Separable hanger sealing sleeve device

A technology of hanger and sealing sleeve, which is applied in sealing/isolation, wellbore/well parts, earthwork drilling and production, etc. It can solve the problems of inconvenient installation of sealing devices, and achieve easy assembly and maintenance, cost reduction, and no jamming Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

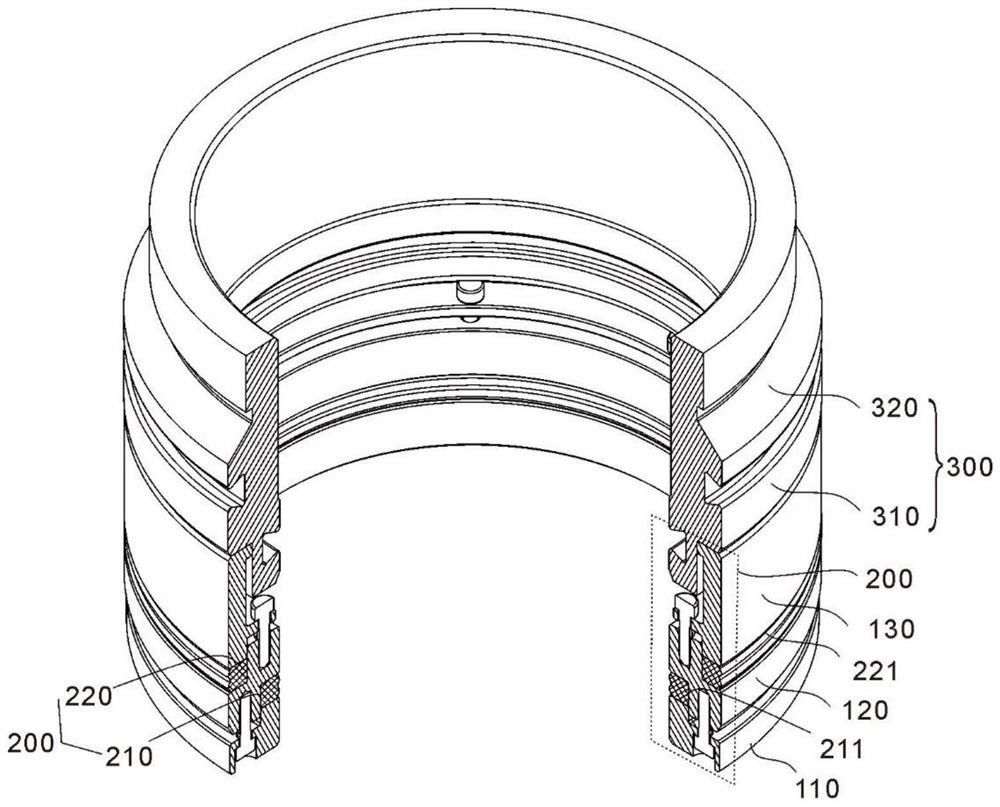

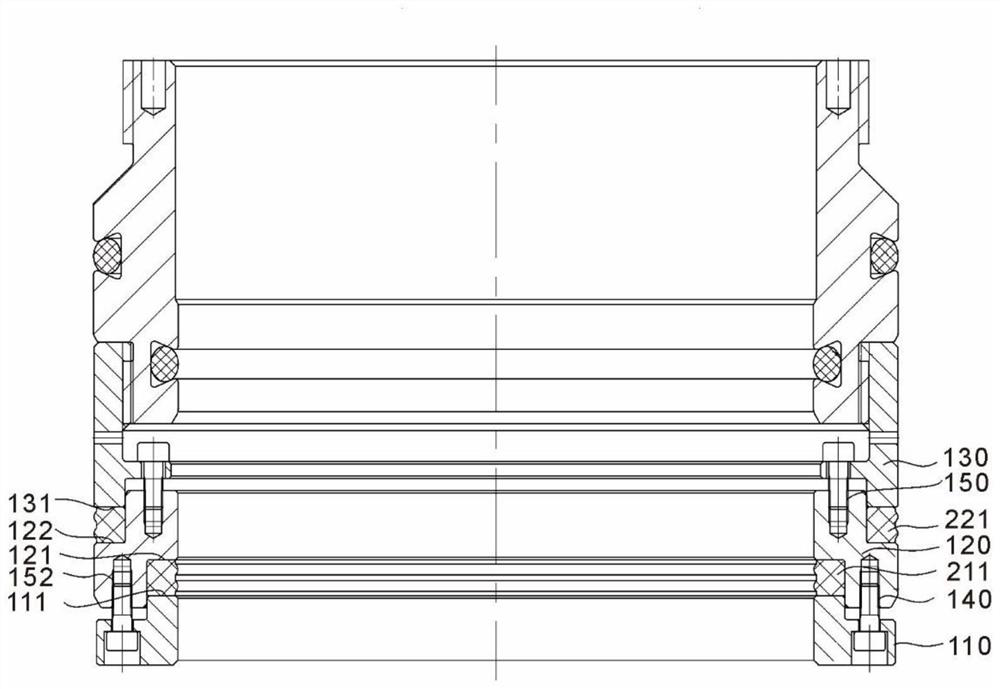

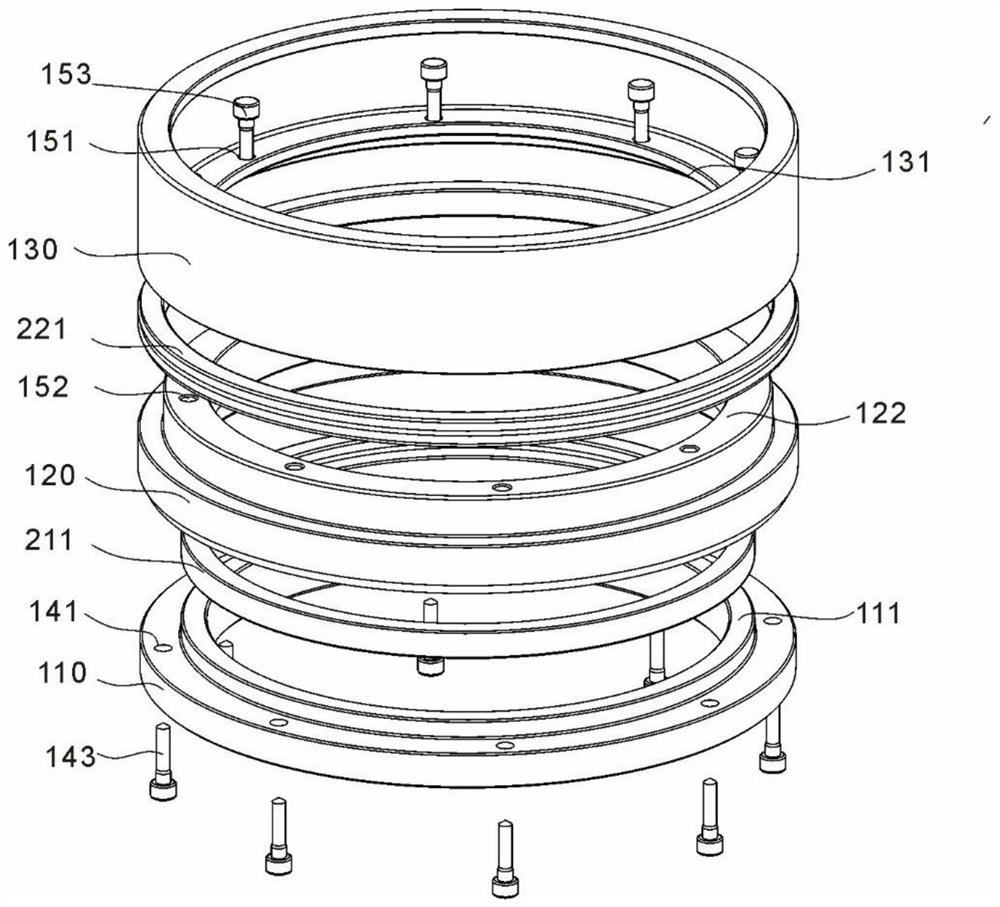

[0029] This embodiment provides a kind of detachable hanger sealing sleeve device, its structure is as follows figure 1 As shown, an extrusion assembly 100 , a sealing assembly 200 and an activation assembly 300 are included.

[0030] Wherein, the extruding assembly 100 is used to provide a movable space, including a bottom plate 110 , a connecting plate 120 movably arranged on the bottom plate 110 , and a pressing plate 130 movably connected on the connecting plate 120 . The movable space among the bottom plate 110 , the connecting plate 120 and the pressing plate 130 can adjust the state of the sealing assembly 200 therein.

[0031] The sealing assembly 200 is used to form a seal between the inner diameter of the casing head and the outer diameter of the hanger, including a first sealing groove 210 formed between the bottom plate 110 and the connecting plate 120, and a first sealing member is arranged in the first sealing groove 210 211, and the second seal groove 220 forme...

Embodiment 2

[0035] The present embodiment provides a detachable hanger sealing sleeve device, including an extrusion assembly 100, including a bottom plate 110, a connecting plate 120 movably arranged on the bottom plate 110, and a pressing plate 130 movably connected on the connecting plate 120; The assembly 200 includes a first sealing groove 210 formed between the bottom plate 110 and the connecting plate 120, a first sealing member 211 is arranged in the first sealing groove 210, and a second sealing groove formed between the connecting plate 120 and the pressure plate 130 220, the second seal groove 220 is provided with a second seal 221; the first seal groove 210 and the second seal groove 220 are respectively located on the inner and outer sides of the extrusion assembly 100; the excitation assembly 300 includes an excitation element connected to the pressure plate 130 310 , a guiding structure 320 is provided on the triggering member 310 , and when the triggering member 310 approac...

Embodiment 3

[0058] This embodiment provides a separable hanger sealing sleeve device, which is different from Embodiment 2 in that the first seal 211 and the second seal 221 in this embodiment are both metal seals 230, and the metal seals 230 include Two metal sealing rings arranged in a staggered manner.

[0059] Specifically, such as Figure 4 As shown, the metal sealing rings in this embodiment are the inner metal ring 231 and the outer metal ring 232 respectively, and the contact surfaces of the inner metal ring 231 and the outer metal ring 232 are inclined surfaces. During the extrusion process of the extrusion assembly 100, the first The outer metal ring 232 of the sealing member 211 moves along the inclined plane and will approach the hanger, while the outer sealing member in the second sealing member 221 will approach the inner wall of the casing head body, thereby completing the simultaneous sealing of the inner and outer sides.

[0060] The metal sealing sleeve device has the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com