Method for enhancing permeability of prepregs

A technology of prepreg and impregnation, which is applied in the processing of textile materials, liquid/gas/steam textile material processing, textiles and papermaking, etc. It can solve the problems of poor impregnation of prepregs and achieve good impregnation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

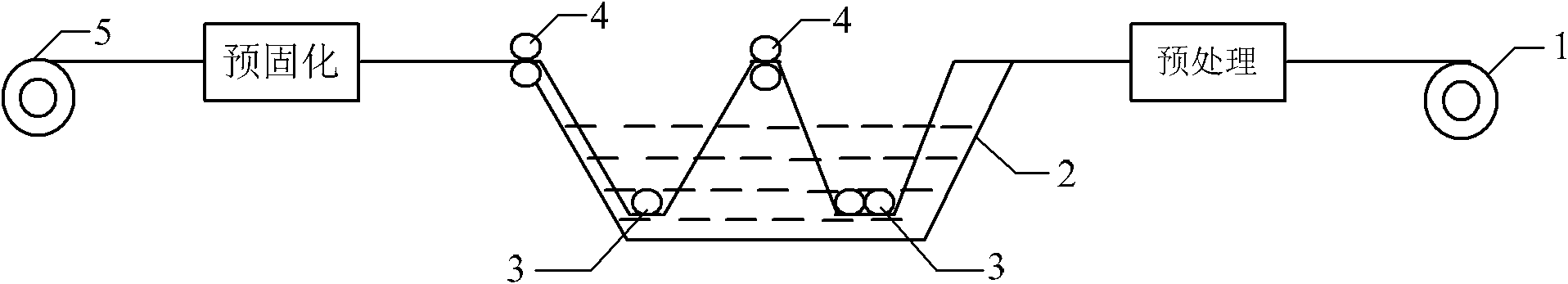

[0015] Specific implementation mode 1. Combination figure 1 Illustrate this specific embodiment, a kind of method that improves prepreg wettability, it is realized by the following steps:

[0016] Step 1. Pretreat the reinforcement material 1 to be processed to obtain the pretreated reinforcement material;

[0017] Step 2. Send the pretreated reinforcing material obtained after step 1 into the dipping tank 2, and use two pressure rollers 3 to impregnate the pretreated reinforcing material in the glue solution in the dipping tank 2. , to obtain the reinforced material after the first dipping;

[0018] Step 3, using the rubber-extruding roller 4 to squeeze the reinforced material obtained in step 2 above the rubber surface in the dipping tank 2 to obtain the reinforced material after the rubber-squeezed;

[0019] Step 4, the reinforced material obtained in step 3 after being extruded is dipped again in the glue solution in the dipping tank with a rubber roller 3 to obtain the ...

specific Embodiment approach 2

[0025] Embodiment 2. The difference between this embodiment and the method for improving the permeability of prepreg described in Embodiment 1 is that in step 5, the extruded reinforcing material is sent into the interior from the dipping tank 2 The prepreg 5 was obtained after pre-curing in a curing oven at a temperature of 110°C.

specific Embodiment approach 3

[0026] Specific embodiment three, in conjunction with concrete parameter, verify the effect of the present invention method: select one volume (wide 1 meter, long 100 meters) of the glass cloth of weaving for use under the traction of motor, send into interior with the speed of 0.6 meter per minute Heat treatment in a heat treatment furnace at a temperature of 150°C, remove surface impurities (dust removal) and then enter the dipping tank, set two pressure rollers near the bottom of the dipping tank to impregnate the glass cloth, and then pass through the dipping tank Squeeze the glue roller on the top of the rubber surface to remove excess glue, then return to the glue in the dipping tank to dip again, and then squeeze the glue again and send it to a curing furnace with an internal temperature of 100°C to pre-cure the resin in the glass cloth , and then rolled to make a prepreg. During the dipping process, the purpose of adding a group of extrusion rollers above the dipping t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com