Construction process of metal reinforced frame bamboo plywood fabricated formwork

A technology of metal reinforcement and combined formwork, applied in construction, building structure, construction material processing, etc., can solve the problems of heavy steel formwork, small formwork area, large investment, etc., to achieve light weight, large area, reduce effect of investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

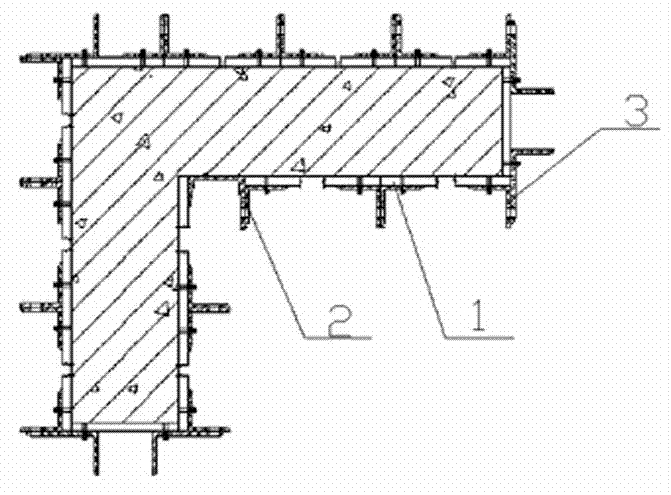

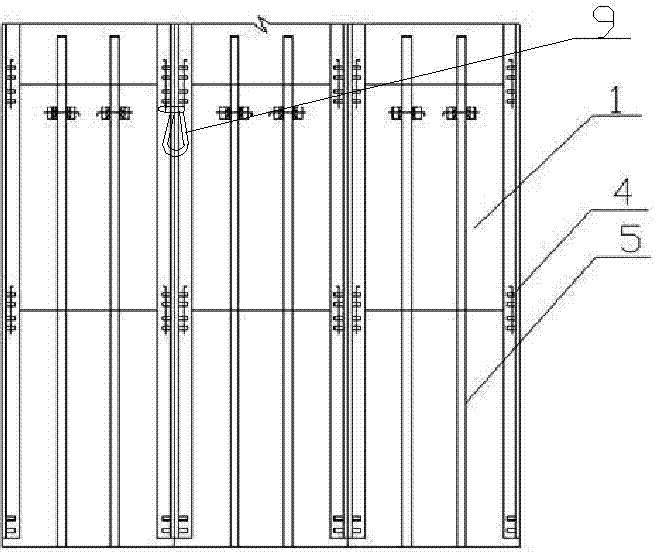

[0024] The construction technology of bamboo plywood combined formwork with metal reinforced frame includes the following steps:

[0025] a. Carry out mold matching and processing according to the template design drawings;

[0026] b. Concrete pouring and pounding on the platform to control the elevation and flatness;

[0027] c. According to the drawings, play the position line of the wall and the position line of the door and window openings, weld the limit steel bars of the formwork, place the pre-buried holes and embedded parts, and brush two release agents on the surface of the formwork;

[0028] d. Install and fix the wall panel formwork on one side, install the corner formwork from the corner of the wall, and then assemble it in a direction perpendicular to each other;

[0029] e. Place through-wall bolts and plastic sleeves;

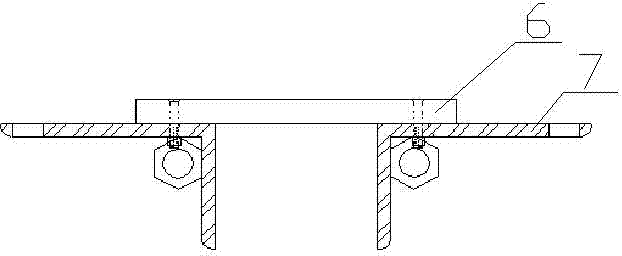

[0030] f. Install the wall plate formwork on the other side, and tighten the wall bolts so that the formwork with holes on both sides is place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com