Nanometer silicon-containing ultraviolet thick film positive photoresist and film forming resin thereof

A technology of film-forming resin and nano-silicon, applied in optics, opto-mechanical equipment, instruments, etc., can solve problems such as failure to meet process requirements, film cracking, and falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

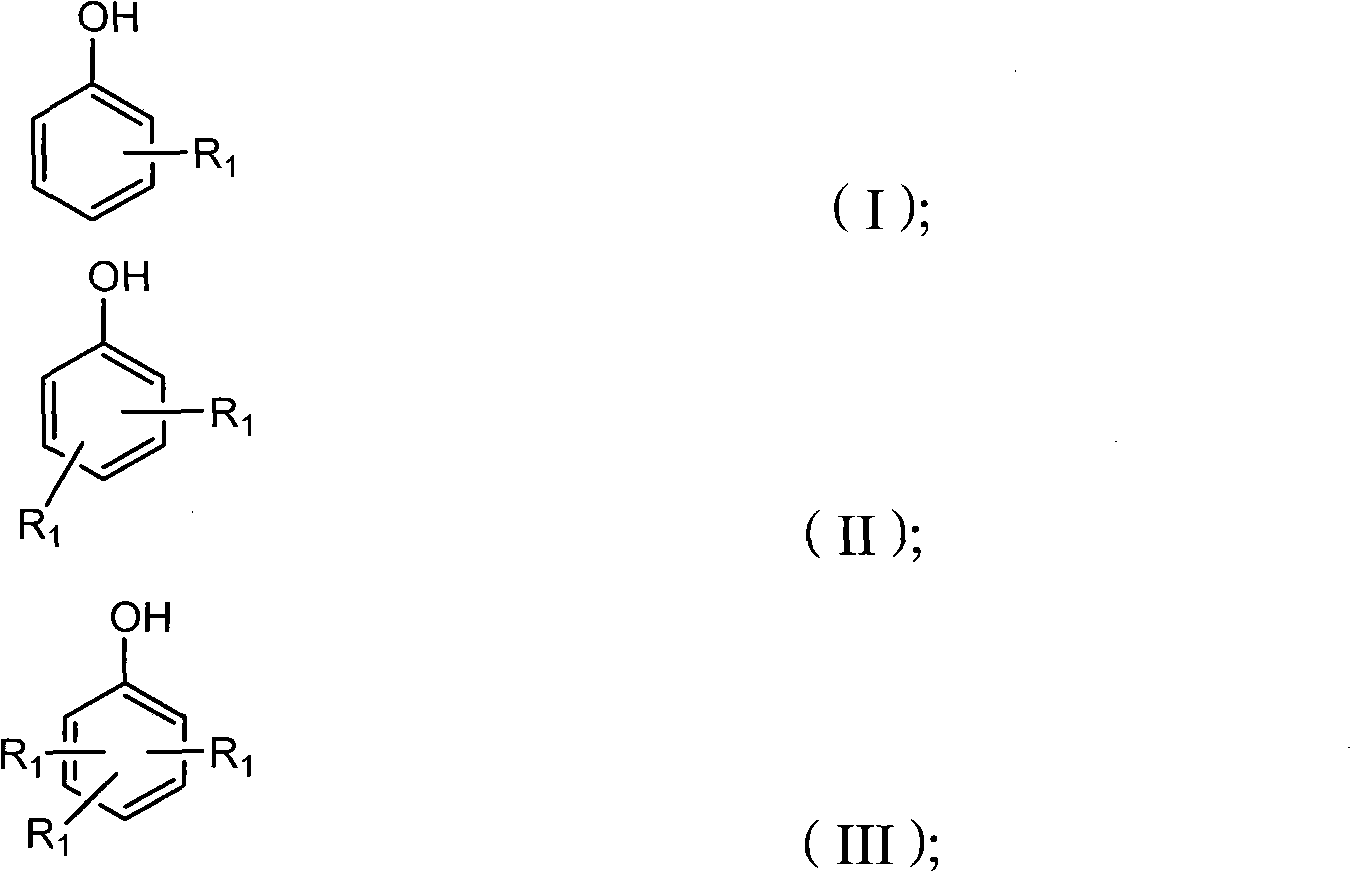

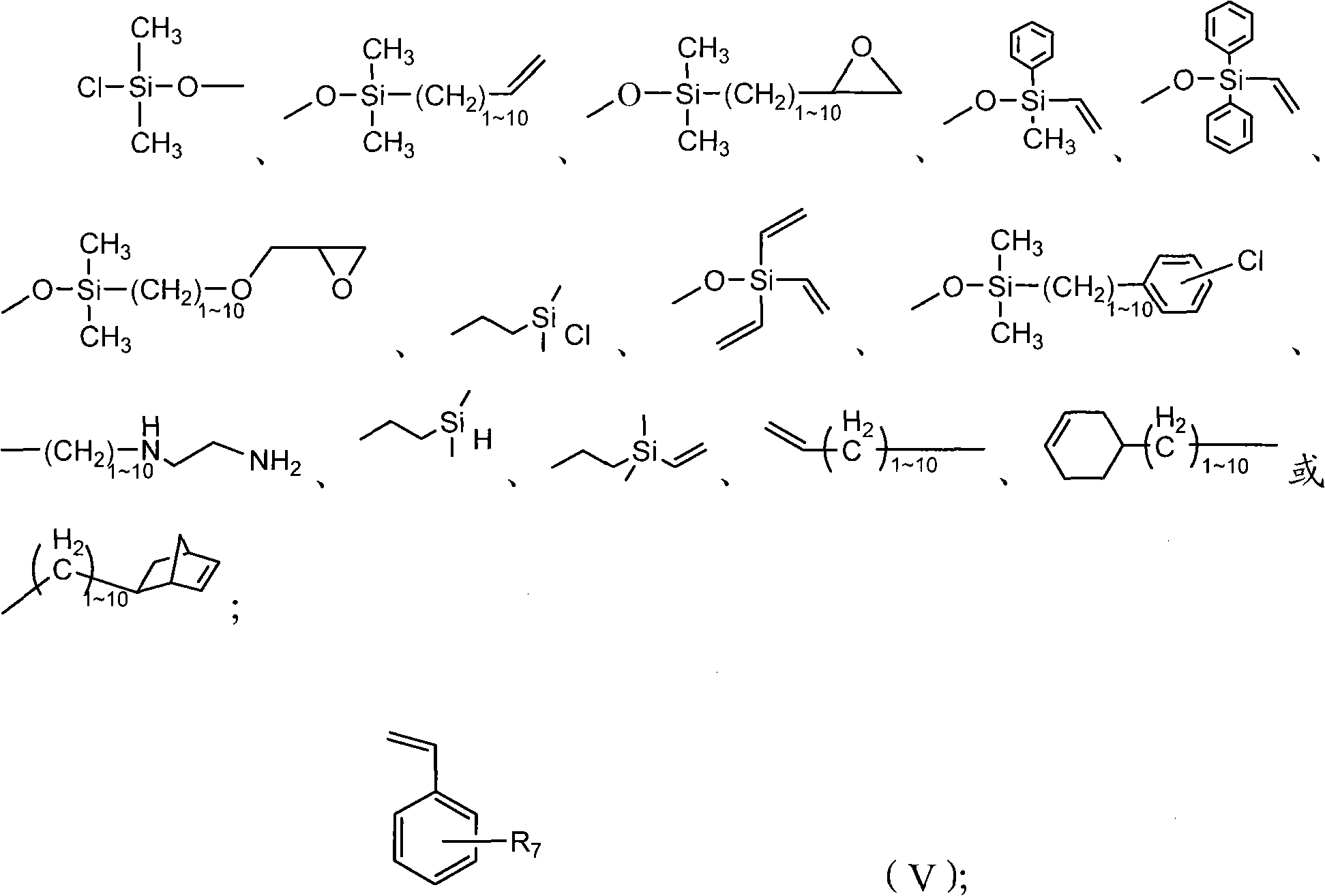

Method used

Image

Examples

Embodiment 1

[0097] Embodiment one: a kind of film-forming resin

[0098] (1), phenolic resin

[0099] Add 100 g (0.93 mol) m-cresol, 150 g (1.39 mol) p-cresol, 150 g (37%) formaldehyde to a 1000 ml flask equipped with a heating stirrer, thermometer, reflux condenser and nitrogen inlet and outlet Aqueous solution (1.85 mol) and 3.2 g oxalic acid. Stirring was started and heated to 90-95° C., and the reaction was maintained at this temperature for 3 hours. Then change the reflux device to a simple distillation device, and slowly heat and distill unreacted cresol, formaldehyde and water at atmospheric pressure until 120-130°C. Thereafter, gradually and slowly distill under reduced pressure, so that the vacuum pressure finally reaches 30-60mmHg, the temperature reaches 180°C, stays for 30 minutes, and finally makes the temperature reach 200-220°C in about 15 minutes, and the reaction ends. Stop heating, remove vacuum, put resin into polytetrafluoroethylene or stainless steel dish as soon a...

Embodiment 2

[0103] Embodiment two: a kind of film-forming resin

[0104] (1), phenolic resin

[0105] The solid phenolic resin was prepared according to the same synthesis method as in Example 1. The raw materials are: 150 grams (1.39mol) of m-cresol, 50 grams (0.46mol) of p-cresol, 50 grams (0.46mol) of o-cresol, 150 grams (37%) of formaldehyde solution (1.85mol) and 3.2 grams of oxalic acid . Obtain 220 grams of powdered solid phenolic resin (2), the average molecular weight is 21,000, and the residual phenol in the solid resin is less than 1%.

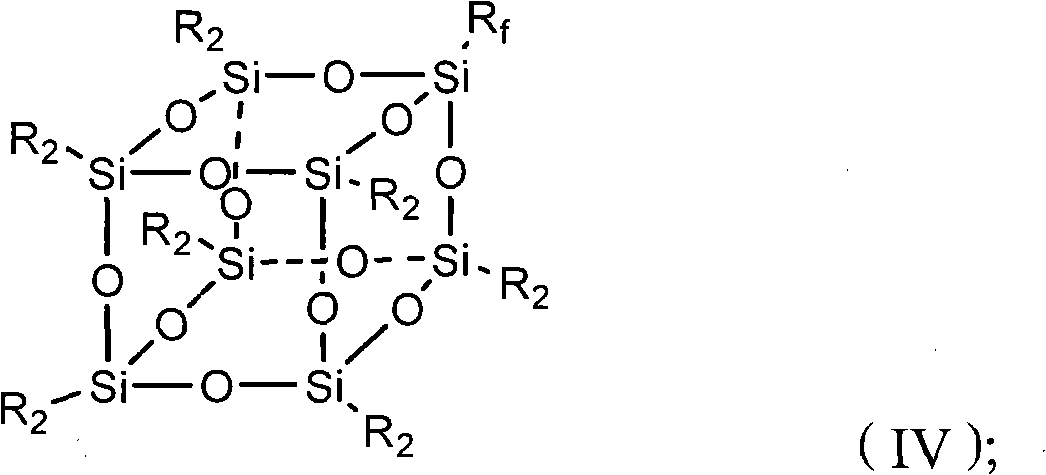

[0106] (2), film-forming resin containing nano-silicon copolymer:

[0107]

[0108] PF-POSS is prepared by reacting the phenolic resin prepared in this example with polyhedral oligomerized silsesquioxane (POSS):

[0109] Add 50 grams of the cresol-formaldehyde resin prepared in Example 6, 500 grams of solvent PGMEA, and 4 grams of glycidyl POSS in a 1000 milliliter flask equipped with heating stirrer, thermometer, reflux condenser and nitr...

Embodiment 3

[0110] Embodiment three: a kind of film-forming resin

[0111] (1), phenolic resin

[0112] The solid resin was prepared according to the same synthesis method as in Example 1. The raw materials are: 125 grams (1.15mol) of m-cresol, 75 grams (0.69mol) of p-cresol, 50 grams of 3.5-xylenol (0.41mol), 150 grams (37%) of formaldehyde solution (1.85mol) and 3.2 grams of oxalic acid. Obtain 200 grams of powdery solid phenolic resin (3), the average resin molecular weight is 19,000, and the residual phenol in the solid resin is less than 1%.

[0113] Synthesis of polyhedral oligomeric silsesquioxane (POSS)-containing copolymer (P-POSS-B):

[0114] (2), film-forming resin containing nano-silicon copolymer:

[0115]

[0116] 1. Preparation of hydroxystyrene chains:

[0117] Glycidyl methacrylate 272 grams;

[0118] Styrene 11 grams;

[0119] β-Hydroxyethyl Methacrylate 70g

[0120] The preparation method is: in a 1000ml three-necked flask equipped with an electric stirrer, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com