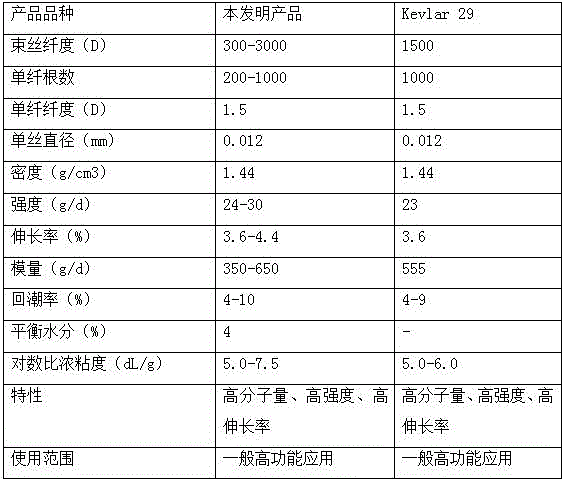

Preparation method of poly (p-phenylene terephthalamide) (PPTA) fiber with high elongation at break

A technology of p-phenylenediamine phthalamide and a manufacturing method, which are applied in the field of man-made fibers, can solve problems such as influence and low elongation at break, and achieve the effects of high process efficiency, few fiber structure defects, and low industrialization cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A kind of manufacture method of high elongation at break poly-p-phenylene terephthalamide fiber, it is characterized in that: take the poly-p-phenylene terephthalamide polymer of logarithmic viscosity 4.5dl / g as raw material, Use 96% concentrated sulfuric acid as a solution to make spinning stock solution, use dry jet wet spinning process, form primary filaments through spinneret, and then enter coagulation bath to solidify and form, and the coagulated and formed fibers are washed, neutralized, dried and Oiling, winding into products, wherein in the process of washing, neutralization, drying, oiling and winding, the yarn tension is controlled at 0.1g / d.

Embodiment 2

[0041] A kind of manufacture method of high elongation at break poly-p-phenylene terephthalamide fiber, it is characterized in that: take the poly-p-phenylene terephthalamide polymer of logarithmic viscosity 7.5dl / g as raw material, 100% concentrated sulfuric acid is used as the solution to make the spinning stock solution, and the dry-jet wet spinning process is used to form primary filaments through the spinneret, and then enter the coagulation bath to solidify and form, and the coagulated and formed fibers are washed, neutralized, dried and Oiling, winding into products, wherein in the process of washing, neutralization, drying, oiling and winding, the yarn tension is controlled at 0.5g / d.

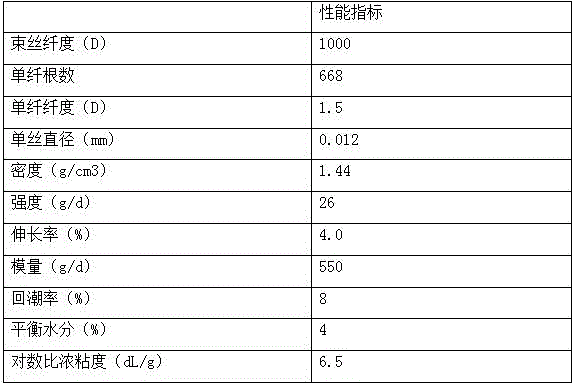

Embodiment 3

[0043] A kind of manufacture method of high breaking elongation poly-p-phenylene terephthalamide fiber, it is characterized in that: take the poly-p-phenylene terephthalamide polymer of logarithmic viscosity 6dl / g as raw material, with 98% concentrated sulfuric acid is used as a solution. After the spinning stock solution is made, the dry jet wet spinning process is used to form primary filaments through the spinneret, and then enter the coagulation bath to solidify and form. The coagulated and formed fibers are washed, neutralized, dried and processed. Oil, coiled into products, wherein in the process of washing, neutralizing, drying, oiling and coiling, the yarn tension is controlled at 0.3g / d.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Logarithmic viscosity | aaaaa | aaaaa |

| Logarithmic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com