Integrated electro-hydraulic proportional hydraulic valve bank

A technology integrating electro-hydraulic and hydraulic valve groups, applied in the field of hydraulic systems, can solve the problems of large action shock and large energy loss, and achieve the effects of stable pressure, compact pipe layout, and favorable pipe layout and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

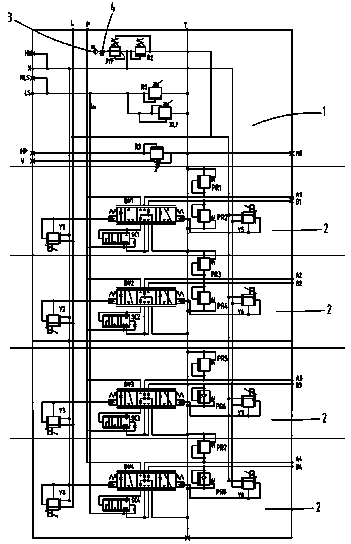

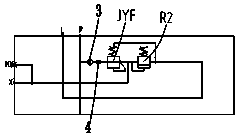

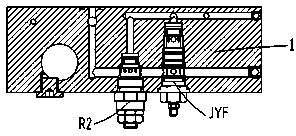

[0024] Such as Figure 1 to Figure 6 As shown, the icon numbers are as follows: oil inlet unit 1, unit basic unit 2, transition net body 3, first damping body 4, valve stem 5, return spring 6, throttle groove 7, working oil passage A, working oil passage B, unit proportional reversing valve DV, pilot pressure reducing valve JYF, drain passage L, sensitive circuit LS, pressure oil passage P, unit secondary relief valve PR, first safety valve R1, second safety valve R2, The third safety valve R3, the unit proportional compensation valve SC, the return oil passage T, the pilot oil passage X, the protection safety valve XLF, and the unit electromagnetic proportional pressure reducing valve Y.

[0025] In the embodiment of the present invention, the integrated electro-hydraulic proportional hydraulic valve group includes the oil inlet unit 1 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com