Full-temperature-range simulated rotating moving bed pressure swing adsorption process for separating and extracting H2/CO from synthesis gas

A pressure swing adsorption and synthesis gas technology, applied in hydrogen separation, separation method, dispersed particle separation, etc., can solve the problems of decreased operational stability, increased equipment investment, high cost of introduction, etc., and achieve the goal of reducing manufacturing complexity and cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

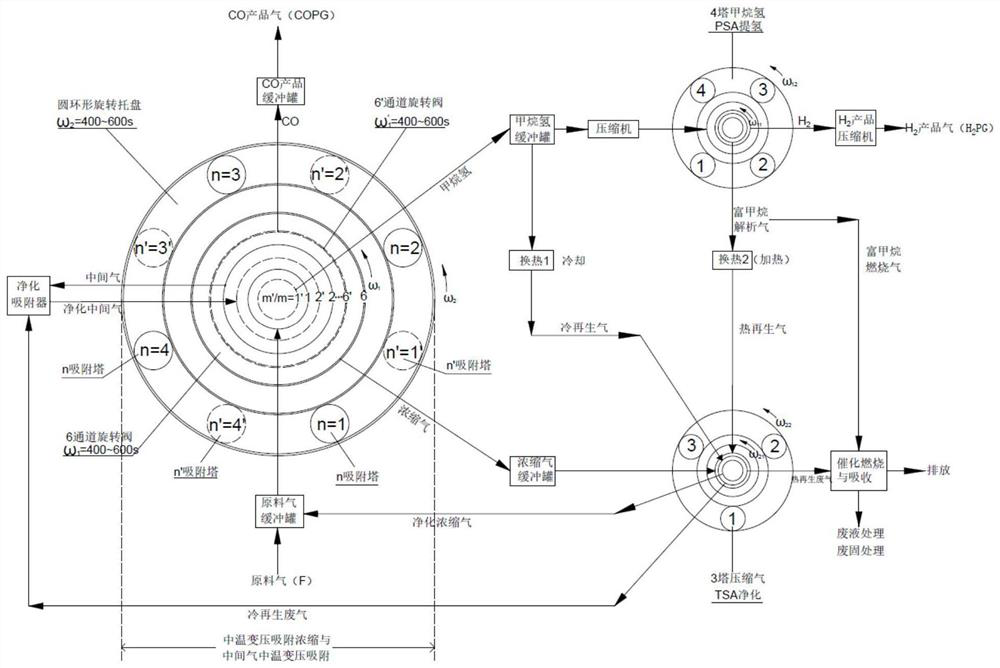

[0039] like figure 1 As shown, the full temperature range of the synthesis gas separation and extraction of H2 / CO simulates the rotary moving bed pressure swing adsorption process, wherein the full temperature range simulates the rotary moving bed pressure swing adsorption system, including a 4 (n=4) axial flow fixed A multi-tower medium-temperature pressure swing adsorption concentration system (including a driving mechanism) of a bed adsorption tower, a multi-tower medium-temperature intermediate gas pressure swing adsorption system (including a driving mechanism) of a 4 (n'=4) axial flow fixed-bed adsorption tower, A 4-column methane hydrogen pressure swing adsorption hydrogen extraction system (including driving mechanism), a 3-column concentrated gas temperature swing adsorption purification system (including driving mechanism), CO product gas / H 2 Product gas / feed gas / methane hydrogen / concentrated gas buffer tank, heat exchange 1 (cooling) / heat exchange 2 (heating) for he...

Embodiment 2

[0041] like figure 1 As shown, on the basis of Example 1, the upper and lower two m (m=6) and m' (m'=6) channel rotary valves in the medium temperature PSA concentration system and the medium temperature intermediate gas PSA system and The rotation direction of the annular rotating tray and its rotation speed (ω 1 / ω 1 ’ and ω 2 ), is the same direction synchronization, that is, the same direction rotation in the counterclockwise direction, and, ω 1 =ω 1 ’=ω 2 =400~600s, at the same time, the rotation direction of the 7-channel rotary valve in the 4-column methane hydrogen PSA hydrogen extraction system and its corresponding annular rotary tray and its rotation speed (ω 11 with ω 12 ) is co-synchronization, that is, co-rotation in the counterclockwise direction, and ω 11 =ω 12 =300~400s, the rotation direction of the 6-channel rotary valve in the 3-column concentrated gas TSA purification system and its corresponding annular rotating tray and its rotation speed (ω 21 ...

Embodiment 3

[0043] like figure 1 As shown, on the basis of Example 1, the m (m=6) channel rotary valve ( figure 1 The middle solid line indicates) a certain channel (such as m=1) and the built-in pipeline connected to the annular rotating tray enter the n adsorption tower ( figure 1 The middle solid line represents the n=1 adsorption tower in the middle temperature PSA concentration process, and the cycle operation steps of adsorption and desorption include adsorption (A)-equal pressure drop (ED) / sequential release (PP)-reverse release (D) ) / flushing (P) - equal pressure rise (ER) - final charge (FR), each adsorption tower (n=1, 2, 3 and 4) of n adsorption towers undergoes the cycle operation steps of adsorption and desorption, The cycle operation steps to realize adsorption and desorption are to alternately flow through each channel of the m-channel rotary valve during the rotation process of the feed gas (F), the intermediate gas (IG), the primary pressure drop gas (E1D) / the primary pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com