Ejection pressurizing type sleeve gas recovery device

A technology for recovering device and casing gas, which is applied in the production of fluids, wellbore/well components, and earth-moving drilling, etc. It can solve the problems of lowering the effective production pressure drop of oil wells, affecting pump efficiency, and large power consumption, avoiding environmental problems. Pollution and waste, ease of installation and transportation, effect of improving plant utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

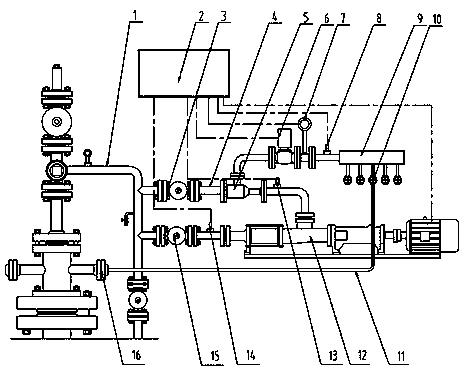

[0012] The structure and implementation of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0013] Part of the crude oil extracted from the oil well enters the device from the upstream of the oil outlet pipeline (1) through the liquid inlet valve (3). After the crude oil flows through the nozzle of the ejector (5), due to the conversion of pressure energy into velocity energy, A vacuum negative pressure chamber is formed, and the casing gas collected in the gas storage tank (9) is sucked into the negative pressure chamber, and the crude oil and the casing gas reach a stable flow state after being mixed and diffused by the diffuser. Due to the pressure drop caused by gas-liquid mixing, the pressure of the mixed fluid is lower than the pressure in the oil outlet pipeline (1), so it is necessary to input the mixed fluid into the gas-liquid mixed delivery pump (12) to increase the pressure to meet the normal delivery pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com