Novel semi-automatic feed mechanism of threading machine

A technology of a feed mechanism and a threading machine, which is applied to the field of mechanical cutting tools, can solve the problems of unstable thread processing quality, bald thread tooth shape, high labor intensity, etc., and achieves compact structure, high processing efficiency, and easy on-site processing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings.

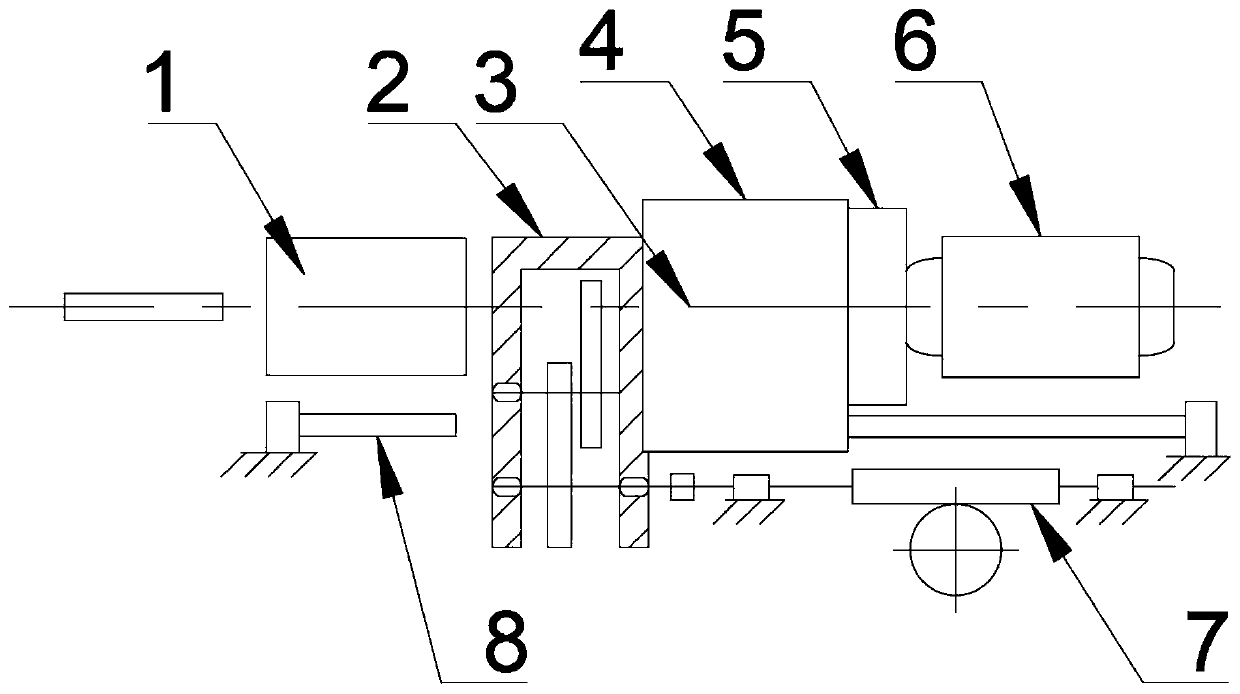

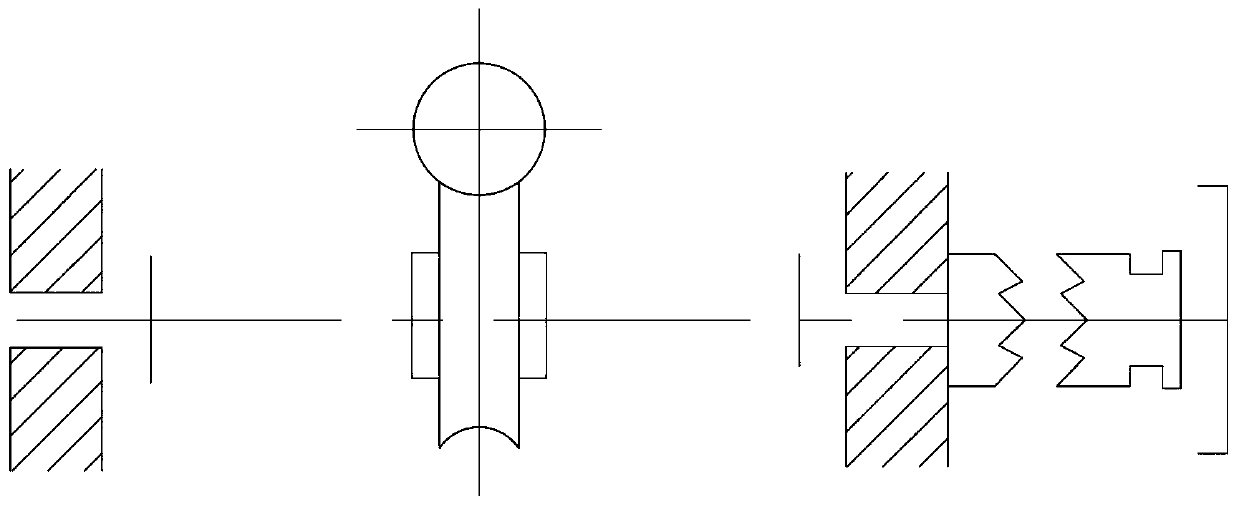

[0014] When the present invention is implemented in practice, a novel semi-automatic feeding mechanism of threading machine includes thread cutting device 1, gear box 2, main shaft 3, sliding base 4, reducer 5, motor 6, worm pair 7, circular guide rail 8. The thread cutting device 1 is a cylindrical tool support frame with four movable die-type tools installed, and one end of the thread cutting device 1 is connected to the main shaft 3 through a coupling, and the gear box 2 is arranged on the thread between the cutting device 1 and the sliding base 4, and the gear box 2 is fixed on one end of the sliding base 4, the main shaft 3 is the output shaft of the driven wheel in the gear box 2, and is fixedly connected with the driven wheel through a keyway structure. The sliding machine base 4 is located at one end of the gear box 2, and the bottom end of the slidin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com