Lower drag helix rope for pelagic trawls and methods

a technology of pelagic trawls and ropes, applied in the field of ropes, can solve the problems of high cost, high operational cost minimizing profitability, and high net manufacturing of trawls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

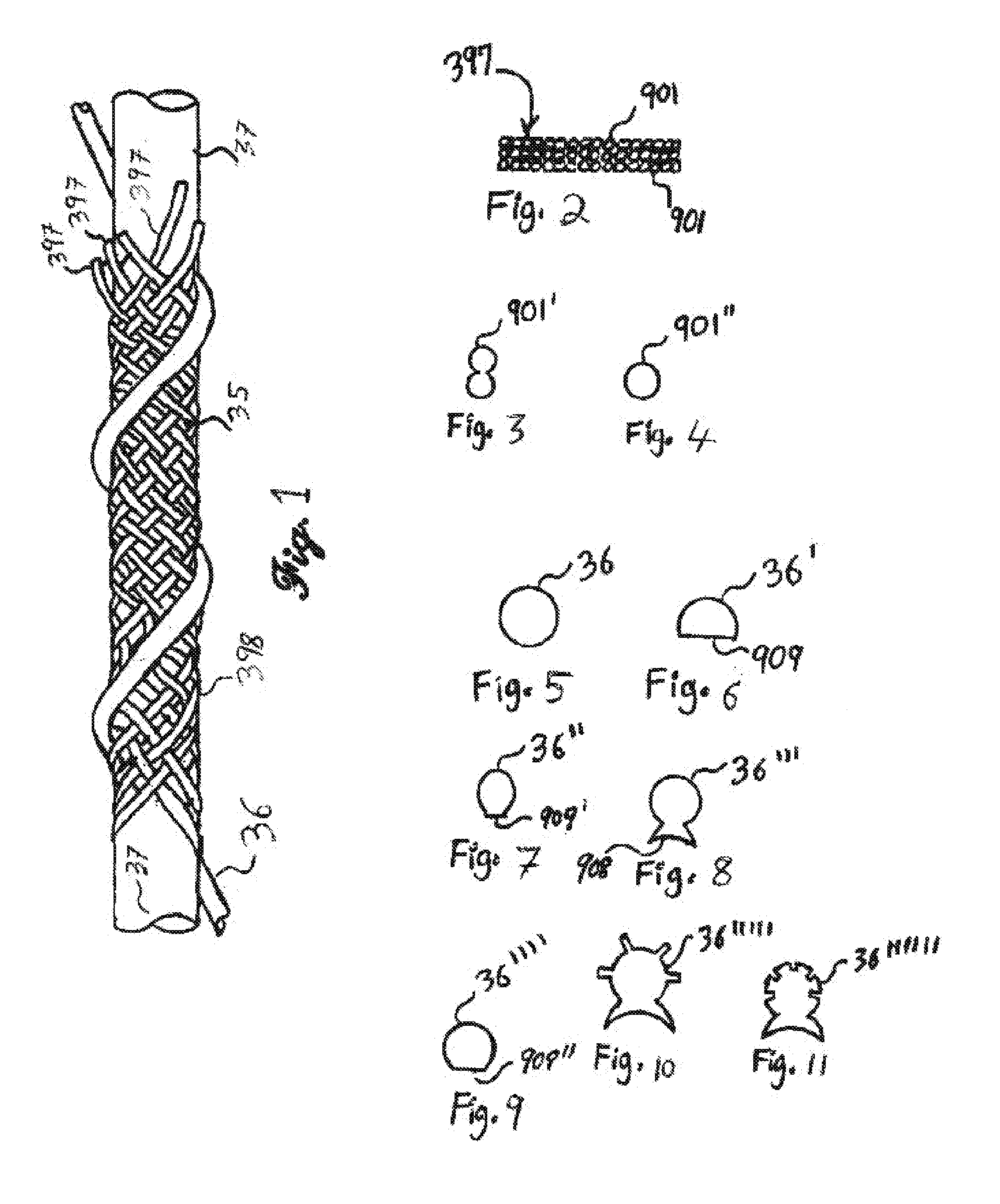

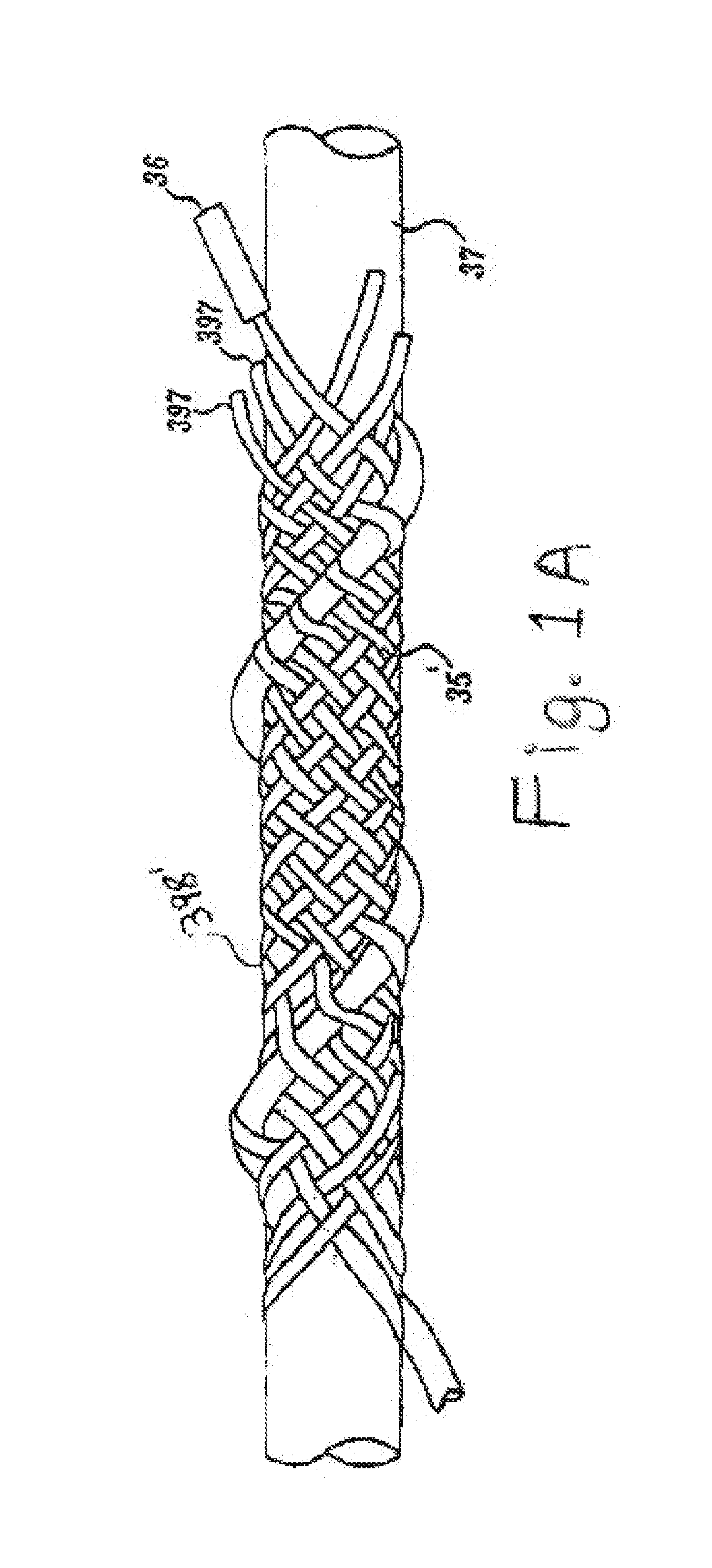

[0028]FIG. 1 illustrates a helix rope in accordance with the present disclosure that is identified by the general reference character 35. In reference to FIG. 1, the helix rope 35 of the present disclosure includes a braided sheath 398 formed about a strength member core 37. The braided sheath 398 is formed of multiple strands 397 and at least one helixing strand 36. The helixing strand 36 may be situated mainly about the outside of the braided sheath 398, such as when helixing strand 36 is formed of a substance such as polyurethane and adhered mainly to the outside of braided sheath 398. Or, as illustrated in FIG. 1A, the helixing strand 36 may be included within and among the weave of the strands forming braided sheath 398′ so as to form alternative embodiment helix rope 35′. That is, the helixing strand 36 may be treated like a strand 397 other than that it is larger in diameter and preferably is more elastic, thereby forming alternative embodiment helix rope 35′.

[0029]The presen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com