Optimization design method for oil casing screwed-joint sealing structure

A sealing structure and threaded joint technology, which is applied in the field of drilling, can solve the problems that the sealing structure cannot be guaranteed, and the structural optimization design method has not been adopted, so as to achieve the effect of improving the sealing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

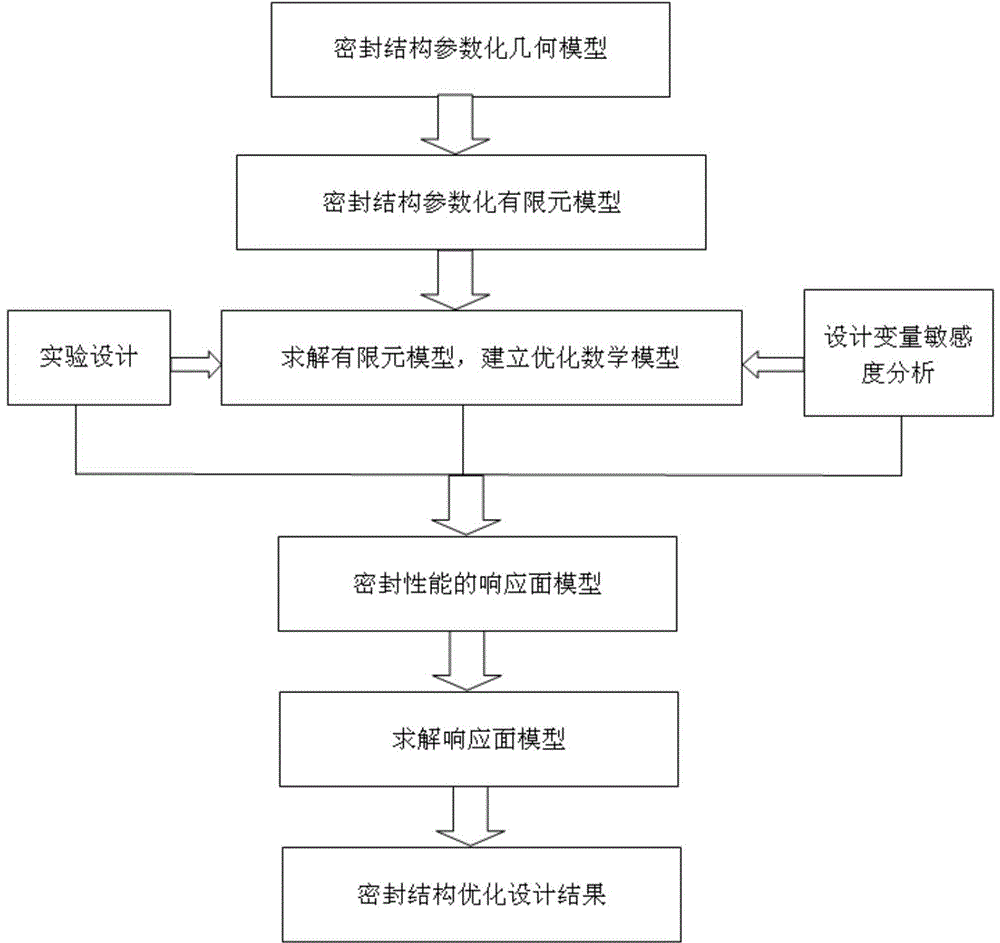

Method used

Image

Examples

Embodiment 1

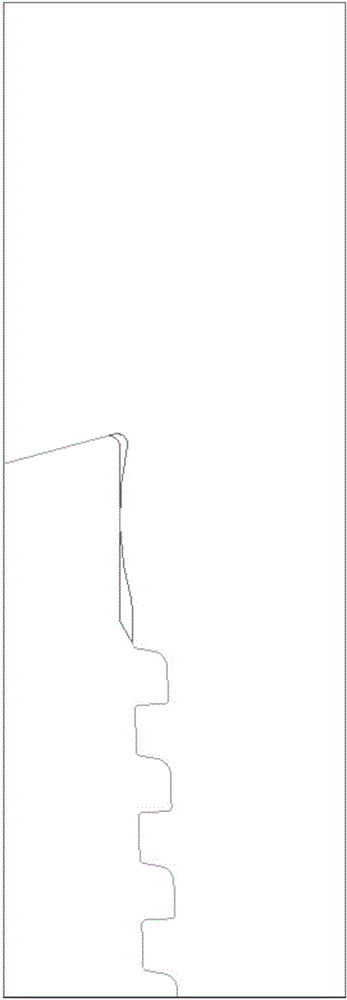

[0048] Taking the threaded joint with the cylindrical / spherical main seal structure as an example, the sealing performance of the threaded casing joint is closely related to its own structural form and the interference of the sealing surface. The contact pressure distribution on the sealing surface directly determines the joint performance. Sealing performance; selection based on the existing cylindrical / spherical main seal structure of common threaded joints And P110 steel grade threaded casing joint, the main seal adopts cylindrical / spherical metal / metal seal structure, the shoulder surface adopts -15°torque shoulder structure, and the thread part adopts API 5B standard partial trapezoidal thread, 5 threads per inch; The hoop length is 255mm, and the geometric model is established by selecting the length of the pipe body to be greater than 3 times the length of the threaded end to eliminate the influence of boundary factors; the casing material model is a dynamic strengtheni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com