Vertical transport device for construction material between building block layers

A vertical transportation and material technology, applied in transportation and packaging, cargo handling equipment, ships, etc., can solve the problems of low construction efficiency, high construction cost, high labor intensity of workers, etc., to improve work efficiency, easy operation, and reduce construction injuries. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

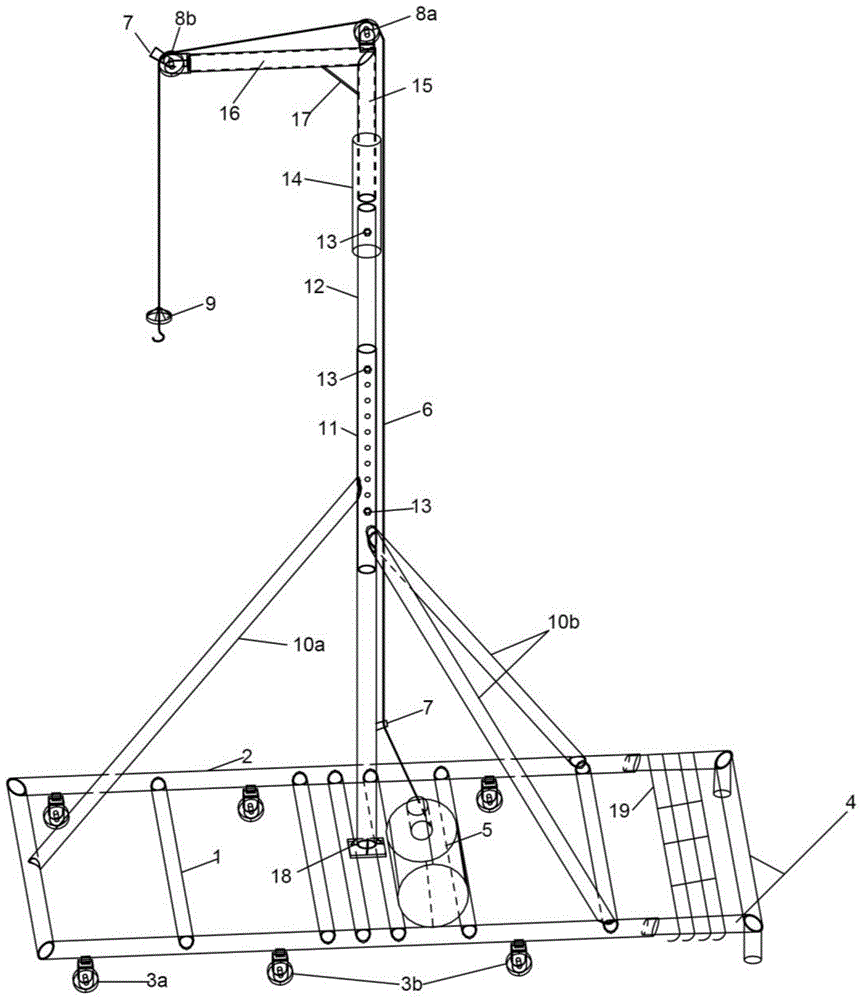

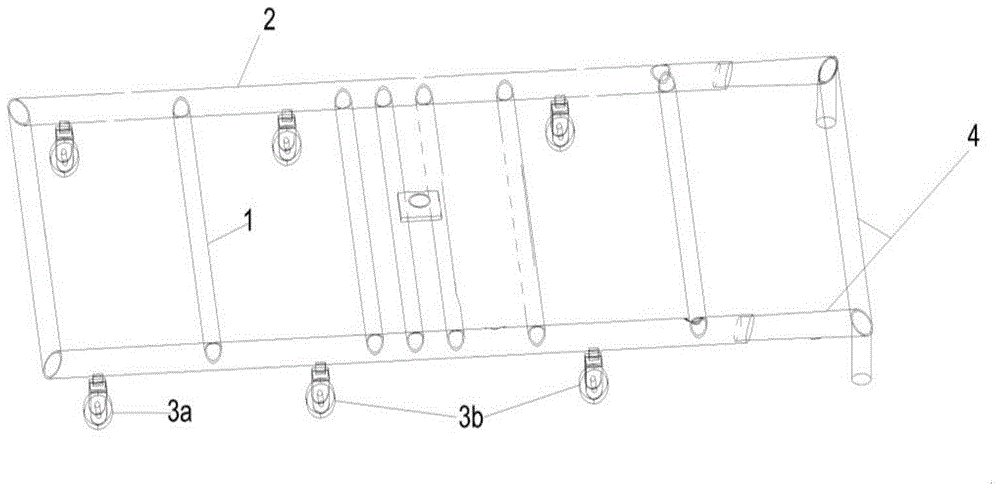

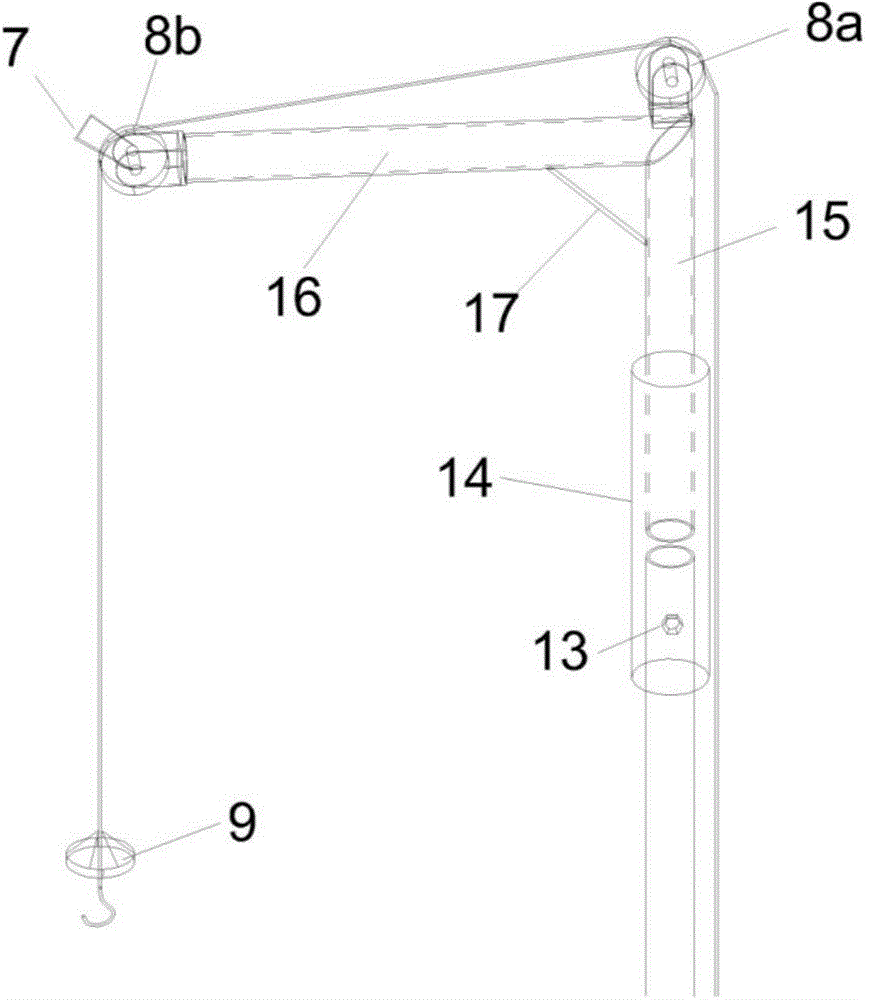

[0026] Such as figure 1 As shown, a vertical transportation device for construction materials between block layers includes a horizontal base, a main mast 11, a telescopic mast 12, a rotary sleeve 14, a rotary mast 15, a horizontal boom 16, a first fixed pulley 8a and a hoist 5, The bottom surface of the horizontal base is equipped with movable rollers, and the main mast 11 is vertically fixed on the horizontal base. The side wall is provided with threaded holes, the upper end of the side wall of the telescopic mast 12, the lower end of the side wall of the telescopic mast 12 and the lower end of the side wall of the rotary sleeve 14 are all provided with threaded holes, and the threaded holes at the lower end of the side wall of the telescopic mast 12 are aligned with any threaded hole at the upper end of the main mast 11 Connected by fixing bolt 13, the threaded hole at the upper end of the side wall of the telescopic mast 12 is aligned with the threaded hole at the lower en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com