Method for producing high-whiteness aluminum hydroxide by two-stage decomposition method

A technology of aluminum hydroxide and decomposition method, applied in the direction of alumina/aluminum hydroxide, etc., can solve problems such as unqualified whiteness and chroma, adverse effects on product quality, fluctuations, etc., to eliminate fluctuations, stabilize product chroma and The effect of whiteness and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

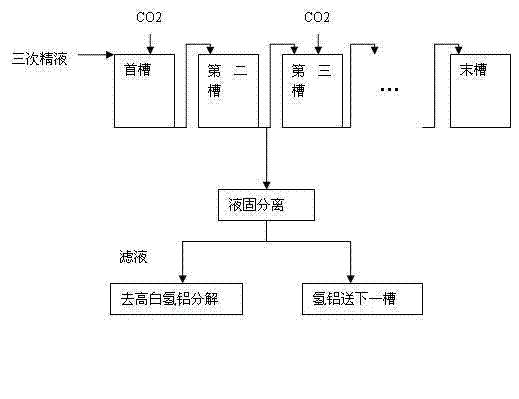

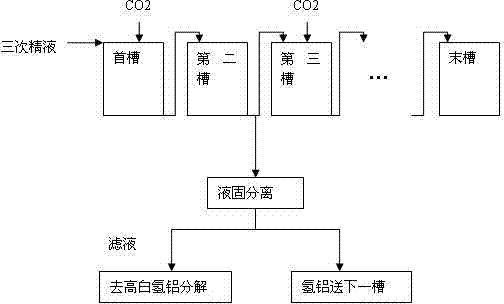

[0017] The carbon sub-tank is connected in series by n carbon sub-tanks, and the semen, that is, 115g / l Na 2 o T , 105g / l Al 2 o 3 Pumped into n carbon tanks in series for n-1 level carbonation decomposition (see figure 1 ), the nth slot is the last slot, that is, the discharge slot. Among them, only the second tank and the last tank are not ventilated, and the other tanks are all ventilated with CO 2 gas. CO in the first tank 2 The gas makes the semen carbonation and decomposition, and the decomposition rate is controlled at 15%. Send the semen decomposed by carbonation to the second tank of the carbon tank (the tank is not connected to CO 2 gas) for uniform stirring. After stirring, take out a part of the slurry from the second tank (the amount of the slurry can be taken out according to actual needs) and filter to separate the solid from the liquid. After filtering, the ion content in the filtrate Fe is less than 1ppm, and the b value drops to 0.7. The solution ob...

Embodiment 2

[0019] The semen, namely 115g / l Na 2 o T , 105g / l Al 2 o 3 Pumped into the series of carbon tanks, the first tank through CO 2 The gas makes the semen carbonation and decomposition, and the decomposition rate is controlled at 10%. Send the semen decomposed by carbonation to the second tank of the carbon tank (the tank is not connected to CO 2 gas) for uniform stirring. After stirring, take out a part of the slurry from the second tank (the amount of the slurry can be taken out according to actual needs) and filter to separate the solid from the liquid. After filtering, the Fe ion content in the filtrate is less than 1ppm, and the b value drops to 0.6. The solution obtained from solid-liquid separation is continuously sorted by the existing seed sorting process, and high white aluminum hydroxide with a whiteness greater than 95% and a b value of 0.4 can be obtained. The solid obtained from the solid-liquid separation is transferred together with the remaining slurry in t...

Embodiment 3

[0021] Na 2 o T 125g / l, Al 2 o 3 115g / l pumped into the series of carbon tanks, the first tank through CO 2 The gas makes the semen carbonation and decomposition, and the decomposition rate is controlled at 5%. The Na after carbonation decomposition 2 o T and Al 2 o 3 Send to the second tank of the carbon tank (the tank is not connected to CO 2 gas) for uniform stirring. After stirring, take a part of the slurry from the second tank (the amount of the slurry can be taken out according to actual needs) and filter to separate the solid from the liquid. After filtering, the Fe ion content of the filtrate is less than 1ppm, and the b value drops to 0.6. The solution obtained from solid-liquid separation is continuously sorted by conventional methods, which is a common process in alumina production, to obtain high-white aluminum hydroxide with a whiteness greater than 95% and a b value of 0.4. The solid obtained from the solid-liquid separation is transferred together ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com