Engraving printing technique for polyacrylonitrile knitted fabric

A printing process and knitted fabric technology, which is applied in the processing of textile materials, textiles and papermaking, liquid/gas/steam textile material processing, etc. It can solve the problems of unstable process and inability to form large-scale production, and achieve bright colors and high quality. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Fabric name: acrylic jersey.

[0058] Specifications: 80% acrylic fiber, 20% wool, 210g / m2 2 , door width 155cm.

[0059] Screen number: 5366×5 flat screen printing machine printing, mesh 1000 mesh.

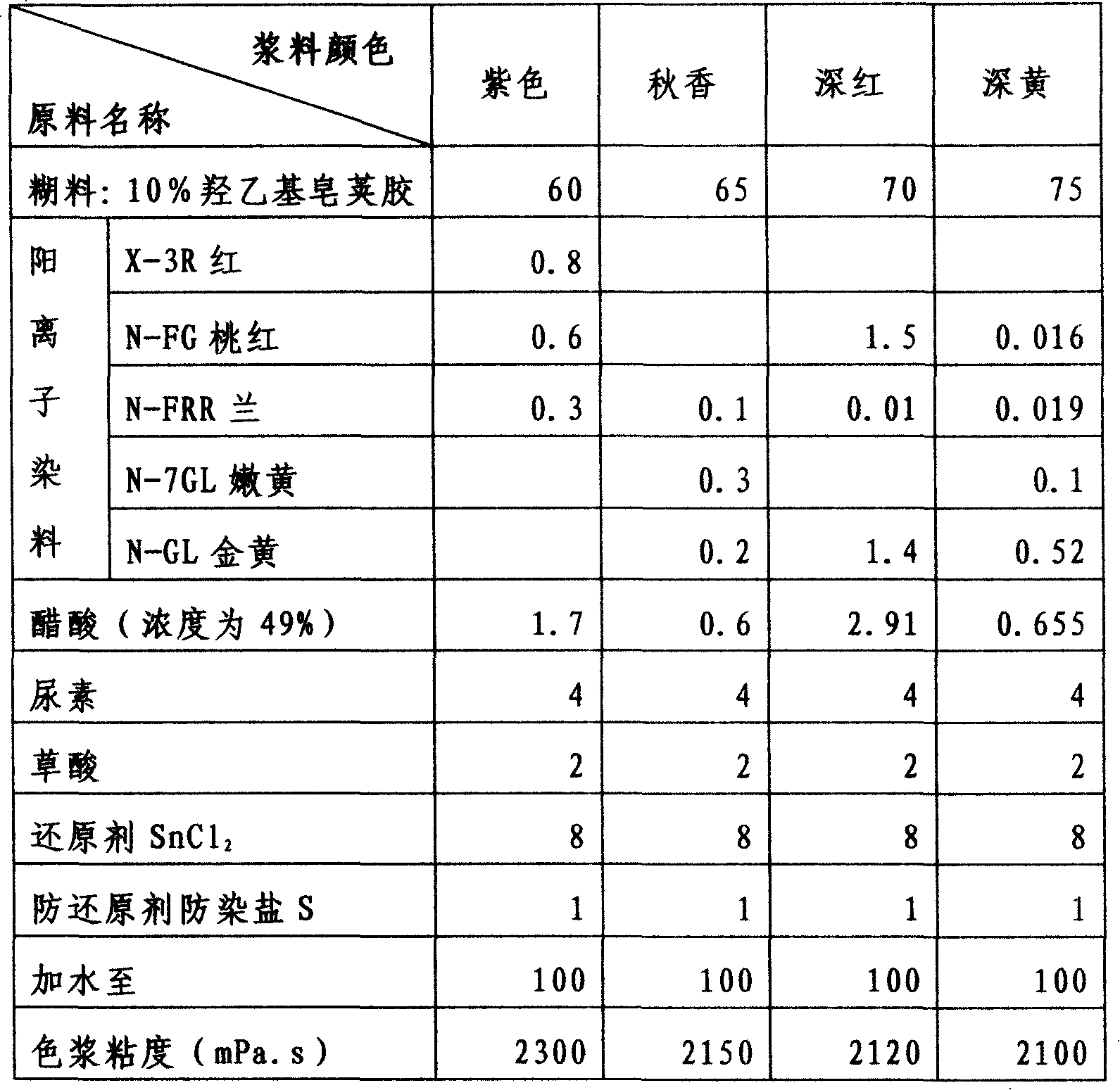

[0060] Requirements: Dye the coffee base color on the polypropylene eye fabric first, and then engrave and print purple, autumn fragrance, deep red and deep yellow flowers on the coffee base color cloth.

[0061] crafting process:

[0062] ●Preparation - net making; adjust the color engraving paste; generally choose 1000 mesh for flat screen printing;

[0063] Dyeing the base color - use cationic dyes to dye the base color of the fabric, after dyeing, dehydration, opening, drying, setting and edge trimming;

[0064] Engraving printing—Using the slurry containing stannous chloride and stannous chloride-resistant cationic dyes that can destroy the chromophoric group of the base color dye, engraving printing on the fabric that has been dyed with the base color in sequence...

Embodiment 2

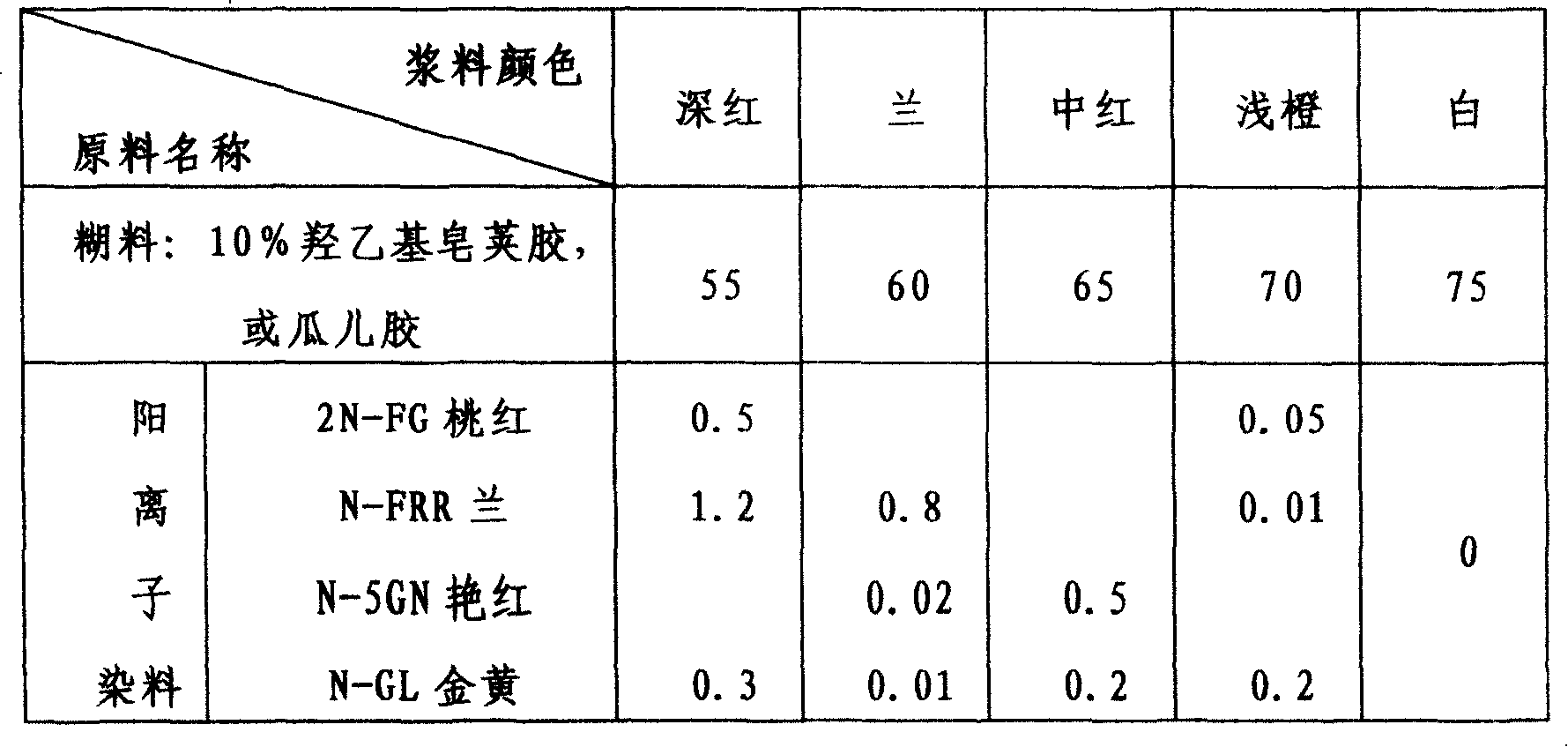

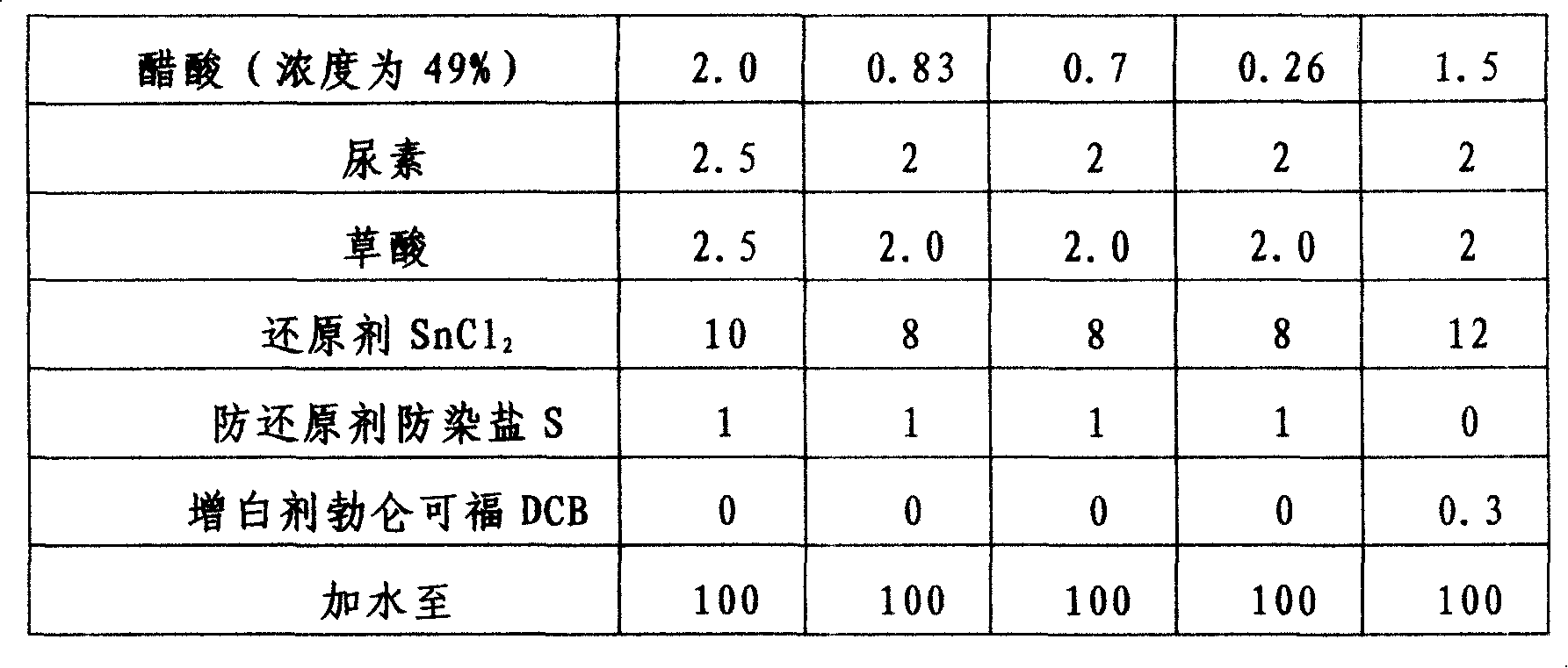

[0083] Example of engraving and printing paste formula: see Table 2

[0084] Table 2 (kg)

[0085]

[0086]

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com