A method for hydrogen production by catalytic methane cracking from modified red mud

A technology for red mud to catalyze methane and red mud, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of high cost and complicated production process of methane cracking catalysts and other issues, to achieve high value-added comprehensive utilization, simplify the preparation process, and prolong the life of the catalyst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The red mud used in this example is the Bayer process red mud.

[0033] The first step: modification of red mud:

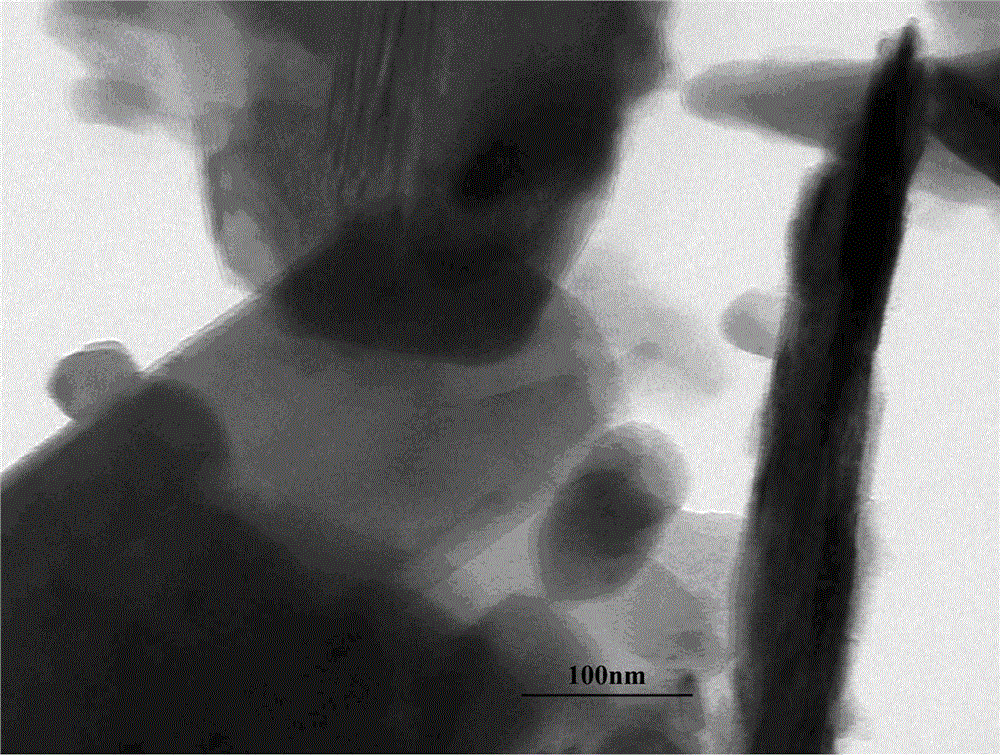

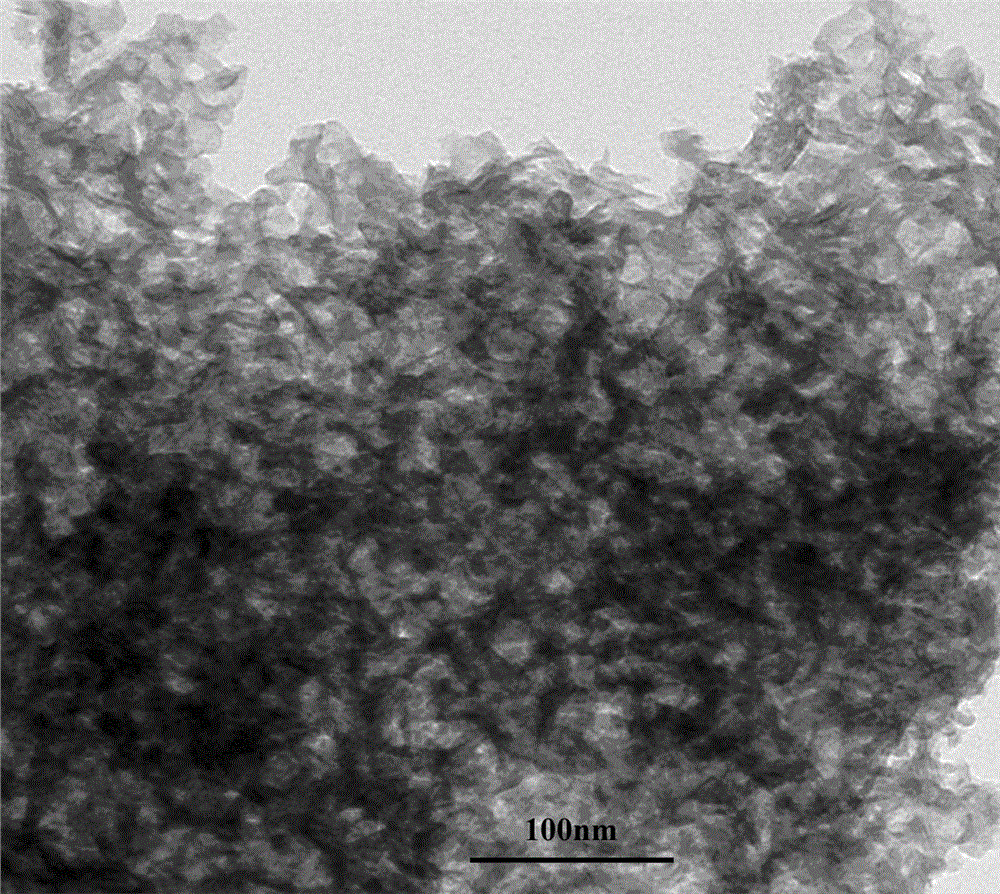

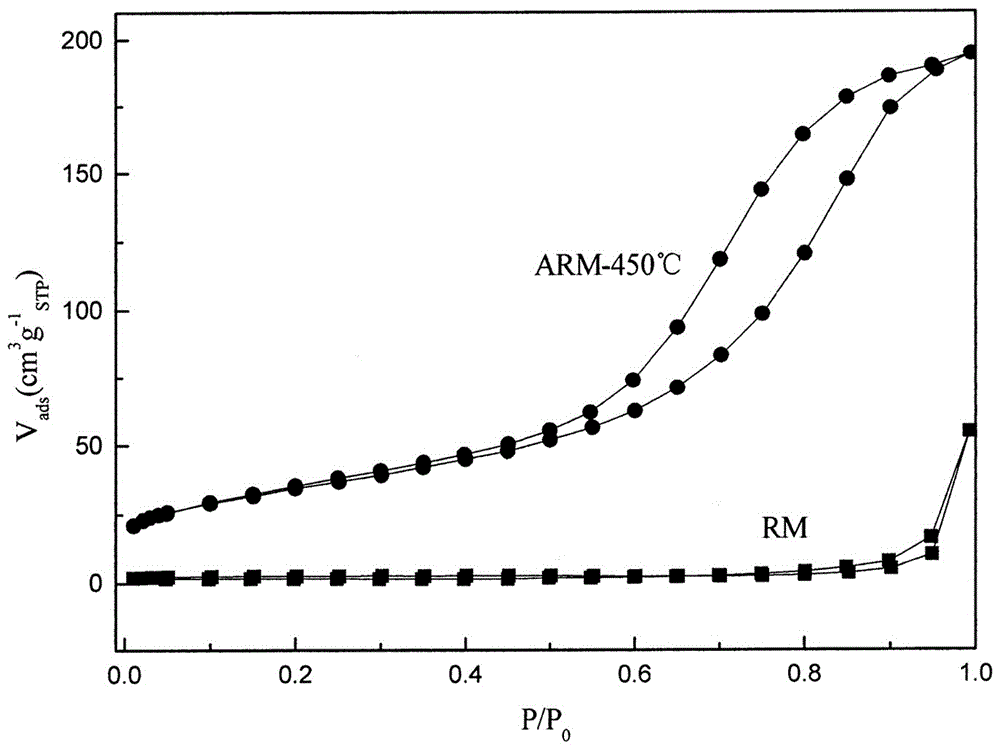

[0034] Dry the red mud at 105°C for 2 hours and then crush it through a 200-mesh sieve. Take 20g of dried and sieved red mud in a 1000ml large container, add 600ml of 2mol / L nitric acid solution to it, and put the container into an ultrasonic cleaner. Take it out after ultrasonication for 5 minutes, put it into a 60°C constant temperature water bath for 4 hours, and stir it with a mechanical stirrer at a constant speed of 90r / min during this period; then vacuum filter the suspension to obtain an orange-yellow transparent solution, and then drip the solution Add ammonia water with a mass fraction of 20% to neutralize the precipitation, stir vigorously with a glass rod, and check the pH value of the solution at the same time. Stop adding ammonia water when the pH is close to about 8; leave the precipitate to stand for aging for 1 hour and then vacuum filter i...

Embodiment 2

[0044] The red mud used in this example is the Bayer process red mud.

[0045] The first step: modification of red mud:

[0046] Dry the red mud at 110°C for 2 hours and then crush it through a 200-mesh sieve. Take 20g of dried and sieved red mud in a 1000ml large container, add 500ml of 2mol / L nitric acid solution to it, and put the container into an ultrasonic cleaner. Take it out after ultrasonication for 5 minutes, put it in a 65°C constant temperature water bath for 4 hours, and stir it with a mechanical stirrer at a constant speed of 90r / min during this period; then vacuum filter the suspension to obtain an orange-yellow transparent solution. Add ammonia water with a mass fraction of 30% to neutralize the precipitation and stir vigorously with a glass rod while checking the pH value of the solution. Stop adding ammonia water when the pH is close to about 8; leave the precipitate to age for 1.5 hours and then vacuum filter it. Wash the precipitate with deionized water un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com