A Simple Supporting Method for Concrete Cylindrical Formwork

A support method and concrete technology, which are applied in the fields of formwork/formwork/work frame, on-site preparation of building components, construction, etc., can solve the problems of high strength and rigidity, difficult to guarantee the effect, and low strength of wood, and achieve simplification. The effect of supporting process, light weight and easy on-site machining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

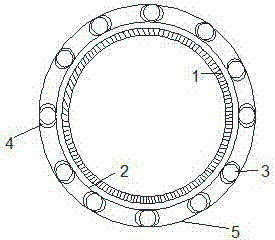

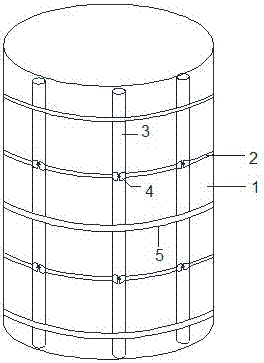

[0030] A simple support method for a concrete cylindrical formwork, comprising an inner flat iron hoop 2, a supporting steel pipe 3 and an outer flat iron hoop 5, characterized in that it also includes a bamboo-wood formwork (1), and the bamboo-wood formwork 1 is more than two A cylindrical structure formed by splicing composite bamboo glue formwork; the inner flat iron hoop 2 is fixedly installed on the outer periphery of the bamboo and wood formwork 1, the supporting steel pipe 3 is fixed on the flat iron hoop 2 through the steel pipe fastener 4, and the outer sleeve of the supporting steel pipe 3 Outer flat iron hoop 5 is arranged.

[0031] In a further technical solution, the bamboo-wood template 1 is two semicircular composite bamboo-glue templates.

[0032] In a further technical solution, the bamboo-wood formwork 1 is a single-layer bamboo sheet radially bonded structure.

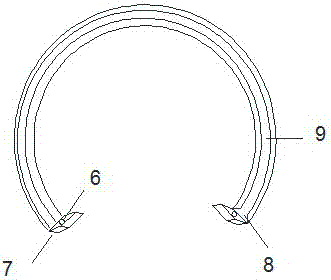

[0033] In a further technical solution, the inner flat iron hoop 2 is an arc-shaped iron hoop pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com