Prefabricated frame plate and application method thereof

An application method and frame plate technology, applied in the field of rail transit, can solve the problems of destroying the structural strength of the ballast bed, affecting the construction efficiency, and difficult to guarantee the construction quality, and achieve the effect of strong scalability, simple and reasonable structure, and suitable for promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

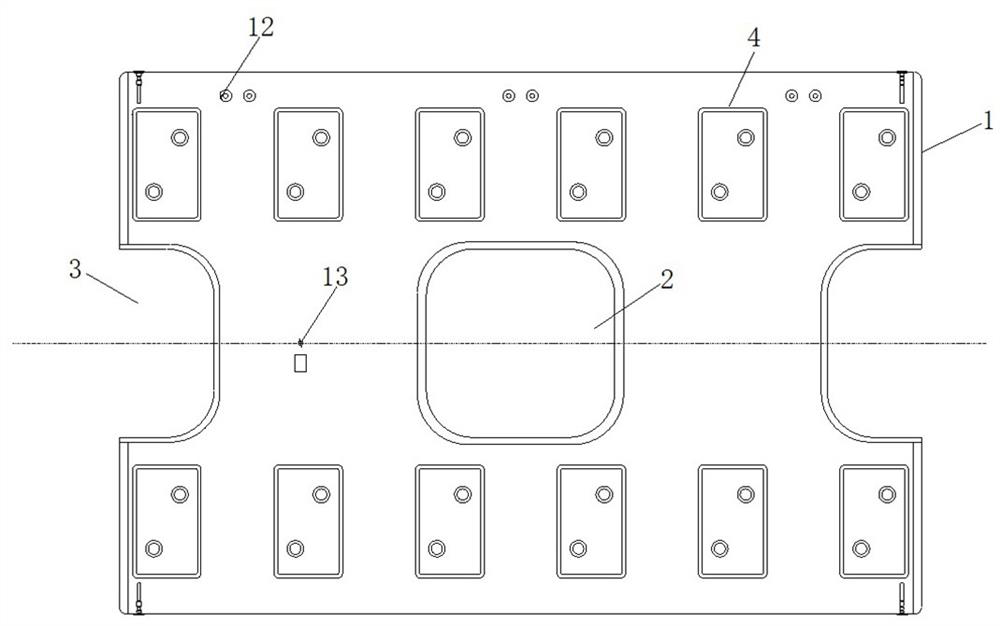

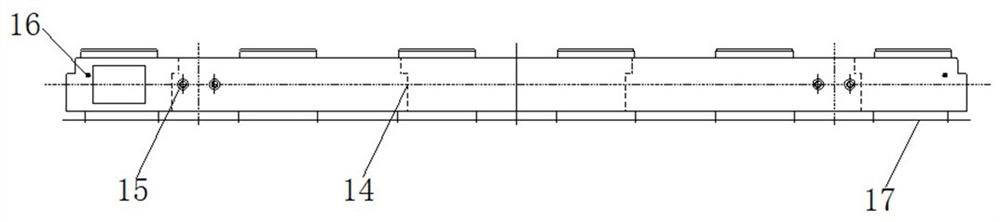

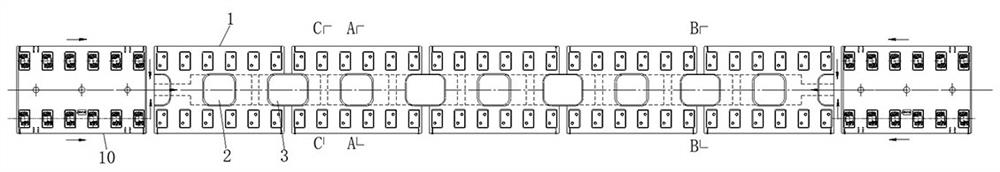

[0031] Example 1: as figure 1 As shown, the prefabricated frame plate in this embodiment is a prefabricated frame plate 1, the middle of the prefabricated frame plate 1 is provided with a hole 2 in the middle of the plate, and the two ends along the line direction are respectively provided with plate end holes 3. On the surface of the prefabricated frame plate 1 and at the positions on both sides of the opening 2 in the plate, there are respectively provided rail support platforms 4 arranged along the line direction, and each rail support platform 4 is used to carry the steel rails.

[0032] combine figure 1 and figure 2 As shown, various auxiliary structures or embedded parts can be arranged on the prefabricated frame plate 1 to improve its use effect or application range. like figure 2 As shown, a three-rail bracket mounting hole 12 can be provided on the surface side of the prefabricated frame plate 1 for installing the three-rail bracket when needed. A settlement obs...

Embodiment 2

[0044] Embodiment 2: as Figure 9 As shown in the figure, the prefabricated frame plate in this embodiment can also be applied to the drainage transition section on both sides of the floating plate. At this time, the prefabricated frame plate 1 is connected between the floating plate 11 and the conventional track plate, and the central water ditch is adopted. For drainage, the hole 2 in the plate and the hole 3 at the end of the plate can be used as dredging holes for the central water ditch. Under the above conditions, the plate seams can be designed with the same distance.

Embodiment 3

[0045] Example three: as Figure 10 and Figure 11 As shown, the prefabricated frame plate in this embodiment can also be applied to the anti-vibration track bed, and this form can be used when the anti-vibration track bed is located at both ends of the floating slab track bed. The prefabricated frame plate 1 is erected on the base 5 below, and a secondary pouring concrete 20 is arranged between the two, and a vibration damping pad 19 is arranged between the secondary pouring concrete 20 and the base 5 for vibration damping. A central water ditch 21 is opened in the middle of the track bed, and the prefabricated frame plate 1 covers the central water ditch 21 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com