Pigment dyed colored cloth production method

A paint dyeing and production method technology, applied in the direction of fabric elongation, fabric, and fabric surface trimming, etc., can solve the problems of poor post-finishing processing characteristics, troublesome surface polishing of garments, and low level of cleanliness at the production site, and improve weaving efficiency. and product quality, improve processing depth and added value, and improve the effect of cleaner production levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below through the description of specific embodiments with reference to the accompanying drawings.

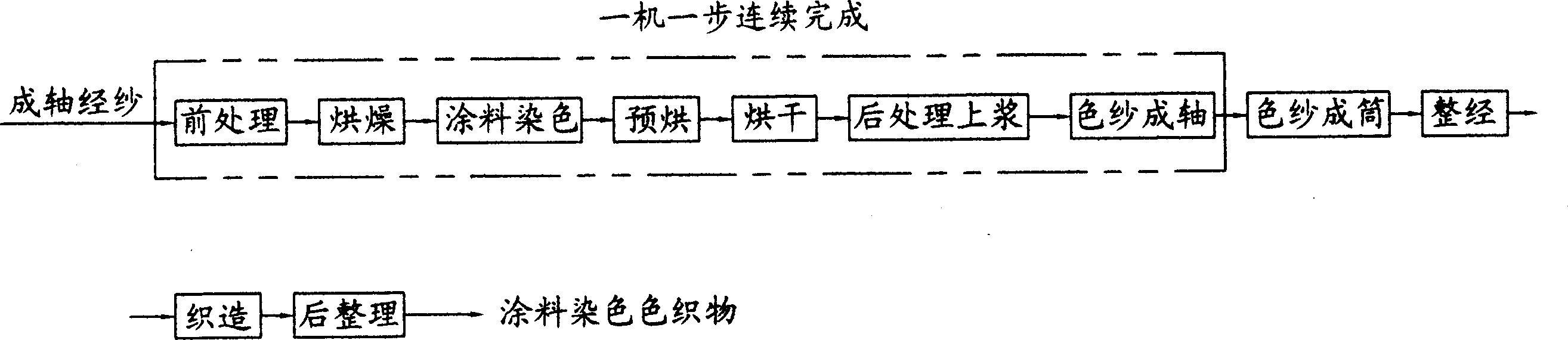

[0041] One of the specific implementation modes, as attached figure 2 shown.

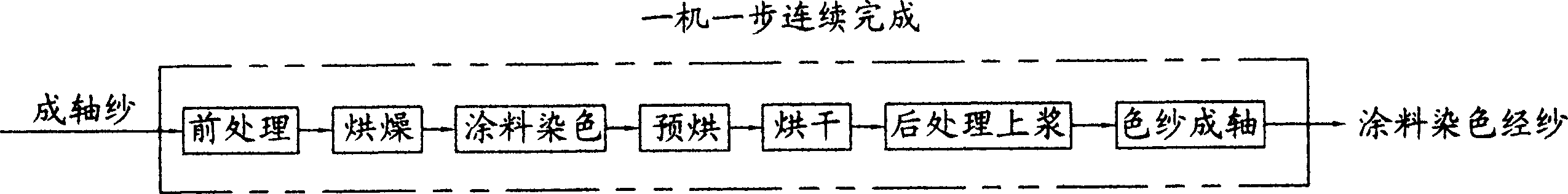

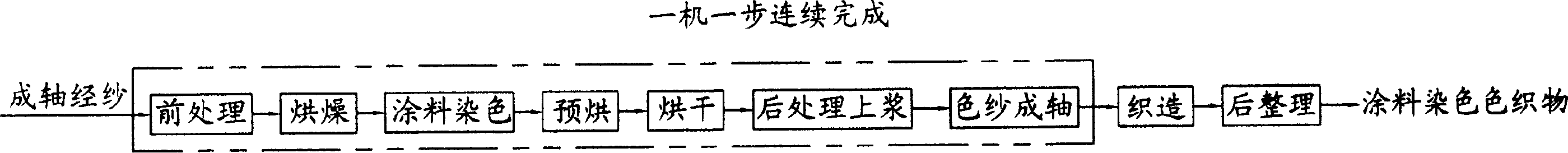

[0042] A method for producing dope-dyed colored fabrics, specifically describing a production method for dope-dyed Oxford spinning, which uses warp-shafted raw yarns as warp yarns, including warp dope dyeing, weaving and post-finishing steps, as well as pretreatment, The steps of drying, pre-drying, drying, post-treatment and shafting of dyed yarn are carried out in sequence according to the following production steps:

[0043] a, pre-treatment: carry out pre-treatment of wet operation by passing the 40S warp yarn into a shaft through a bath;

[0044] b, drying; removing the soaking moisture contained in the warp yarn processed through step a;

[0045] c, paint dyeing; in the dye solution bath tank that has paint and auxiliary agent to mix, car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com