Method for pouring crusher composite tooth plate and composite tooth plate

A compound tooth and crusher technology, which is applied to casting molding equipment, casting molds, cores, etc., can solve the problems of easy disassembly, low hardness of the working surface, and poor wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

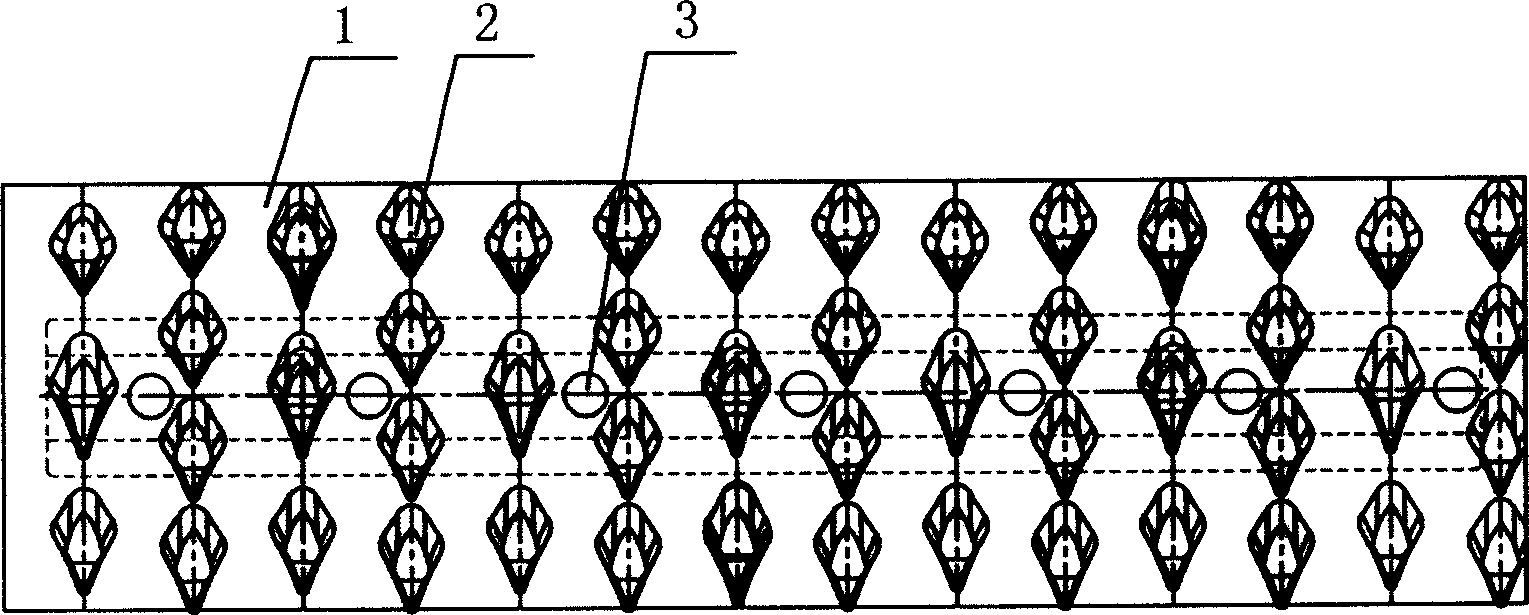

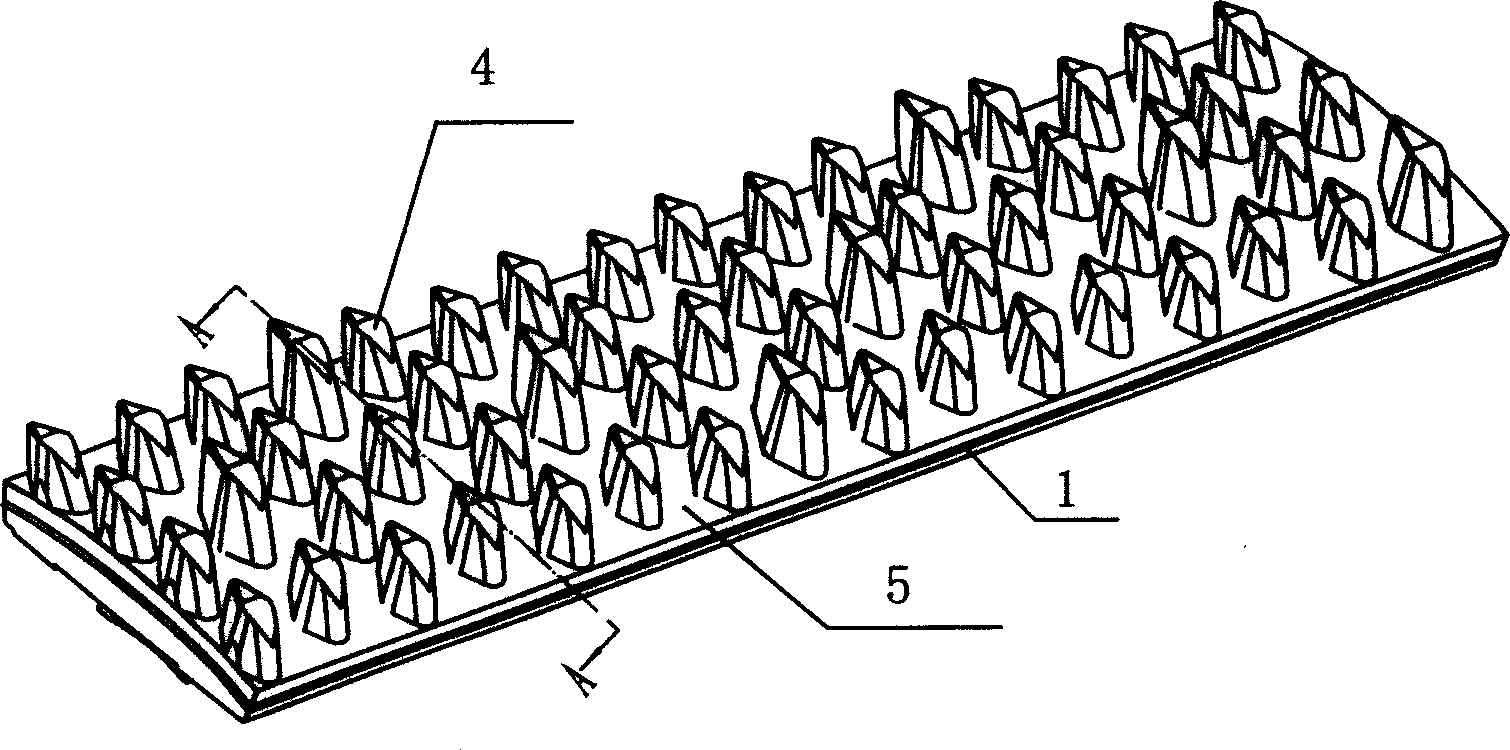

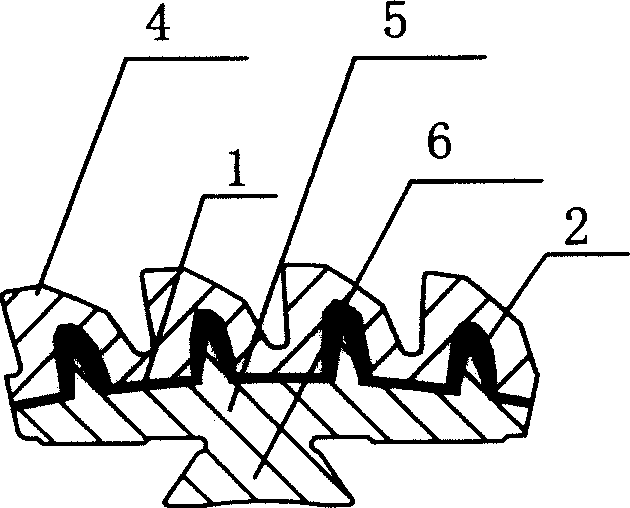

[0013] The present invention will be further described below in conjunction with embodiment (accompanying drawing). refer to figure 1 As shown, the tooth-shaped partition is composed of a partition body 2 and teeth 1, the number of the teeth 1 is the same as the tooth cavity in the mold cavity, and the shape matches. Establish garden-shaped hole 3 on the tooth-shaped dividing plate, and this tooth-shaped dividing plate casts or punches with low carbon steel or medium carbon steel and makes. The method of pouring the composite tooth plate is to design the mold cavity. One side of the mold cavity has a tooth cavity and the other side has a dovetail cavity. In the tooth cavity of the mold cavity, the space between the tooth 1 and the tooth cavity is the poured high chromium alloy cast iron layer. At the same time, high-chromium alloy cast iron solution and carbon steel solution are respectively injected into the two cavities separated by the tooth-shaped partition. At the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com