Double-stepping servo guide belt control system

A control system and servo control technology, applied in printing and inking devices, etc., can solve problems affecting the measurement accuracy of tension, ribbon deviation, unreliability, etc., and achieve simplified mechanical mechanism and circuit design, and constant ribbon tension , Guarantee the effect of motor speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

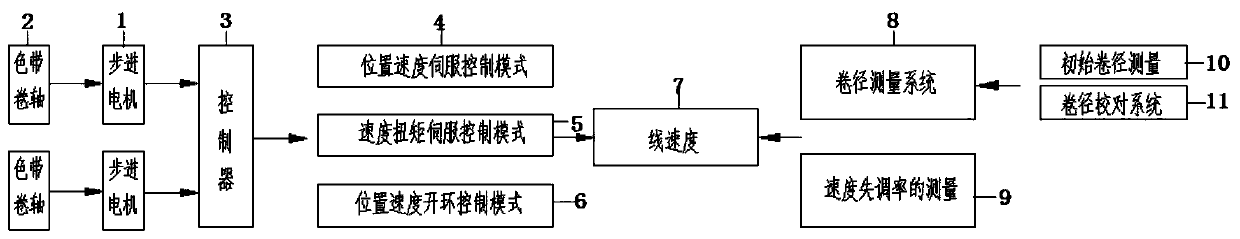

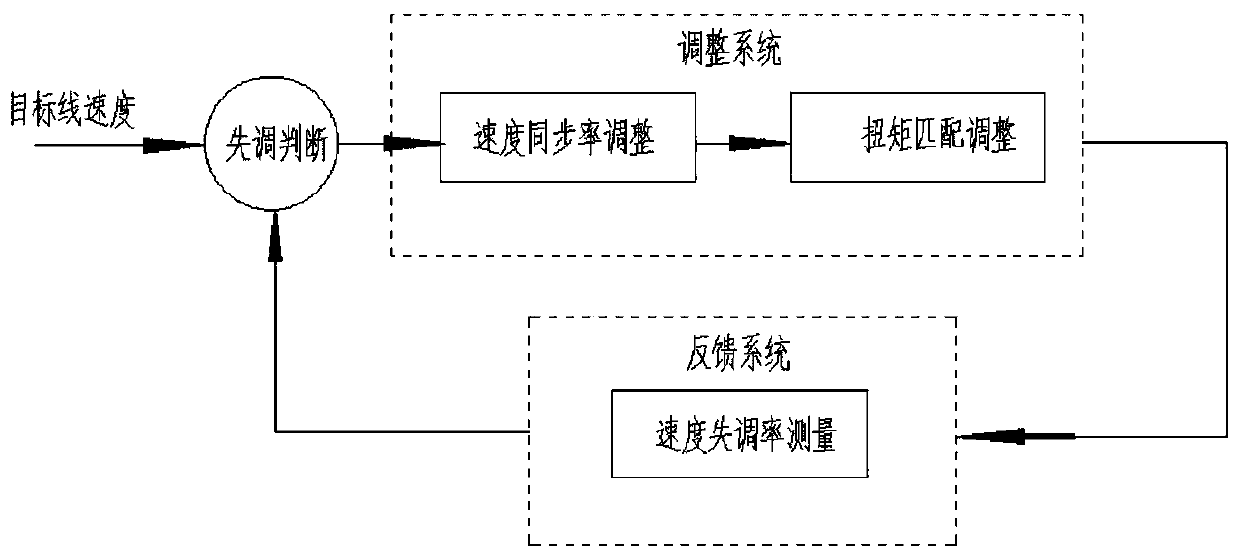

[0013] Such as figure 1 and figure 2 Shown is a dual-step servo servo guide control system, the dual-step servo guide belt control system includes a stepper motor 1, a ribbon reel 2, a controller 3, the stepper motor 1 and the ribbon reel 2 are provided with two, the stepper motor 1 is connected to the ribbon reel 2 bearings, the stepper motor 1 is electrically connected to the controller 3, and the controller 3 is equipped with a position speed servo control mode 4, speed torque Servo control mode 5 and position speed open loop control mode 6;

[0014] The accuracy of the line speed 7 of the position speed servo control mode 4, the speed torque servo control mode 5 and the position speed open loop control mode 6 depends on the measurement system 8 of the coil diameter and the measurement 9 of the speed imbalance rate. The coil diameter measurement system 8 includes an initial roll diameter measurement 10 and a roll diameter correction system 11, the roll diameter correctio...

Embodiment 2

[0016] Such as figure 1 and figure 2 Shown is a dual-step servo servo guide control system, the dual-step servo guide belt control system includes a stepper motor 1, a ribbon reel 2, a controller 3, the stepper motor 1 and the ribbon reel 2 are provided with two, the stepper motor 1 is connected to the ribbon reel 2 bearings, the stepper motor 1 is electrically connected to the controller 3, and the controller 3 is equipped with a position speed servo control mode 4, speed torque Servo control mode 5 and position speed open loop control mode 6;

[0017] The accuracy of the line speed 7 of the position speed servo control mode 4, the speed torque servo control mode 5 and the position speed open loop control mode 6 depends on the measurement system 8 of the coil diameter and the measurement 9 of the speed imbalance rate. The coil diameter measurement system 8 includes an initial roll diameter measurement 10 and a roll diameter correction system 11, the roll diameter correctio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com