Forging process and equipment for high-temperature-resistant and high-pressure-resistant stainless steel ring

A stainless steel ring and high-pressure-resistant technology, applied in the field of forging, can solve the problems of reduced production efficiency, fast cooling speed, and increased energy consumption, and achieve the effects of reducing the number of reheating times, delaying cooling speed, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

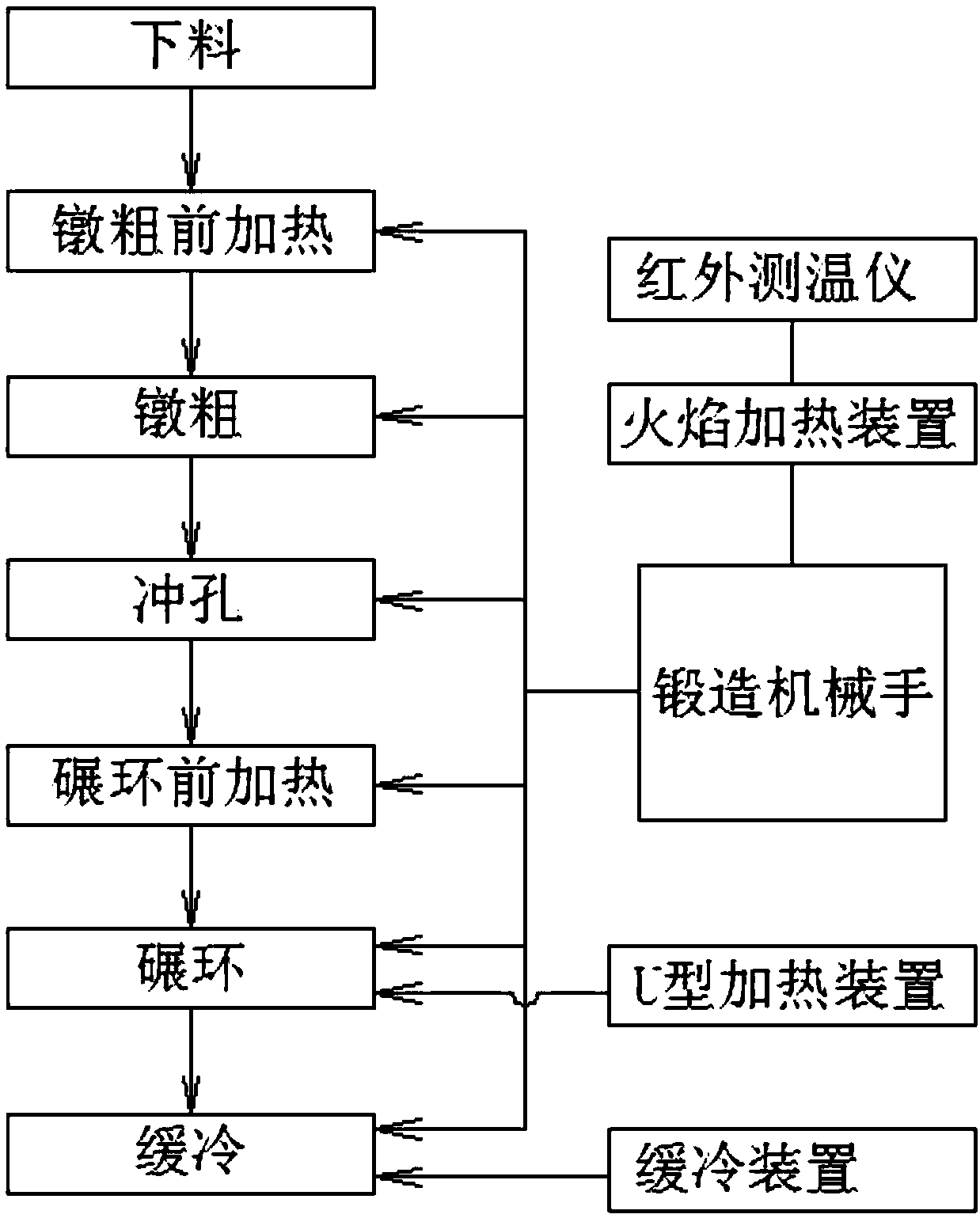

[0051] Such as Figures 1 to 5 Shown is an embodiment of the forging process of a high temperature and high pressure resistant stainless steel ring of the present invention, including the following process steps:

[0052] Step 10, blanking: sawing the steel ingot as a blank for forging;

[0053] Step 20, heating before upsetting: using a heating furnace to heat the billet before upsetting;

[0054] Step 30, Upsetting: Using the forging manipulator 21, the billet is taken out from the heating furnace and transferred to a press, and the billet is rounded and upset by the press;

[0055] Step 40, punching: punching with a punch on the press after upsetting;

[0056] Step 50, heating before ring rolling: using forging manipulator 21 to transfer the blank to the heating furnace, turning on the heating furnace, and heating the blank before ring rolling;

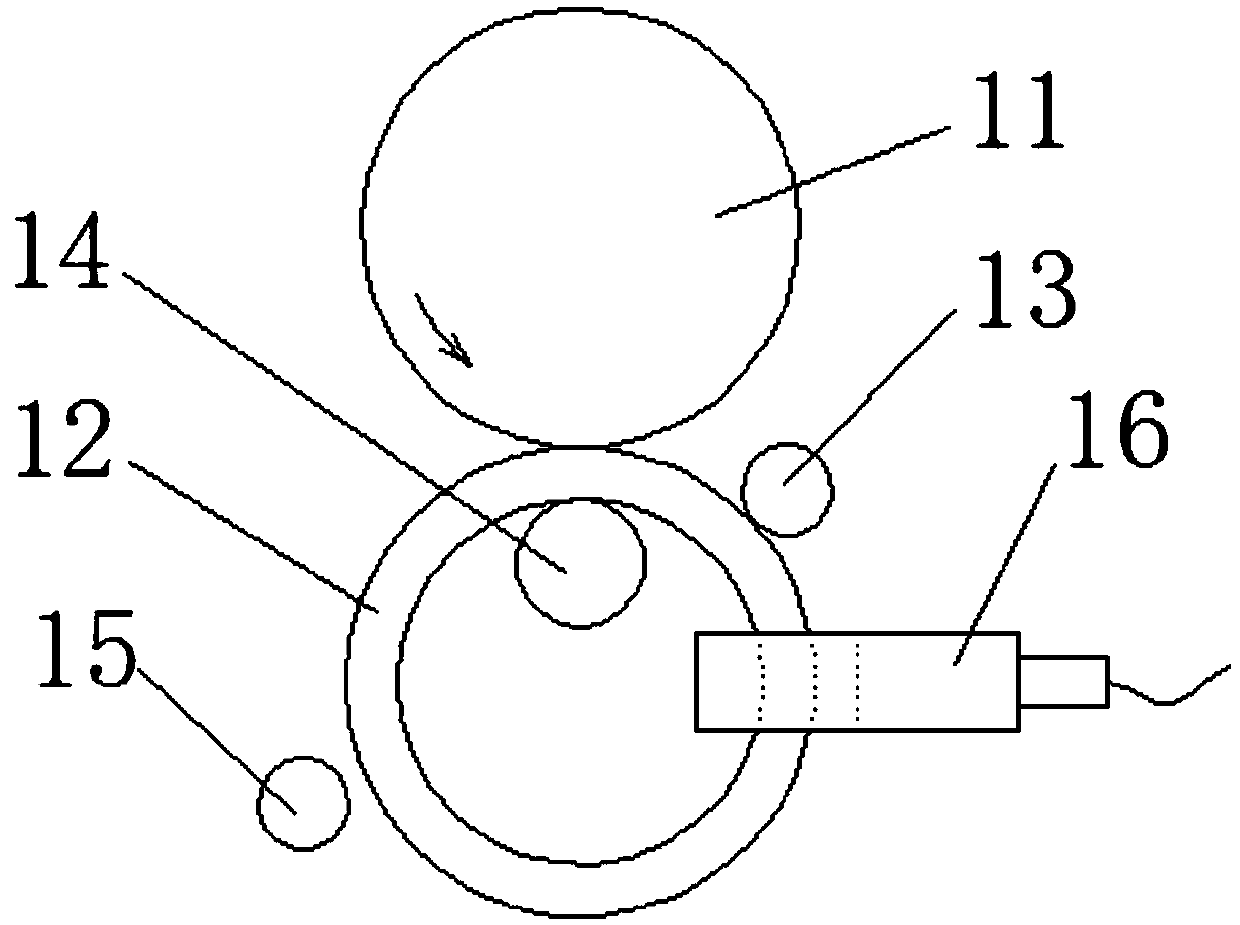

[0057] Step 60, ring rolling: using the forging manipulator 21, the blank has been sent to the ring rolling machine, and the r...

Embodiment 2

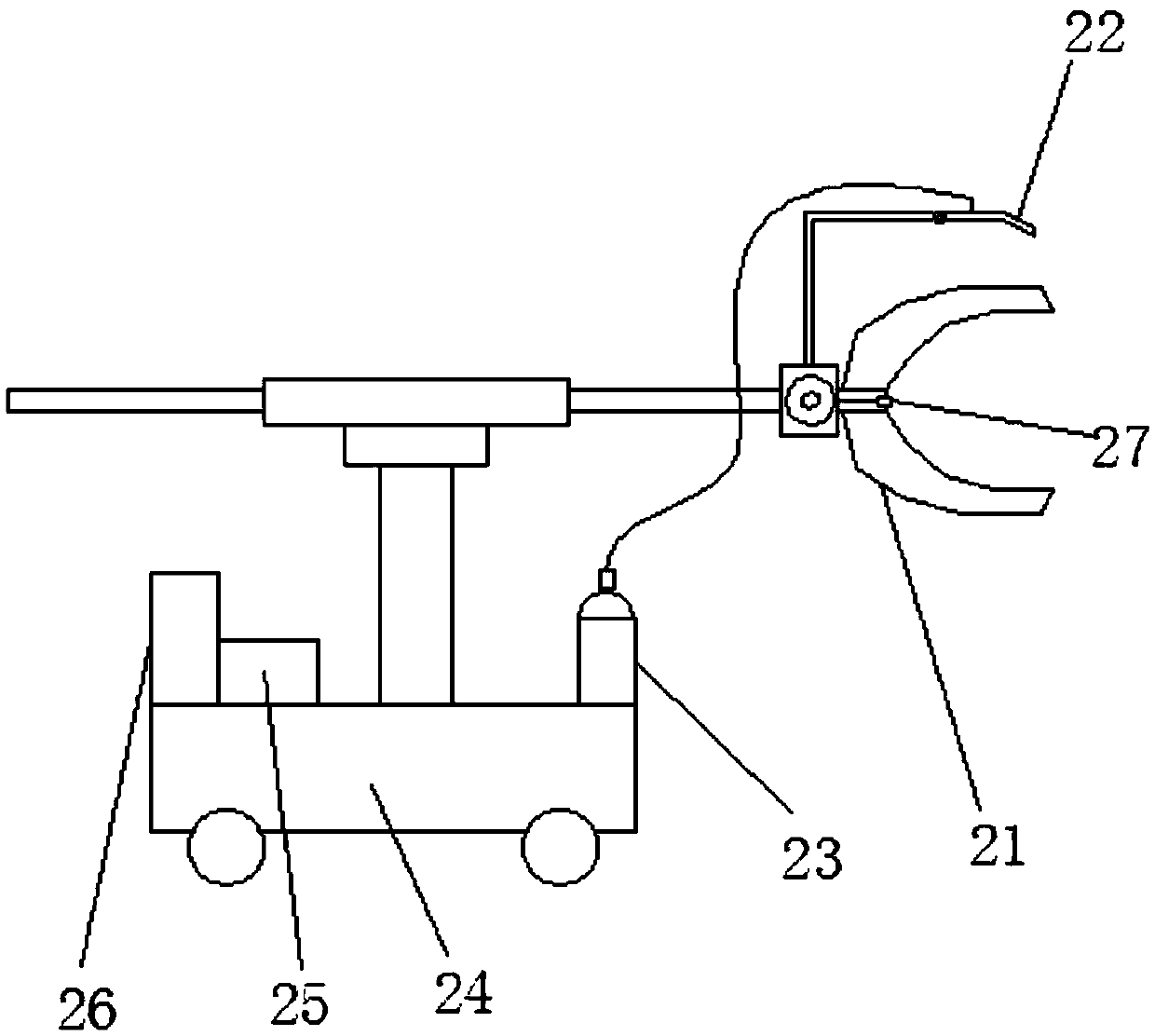

[0077] Such as Figures 1 to 5 Shown is the equipment adopting the forging process of stainless steel rings in Example 1, including a forging manipulator 21, a ring rolling machine and a slow cooling device, the forging manipulator 21 is provided with a flame heating device 22, and the ring rolling machine is provided with a U type heating device 16, the slow cooling device includes a wire mesh container 31, and the slow cooling agent is arranged in the wire mesh container 31, and the slow cooling agent is cinder powder and lime powder in a weight ratio of 2:1 Composition of mixed powder.

[0078] Such as figure 2 As shown, the forging manipulator 21 is installed on the mobile base 24, the front end of the forging manipulator 21 is provided with a flame heating device 22, the forging manipulator 21 is also provided with an infrared thermometer 27, and the mobile base 24 is also provided with a control system 26, drive Apparatus 25 and cylinders 23 for providing flame heatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com