Emulsifier for remote distribution of emulsion matrix and preparation method and application thereof

A latex matrix and emulsifier technology, which is applied in the direction of offensive equipment, non-explosive/non-thermal agent components, explosives, etc., can solve the problems of difficult remote distribution of latex matrix, poor anti-turbulence and pumping performance, and poor fluidity. Good anti-turbulence and pumping performance, good emulsification stability, and good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

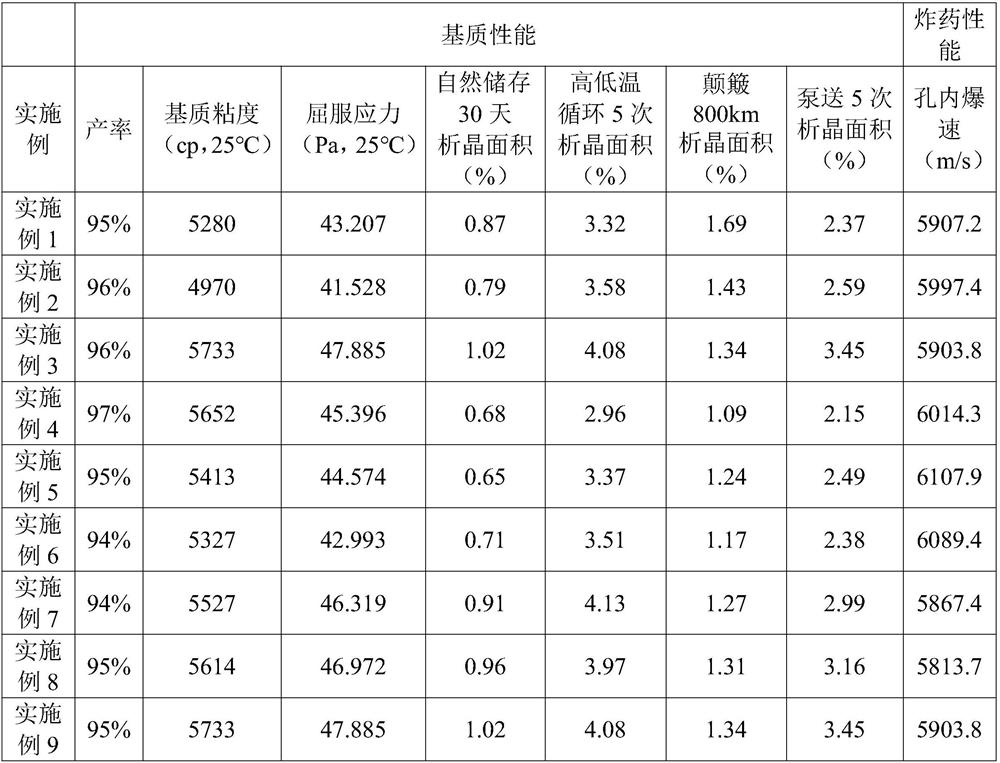

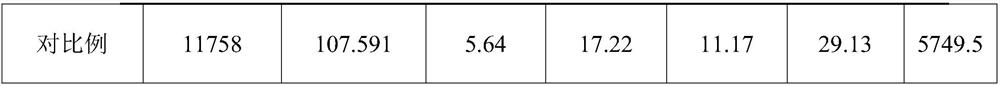

Examples

Embodiment 1

[0031] The raw materials of the emulsifier in this embodiment are: polypropylene succinic anhydride for polyolefin carboxylic anhydride, neopentyl glycol for alcohol, adipic hydrazide for dihydrazide, and 60SN base oil for diluent oil.

[0032] A preparation method for an emulsifier for latex matrix remote distribution, comprising the following steps:

[0033] S1, adding 1mol polypropylene succinic anhydride in the reactor;

[0034] S2, feed ammonia in the reactor;

[0035] S3, add 1.1mol of neopentyl glycol in the reactor, weigh the weight of 60SN base oil so that the quality of 60SN base oil is 0.8 times of 1mol of polypropylene succinic anhydride, then add 60SN base oil, heat up to 120 ℃, keep warm for 2h;

[0036] S4. Heat up to 170°C, add 0.8 mol of adipic hydrazide under ammonia gas, and keep stirring for 4 hours;

[0037] S5. Obtain the finished product after filtering while it is hot.

Embodiment 2

[0039] The raw materials of the emulsifier in this embodiment are: polyisobutylene succinic anhydride for polyolefin carboxylic anhydride, 1,6-hexanediol for alcohol, glutaryl hydrazide for dihydrazide, and 220SN base oil for diluent oil.

[0040] A preparation method for an emulsifier for latex matrix remote distribution, comprising the following steps:

[0041] S1, add 1mol polyisobutylene succinic anhydride in the reactor;

[0042] S2, feed ammonia in the reactor;

[0043] S3, add 1.2mol of 1,6-hexanediol in the reactor, weigh the weight of 220SN base oil so that the quality of 220SN base oil is the same as the quality of 1mol polyisobutylene succinic anhydride, then add 220SN base oil, and heat up Heat to 110°C, keep warm for 3h;

[0044] S4. Heating up to 160°C, adding 0.7 mol of glutaryl hydrazide under ammonia gas, and stirring for 6 hours while insulated;

[0045] S5. Obtain the finished product after filtering while it is hot.

Embodiment 3

[0047] The raw materials of the emulsifier in this embodiment are: polypentene succinic anhydride is selected for polyolefin carboxylic anhydride, trimethylolpropane is selected for alcohol, pimelic hydrazide is selected for dihydrazide, and 150SN base oil is selected for diluent oil.

[0048] A preparation method for an emulsifier for latex matrix remote distribution, comprising the following steps:

[0049] S1, add the polypentene succinic anhydride of 1mol in reactor;

[0050] S2, feed ammonia in the reactor;

[0051] S3, add the trimethylol propane of 1mol in reactor, weigh the weight of 150SN base oil so that the quality of 150SN base oil is 0.5 times of the polypentene succinic anhydride of 1mol, then add 150SN base oil, heat up to 120℃, keep warm for 3h;

[0052] S4. Heat up to 180°C, add 1 mol of pimelic hydrazide under ammonia gas, and keep stirring for 4 hours;

[0053] S5. Obtain the finished product after filtering while it is hot.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com