A Dividable Combined Turning, Milling and Boring Machine

A combined and indexing technology, which is applied to other manufacturing equipment/tools, metal processing machinery parts, precision positioning equipment, etc., can solve the problems of difficult to guarantee accuracy, high work intensity, high manufacturing cost, etc., and achieve processing accuracy assurance and improvement Production efficiency and the effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

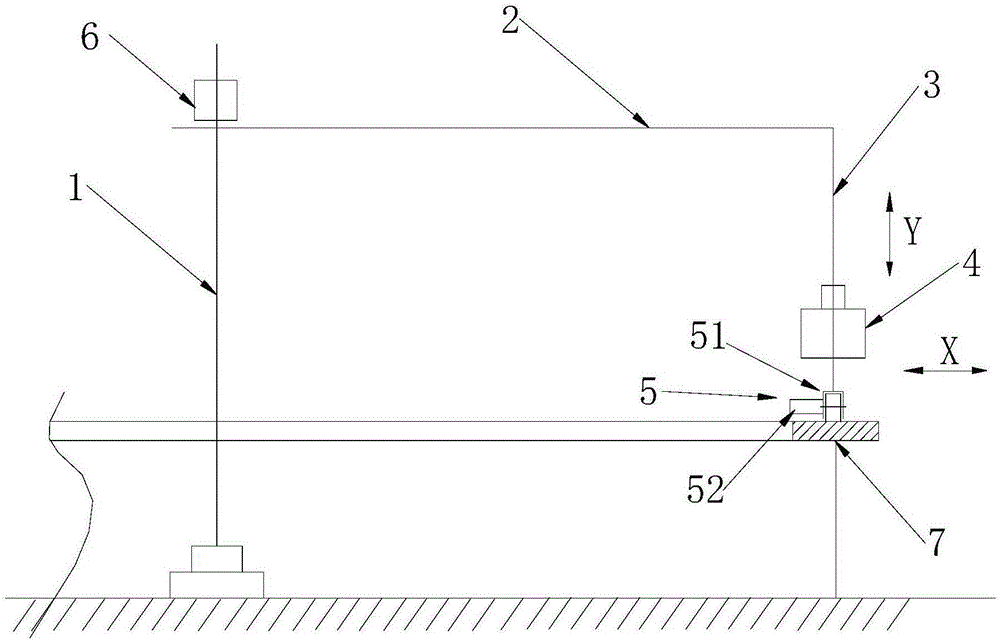

[0030] Such as Figure 1~3 As shown, the indexable combined turning milling boring machine of this embodiment includes a positioning shaft 1, a beam body, a power head 4, a traction device 5, an indexing detection device 6 and an indexing control device (not shown).

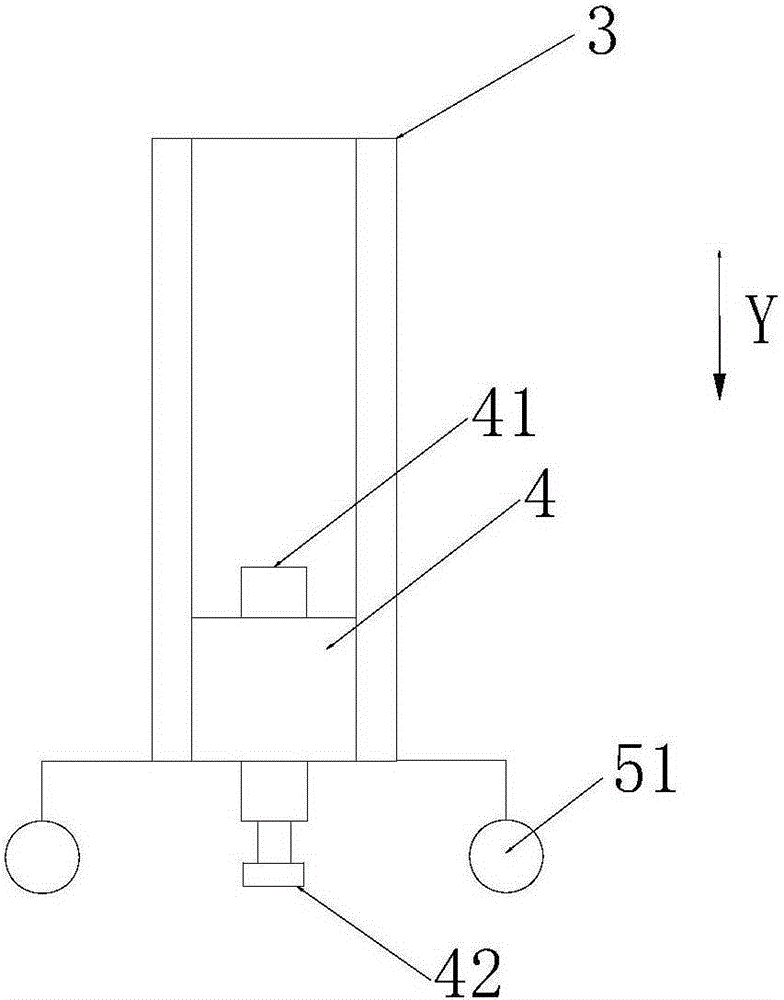

[0031] The workpiece 7 to be processed is a cylindrical body with a ring-shaped end face and a diameter of 13 meters. The positioning axis 1 is fixed on the central axis of the workpiece 7 to be processed. The beam body includes a beam 2 and a longitudinal beam 3. The beam 2 is fixed on the positioning axis 1 in a horizontally rotatable manner. The transverse length of the beam 2 can be adjusted. The longitudinal beam 3 and the beam 2 The end of the detachably connected and parallel to the positioning shaft 1, the power head 4 is slidably arranged on the longitudinal beam 3, which includes a main driver 41, a cutting head 42 and a power box (not shown), the power head 4 can be It moves in two directions, horizon...

Embodiment 2

[0037] Such as Figure 4~6 As shown, the indexable combined turning milling boring machine of the present embodiment includes a positioning shaft 1, a crossbeam 2, a longitudinal beam 3, a power head 4, a traction device 5, an indexing detection device 6, and an indexing control device (not shown). ), indexing fixture 10 and ring guide rail 8.

[0038] The structure, connection mode and function of the positioning shaft 1, the beam 2, the longitudinal beam 3, the traction device 5, the index detection device 6 and the index control device are the same as those in the first embodiment.

[0039]The power head 4 is arranged on the middle part of the longitudinal beam 3, the power head 4 includes a main drive 41, a cutting head 42 and a power box (not shown), and the cutting head 42 can be horizontal (that is, the X direction shown in the figure) and vertical (that is, the Y direction shown in the figure) to move in two directions. In this embodiment, the main driver 41 is the m...

Embodiment 3

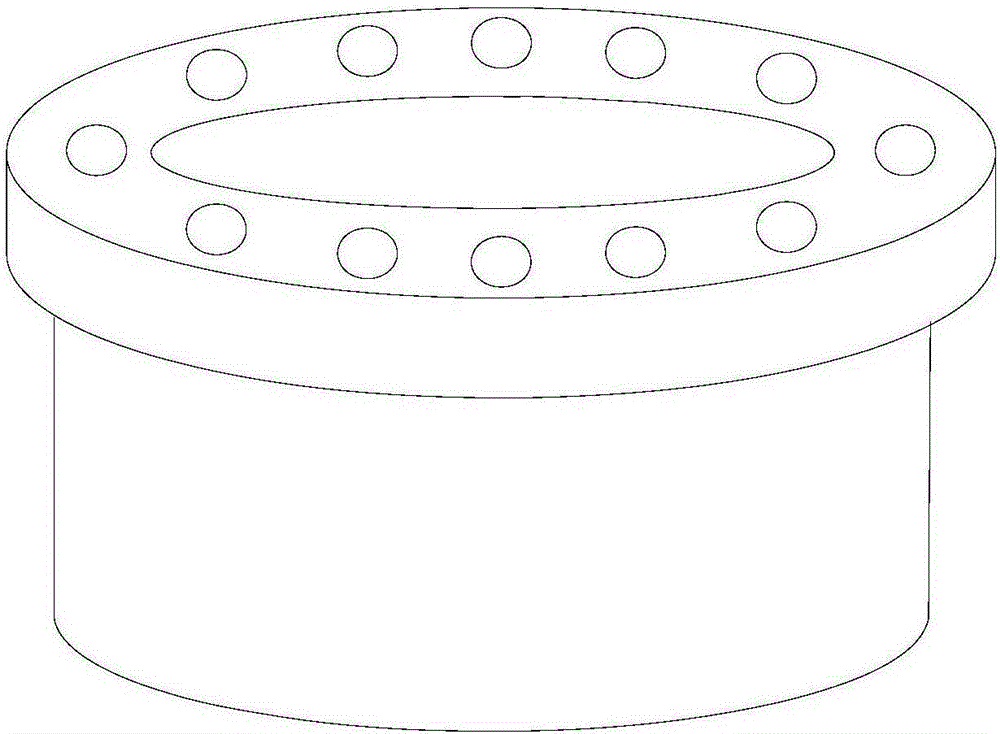

[0044] Such as Figure 7-8 As shown, the indexable combined turning milling boring machine includes a positioning axis 1, a beam 2, a longitudinal beam 3, a power head 4, a roller 51, an indexing detection device 6, an indexing control device (not shown), and a circular guide rail 8 And two fixed brackets 9.

[0045] The structure, connection mode and function of the positioning shaft 1, the beam 2, the longitudinal beam 3 and the index detection device 6 are the same as those in the second embodiment. The workpiece 7 to be processed in this embodiment is a stator frame, and the annular guide rail 8 is located inside the workpiece 7 to be processed.

[0046] In this embodiment, no traction device is provided, and the positioning shaft 1 drives the rotation of the beam 2 and the longitudinal beam 3 . The rollers 51 are directly arranged on the bottom of the longitudinal beam 3 .

[0047] The power head 4 is arranged in the middle of the longitudinal beam 3, and its structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com