Combustor special for coal water slurry combustion type cracking furnace

A technology of burners and cracking furnaces, which is applied in the direction of burners, lighting and heating equipment, etc., can solve problems such as irrational use of energy, and achieve the effects of saving manpower, improving economy and operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

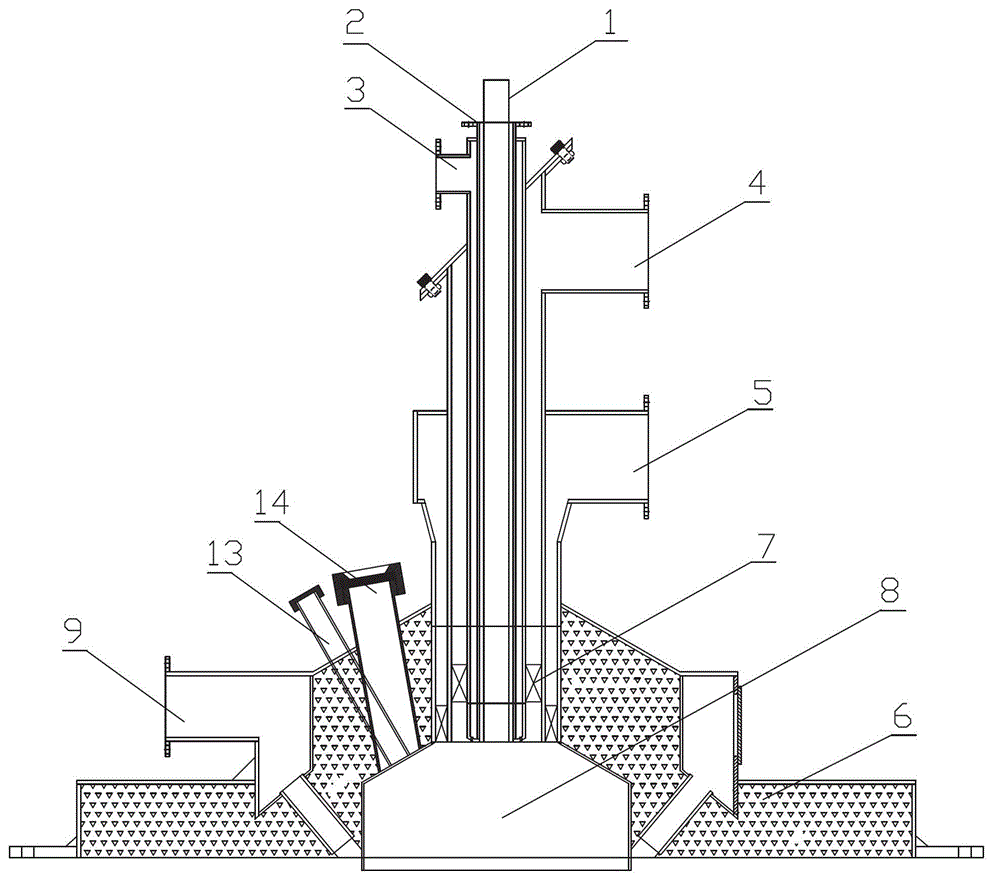

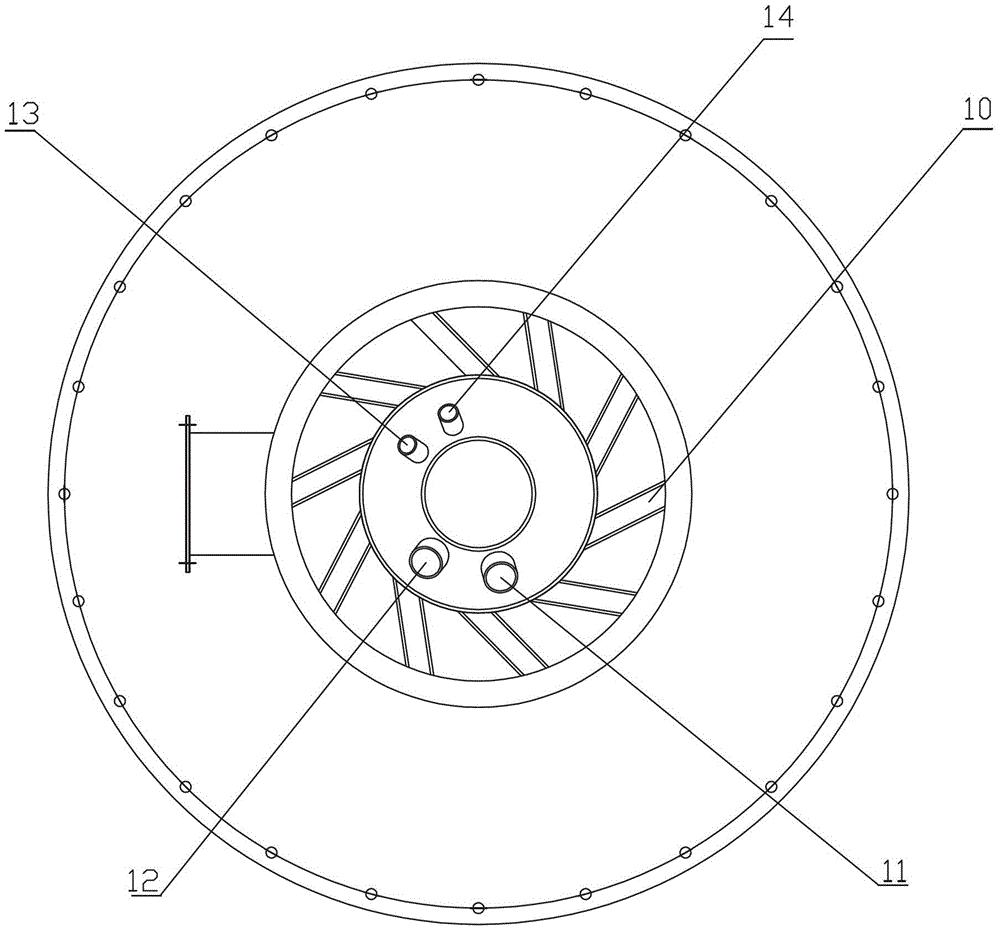

[0021] Below in conjunction with accompanying drawing, embodiment of the present invention is set forth:

[0022] The main body of the special burner for the coal-water slurry type cracking furnace has horizontally extending edges and the center is convex, forming a hollow pre-combustion chamber 8; The slurry spray gun 1 is centered with a protective sleeve 2, a gas jacket 3, a primary air pipe 4 and a gas air sleeve 5 in sequence. The primary air pipe 4 and the gas air sleeve 5 are respectively provided with impeller swirlers 7 to ensure that the primary air and the gas air have a tangential velocity. The secondary air pipe 9 is connected to 10 secondary air outlets 10 provided on the top side of the pre-combustion chamber 8, and each secondary air outlet 10 is evenly spaced on the wall of the pre-combustion chamber 8, and the distance from the corresponding radial centerline Form the same rotation angle between them, so that they are arranged in a clockwise direction; on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com