Piston sealing piece manufacturing process and piston sealing piece

A technology of piston seals and manufacturing process, which is applied in the field of pneumatic seals and hydraulic pressure, can solve the problems of poor anti-extrusion performance and large frictional resistance, and achieve the effect of low friction and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

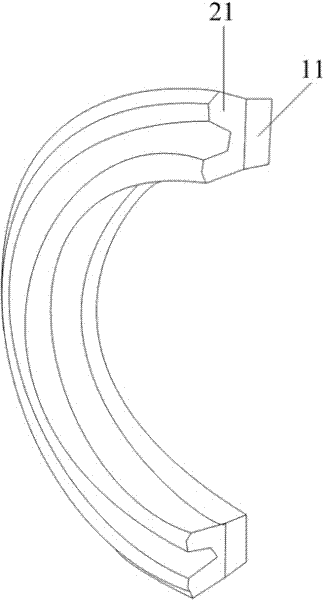

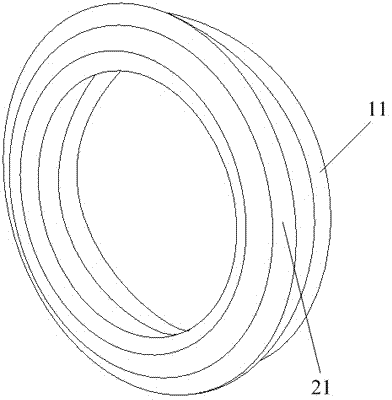

[0023] The annular body of the piston seal of the present invention is made of hard polyurethane material, and the sealing part is made of soft polyurethane material, which not only has a simple structure, but also meets the requirements for low friction of the sealing part and the strong extrusion resistance of the annular body The capacity requirements are fully in line with the actual working conditions.

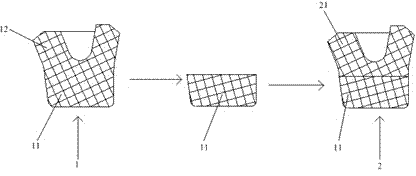

[0024] see figure 1 , the manufacturing process of piston seal of the present invention, comprises the following steps:

[0025] 1) Injection molding a hard polyurethane material in a mold to form a first sealing member 1, the first sealing member includes a ring body 11 and a sealing portion 12 connected to the upper part of the ring body. Wherein, the hard polyurethane material includes thermoplastic polyurethane, and its hardness is 75ShA~55ShD.

[0026] The specific operation is as follows:

[0027] Melting: melting the solid raw material of thermoplastic polyureth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com