A method of manufacturing prefabricated components

A production method and technology of prefabricated components, which are applied in the direction of manufacturing tools, mold auxiliary parts, mold fixing devices, etc., can solve the problems of inconvenient operation and low work efficiency, and achieve the effects of convenient installation, simple disassembly and assembly, and convenient construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

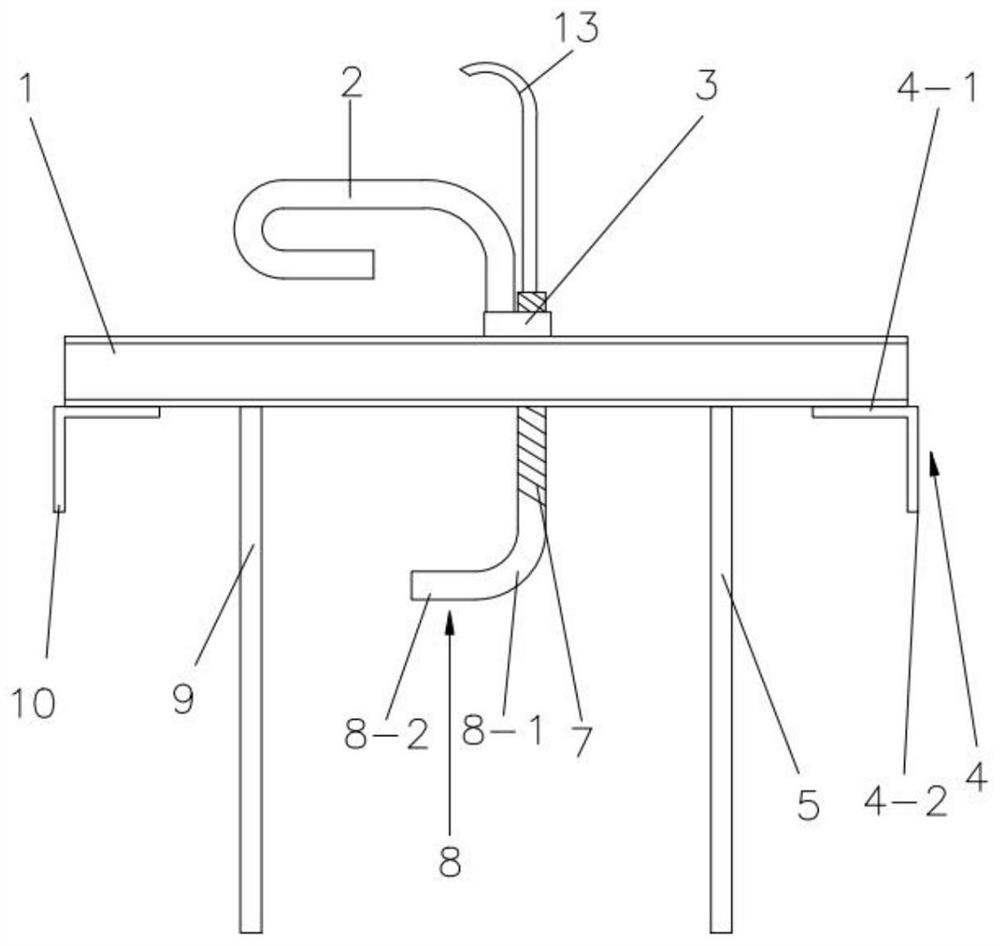

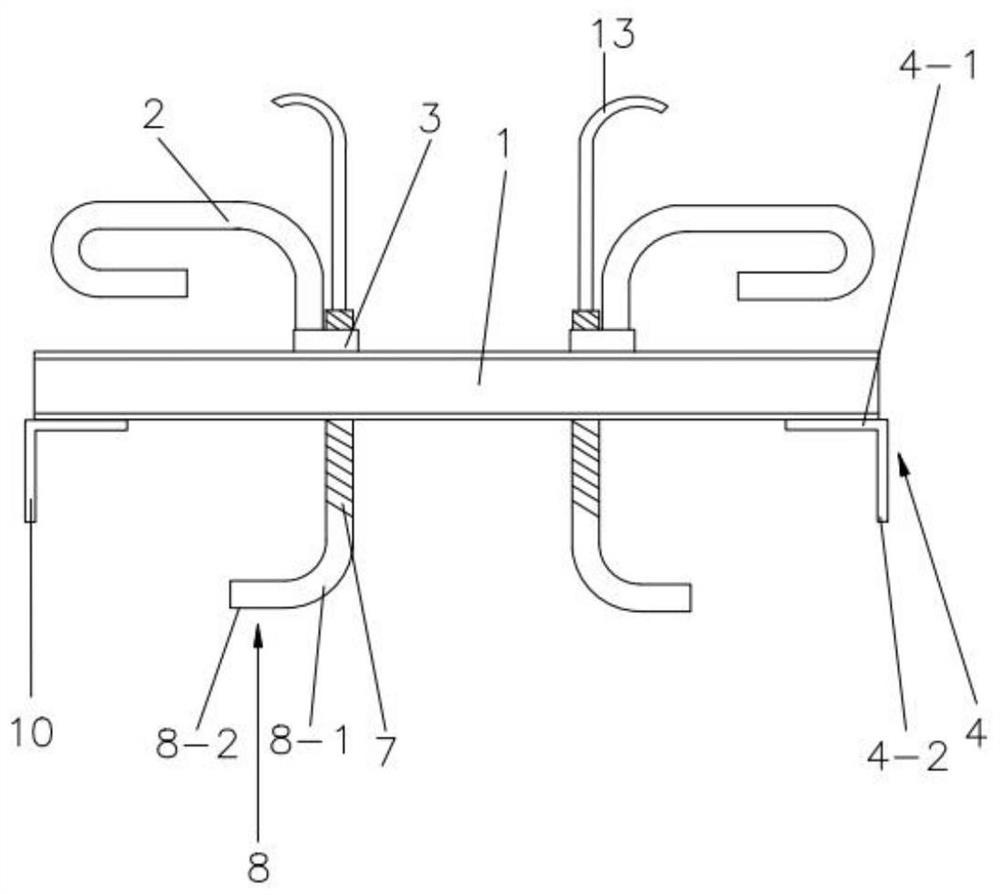

[0069] Such as Figure 7 Shown is a method for making a prefabricated component, the method comprising the following steps:

[0070] Step 1, welding of steel skeleton:

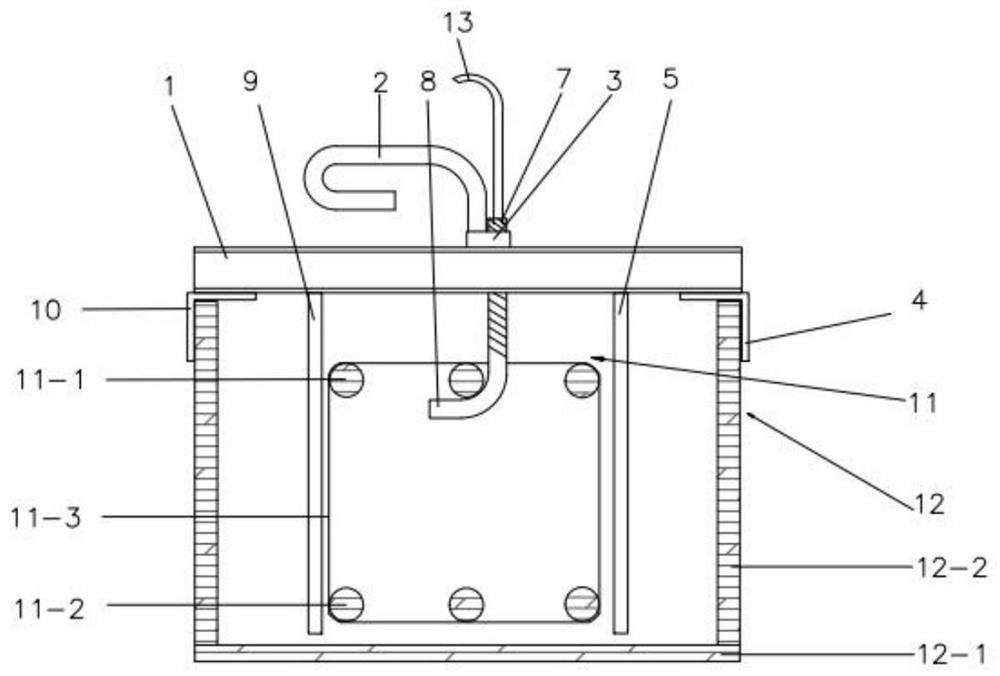

[0071] Welded steel bar skeleton 11; wherein, steel bar skeleton 11 comprises upper row of steel bars and lower row of steel bars, and stirrups 11-3 welded along the length direction of said upper row of steel bars and said lower row of steel bars, and said upper row of steel bars includes multiple The upper reinforcement bar 11-1, the lower row of reinforcement bars includes a plurality of lower reinforcement bars 11-2;

[0072] Step 2. Formwork support and installation of positioning fixtures:

[0073] Formwork is supported on the outside of the reinforcement frame 11, and a plurality of positioning fixtures are installed on the top of the formwork;

[0074] Step 3. Adjustment of steel skeleton:

[0075] The method of adjusting the distance between the reinforcement frame 11 and the bottom of the formwor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com