Heading machine using supercritical carbon dioxide jet flow to break rock

A carbon dioxide and supercritical technology, which is applied in mining equipment, mining equipment, earthwork drilling, etc., can solve the problems of high cost, easy abnormal damage of disc-shaped hob, low driving efficiency, etc., and achieve the effect of ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

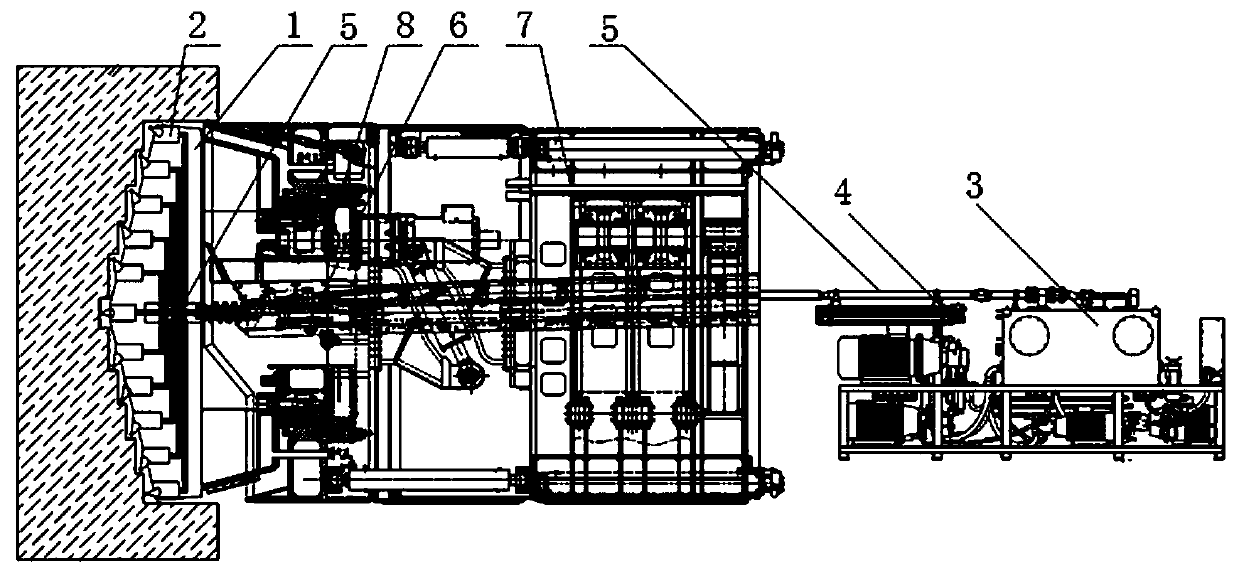

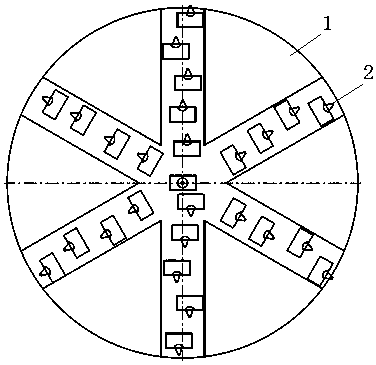

[0014] Embodiment 1, utilize supercritical carbon dioxide jet to break the roadhead machine of rock, as figure 1 and figure 2 As shown, a cutter head system 1 is included, and a supercritical carbon dioxide injection nozzle 2 is arranged on the cutter head system 1, and the supercritical carbon dioxide injection nozzle 2 is connected with a supercritical carbon dioxide generator 3 through a high-pressure pipeline 5 . Supercritical carbon dioxide generator 3 can produce supercritical carbon dioxide, and supercritical carbon dioxide generator 3 can deliver the supercritical carbon dioxide produced to supercritical carbon dioxide injection nozzle 2 through high-pressure pipeline 5, and supercritical carbon dioxide injection nozzle 2 will supercritical carbon dioxide It is ejected at an ultra-high speed to form a jet beam with highly concentrated energy. This jet beam has the effects of cavitation damage, water jet impact, water wedge and thermal fracture, and can crack rocks to ...

Embodiment 2

[0016] Embodiment 2, using supercritical carbon dioxide jets to break rocks, the supercritical carbon dioxide injection nozzle 2 and the high-pressure pump station 4 are all connected to the control system, and the control system can remotely adjust the output pressure of the high-pressure pump station 4 and control the supercritical The opening and closing of the carbon dioxide injection nozzle 2 can conveniently adjust the pressure of the supercritical carbon dioxide injected by the supercritical carbon dioxide injection nozzle 2 according to different geology.

[0017] Other structures of this embodiment may be the same as Embodiment 1.

Embodiment 3

[0018] Embodiment 3, utilizing supercritical carbon dioxide jets to break rocks, the high-pressure pipeline 5 between the high-pressure pump station 4 and the supercritical carbon dioxide injection nozzle 2 is provided with a pressure gauge, which can be monitored in real time according to the pressure gauge. The pressure of the supercritical carbon dioxide can be adjusted in real time through the high-pressure pump station 4.

[0019] Other structures of this embodiment may be the same as those of Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com