Blade leading edge double-rotational-flow impingement cooling experiment testing system and method

A technology for the leading edge of the blade and the test system, which is applied to the supporting elements of the blade, the engine element, the machine/engine, etc., can solve the problem of effectively revealing the cooling mechanism of the double swirl cooling technology without experimental means, and achieves simple structure and convenient construction. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

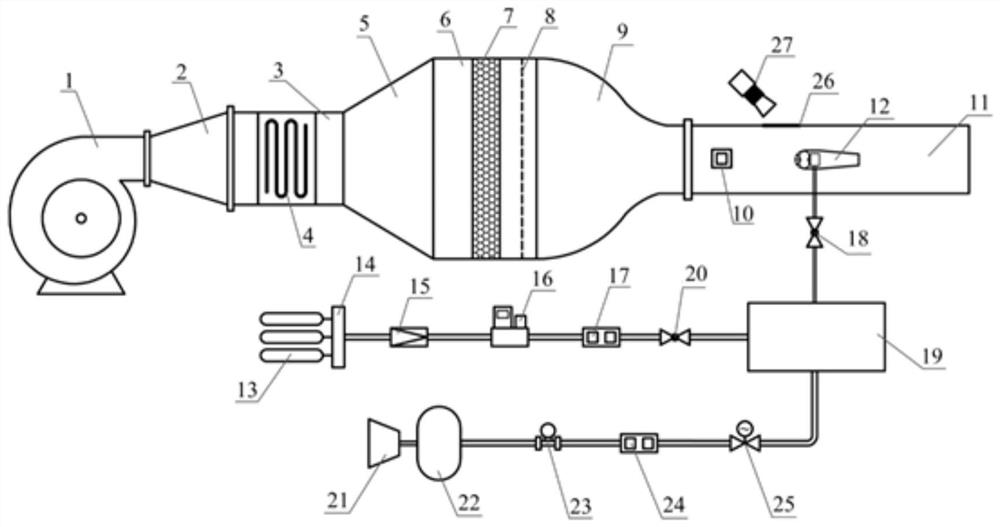

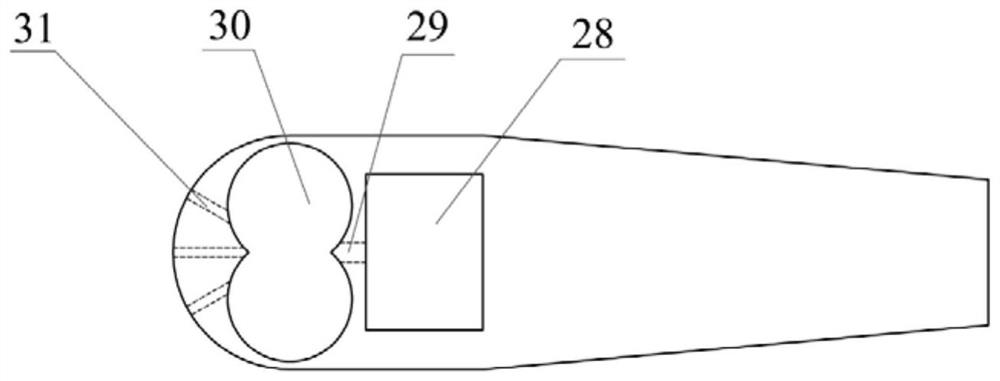

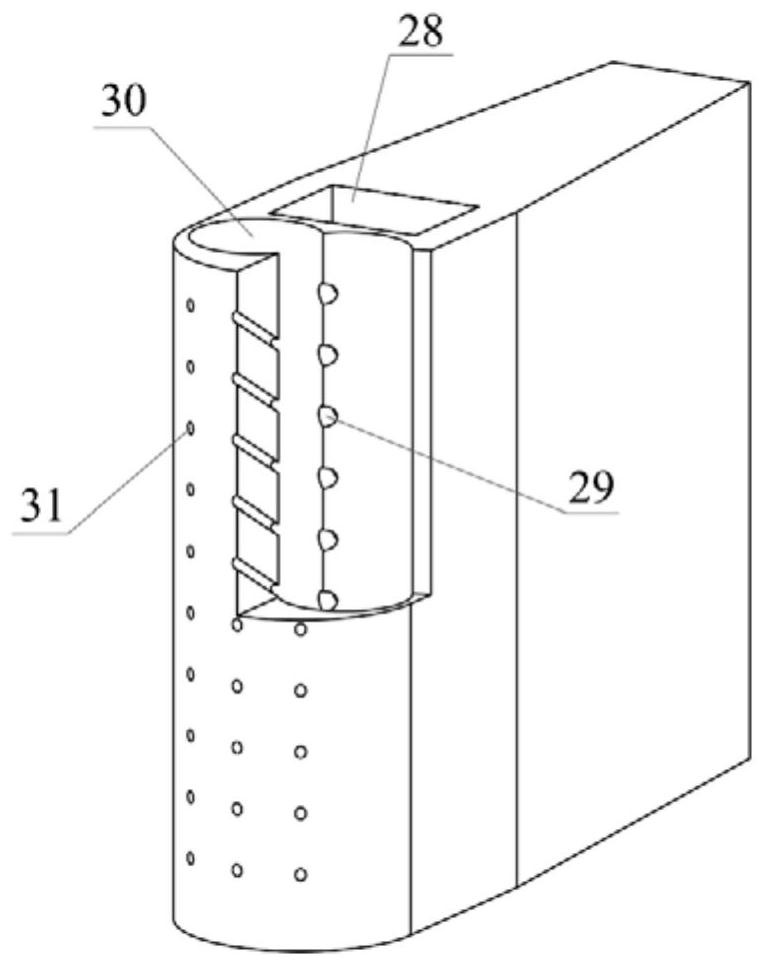

[0036] Such as figure 1 As shown, the present invention provides a kind of blade leading edge dual-swirl impingement cooling experiment test system, including main flow channel, blade leading edge experiment section 11, secondary flow cooling system and infrared thermal imaging system; wherein, the outlet of main flow channel and The inlet of the blade leading edge test section 11 is connected by a flange; the frame of the blade leading edge test section 11 is made of plexiglass, and a blade leading edge double swirl impact test piece 12 and a temperature measuring device 10 are arranged inside; the front side of the test piece 45 An infrared shooting window 26 is arranged in the direction, and the infrared optical thermal imager 27 can measure the temperature directly to the experimental observation area through the window; the secondary flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com