Process and device for producing methane-rich coal gas by moving bed pressurized coal gasification

A technology of pressurized gasification and moving bed, which is applied in fixed bed gasification, chemical industry, sustainable manufacturing/processing, etc., to achieve the effect of extending the length of time period, improving thermal efficiency and increasing production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

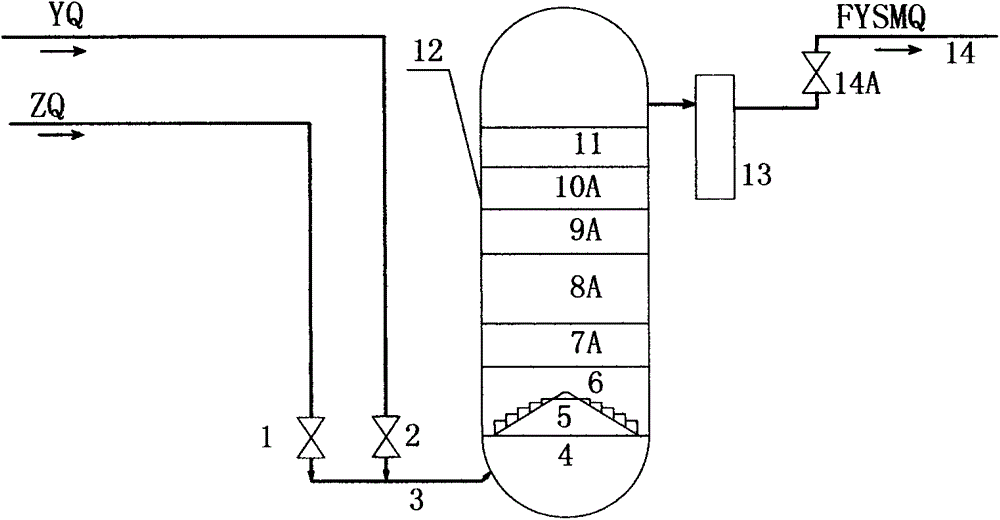

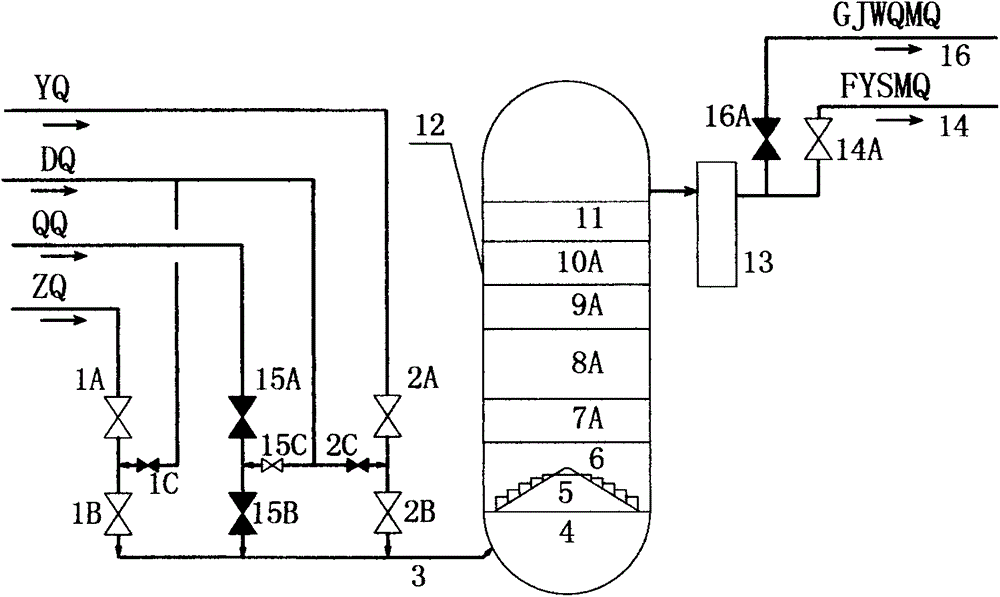

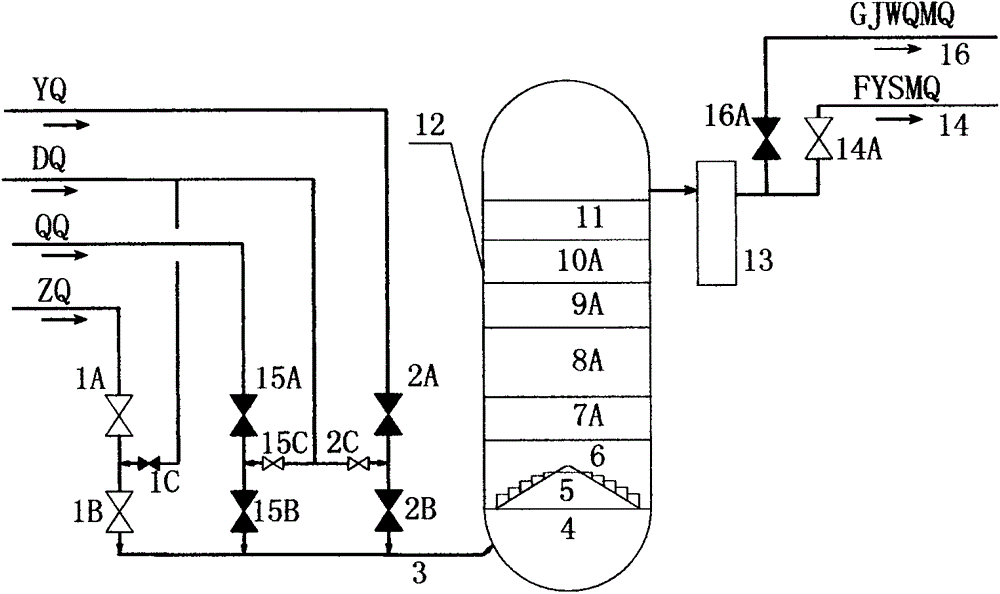

Method used

Image

Examples

Embodiment Construction

[0070] The specific implementation method is described with the methane-enriched coal gas scale device required to produce 1 million Nm3 natural gas per day;

[0071] 4 Φ3.8m pressurized fixed-bed gasifiers, bed height-to-diameter ratio 1.5;

[0072] Gasification pressure 3.0MPa;

[0073] Gasification cycle T=240 seconds, T1=100 seconds, T2=10 seconds, T3=120 seconds, T4=10 seconds;

[0074] Raw coal contains 35% water; calorific value ~ 15MJ / kg; ash melting point T2 ~ 1200°C; lignite, volatile matter 48%; coal particle size 15mm ~ 70mm;

[0075] Oxygen 10000Nm per hour 3 / h (heat consumption 6MJ / Nm 3 ); Steam 50t / h (4MJ / kg); Hydrogen 60000Nm 3 / h(14MJ / Nm 3 ); isolation inert gas 100Nm 3 / h(3MJ / Nm 3 );

[0076] Raw coal consumption per hour is 140t / h, (15MJ / kg);

[0077] The composition and volume of methane-rich gas are shown in the table below:

[0078]

[0079] Total output of oil hydrocarbons per hour: ~8t / h (average calorific value 35MJ / kg);

[0080] The tot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com