Method for extracting valuable metal from submarine metallic ore

A technology of valuable metals and metal mines, which is applied in the field of metallurgy, can solve the problems of high raw material transportation costs, large carbon emissions, and high energy consumption, and achieve the goal of saving raw material transportation costs, zero carbon emissions, and low energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

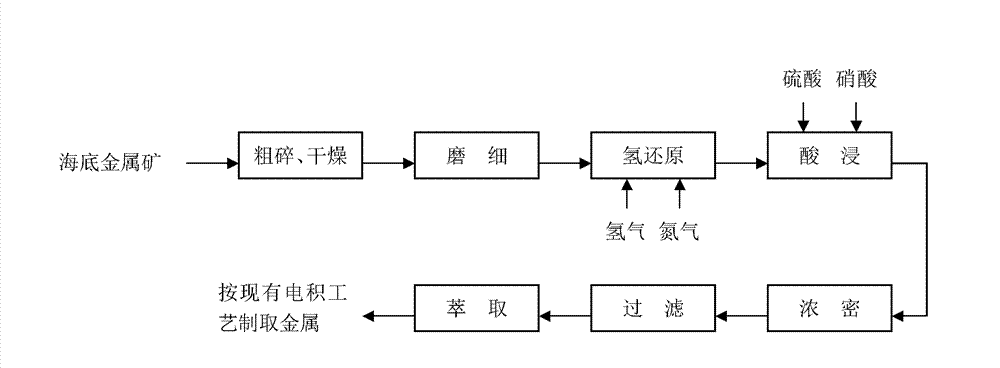

[0024] a kind of like figure 1 Shown the present invention extracts the method for valuable metal from seabed metal ore, comprises the following steps:

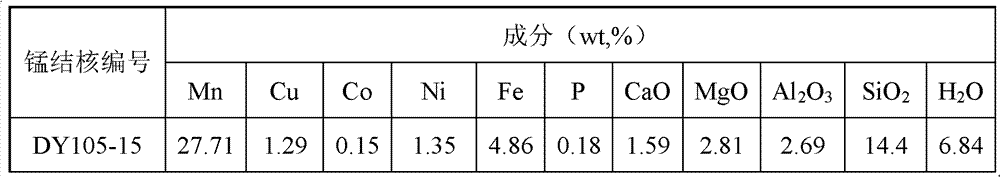

[0025] (1) Coarse crushing and drying: coarsely crush oceanic polymetallic nodules (manganese nodules) to less than 30mm, and dry until the moisture content is <18%;

[0026] (2) Grinding: take 45g of dried polymetallic nodules and grind them to below 0.5mm, wherein particles below 0.1mm account for 60%;

[0027] (3) Hydrogen reduction: Add polymetallic nodule powder into a tubular resistance furnace (either horizontal fixed bed or gas-solid fluidized bed, the same below), and when heated to 300°C, N 2 , H was introduced at 390°C 2 And maintain the reduction at 390°C for 60min. N 2 and H 2 Ratio 1:1 (volume ratio), N 2 and H 2 The flow rate is controlled at 15m respectively 3 / t material min; after reduction in N 2 Cool down to below 150°C under protection and release from the furnace to obtain 33g of discharged mate...

Embodiment 2

[0031] A method for extracting valuable metals from seabed metal ore of the present invention comprises the following steps:

[0032] (1) Coarse crushing and drying: coarsely crush oceanic polymetallic nodules (manganese nodules) to less than 30mm, and dry until the moisture content is <18%;

[0033] (2) Grinding: take 45g of dried polymetallic nodules and grind them to below 0.5mm, wherein particles below 0.1mm account for 60%;

[0034] (3) Hydrogen reduction: Add the polymetallic nodule powder into the tubular resistance furnace, and feed N to 300°C. 2 , H was introduced at 450°C 2 and maintained at 450°C for 30min, N 2 and H 2 Ratio 1:4 (volume ratio), N 2 and H 2 The flow rate is controlled at 10m respectively 3 / t material min and 45m 3 / t material min, after reduction in N2 Cool down to below 150°C under protection and release from the furnace to obtain 32.7g of discharged material;

[0035] (4) Acid leaching: Take 25g of the reduced discharge and add it to the s...

Embodiment 3

[0041] A method for extracting valuable metals from seabed metal ore of the present invention comprises the following steps:

[0042] (1) Coarse crushing and drying: coarsely crush oceanic polymetallic nodules (manganese nodules) to less than 30mm, and dry until the moisture content is <15%;

[0043] (2) Grinding: take 45g of dried polymetallic nodules and grind them to below 0.5mm, wherein particles below 0.1mm account for 60%;

[0044] (3) Hydrogen reduction: Add the polymetallic nodule powder into the tubular resistance furnace, and feed N to 300°C. 2 , H was introduced at 420°C 2 and maintained at 420°C for 30min, N 2 and H 2 Ratio 2:1 (volume ratio), N 2 and H 2 The flow rate is controlled at 10m respectively 3 / t material min and 5m 3 / t material min; after reduction in N 2 Cool down to below 150°C under protection and release from the furnace to obtain 32.8g of discharged material;

[0045] (4) Acid leaching: Take 25g of the reduced material and add it to the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com