High-temperature-resistant ethylene propylene rubber sealing pad and preparation method and application thereof

A technology of ethylene-propylene rubber and sealing gaskets, which is applied in the field of high-temperature-resistant ethylene-propylene rubber sealing gaskets and its preparation, can solve the problems of low temperature and short-term or intermittent use at 150°C, and achieve excellent weather resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

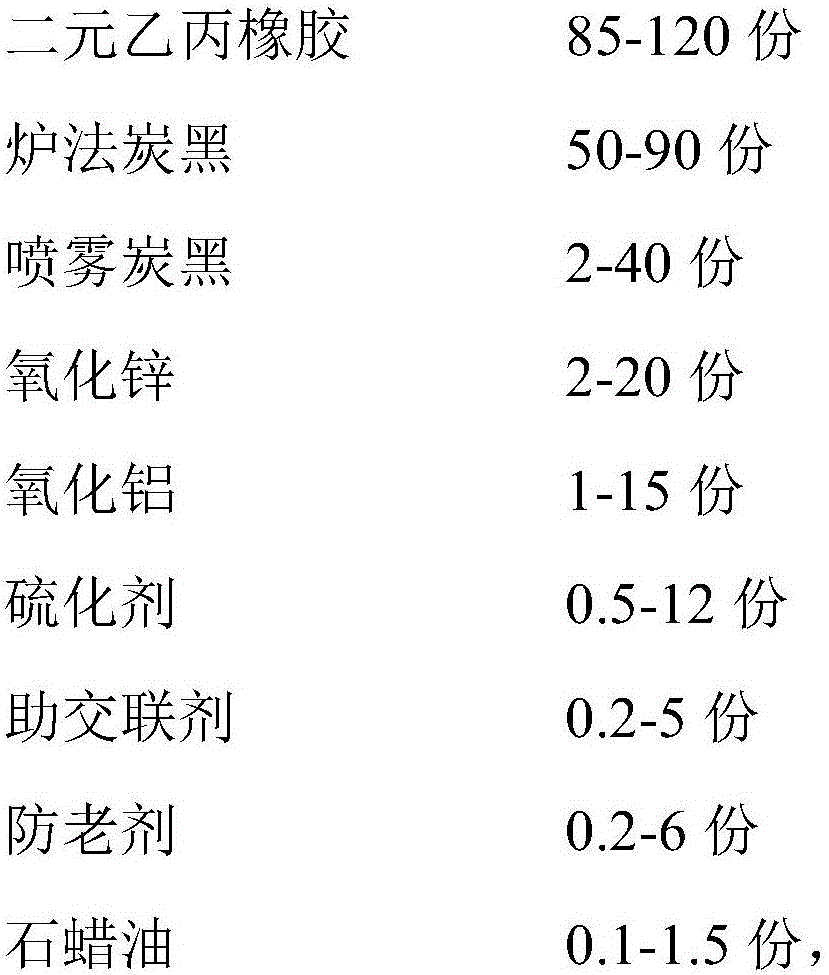

[0060] A high-temperature-resistant ethylene-propylene rubber sealing gasket provided by the present invention is made of the following components in parts by weight:

[0061]

Embodiment 2

[0063] The preparation method of embodiment 1 high temperature resistant ethylene propylene rubber sealing gasket, comprises the following steps:

[0064] (1) 85 parts of binary ethylene propylene rubber K740, 80 parts of carbon black N550, 20 parts of spray carbon black, 3 parts of zinc oxide, 3 parts of aluminum oxide, 5 parts of paraffin oil, 1 part of vulcanizing agent DCP, auxiliary Mix 0.5 parts of cross-linking agent HVA-2 and 0.2 parts of anti-aging agent 445 and banbury for 5 minutes, the temperature is less than 100 ° C, then pour out the mixed rubber material and add it to the open mixer to make a triangular bag and knead for 5 times. Parked for 10h to obtain the mixed rubber;

[0065] (2) Re-milling the mixed rubber in an open mill, and when the temperature of the rubber material reaches 70° C., a rectangular rubber strip is produced, and then added to an extruder for extrusion molding to obtain a cylindrical rubber strip;

[0066] (3) The mold is added to the vul...

Embodiment 3

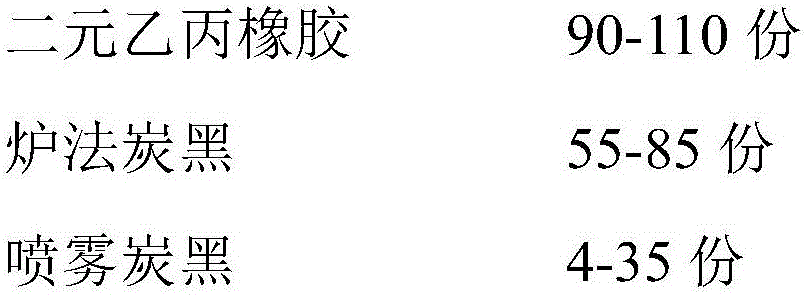

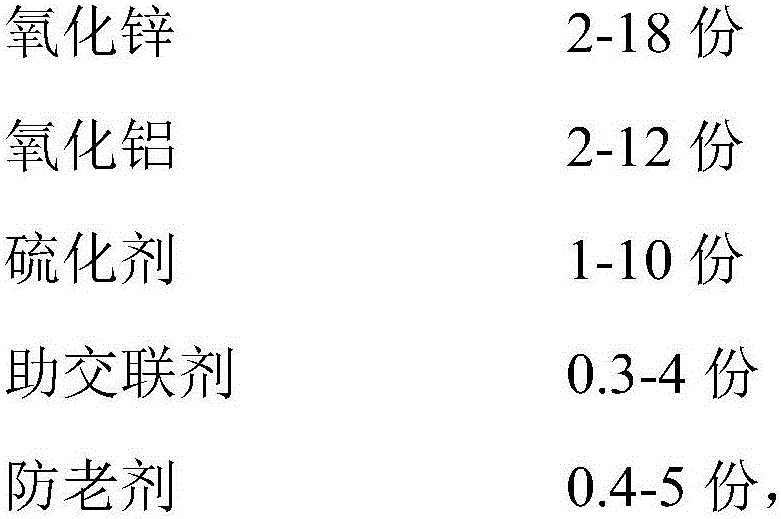

[0068] A high-temperature-resistant ethylene-propylene rubber sealing gasket provided by the present invention is made of the following components in parts by weight:

[0069]

[0070] Wherein, the ratio between carbon black N330 and N550 is 1:1, and the parts by weight of carbon black N330 and carbon black N550 are both 45 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com