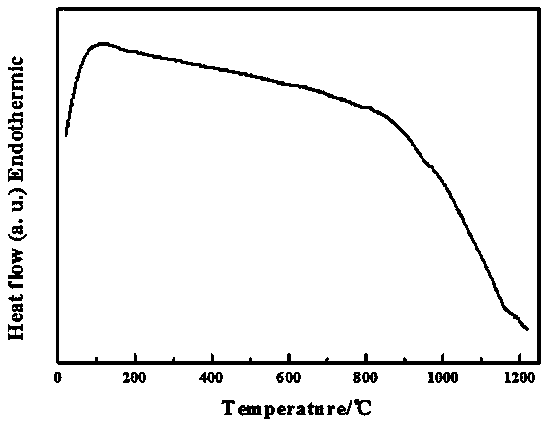

Safe nuclear reactor shell high-entropy alloy material and preparation method thereof

ActiveCN109930052AHigh melting pointMeet the needs of useNuclear energy generationContainmentElemental compositionHigh entropy alloys

The invention discloses a safe nuclear reactor shell high-entropy alloy material and a preparation method thereof. The high-entropy alloy material consists of five elements of Al, Cr, Fe, Mo and Nb, wherein the atomic percentage of the element aluminum is 4%-8%, the atomic percentage of the element chromium is 8%-13%, the atomic percentage of the element iron is 25%-30%, the atomic percentage of the element molybdenum is 20%-35%, and the atomic percentage of the element niobium is 25%-30%. According to the high-entropy alloy material and the preparation method thereof, a mother alloy button ingot is obtained in a vacuum arc smelting mode; the alloy has a relatively high melting point, and can be used in a high-temperature environment; and due to the fact that no zirconium element is used in the experiment, explosive hydrogen cannot be generated under the extreme high-temperature condition, so that the use safety is greatly improved.

Owner:KUNMING UNIV OF SCI & TECH

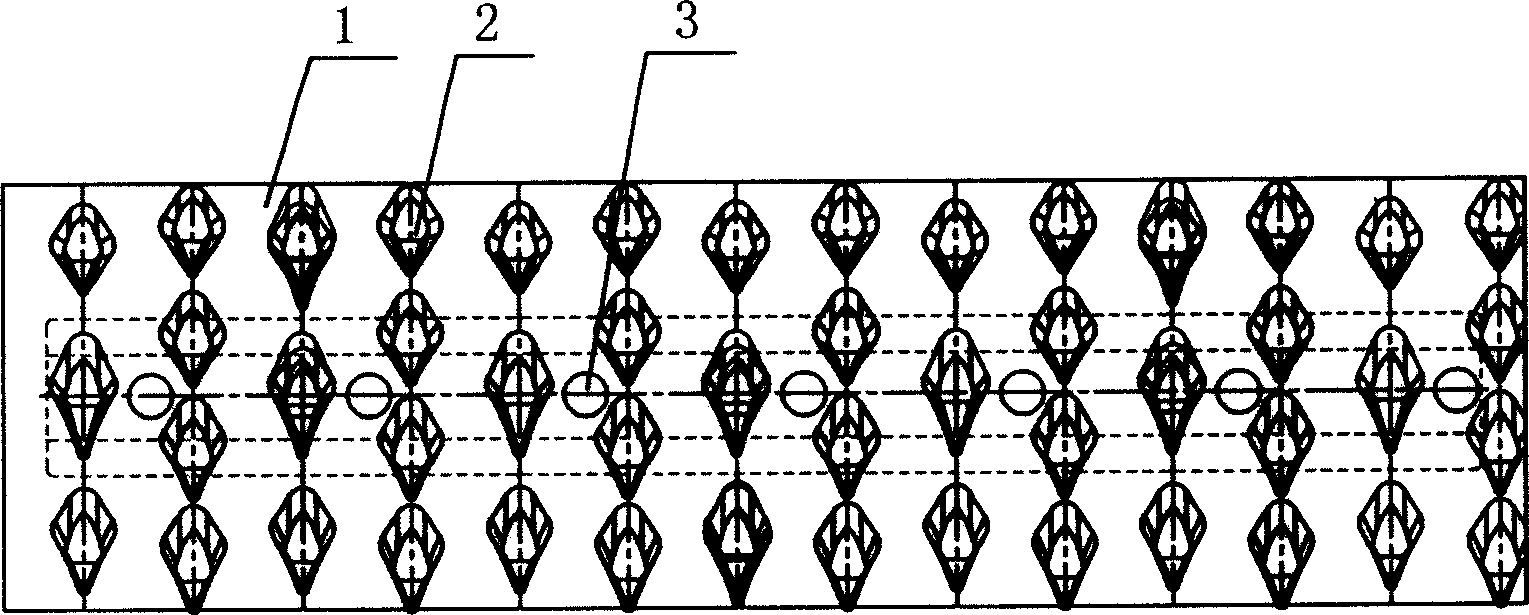

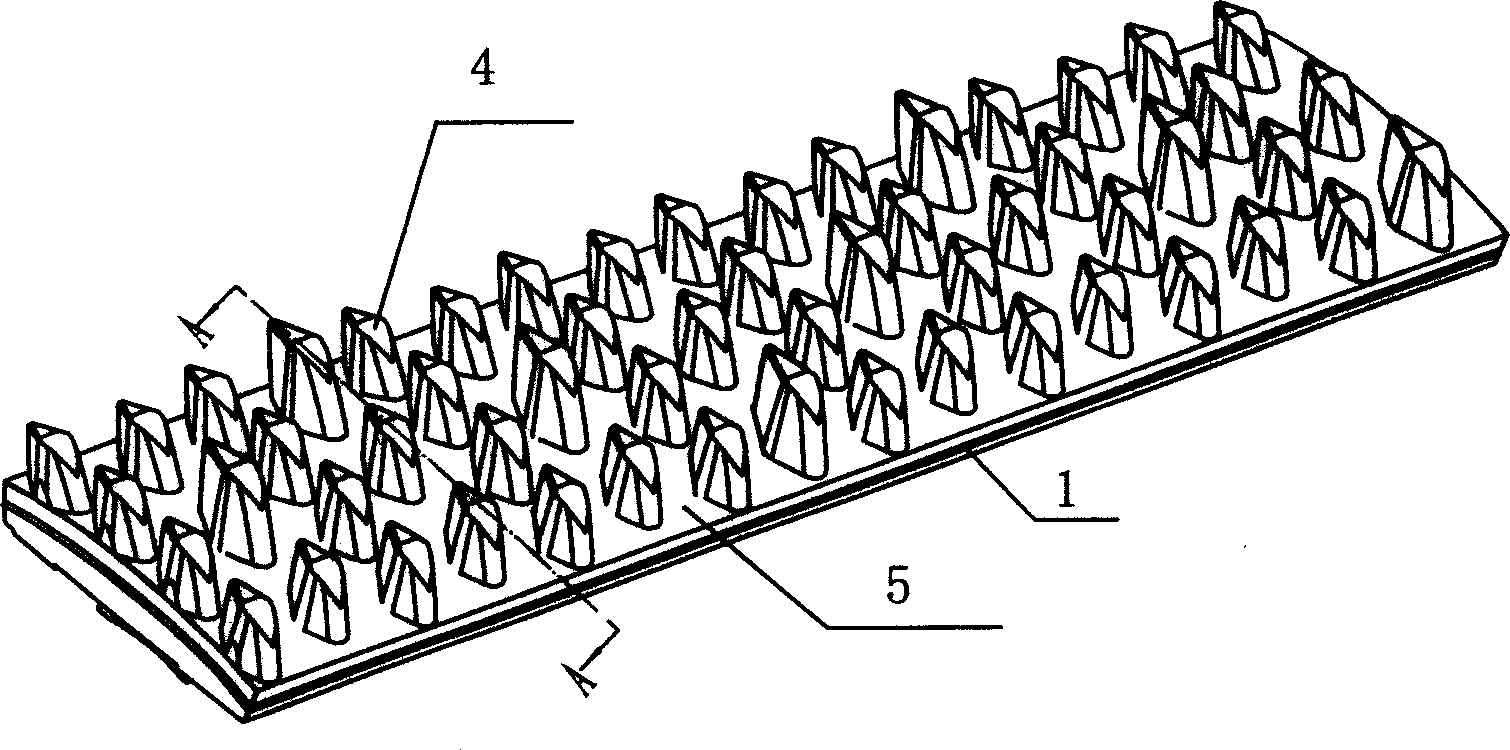

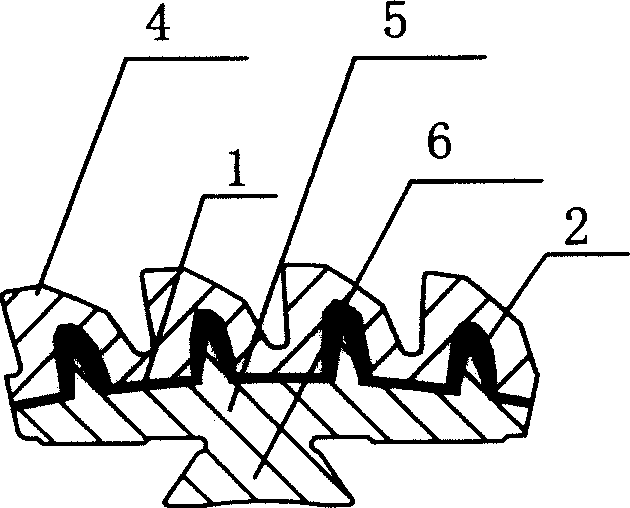

Method for pouring crusher composite tooth plate and composite tooth plate

The present invention discloses casting process and structure of composite toothed plate for crusher. The present invention has altered casting partition structure and thus altered distribution of high-chromium alloy cast iron layer and carbon steel in the work surface, raised inherent tooth toughness, increased coupling force of two kinds of alloy and obtained composite toothed plate with work surface of high-chromium alloy cast iron layer and processing surface of carbon steel layer. The composite toothed plate has dove tail tenon, lower part of the arced plate and inner layer of the teeth made of carbon steel, and upper part of the arced plate and the outer layer of the teeth made of alloy cast iron layer, and is suitable for production.

Owner:四川皇龙智能破碎技术股份有限公司

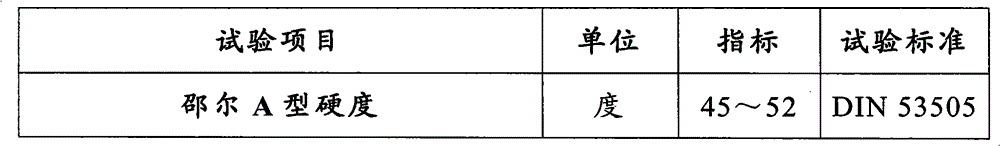

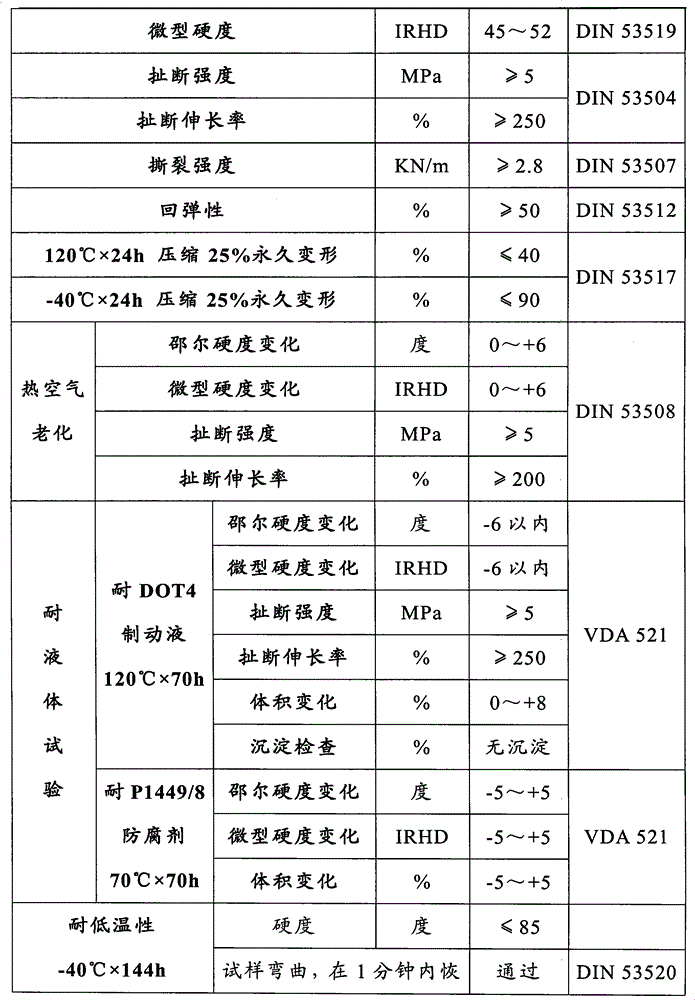

Piston dust shield material for automobile braking system and preparation method thereof

The invention discloses a piston dust shield material for an automobile braking system and a preparation method thereof. The material comprises the following raw materials in parts by weight: 50-180 parts of silicon rubber, 0.5-2 parts of vulcanizing agent, 0.1-0.4 part of pigment A and 0.4-1.5 parts of pigment B. The preparation method comprises the following steps: soaking a frame into an adhesive, forming raw materials, preheating the frame, and carrying out two-time sectional vulcanization. The piston dust shield material disclosed by the invention has the advantages of excellent high / low temperature resistance, favorable ductility, tear resistance, low compressive deformation and resistance to various greases, conforms to the requirements for working conditions of automobile braking air valves, and can be completely used instead of imported parts.

Owner:DATWYLER SEALING TECH ANHUI

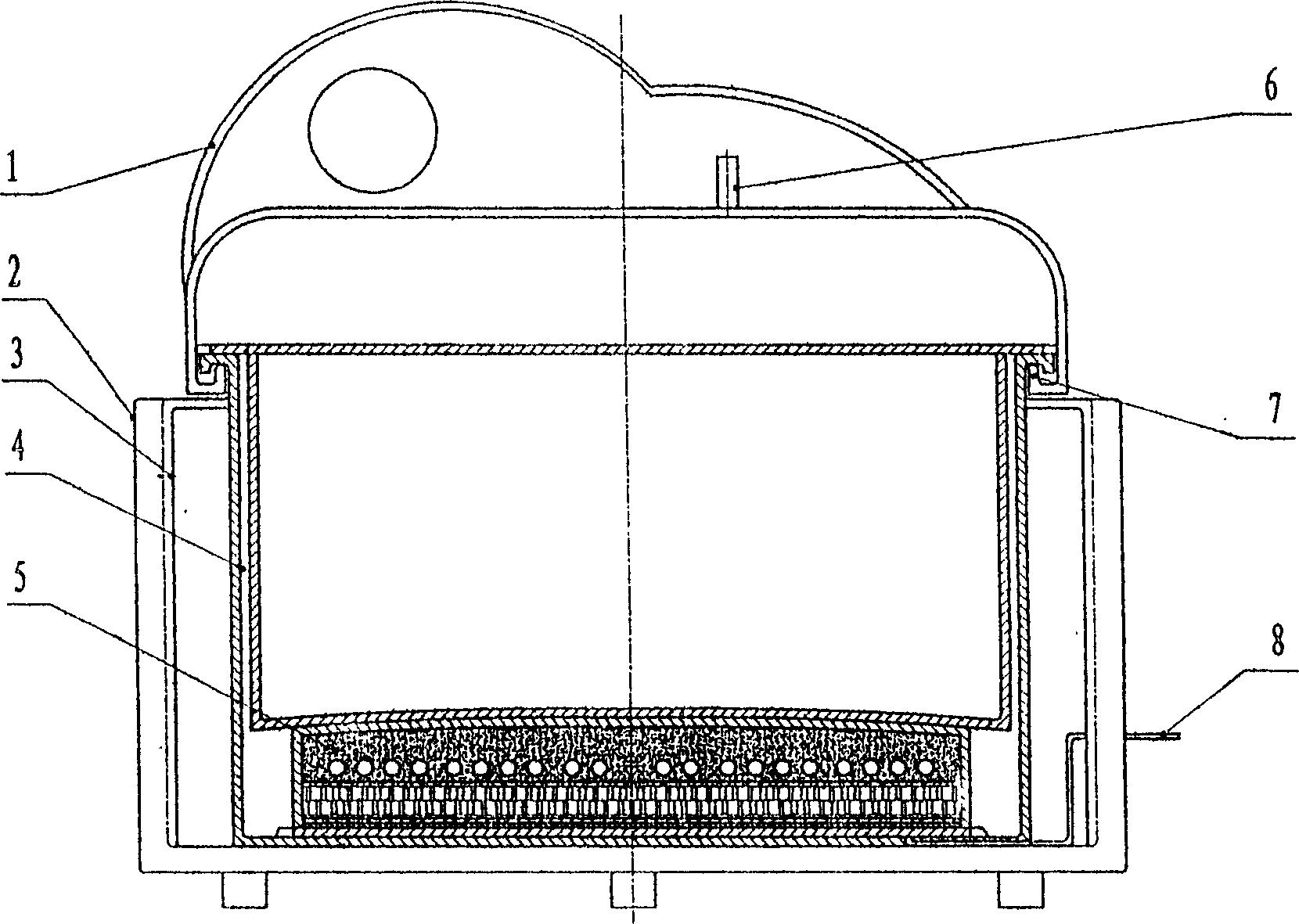

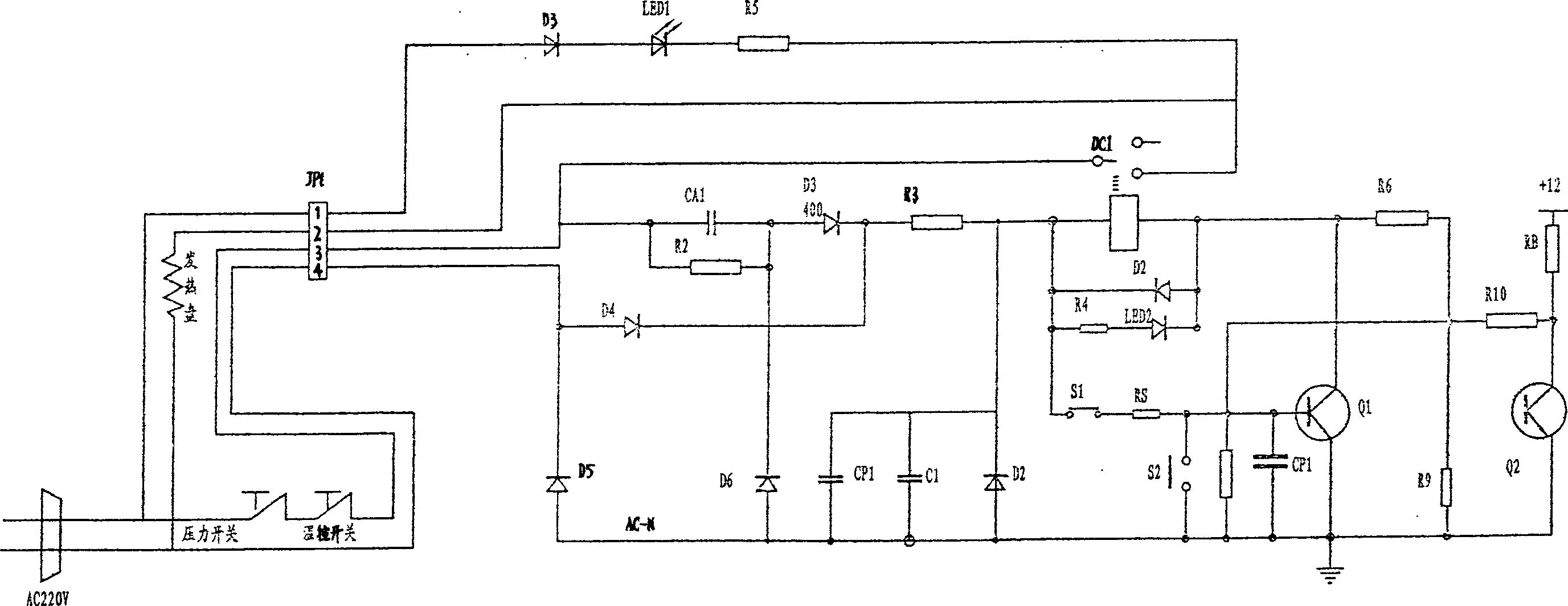

Heat-storing constant-pressure electric pressure cooker

The heat-accumulating constant pressure type electric pressure cooker consists of mainly cover, outer casing, outer pot, inner pot, heating and energy accumulating tray, pressure release valve, cover locking mechanism, control circuit system and other parts. The heating and energy accumulating tray consists of casing, heating layer with heating resistor wire and heat accumulating insulation layer, and is installed via one installation board to the bottom of the cooker. The electric pressure cooker has simple on-off type control circuit system, outer pot with rigid bottom, and temperature inducing controlled pressure switch. The electric pressure cooker has simple structure, low cost, high reliability, high safety, low power consumption, environment friendship and other advantages. With constant pressure, the electric pressure cooker has its cooked food possessing good taste.

Owner:何顺文

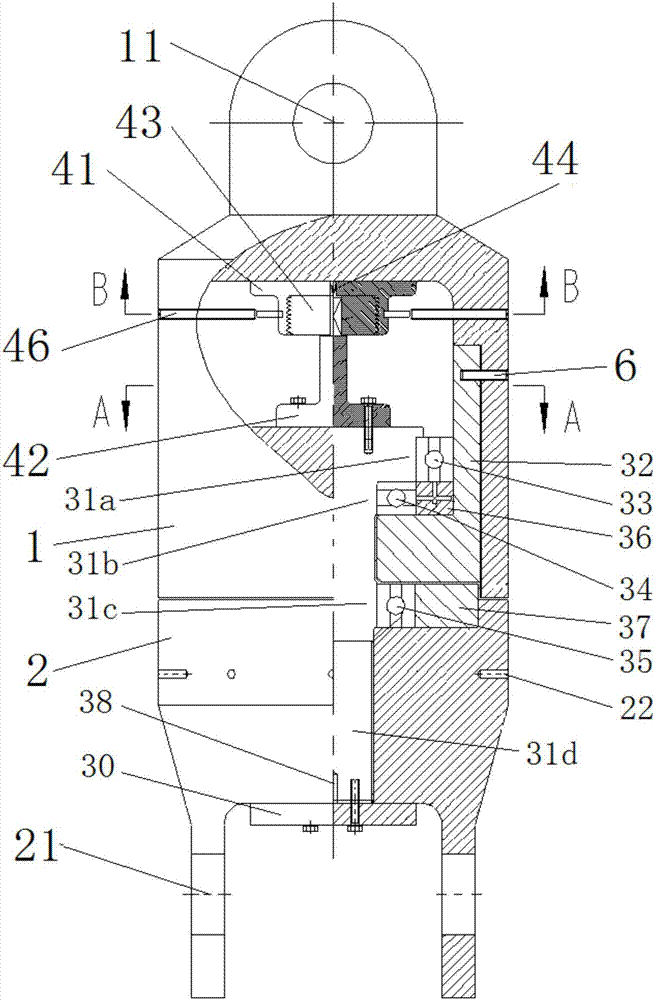

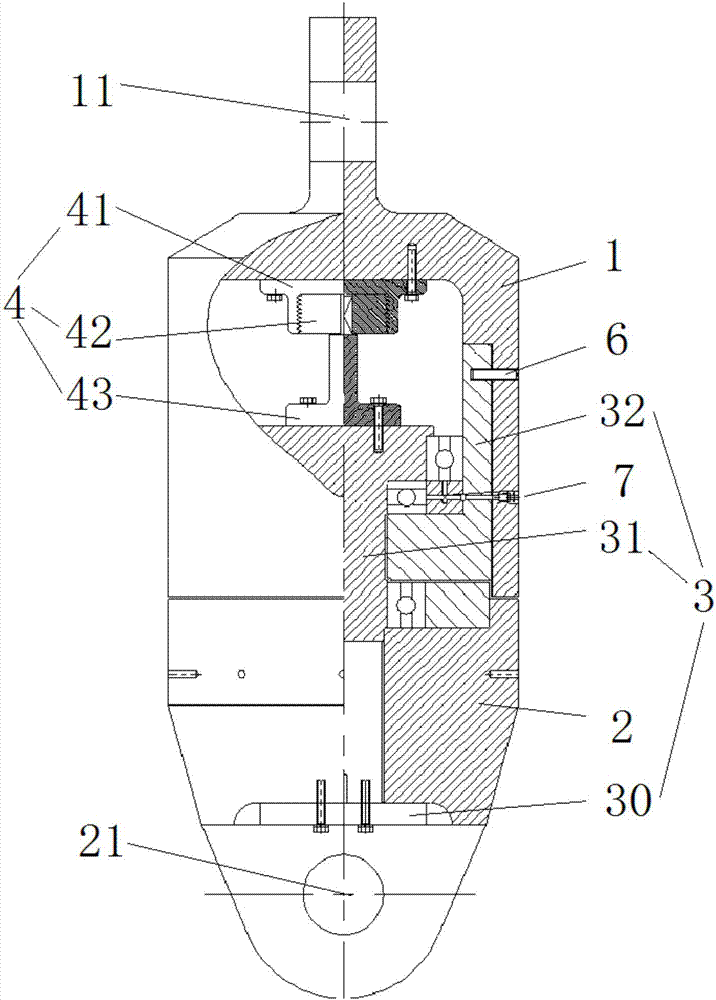

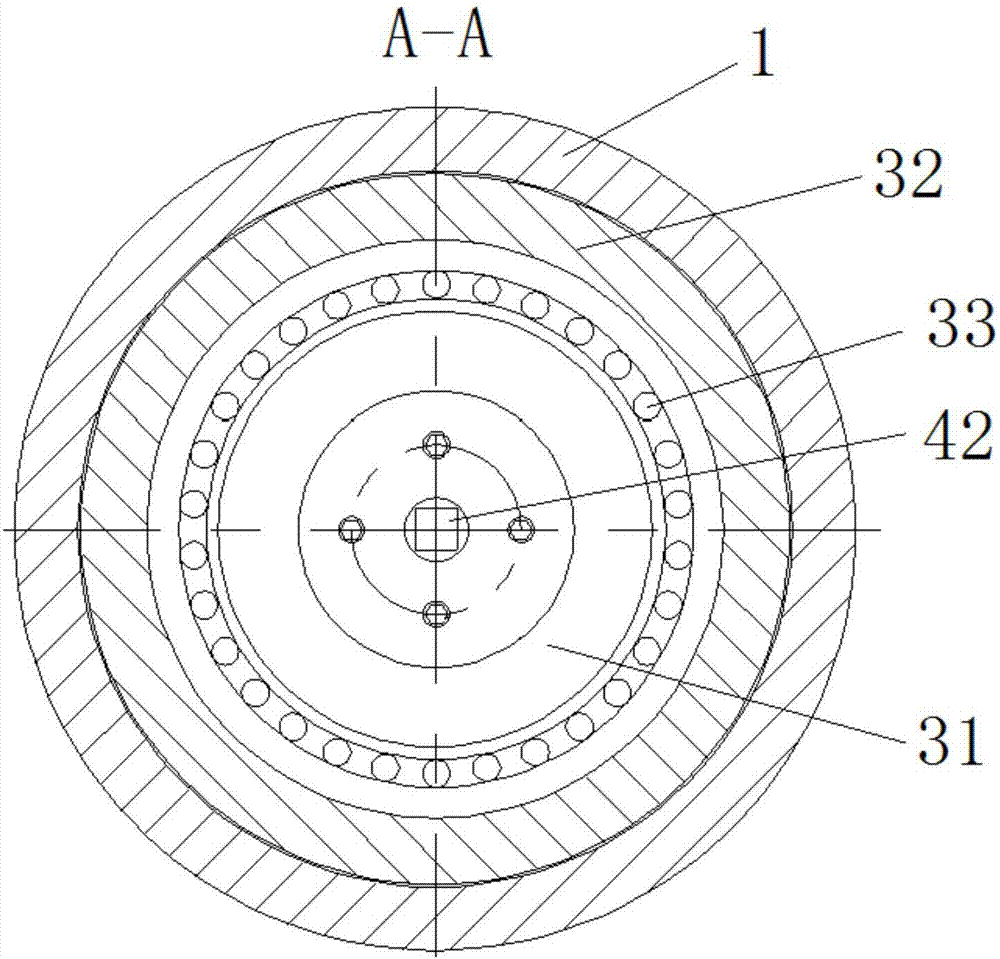

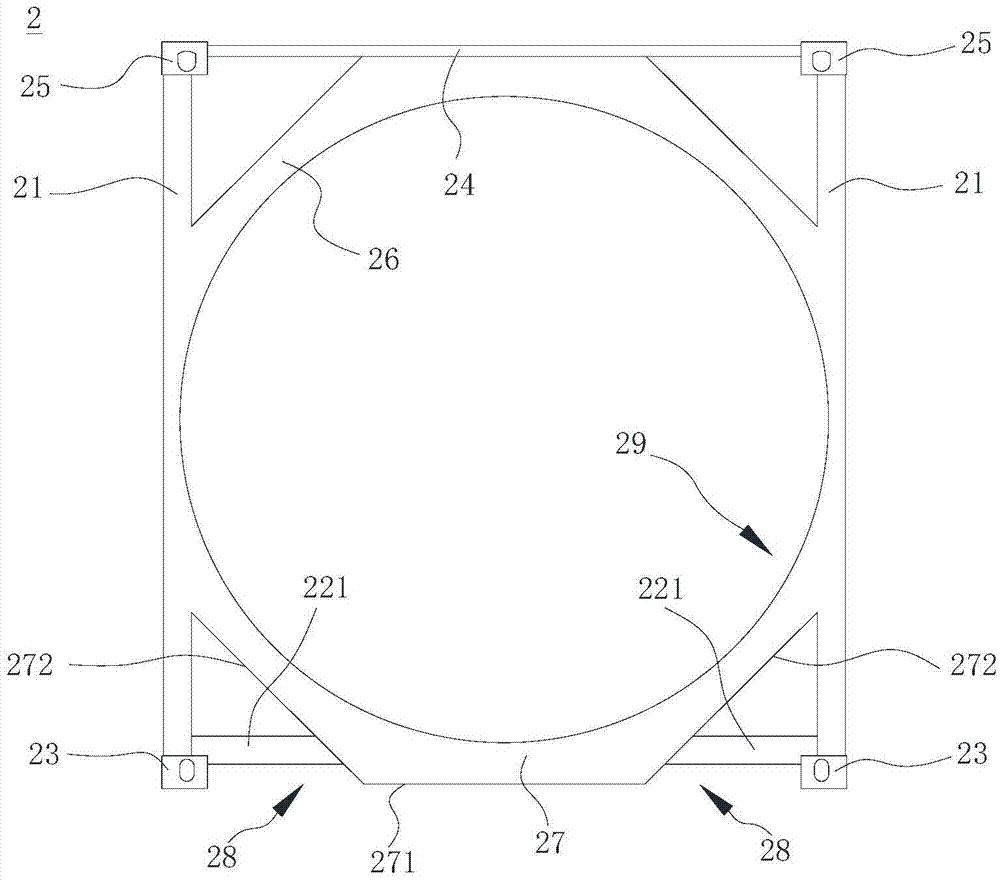

Damping-variable steel wire rope torsional force release device

ActiveCN107226414AIncrease frictionReduce frictionShock absorbersLoad-engaging elementsEngineeringWire rope

The invention discloses a damping-variable steel wire rope torsional force release device. The damping-variable steel wire rope torsional force release device comprises an upper cavity housing, a lower cavity housing, an upper cavity and lower cavity connecting assembly and a damping adjusting mechanism, wherein the upper cavity housing and the lower cavity housing are cylindrical, arranged oppositely up and down, connected with each other through the upper cavity and lower cavity connecting assembly, and used for being connected with ends of a steel wire rope; and the damping adjusting mechanism is installed in the upper cavity housing and located between the upper cavity and lower cavity connecting assembly and the upper cavity housing, and used for adjusting the rotation speed when the torsional force of the steel wire rope is released. The damping-variable steel wire rope torsional force release device can be directly installed on the steel wire rope, and can release the torsional action force generated by the rope in the operation process stably in time, the operation is simple, easy to implement and reliable, the defect that the torsional action force of the rope cannot be released or is released too fast in the working process to cause reverse breaking is overcome, the problem of the poor working condition of the rope is solved, the service life of the rope is prolonged, and the using safety of the rope is improved.

Owner:QINGDAO HAIXI HEAVY DUTY MASCH CO LTD

Tank container and end frame thereof

The invention provides a tank container and an end frame thereof. The end frame comprises two columns, a lower saddle seat, base corner members arranged at bottoms of the two columns and top corner members arranged at top ends of the two columns; the top surfaces of the top corner members are provided with hoisting holes; the bottom surfaces of the base corner members are provided with bolt fixing holes; the lower saddle seat is positioned between the two columns and two ends of the lower saddle seat are fixed to or integrated at the middle zone or lower position of the two columns; the lower saddle seat is provided with a recessed arc supporting surface which is used for supporting the bottom wall of the tank; supporting members are connected to the two columns and / or one side facing the lower saddle seat and the lower saddle seat. The tank container end frame solves the problem of effective connection between a tank and an end frame which cannot be connected through welding so that the tank container can bear the loads of use conditions such as transportation, hoisting and stacking and the function is guaranteed to realize.

Owner:NANTONG CIMC TANK EQUIP CO LTD

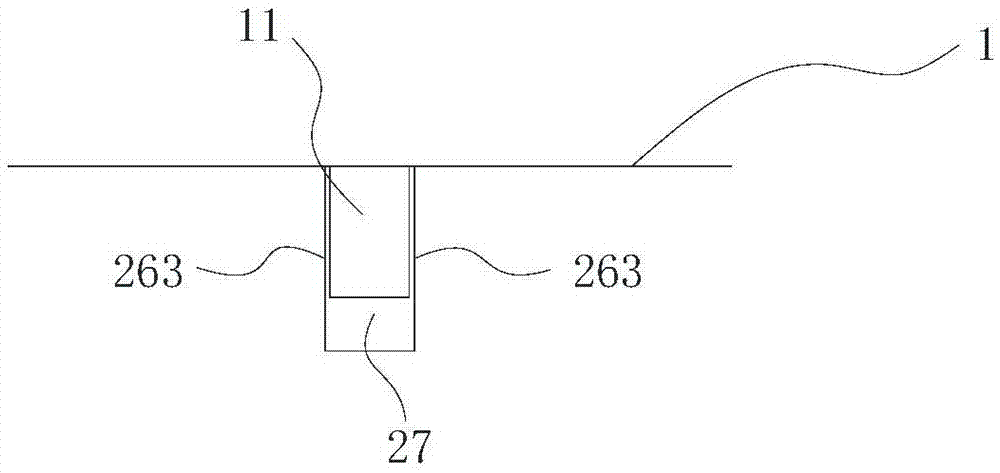

Combustor special for coal water slurry combustion type cracking furnace

ActiveCN102878554AEasy to switchMeet the requirements of working conditionsBurnersCoal waterAutomatic control

The invention relates to a combustor technology, and aims to provide a combustor special for a coal water slurry combustion type cracking furnace. A combustor main body is provided with a hollow pre-combustion chamber; a coal water slurry spray gun is arranged on the top of the pre-combustion chamber; a protecting sleeve, a gas jacket, a primary air pipe and a gas air sleeve are sequentially sleeved around the coal water supply spray gun; a secondary air pipe is connected to a plurality of secondary air outlets which are formed in the side surface of the top of the pre-combustion chamber; the secondary air outlets are uniformly distributed in a wall of the pre-combustion chamber at intervals; the same rotating included angles are formed between the secondary air outlets and the corresponding radial center lines; and an oil gun hole is also formed in the side surface of the top of the pre-combustion chamber, and an oil gun is inserted in the oil gun hole. The combustor can be powered by fuels such as coal water slurry, light diesel oil and hydrogen-methane / natural gas; the coal water slurry is mainly used and can replace the hydrogen-methane, and products with high additional values can be produced; and the combustor is switched over quickly and conveniently in a running process so as to meet requirements on various working conditions, labor can be saved by an automatic control system, and economical efficiency and operability are improved.

Owner:ZHEJIANG UNIV +1

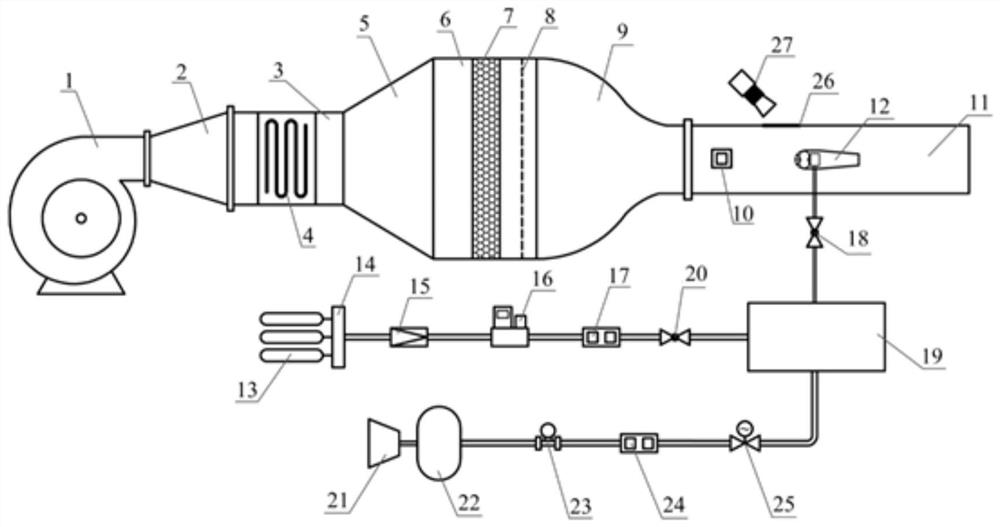

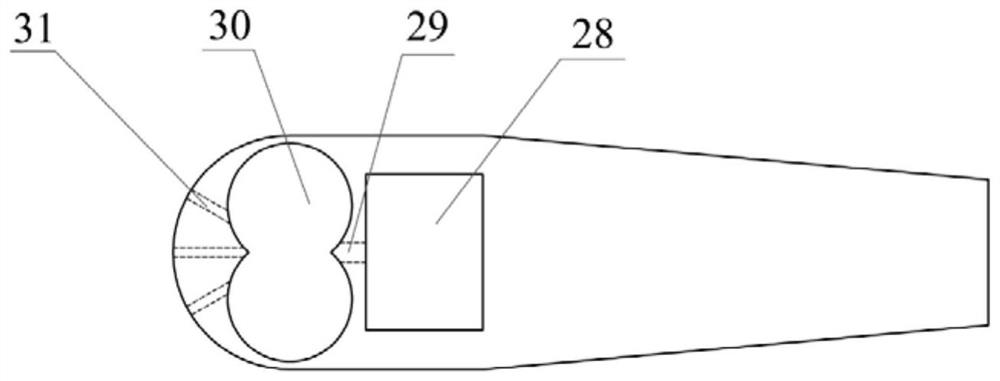

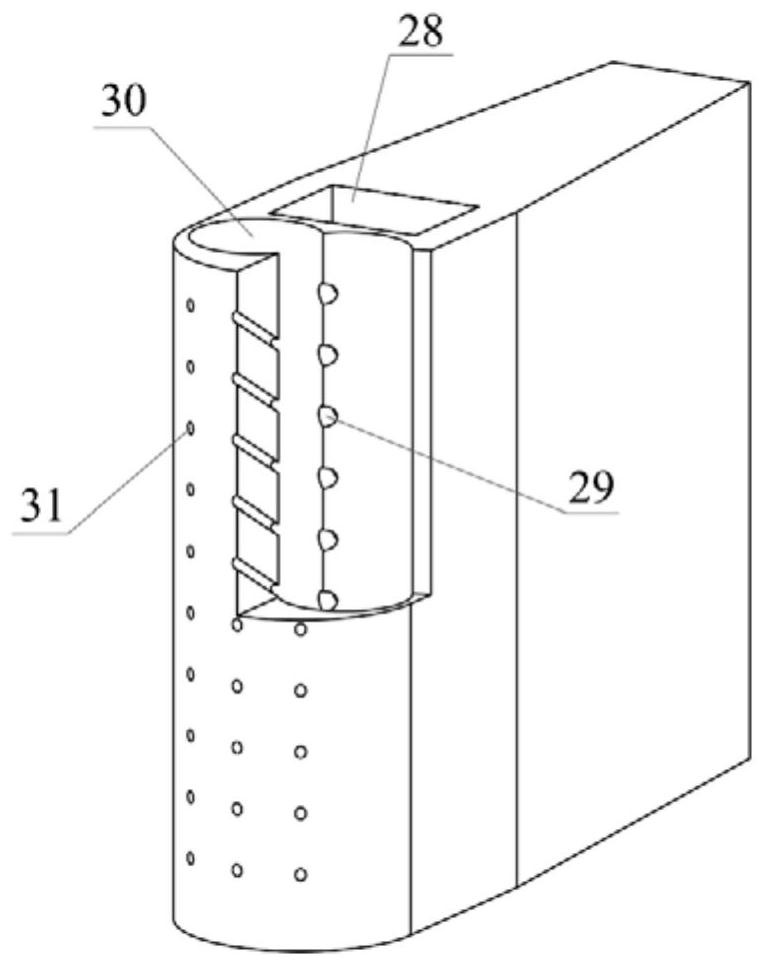

Blade leading edge double-rotational-flow impingement cooling experiment testing system and method

The invention discloses a blade leading edge double-rotational-flow impingement cooling experiment testing system and method. The system comprises a main flow channel, a blade leading edge experiment section, a secondary flow cooling system and an infrared thermal imaging system. Heated air is introduced into an inner cavity of the main flow channel, and an outlet of the main flow channel is connected with the blade leading edge experiment section; a blade leading edge double-rotational-flow impact experiment piece is placed in an inner cavity of the blade leading edge experiment section; the secondary flow cooling system comprises an air branch and a high-density gas branch, an outlet of the air branch and an outlet of the high-density gas branch are connected with a gas collection chamber, an outlet of the gas collection chamber extends into an inner cavity of the blade leading edge double-rotational-flow impact experiment piece, and a first ball valve is arranged on the outlet of the gas collection chamber; and the infrared thermal imaging system monitors the surface temperature field distribution of the blade leading edge double-rotational-flow impact experiment piece. The system is simple in structure, low in cost and convenient to build, and provides a reference basis for advanced cooling design of gas turbines in the future.

Owner:XI AN JIAOTONG UNIV

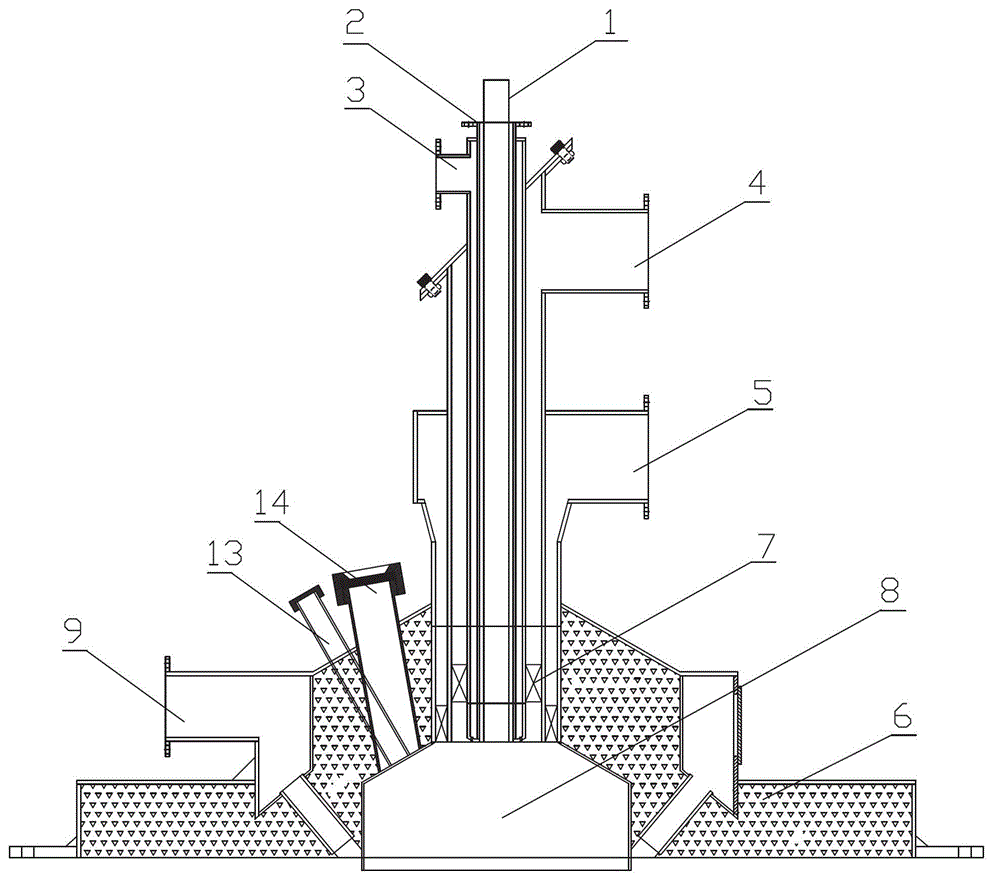

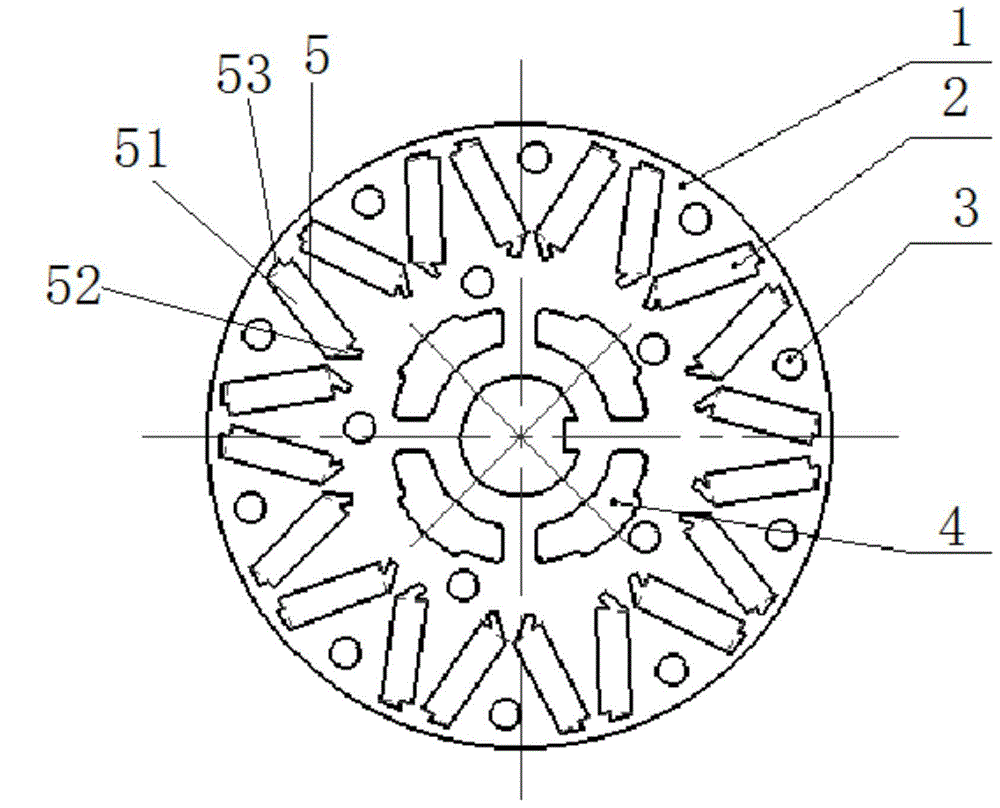

Low-power sine wave motor

InactiveCN105141054ALow demagnetization rateAvoid damageMagnetic circuit rotating partsStructural associationElectric machineryEngineering

The invention discloses a low-power sine wave motor, which comprises a housing and a hall circuit board, wherein a rotor (1) and a stator, which cooperatewith each other, are arranged in the housing; a counterweight groove and a magnetic steel caulking groove (5) are sequentially formed in the rotor (1) from inside to outside; the counterweight groove and the magnetic steel caulking groove (5) are formed along the circumferential direction of the rotor (1); a counterweight block (4) is arranged in the counterweight groove; magnetic steel (3) is embedded into the magnetic steel caulking groove (5); a rotating shaft through hole is formed in the hall circuit board; the hall circuit board is arranged on the inner surface of the housing; and meanwhile, a rotating shaft of the rotor (1) passes through the rotating shaft through hole in the hall circuit board. The motor is good in operation, long in service life, low in noise and high in torque.

Owner:XUZHOU NANPU ELECTRICAL TECH

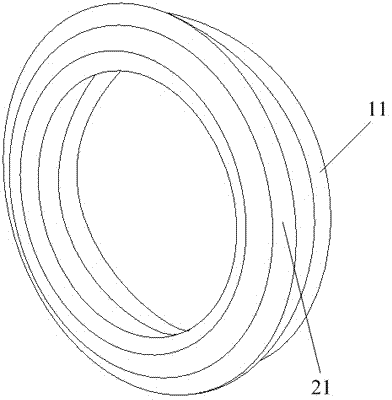

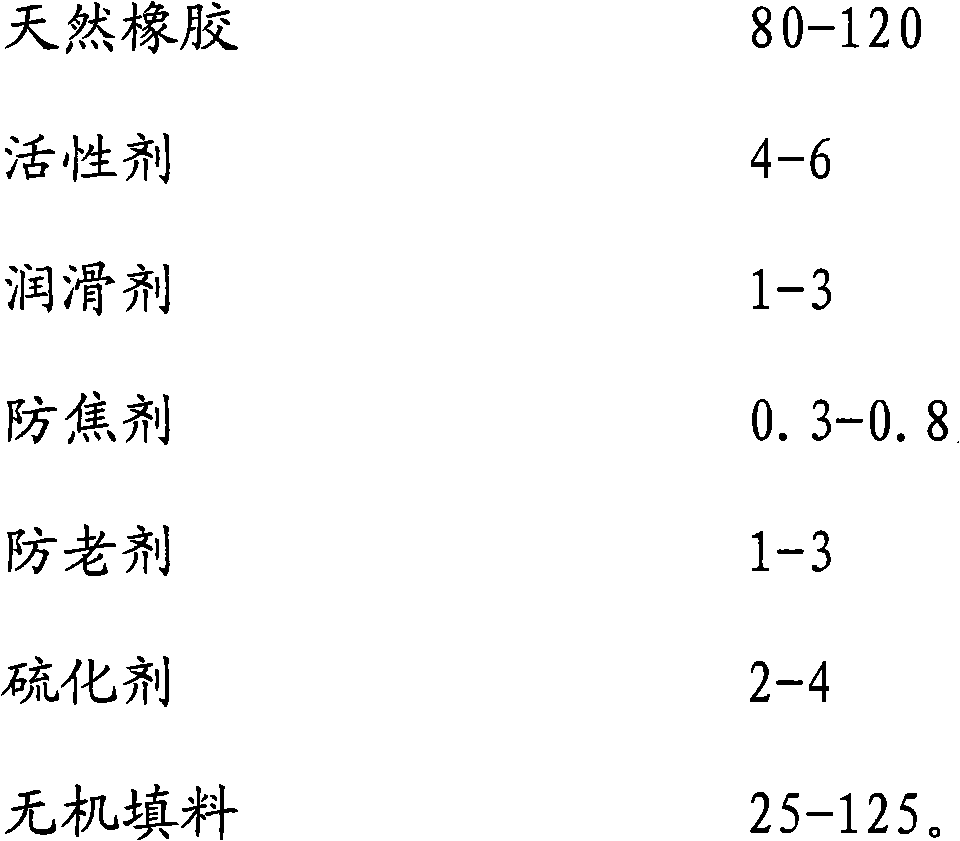

Oil inlet sealing ring material for vehicle brake master cylinder and process thereof for manufacturing sealing ring

The invention discloses an oil inlet sealing ring material for a vehicle brake master cylinder and a process thereof for manufacturing a sealing ring. The material is prepared from the following components in part by weight: 80 to 120 parts of ethylene propylene rubber, 4 to 6 parts of active agent, 1 to 3 parts of lubricant, 2 to 4 parts of acid-base balance agent, 1 to 3 parts of age resistor, 2 to 4 parts of sulfurizing agent and 25 to 35 parts of inorganic filler; then the components are subjected to the processes, namely mixing and molding, primary sulfurizing, punching and edge removingand secondary sulfurizing to obtain the oil inlet sealing ring material product with high strength, low compression deformation, tear resistance, resistance to braking fluid corrosion, resistance to low and high temperatures and excellent performance for the vehicle brake master cylinder; and the production efficiency and the product percent of pass are high, and the product can completely substitute similar imported products.

Owner:DATWYLER SEALING TECH ANHUI

Tunable Integrated High Voltage Gate Pulse Modulator

ActiveCN103929847BMeet the requirements of working conditionsPerfect protection circuitElectric light circuit arrangementPower conversion systemsLow voltageFeedback circuits

The invention relates to an adjustable integrated high-voltage grid electrode pulse modulator. An improved design is conducted on a filament high potential power supply circuit, a positive biased high potential power supply circuit, a negative biased high potential power supply circuit and a grid electrode pulse modulator circuit, and the high dense integration of the three high potential power supply circuits and the grid electrode pulse modulator circuit is achieved; a feedback circuit of a high potential power supply is improved, a magnetism feedback high voltage isolation sampling technology is adopted, and respectively independent adjustment to the high potential power supply output voltage values is achieved at the low voltage side; a high potential integrated failure detecting circuit is added, and the high potential power supply multi-circuit failures are integrated into one circuit signal; a pulse driving circuit is improved, and a dual-level denoising circuit is added; a grid electrode floating plate modulating circuit is improved, and an fire-making resistance protection circuit protection modulator and a traveling wave tube are added; a high-voltage transformer structure used for the modulator is improved, the size is reduced, and high-voltage isolation is achieved.

Owner:CNGC INST NO 206 OF CHINA ARMS IND GRP

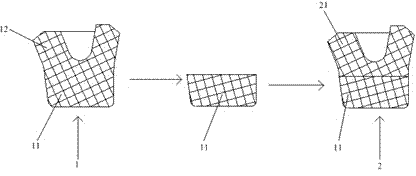

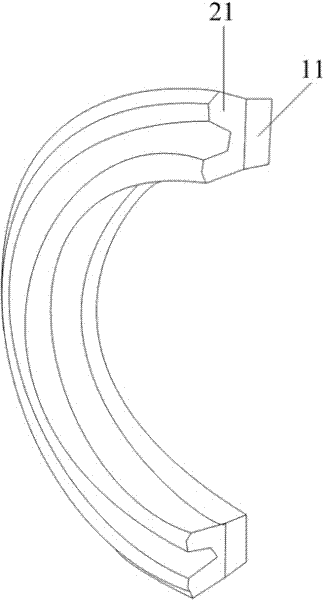

Piston sealing piece manufacturing process and piston sealing piece

InactiveCN102506170AMeet the requirements of strong extrusion resistanceMeet low friction requirementsPiston ringsEngineeringMechanical engineering

The invention discloses a piston sealing piece manufacturing process, which comprises the following steps of: 1) performing injection molding on a hard polyurethane material in a die to form a first sealing piece, wherein the first sealing piece comprises an annular body and a sealing part connected to the upper part of the annular body; 2) cutting off the sealing part of the first sealing piece formed in the step 1), and only retaining the annular body; and 3) putting the annular body into the die in the step 1), and performing injection molding on a soft polyurethane material in the die to form a second sealing piece, wherein the second sealing piece comprises the annular body formed by performing injection molding on the hard polyurethane material and a sealing part formed by performing injection molding on the soft polyurethane material, and thus obtaining the piston sealing piece. Compared with the prior art, the piston sealing piece manufacturing process has the advantages that: the annular body of the piston sealing piece is made of the hard polyurethane material, and the sealing part is made of the soft polyurethane material, so that the piston sealing piece has a simple structure, and can meet a low-friction requirement on the sealing part and a high anti-squeezing capacity requirement on the annular body and totally accord with the actual working condition requirement.

Owner:上海唯万密封科技股份有限公司

Rubber spring material for automobile braking double-cavity serial brake valve and preparation method thereof

InactiveCN102167850AMeet the requirements of working conditionsHigh strengthActive agentCarbon black

The invention discloses a rubber spring material for an automobile braking double-cavity serial brake valve and a preparation method thereof. The rubber spring material comprises the following raw materials in parts by weight: 80 to 120 parts of natural rubber, 4 to 6 parts of activating agent, 1 to 3 parts of lubricating agent, 0.3 to 0.8 part of antiscorching agent, 2 to 4 parts of vulcanizing agent and 75 to 125 parts of carbon black. The preparation method comprises the following steps of: performing hybrid forming on the raw materials; vulcanizing; removing edges through punching; and detecting. The prepared rubber spring material for the automobile braking double-cavity serial brake valve has the advantages of high strength, tear resistance, low compressive deformation, brake fluid resistance and superior aging resistance; qualification rate and production efficiency of a product can be guaranteed by using a vulcanization molding process; and a domestication process of high-end automobile parts is accelerated.

Owner:DATWYLER SEALING TECH ANHUI

Integrated electro-hydraulic proportional hydraulic valve bank

ActiveCN102705287BEasy maintenanceSmooth pipingServomotor componentsSuperimpositionElectro hydraulic

The invention discloses an integrated electro-hydraulic proportional hydraulic valve bank, which includes an oil inlet pair and a unit basic pair that are matched in an adhering way, wherein the oil inlet pair is internally provided with a pilot-operated reducing valve and a first safety valve; the inlets of the pilot-operated reducing valve and the first safety valve are connected with a pressure oil passage; the outlet of the pilot-operated reducing valve is connected with a pilot oil passage, and the outlet of the first safety valve is connected with an oil return passage; the unit basic pair is internally provided with unit proportional reversing valves, and unit electromagnetic proportional reducing valves are mounted at the two drive ends of each unit proportional reversing valve; the pressure opening of each unit proportional reversing valve is connected with the pilot oil passage; the proportional speed regulation superimposition and multiple actuating mechanisms are adopted, and the proportional flowrate distribution during the linkage operation is free from the influences of the external load variation and the maximum pump output; the pressure stabilizing oil source arranged on the oil inlet pair provides a pilot oil source for the system; and by adopting the electromagnetic proportional reducing valve on the two sides of the basic pair to control the pushing of the valve rod, the electric signals are converted into hydraulic force, and the repeatability precision is high.

Owner:卢宇

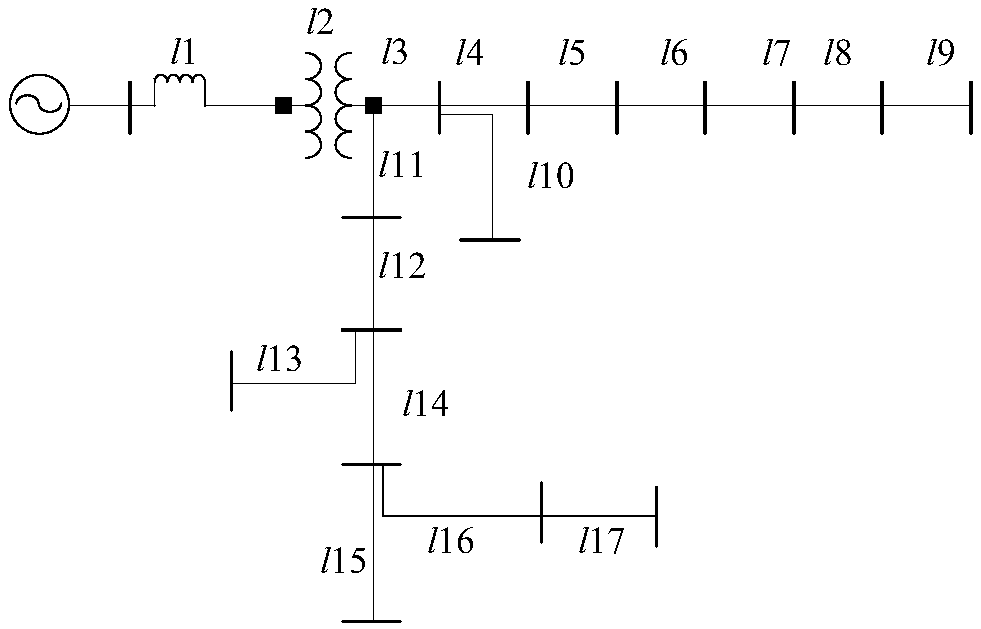

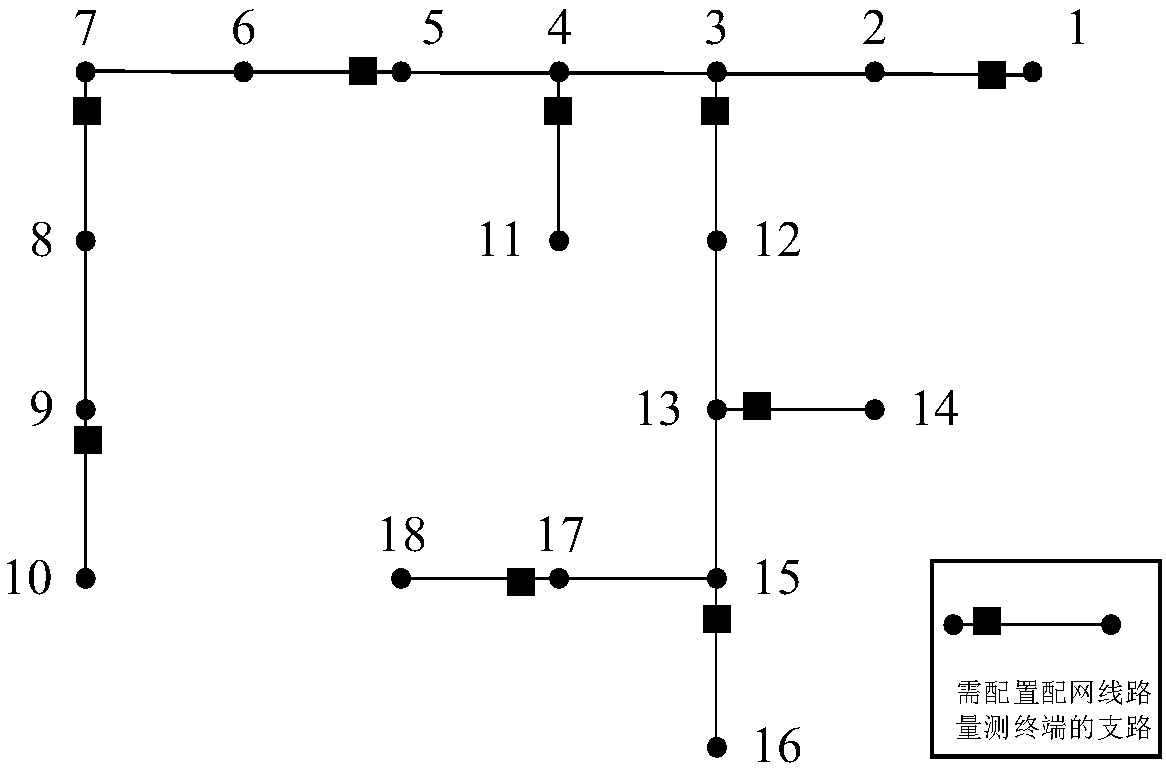

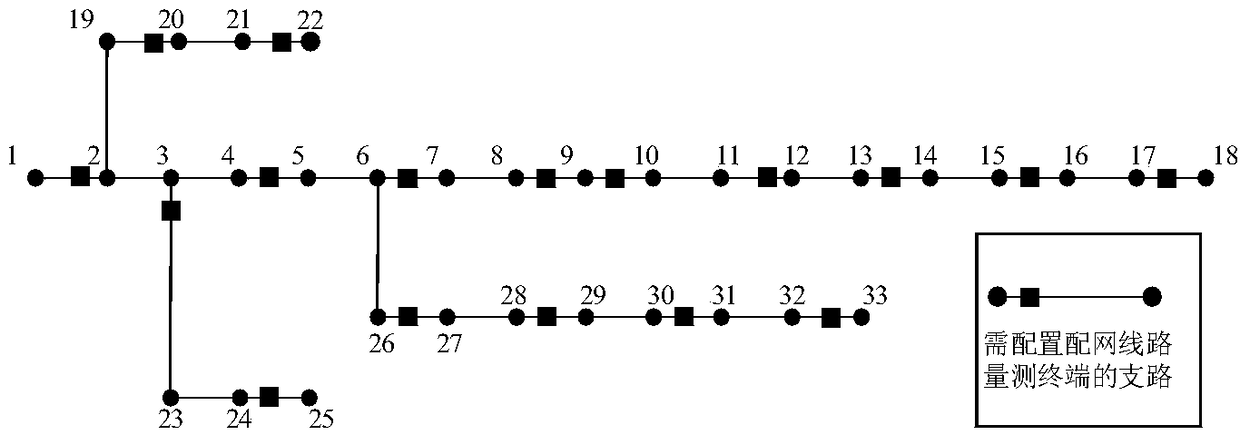

An optimal distribution network measurement configuration method based on improved 0-1 integer programming

PendingCN109359425AImprove applicabilityGuaranteed substantialGeometric CADForecastingComputer scienceDistribution networks

An optimal distribution network measurement configuration method based on improved 0-1 integer programming is disclosed. which includes: introducing the relevant theories and methods of 0-1 integer planning into the optimal configuration of the distribution network measuring device, and effectively realize the optimal configuration of the distribution network measuring device according to the economic environment factors, network nature factors and related constraints of the distribution network. The method is of great significance for the analysis and calculation of the optimal configurationof the distribution network measuring device.

Owner:JINING POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO +1

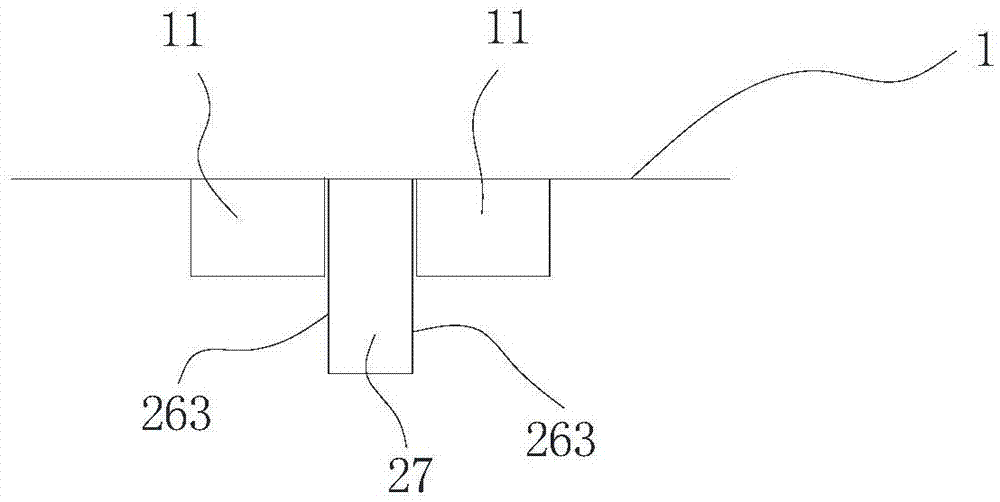

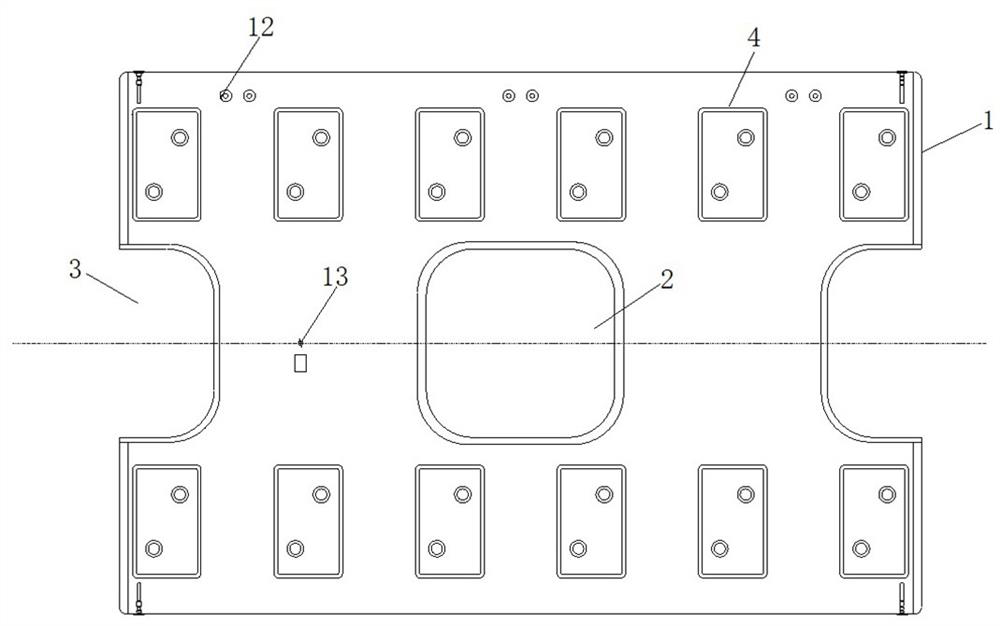

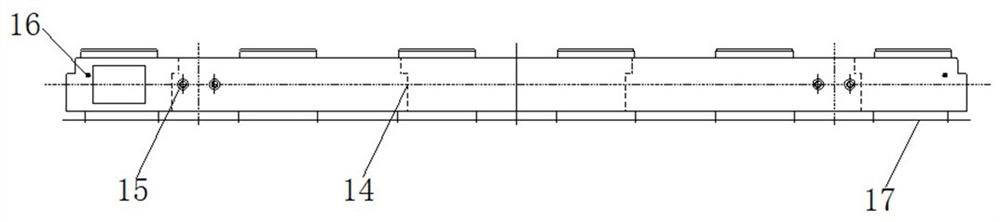

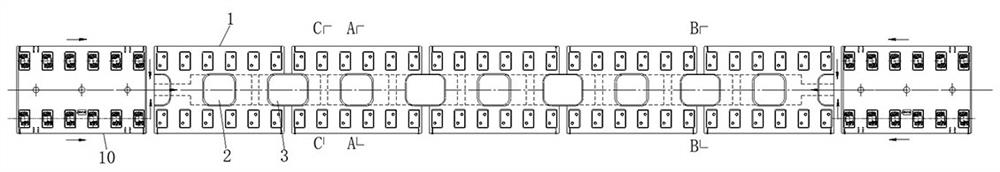

Prefabricated frame plate and application method thereof

PendingCN114808555AMeet the needs of full prefabricationEasy maintenance and repairBallastwayConstruction engineeringStructural engineering

The invention relates to the technical field of rail transit, in particular to a prefabricated frame plate and an application method thereof, open holes are formed in the plate middle and the plate end of the prefabricated frame plate respectively, notches are formed in the positions of the open holes in the plate middle and the open holes in the plate end of the prefabricated frame plate, and the notches are used for installing cover plates. The device has the advantages that the structure is simple and reasonable, and installation is convenient; the use is convenient, and particularly, the built-in pump room structure is convenient to maintain and overhaul; the ballast bed evacuation function is not influenced; the requirements of using working conditions such as a built-in pump room section and drainage transition sections on the two sides of the floating slab can be met, the application range is wide, the expansibility is high, and the method is suitable for popularization.

Owner:CHINA RAILWAY SHANGHAI DESIGN INST GRP

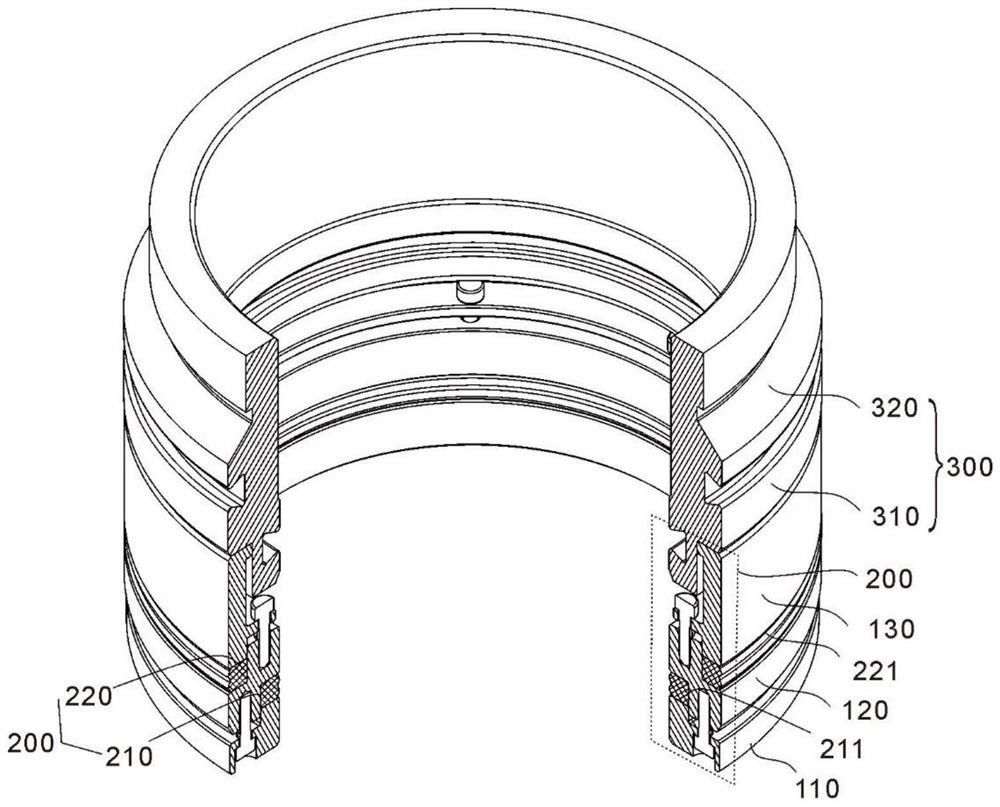

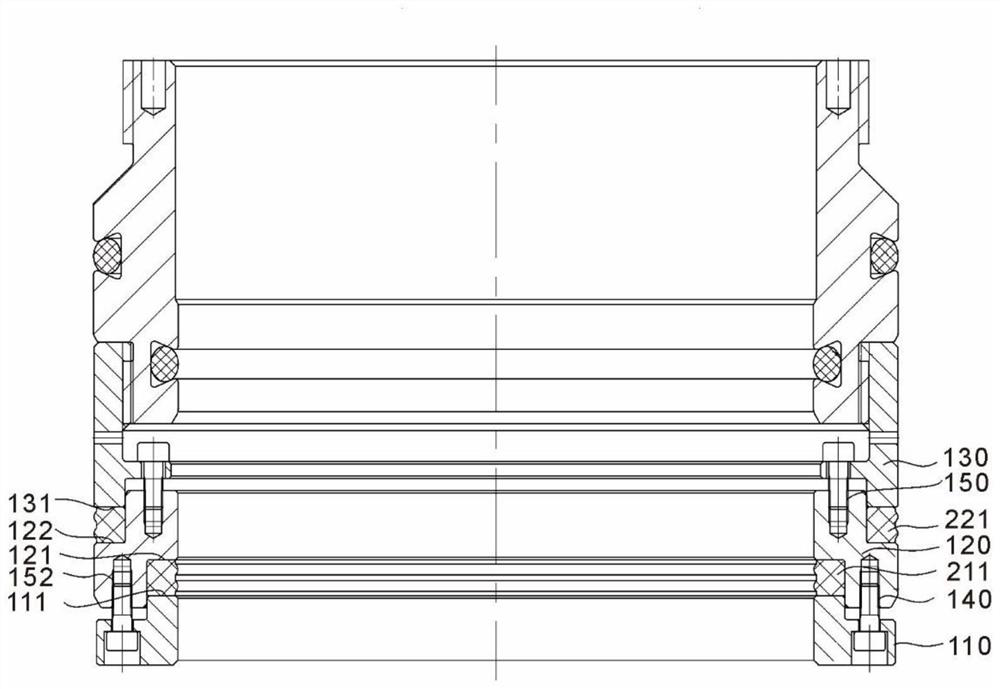

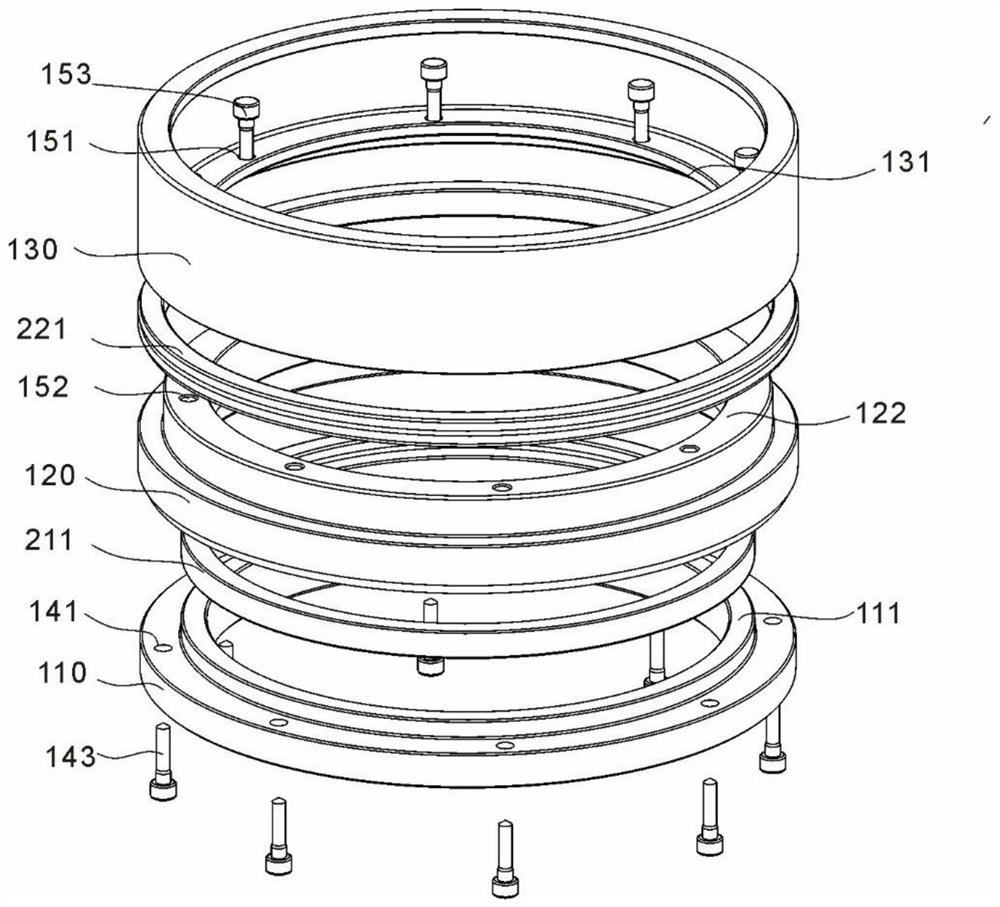

Separable hanger sealing sleeve device

The invention provides a separable hanger sealing sleeve device. Bidirectional sealing is formed between the inner diameter of a casing head and the outer diameter of a hanger body, and the bidirectional sealing is contracted between a connecting plate and a bottom plate or a pressing plate before a sealing ring is lowered, so that a sealing sleeve device is smooth in lowering, and free of jammingphenomenon and convenient to install, and the embedded sealing sleeve device forms the bidirectional sealing by utilizing an excitation assembly, so that the assembly and the maintenance are convenient, meanwhile, a sealing element can be designed to be rubber sealing or metal sealing as well, the type of the sealing ring can be selected according to actual working conditions, the cost is reduced, and meanwhile the requirements of the working conditions can be met as well.

Owner:JIANGSU JINSHI MACHINERY GROUP

Gear box with function of positive and negative rotation

The invention relates to a gear box with a function of positive and negative rotation. The gear box comprises non-circular gears, an input shaft, a driven solid shaft, a driven hollow shaft, a planet carrier, planetary gears, sun wheels, an output shaft, a box body and the like. A full-mechanical transmission structure which is jointly composed of the non-circular gears and a planetary gear train composed of circular gears is adopted. When the gear box works, movement is introduced through the input shaft, and is output through the output shaft if being engaged to the gears of the gear box. When the input is in a continuous single direction, the output of the gear box is in two directions of positive and negative rotation; the angular velocities and the angular accelerations of positive and negative rotation as well as the angles of the positive and negative rotation of the output shaft can be changed by changing the shape of a pitch curve of the non-circular gear or the gear compatibility of the non-circular gear. The planetary gear trains are of symmetrical structures. The gear box is low in price, convenient to maintain and suitable for long-term work in severe environments such as high power, high load and the like.

Owner:张弘

Multifunctional sludge formation slitting machine

PendingCN108673932AGuaranteed continuous supplyMeet shapeShaping pressDrive wheelReciprocating motion

The invention discloses a multifunctional sludge formation slitting machine and relates to the field of sludge drying. The upper portion of a forming cavity is connected with a feeding device. The forming cavity serves as a supporting structure and a running space and is internally provided with two sets of forming engagement rollers. Each set of forming engagement roller is formed by connecting adrive wheel and a driven wheel side by side in a gear-engaged mode. The forming engagement rollers are connected with electrical control devices used for enabling the forming engagement rollers to rotate and controlling the rotation number of the forming engagement rollers. The upper portions of the forming engagement rollers are connected with a telescopic device, and the telescopic device comprises a telescopic rod and drooping flat scrapers evenly connected to the telescopic rod. The telescopic rod drives the drooping flat scrapers to move back and forth, so that viscosity of materials isoffset, the materials can be supplied continuously, the telescopic rod is connected with a cylinder device, and the cylinder device is connected with the forming cavity through a fixing device. According to the multifunctional sludge formation slitting machine, required shapes before sludge enters a drying machine are met, the drying efficiency is greatly improved, meanwhile, sludge of different types can be processed correspondingly through the identical drying machine, and the application range is extended.

Owner:DALIAN HUANZI TECH

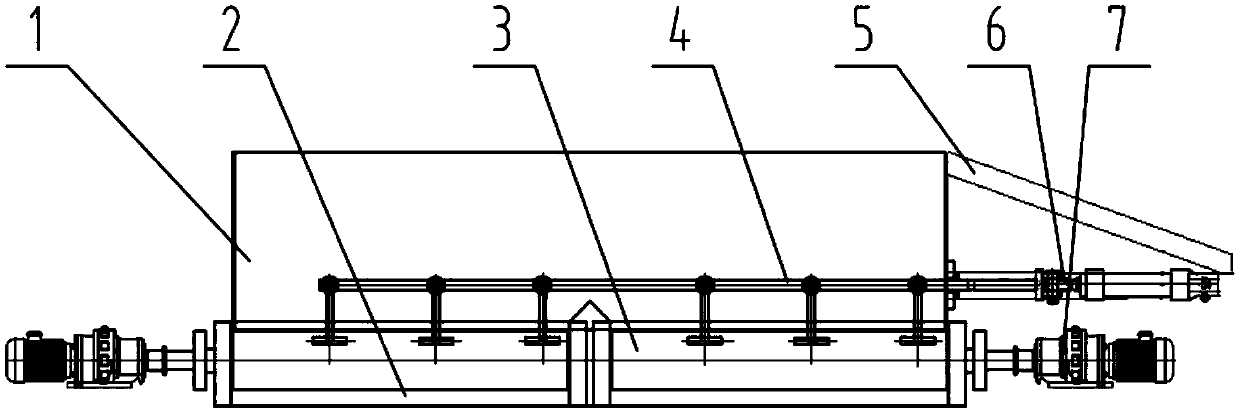

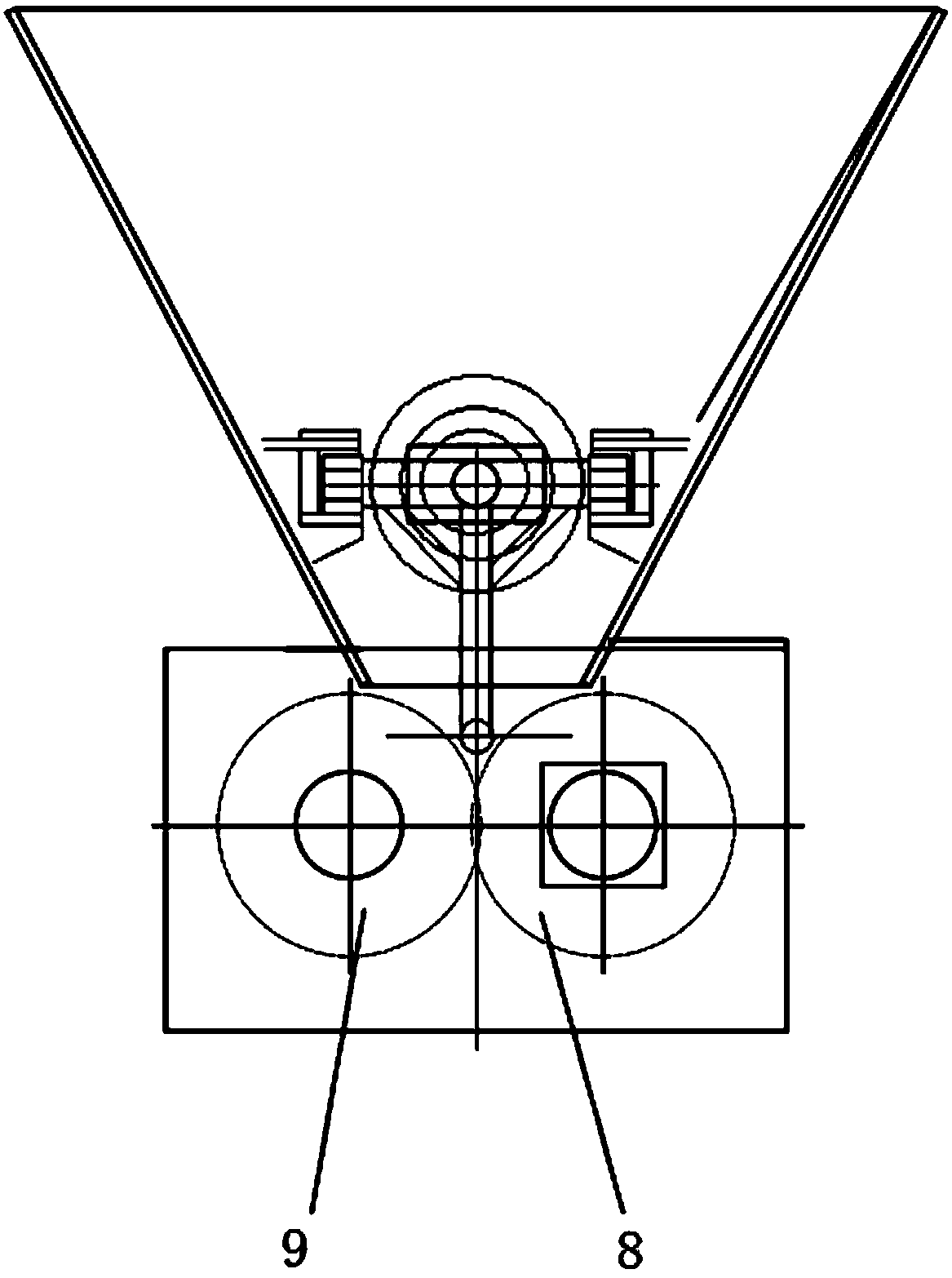

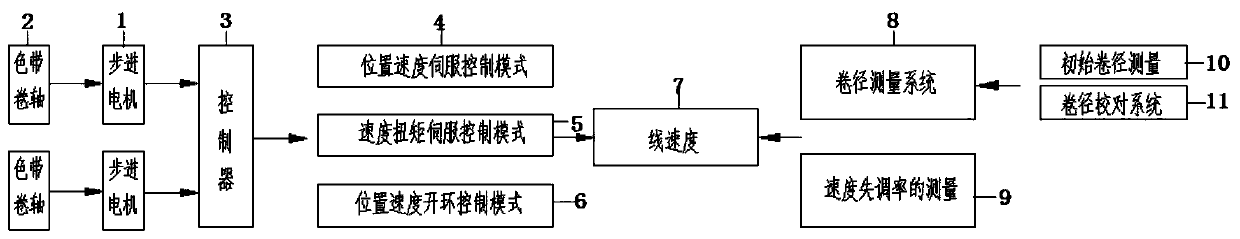

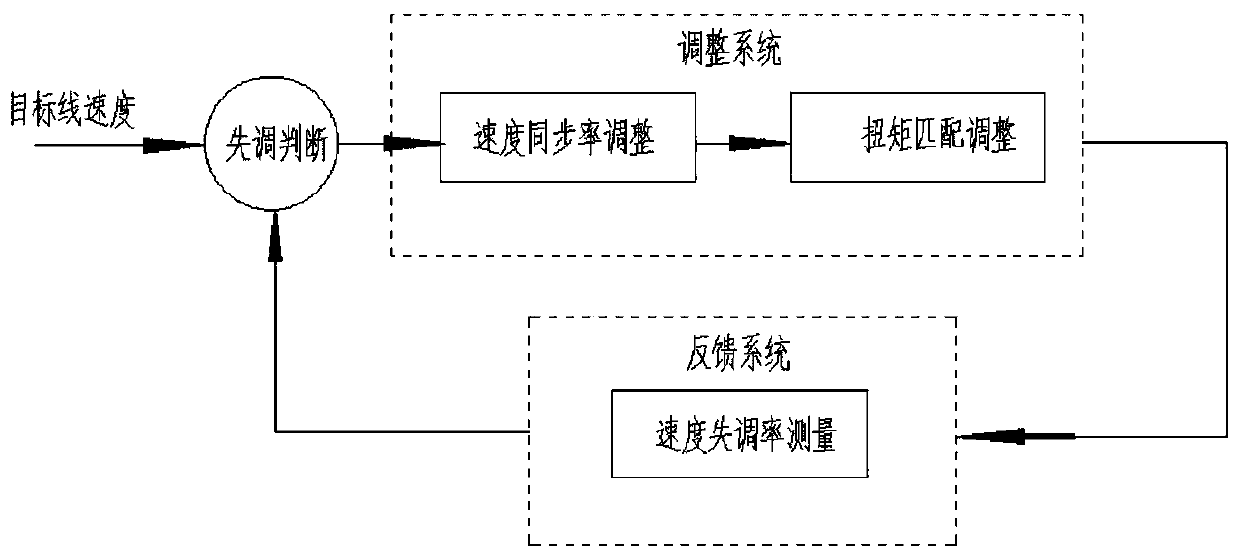

Double-stepping servo guide belt control system

The invention discloses a double-stepping servo guide belt control system. The double-stepping servo guide belt control system comprises stepping motors, ribbon reels and a controller, wherein the stepping motors and the ribbon reels are both provided with two, the stepping motors are connected to the ribbon reels in a bearing mode, and the stepping motors are electrically in connection with the controller; and the controller is internally provided with a position speed servo control mode, a speed torque servo control mode and a position speed open loop control mode. According to the double-stepping servo guide belt control system, the two motors are adopted independent servo control modes and do not depend on other sensors or circuits to assist in measuring the tension of a ribbon, so that the mechanical mechanism and the circuit design are simplified.

Owner:上海创马特智能标识技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com