Aerated concrete block masonry composite wall reinforced with embedded reinforcements and borehole core columns

A kind of aerated concrete, embedded technology, applied in the direction of wall, building material processing, building components, etc., to achieve good promotion and application prospects, to achieve the effect of wall insulation and load-bearing integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

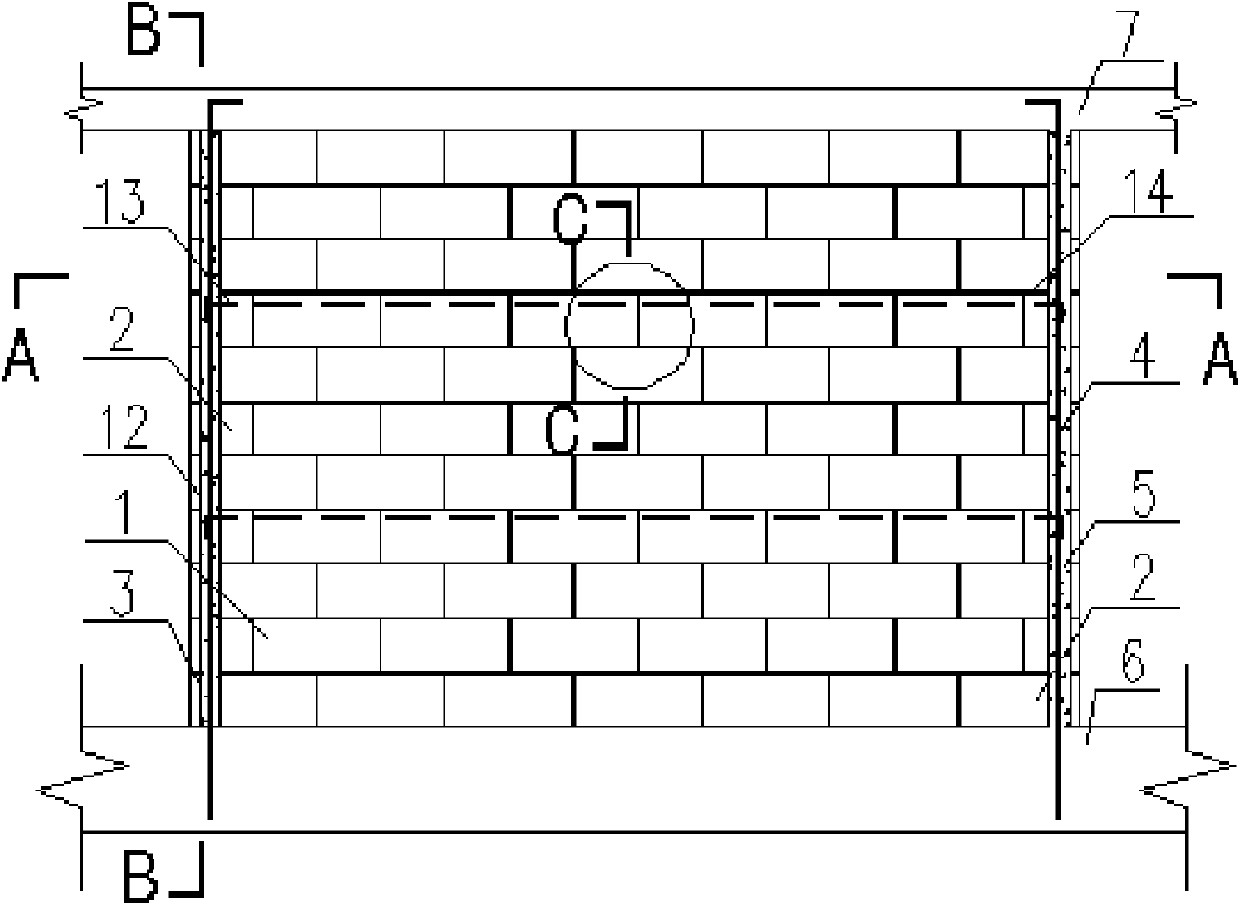

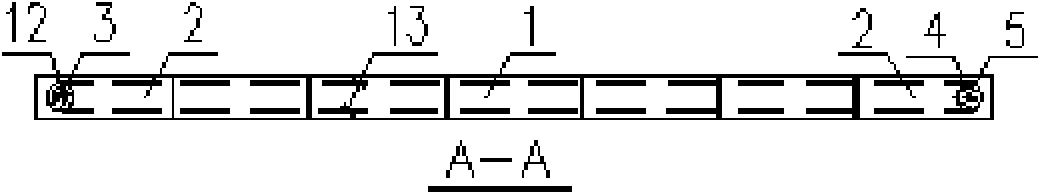

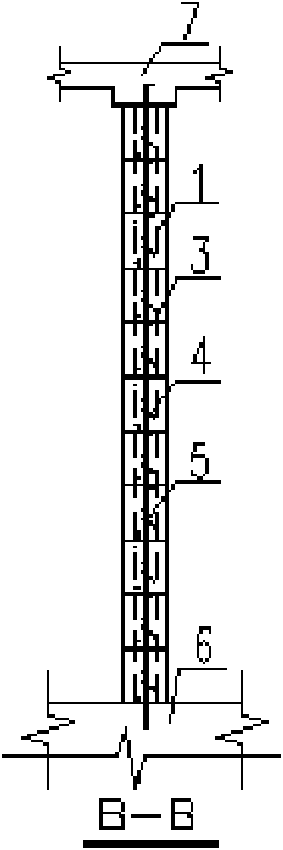

[0031] Figure 1 ~ Figure 4 It is a wall without openings, and its main part 1 is made of aerated concrete blocks and mortar. Before masonry, all the outermost blocks 2 on the left and right sides of the wall are drilled into cylindrical holes 3. The holes of the block penetrate up and down, and there are long longitudinal steel bars 4 inside. The steel bars extend from the reinforced concrete cast-in-place beam slab (or foundation) 6 at the lower end of the wall of the floor and extend into the reinforced concrete cast-in-place beam at the upper end of the wall Inside the plate 7, the upper and lower ends are reliably anchored. In the construction, when the wall is built to the place where the built-in reinforcement is to be installed, the upper surface of the block is drilled through the long groove 11 along the length of the wall, and the horizontal steel bar 13 is placed inside, and the steel bar The two ends extend into the holes provided for the pouring core column 12 at ...

Embodiment 2

[0033] Figure 5 ~ Figure 8 It is a wall with a door opening. The main part 1 of the wall is made of aerated concrete blocks and mortar. The door opening separates the wall into left and right wall limbs. Core columns 12 are provided at both ends of the wall and both sides of the door opening. Before masonry, drill cylindrical holes 3 on all the outermost blocks 2 on the left and right sides of the wall, the blocks 9 on both sides of the door opening and the corresponding positions of the two ends of the door lintel 8 and the corresponding positions of the blocks 10 above. When masonry, the hole of the block is penetrated up and down, and there are long longitudinal steel bars 4 inside. The steel bars extend from the reinforced concrete cast-in-place beam slab (or foundation) 6 at the lower end of the wall of the floor and extend into the upper end of the wall. Inside the cast-in-place concrete beam slab 7, the upper and lower ends are reliably anchored. The left and right lim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com