Electric hydraulic modeling clamp

A hydraulic and electric technology, applied to tools used in roofing, roofing, construction, etc., can solve the problems of drilling, water leakage, time-consuming and labor-intensive problems, and achieve the effect of small strength loss and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

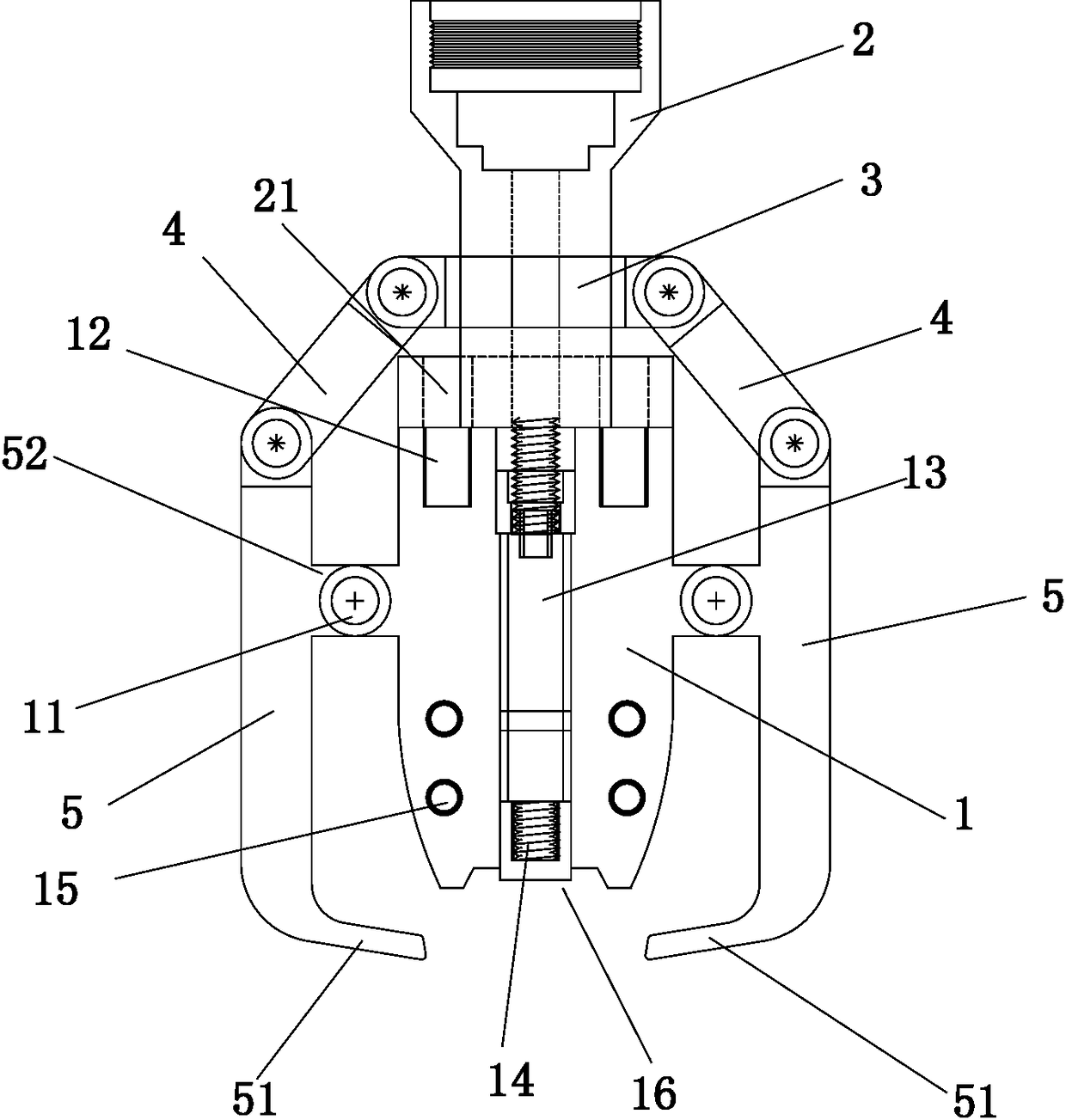

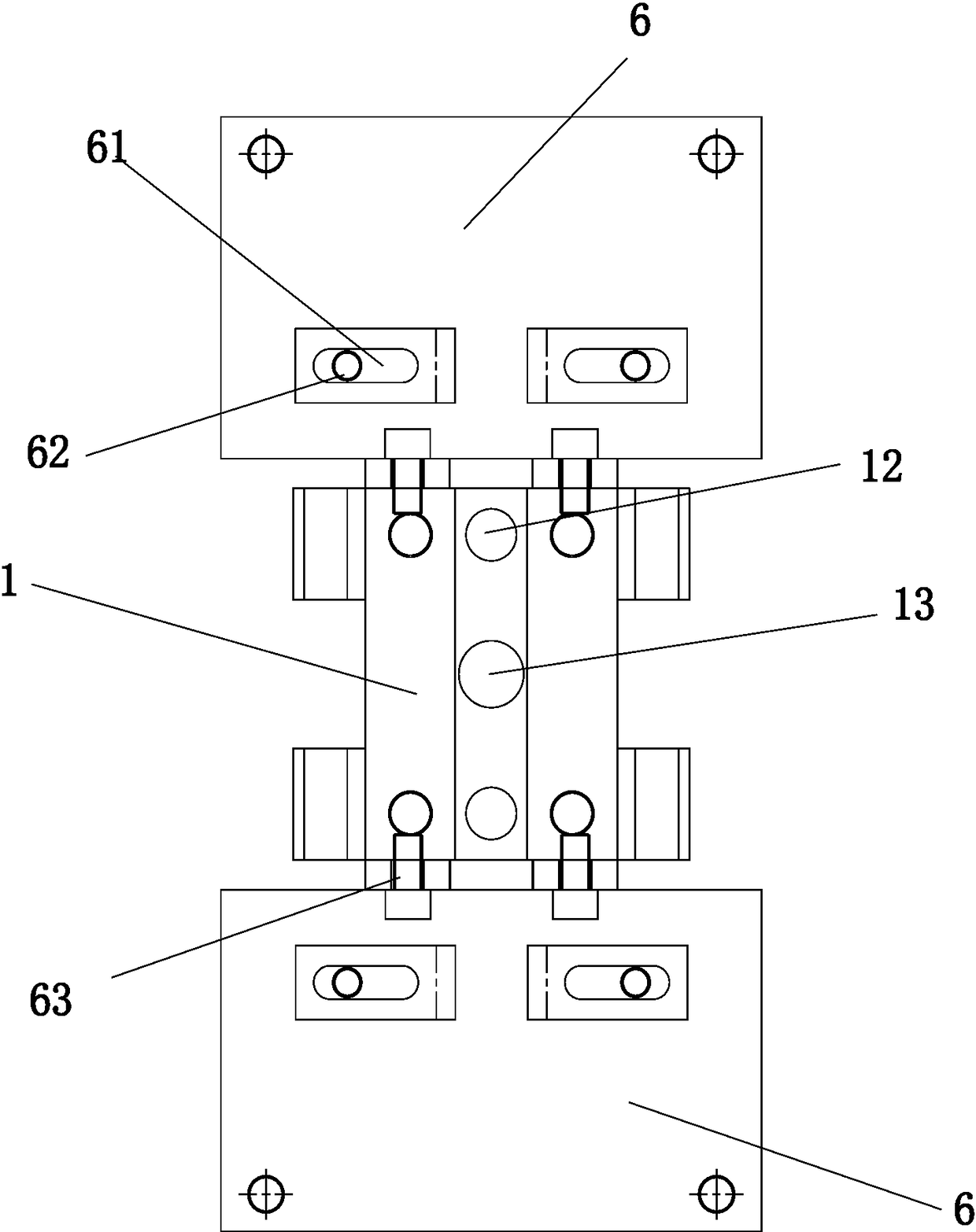

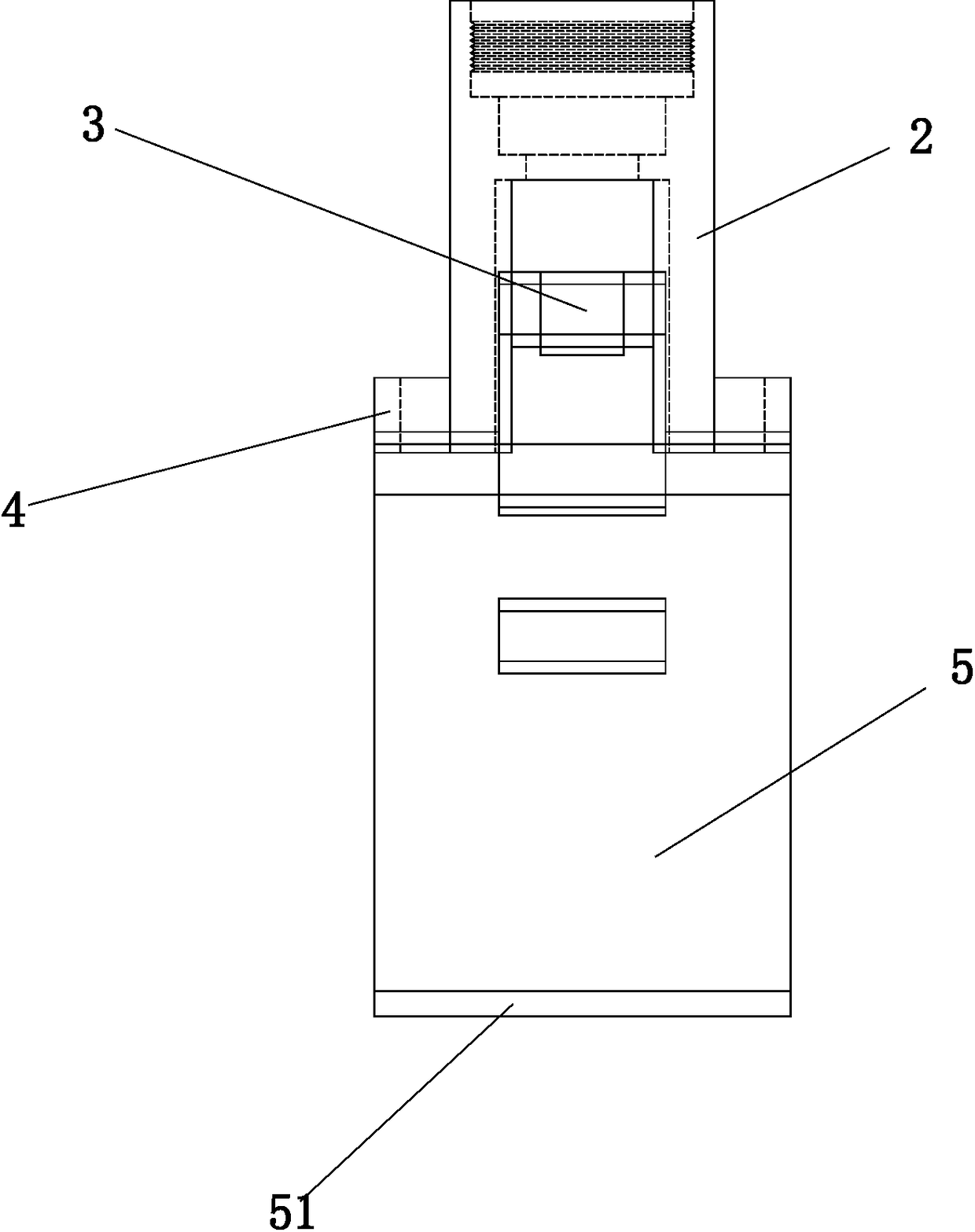

[0018] Embodiment one: if Figure 1 to Figure 3 As shown, an electro-hydraulic molding pliers includes a support 1, the top of the support 1 is provided with a pressure receiving part 2, and the pressure receiving part 2 is provided with a detachable pressure applying device, so The pressure applying device described above includes hydraulic devices, pneumatic devices, screw devices and other devices that generate pressure. The pressure-receiving part 2 is also provided with a pressure-receiving plate 3, the pressure-receiving plate 3 bears the pressure transmitted by the pressure-receiving part 2, and the pressure-receiving plate 3 is arranged on the support 1 Above, the two ends of the pressure bearing plate 3 are connected with transmission bars 4 , and the pressure bearing plate 3 is connected with the transmission bars 4 in rotation. The drive bar 4 is provided with an extruded part 5, and the extruded part 5 is connected to the support 2 and the drive bar 4 in a transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com