Pendulum guide rod type pumping unit

A technology for swinging guide rods and pumping units, which is applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc. It can solve the problems of reduced reliability of flexible connecting rods, large peak net torque of the crankshaft, and increased energy consumption, etc. problems, to achieve the effect of improved balance, improved reliability, and large corners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

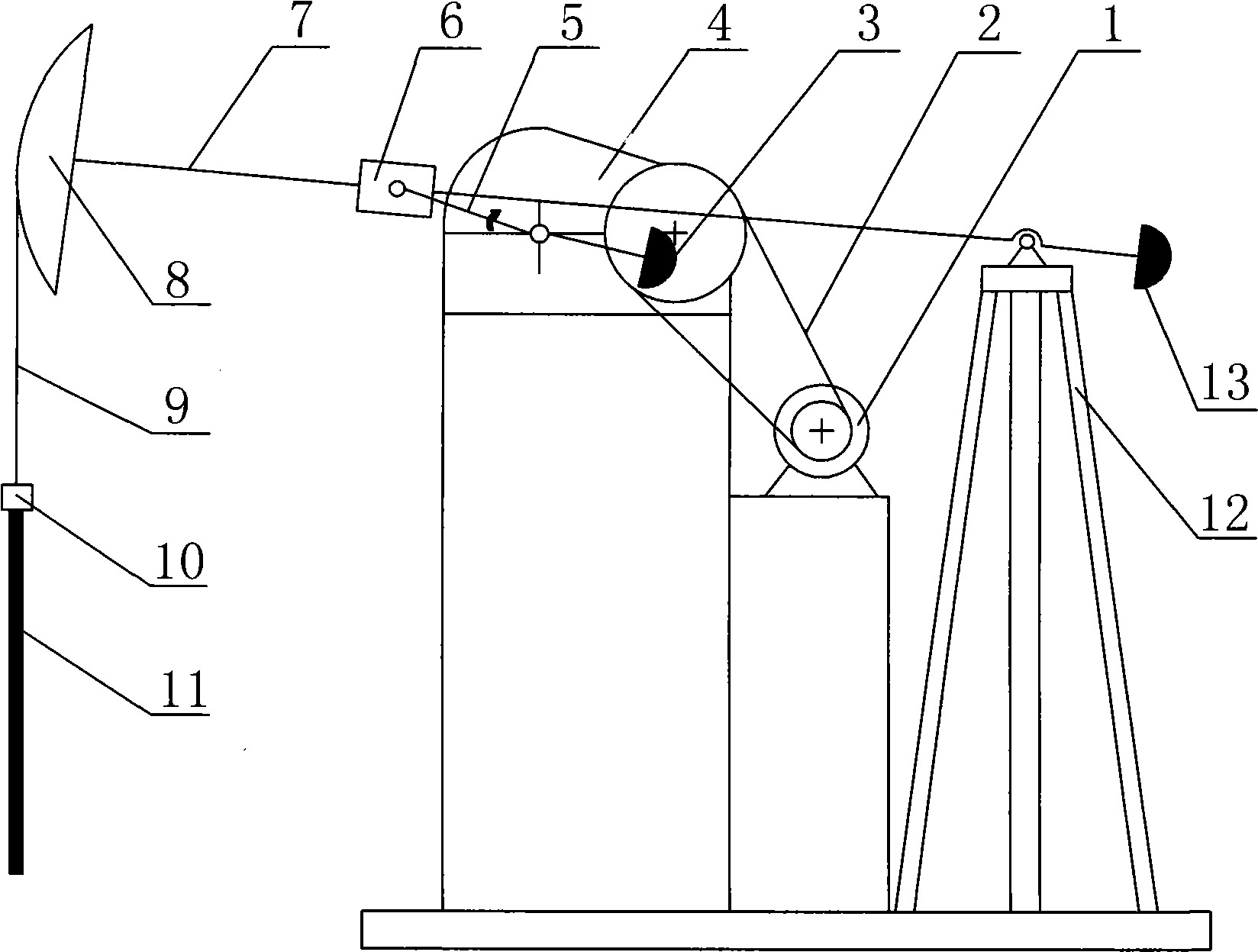

[0021] Such as figure 1 As shown, the present invention comprises electric motor 1, belt transmission mechanism 2, speed reducer 4, crank 5, frame 12, fork 7, donkey head 8, steel rope 9 and sucker rod 11, wherein, the output shaft of electric motor 1 and The input shaft of the belt transmission mechanism 2 is connected through the connection key, the output shaft of the belt transmission mechanism 2 is connected with the input shaft of the reducer 4 through the connection key, and the crank 5 is installed on the output shaft of the reducer 4 through the connection key. Driven by the output shaft of the speed reducer 4, it rotates synchronously with the output shaft of the speed reducer 4. Wherein, the speed reducer 4 is a two-stage gear reduction box.

[0022] The slider 6 is installed on the front end of the crank 5 through the pin shaft, and the rear end of the crank 5 protrudes outside the output shaft of the reducer 4, that is, the reducer 4 is connected to the middle pa...

Embodiment 2

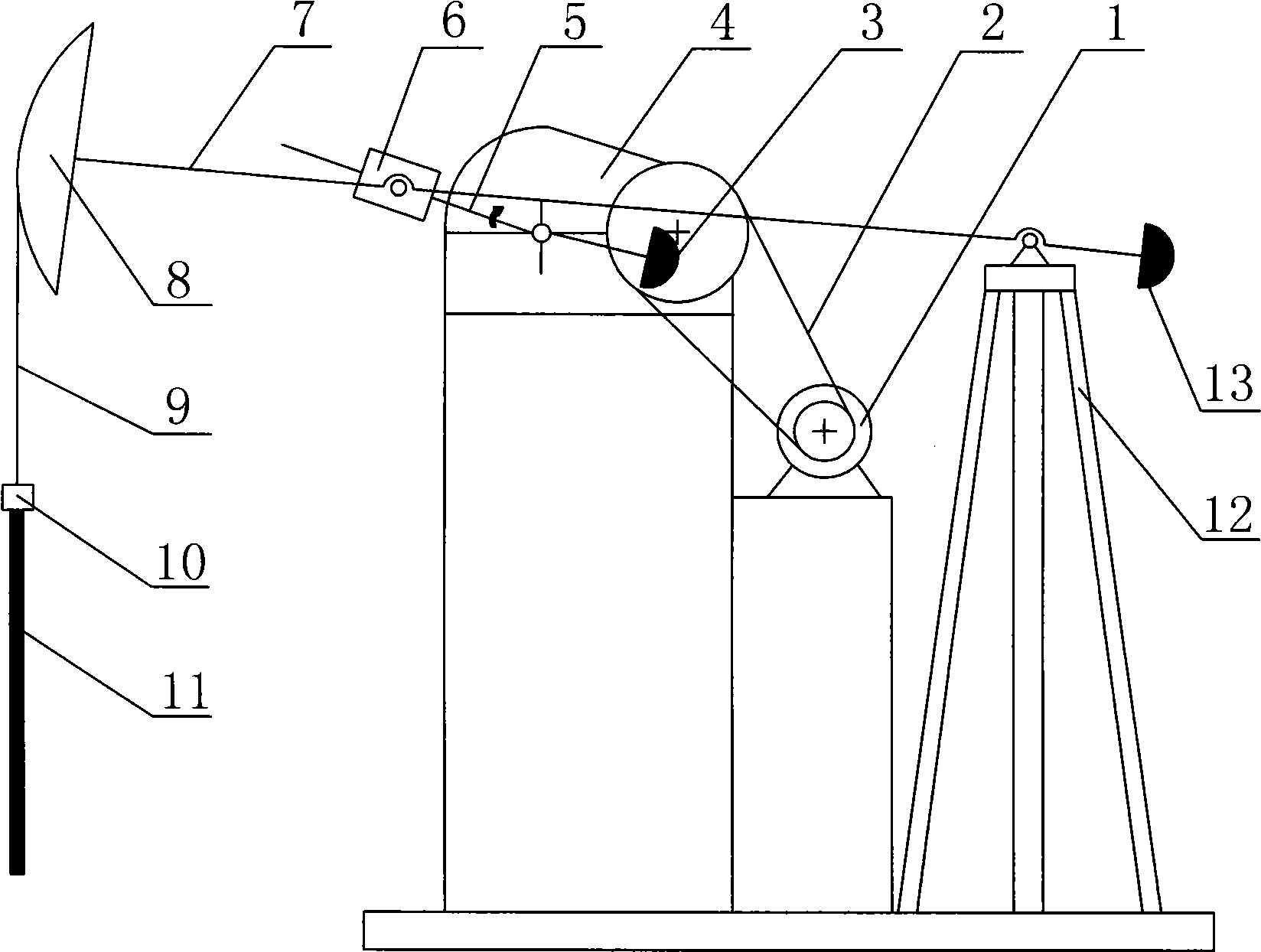

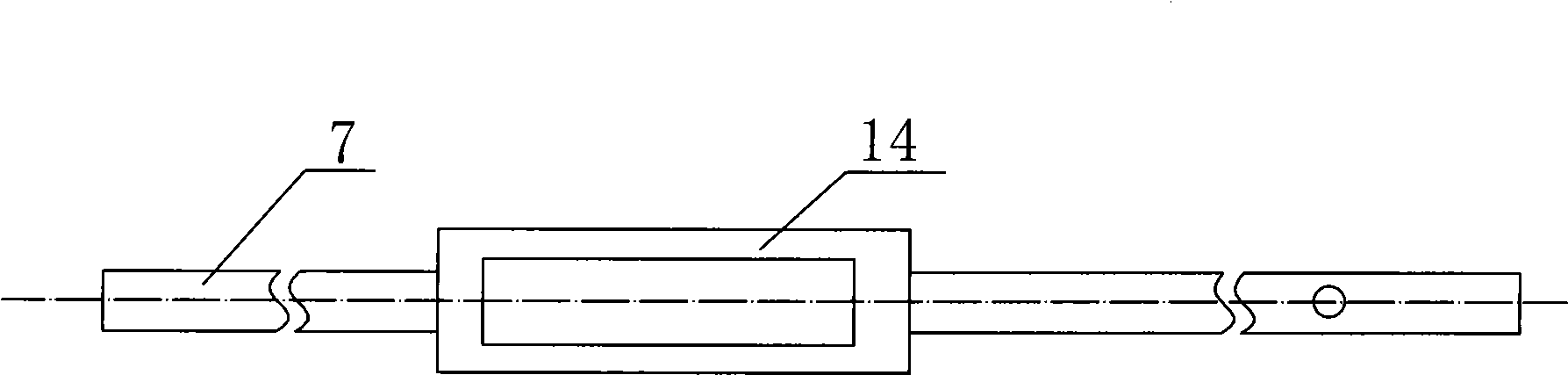

[0026] Such as figure 2 and Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that a slider 6 is fixedly installed on the front part of the swing rod 7 through a pin shaft, and a guide rail 14 is fixedly installed on the front part of the crank 5, and the slider 6 is arranged on the guide rail. 14 miles and slide along the guide rail 14. In this way, during the rotation of the crank 5, through the sliding of the slider 6 on the guide rail 14, the crank 5 drives the swing bar 7 to swing up and down with the frame 12 as the fulcrum, and at the same time, the donkey head 8 on the swing bar 7 Drive the sucker rod 11 to reciprocate up and down.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com