Method for preparing high-purity liquefied natural gas from ammonia synthesis tail gas

A liquefied natural gas, high-purity technology, applied in gaseous fuels, organic chemistry, and hydrocarbon production from carbon oxides, etc., can solve problems such as aggravating the greenhouse effect, wasting energy, and polluting the environment, so as to avoid pollution, reduce waste of resources, and avoid The effect of waste of energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

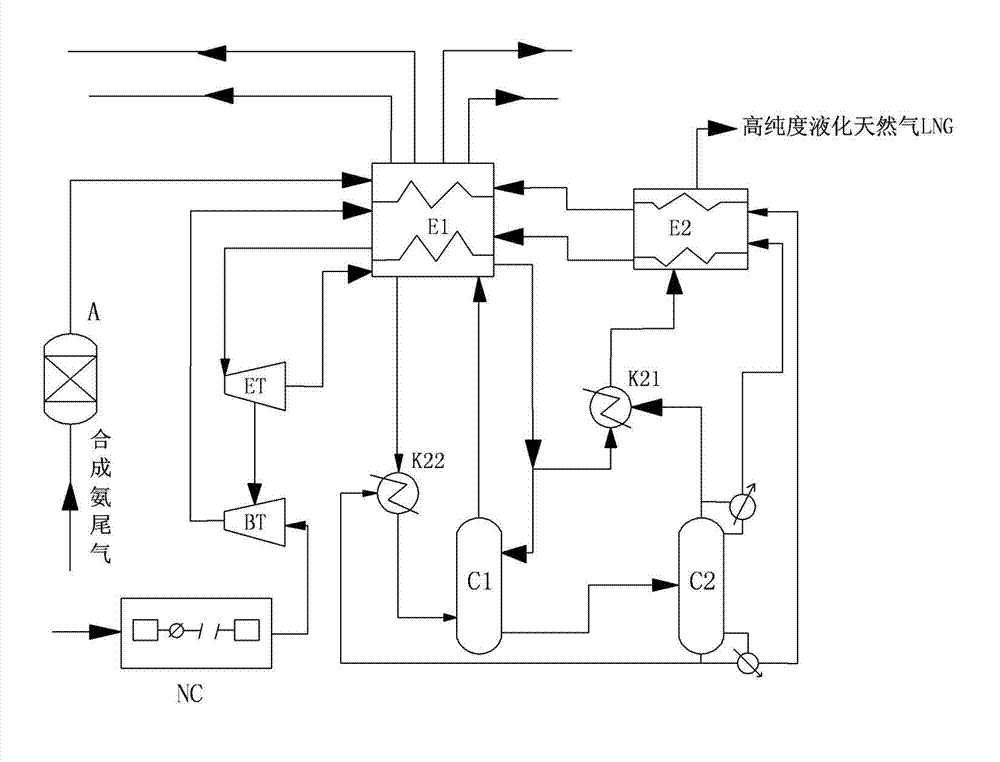

[0027] See attached figure 1 , figure 1 Among them, A is the molecular sieve adsorber, NC is the nitrogen compressor, ET is the expander, BT is the supercharger, E1 is the main heat exchanger, E2 is the subcooler, K22 is the evaporator, K21 is the condenser, and C1 is the degasser. Hydrogen rectification tower, C2 is product rectification tower.

[0028] The present invention utilizes synthetic ammonia tail gas to prepare the method for high-purity liquefied natural gas, and the detailed steps of this method are as follows:

[0029] a. Purification treatment of tail gas: firstly, the tail gas discharged from the ammonia synthesis unit is passed into the molecular sieve adsorber A for adsorption and separation, and the trace amount of water and trace ammonia contained in the tail gas is removed through the adsorption and separation of the molecular sieve adsorber;

[0030] The tail gas discharged from the ammonia synthesis unit mainly contains hydrogen, methane, argon and n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com